Beruflich Dokumente

Kultur Dokumente

Instrument Codes and Symbols Continued

Hochgeladen von

jokish0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

24 Ansichten2 SeitenInstrument Codes and Symbols Continued

Copyright

© © All Rights Reserved

Verfügbare Formate

DOCX, PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenInstrument Codes and Symbols Continued

Copyright:

© All Rights Reserved

Verfügbare Formate

Als DOCX, PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

24 Ansichten2 SeitenInstrument Codes and Symbols Continued

Hochgeladen von

jokishInstrument Codes and Symbols Continued

Copyright:

© All Rights Reserved

Verfügbare Formate

Als DOCX, PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 2

Instrument codes and symbols continued

Emergency or Safety Instrument Codes

A list is given below, for the abnormal conditions, which

must be measured by function qualification instruments.

State display or alarm signals from such instruments are

for the purpose of alerting the process operator, thus

enabling corrective action to be taken. In cases of

emergency or to safeguard vital equipment, the

instruments automatically initiate trip or shutdown

actions.

- High level (H) initiates an alarm.

- Extreme high level (HH) trips the inlet valve shut.

- Low level (L) initiates an alarm.

- Extreme low level (LL) trips the outlet valve shut.

Low flow (L) initiates an alarm and may also open a

minimum flow spill-back or recycle valve to prevent the

pump from overheating. Extreme low flow (LL) trips the

pump motor to prevent damage.

High-pressure (H) increases the overhead condenser

coolant flow. Extreme high pressure (HH) initiates an

alarm and opens a vent valve to flare. High temperature

(H) initiates an alarm. Extreme high temperature (HH)

trips the fuel inlet valves to protect the furnace coil from

overheating.

Structure of the Instrument Codes

In general, every conventional measuring or controlling

instrument Installed in a process unit is identified by

three separate codes as follows.

A location number code indicates the specific process

unit in which the instrument is installed.

A function letter code indicates the property or process

variable being measured or controlled.

A serial number code identifies the specific instrument

and therefore prevents confusion when there are several

Instruments In a single process unit, each having the

same function letter code.

The combination of the three codes is known as the

Instrument tag number, which has the basic format - xx a

- yyy

TAG NUMBERS

xx is a two-digit number used to identify the process

unit. 'a is a letter code containing two or more capital

letters and is used to identify the

instrument function. 'yyy' is a three-digit number used to

identify the particular instrument. When the instrument

code or tag number is written on a drawing or document,

a dash is inserted between the 'a' and the 'yyy' sections

of the format. For example, a pressure indicating

controller installed in a process unit coded 10 and

identified by serial number 101, is described in written

form as 10 - PIC - 101. In the case of the same tag

numbers, the process pressure correcting element,

usually a control valve, often has the same tag number as

the control instrument. However, when the controller

operates two valves in a split range mode, the valves are

tagged and numbered consecutively, for example,

10 - PIC - 101 10 PCV 101-1

10 PCV 101-2

NOTE:

Refer to the Following reference documents in the next

pages:

1- List of General Abbreviations

2- List of Instrument Identification Code

3- Instrument Symbols (ISA S501)

4- Legend of Symbols

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Floret Fall Mini Course Dahlia Sources Updated 211012Dokument3 SeitenFloret Fall Mini Course Dahlia Sources Updated 211012Luthfian DaryonoNoch keine Bewertungen

- Bound Moisture. This Is Water Retained So That It Exerts A Vapour Pressure Less Than ThatDokument1 SeiteBound Moisture. This Is Water Retained So That It Exerts A Vapour Pressure Less Than ThatjokishNoch keine Bewertungen

- How A Steam Jet EjectorDokument1 SeiteHow A Steam Jet EjectorjokishNoch keine Bewertungen

- Notes On Plant Layout Part 1Dokument1 SeiteNotes On Plant Layout Part 1jokishNoch keine Bewertungen

- Calculation of The LFL and UFL of MixturesDokument1 SeiteCalculation of The LFL and UFL of MixturesjokishNoch keine Bewertungen

- ConductanceDokument1 SeiteConductancejokishNoch keine Bewertungen

- Bound Moisture. This Is Water Retained So That It Exerts A Vapour Pressure Less Than ThatDokument1 SeiteBound Moisture. This Is Water Retained So That It Exerts A Vapour Pressure Less Than ThatjokishNoch keine Bewertungen

- What Is CommissioningDokument1 SeiteWhat Is CommissioningjokishNoch keine Bewertungen

- Typical Overall Heat-Transfer CoefficientsDokument2 SeitenTypical Overall Heat-Transfer CoefficientsjokishNoch keine Bewertungen

- Chemical Engineering ReferenceDokument2 SeitenChemical Engineering Referencejokish0% (1)

- How To Do Sundarkand Path & BenifitsDokument1 SeiteHow To Do Sundarkand Path & BenifitsjokishNoch keine Bewertungen

- Preliminary Heat Exchanger Design ExampleDokument4 SeitenPreliminary Heat Exchanger Design ExamplejokishNoch keine Bewertungen

- Humid PDFDokument4 SeitenHumid PDFFrank MtetwaNoch keine Bewertungen

- Impeller TypesDokument1 SeiteImpeller TypesjokishNoch keine Bewertungen

- Systems Review: Systems Are Defined As A Set of Interacting or Interdependent Equipment and ProcessDokument2 SeitenSystems Review: Systems Are Defined As A Set of Interacting or Interdependent Equipment and ProcessjokishNoch keine Bewertungen

- Systems and ProcessesDokument2 SeitenSystems and ProcessesjokishNoch keine Bewertungen

- Definition of Modelling and SimulationDokument2 SeitenDefinition of Modelling and Simulationjokish100% (1)

- Use of Simulated Process ModelDokument2 SeitenUse of Simulated Process ModeljokishNoch keine Bewertungen

- Intro To Mechanical Draft CoolersDokument1 SeiteIntro To Mechanical Draft CoolersjokishNoch keine Bewertungen

- SEPARATOR Design ConsiderationsDokument1 SeiteSEPARATOR Design ConsiderationsjokishNoch keine Bewertungen

- Flow and Capacity CalculationsDokument1 SeiteFlow and Capacity CalculationsjokishNoch keine Bewertungen

- Separators: Introduction: 2-Phase Separators 3-Phase SeparatorsDokument1 SeiteSeparators: Introduction: 2-Phase Separators 3-Phase SeparatorsjokishNoch keine Bewertungen

- NPSHADokument5 SeitenNPSHAjokishNoch keine Bewertungen

- White Vaseline: Safety Data SheetDokument9 SeitenWhite Vaseline: Safety Data SheetHilmi FauziNoch keine Bewertungen

- Buss 37 ZemaljaDokument50 SeitenBuss 37 ZemaljaOlga KovacevicNoch keine Bewertungen

- Lecture 8 - ThermodynamicsDokument65 SeitenLecture 8 - ThermodynamicsHasmaye PintoNoch keine Bewertungen

- Removing Eyelid LesionsDokument4 SeitenRemoving Eyelid LesionsMohammad Abdullah BawtagNoch keine Bewertungen

- Assignment On Inservice Education Sub: Community Health NursingDokument17 SeitenAssignment On Inservice Education Sub: Community Health NursingPrity DeviNoch keine Bewertungen

- An Energy Saving Guide For Plastic Injection Molding MachinesDokument16 SeitenAn Energy Saving Guide For Plastic Injection Molding MachinesStefania LadinoNoch keine Bewertungen

- My Public Self My Hidden Self My Blind Spots My Unknown SelfDokument2 SeitenMy Public Self My Hidden Self My Blind Spots My Unknown SelfMaria Hosanna PalorNoch keine Bewertungen

- Unit-7 (EVS)Dokument32 SeitenUnit-7 (EVS)g6614134Noch keine Bewertungen

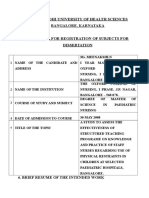

- Rajivgandhi University of Health Sciences Bangalore, KarnatakaDokument19 SeitenRajivgandhi University of Health Sciences Bangalore, KarnatakaHUSSAINA BANONoch keine Bewertungen

- Universal ING - LA.Boschi Plants Private LimitedDokument23 SeitenUniversal ING - LA.Boschi Plants Private LimitedAlvaro Mendoza MaytaNoch keine Bewertungen

- He 3 Basic Types of Descriptive Research MethodsDokument2 SeitenHe 3 Basic Types of Descriptive Research MethodsRahul SarinNoch keine Bewertungen

- Total Elbow Arthroplasty and RehabilitationDokument5 SeitenTotal Elbow Arthroplasty and RehabilitationMarina ENoch keine Bewertungen

- 3 Ways To Take Isabgol - WikiHowDokument6 Seiten3 Ways To Take Isabgol - WikiHownasirNoch keine Bewertungen

- Social Style InventoryDokument12 SeitenSocial Style InventoryMaheshwari JaniNoch keine Bewertungen

- ANATOMY 1 NILEM and Cat FISHDokument19 SeitenANATOMY 1 NILEM and Cat FISHAnisatul Khabibah ZaenNoch keine Bewertungen

- Chapter FourDokument9 SeitenChapter FourSayp dNoch keine Bewertungen

- Hubungan Body Image Dengan Pola Konsumsi Dan Status Gizi Remaja Putri Di SMPN 12 SemarangDokument7 SeitenHubungan Body Image Dengan Pola Konsumsi Dan Status Gizi Remaja Putri Di SMPN 12 SemarangNanda MaisyuriNoch keine Bewertungen

- The Impact Behaviour of Composite MaterialsDokument6 SeitenThe Impact Behaviour of Composite MaterialsVíctor Fer100% (1)

- PPC Production PlantDokument106 SeitenPPC Production PlantAljay Neeson Imperial100% (1)

- 21A Solenoid Valves Series DatasheetDokument40 Seiten21A Solenoid Valves Series Datasheetportusan2000Noch keine Bewertungen

- IB Final ShellDokument25 SeitenIB Final ShellsnehakopadeNoch keine Bewertungen

- Frequency Inverter: User's ManualDokument117 SeitenFrequency Inverter: User's ManualCristiano SilvaNoch keine Bewertungen

- PulpectomyDokument3 SeitenPulpectomyWafa Nabilah Kamal100% (1)

- NCR RepairDokument4 SeitenNCR RepairPanruti S SathiyavendhanNoch keine Bewertungen

- ომარ ხაიამი - რობაიები (პარალელური ტექსტები)Dokument31 Seitenომარ ხაიამი - რობაიები (პარალელური ტექსტები)გენო მუმლაძეNoch keine Bewertungen

- Boeco BM-800 - User ManualDokument21 SeitenBoeco BM-800 - User ManualJuan Carlos CrespoNoch keine Bewertungen

- Практичне 25. Щодений раціонDokument3 SeitenПрактичне 25. Щодений раціонAnnaAnnaNoch keine Bewertungen

- NURTURE Module-V 11 1 en PDFDokument4 SeitenNURTURE Module-V 11 1 en PDFJorge SingNoch keine Bewertungen

- Menu Siklus RSDokument3 SeitenMenu Siklus RSChika VionitaNoch keine Bewertungen