Beruflich Dokumente

Kultur Dokumente

AMERICAN Ductile Iron Flanged Fittings

Hochgeladen von

David BerríoCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

AMERICAN Ductile Iron Flanged Fittings

Hochgeladen von

David BerríoCopyright:

Verfügbare Formate

AMERICAN Ductile Iron Flanged Fittings

The principal standard covering flanged fittings is ANSI/AWWA C110/A21.10. 5464 flanged fittings are covered in ANSI/

AWWA C153/A21.53. These and other standards are referenced throughout this section either by the full ANSI/AWWA

designation or by only the AWWA numbering, such as AWWA C110 or C153.

AMERICAN produces a complete line of

standard as well as specialized flanged fittings

for various types of service including water,

sewage, and air.

Fittings ANSI/AWWA C110/A21.10

Most of the flanged fittings furnished by

AMERICAN are manufactured in accordance

with the requirements of this standard. The

tables in this section in which these fittings

are listed have heading ANSI/AWWA C110/

A21.10. The AWWA C110 fitting flanges

have facing and drilling that match AWWA

C115 threaded-on flanges (see Section 8) and

also match ANSI B16.1 Class 125 flanges.

AMERICAN manufactures some fittings

that are not included in AWWA C110 including

long radius 90 bends, reducing bends, wyes,

and various other fittings that are commonly

used in plant piping. These have AWWA C110

flanges and are listed in the tables with heading AMERICAN Standard. The pressure ratings shown are AMERICAN standard and are

based on AWWA C110 design principles.

The AWWA C110 flanges are adequate

for a water working pressure of 250 psi with

the body of the fitting being suitable for 150

psi or 250 psi, as indicated in the tables. In

some cases, these fittings have been supplied

for greater water working pressure applications, particularly when used with AMERICAN

Toruseal gaskets.

Fittings ANSI/AWWA C153/A21.53

54, 60 and 64 fittings are manufactured in accordance with AWWA C153.

These fittings are compact, and the bodies

are essentially the same as ISO 2531 fittings

in these sizes. Tables including these sizes

will include C153/A21.53 in the heading.

Flanges match AWWA C115 and ANSI B16.1

(Class 125) flanges and are adequate for a water working pressure of 250 psi. (64 flanges

match 66 flanges. See Table No. 6-1.) The

bodies of these fittings are suitable for 150

psi or 250 psi as indicated in the tables. In

some cases, these fittings have been supplied

for greater water working pressure applications, particularly when used with AMERICAN

Toruseal gaskets.

Fittings Class 250 F&D

Except for a transition piece from an ANSI

B16.1 Class 250 flange to a standard AWWA

C110 flange, AMERICAN no longer makes fittings with flanges faced and drilled per ANSI

B16.1 Class 250. As noted in AWWA C111,

flange joints in the 24 and smaller sizes may

be rated for up to 350 psi with the use of special gaskets such as AMERICANs Toruseal.

Furthermore, AMERICAN is able to rate

flange pipe and fittings higher than 250 or

even 350 psi on special applications. Information on fittings Class 250 F&D previously

furnished by AMERICAN can be found in the

Historical Data Section of this Pipe Manual.

AMERICAN offers a complete line of 4 64 flanged pipe and fittings for treatment

plant piping.

6-1

Elevated Pressure/Temperature Applications

Contact AMERICAN for elevated pressure and/or temperature capabilities of ductile iron flanges.

General Notes Relating to Flanged Fittings

1. Fittings in the following tables headed ANSI/AWWA C110/A21.10 or C153/

A21.53 are as specified in these standards,

except as noted. Fittings listed in tables headed AMERICAN Standard are either not included in this ANSI/AWWA standard or vary in

weights and/or dimensions. AMERICAN does

not manufacture any fittings to the requirements of ANSI B16.1 except for laying dimensions, and facing and drilling as specifically

noted.

2. Fittings are manufactured of ductile iron grade 70-50-05 (minimum tensile

strength: 70,000 psi; minimum yield strength:

50,000 psi; minimum elongation: 5%) as specified in AWWA C110 or C153.

3. Flanges can be tapped for studs when

specified. (See Section 8, Table No. 8-3.)

4. All pressure ratings shown are for water

service.

5. Unless otherwise specified, flanges will

have bolt holes straddling centerline. Bolt hole

drilling can be rotated when so specified.

6. Center-to-face dimensions of reducing

tees and crosses, with or without side outlet,

and of reducing wyes are as follows (See Table

No. 6-2).

a. 16 and smaller sizes have the same

center-to-face dimensions as straight sizes corresponding to the size of the largest opening.

b. The center-to-face dimensions of 18

and larger sizes are governed by the size of

the branch or side outlet; for fittings with both

branch and side outlet, the larger of the two

governs.

7. Tees, crosses and wyes, reducing on the

run only, have the same dimensions

center-to-face and face-to-face as straight size

fittings corresponding to the size of the largest

opening.

8. Reducing bends have the same centerto-face dimensions as straight size bends corresponding to the size of the largest opening.

6-2

9. Reducers and eccentric reducers for all

reductions have the same face-to-face dimensions based on the larger opening.

10. Flanged fittings are manufactured to

the following tolerances:

Flange thickness

Sizes 2-12 inclusive, 0.12 in.

Sizes 14-24 inclusive, 0.19 in.

Sizes 30-64 inclusive, 0.25 in.

Laying Length

Sizes 2-10 inclusive, 0.06 in.

Sizes 12-64 inclusive, 0.12 in.

Laying length tolerances are for face-toface dimensions; the center-to-face tolerances

are one half of the face-to-face tolerances.

11. The largest opening of the fitting governs the laying length tolerances for all openings. For compliance with the flange thickness

tolerance, flanges may be back faced or spot

faced, AMERICANs option.

12. Some fittings are available with body

metal thickness other than as listed. Some fittings are available in different sizes and with

different size combinations than shown. All

sizes and body metal thicknesses listed may not

be available due to changes in foundry practice. Check AMERICAN regarding any special

requirements.

13. Weights of fittings can vary due to

changes in foundry practice.

14. See Section 7 for AMERICAN specials.

15. AMERICANmay furnish fittings manufactured by others. Any such fittings will be

manufactured in accordance with appropriate

ANSI/AWWAstandards.

16. While AWWAC153 shows 54-64

with 150 psi ratings, AMERICAN rates most

54-64 fittings 250 psi as AMERICAN standard based on performance testing.

AMERICAN Ductile Iron Flanged Fittings

Applications of Standard Fittings

In many cases, special fittings for various conditions are required. Some of the more

common of these are shown above in columns headed Required. Under the columns

headed Alternate, are shown combinations of standard fittings that in some situations

will provide the desired connection. For economy and/or shipment from stock, it is often

advantageous to use the standard fittings.

*Note: In lieu of tees, blow-off branches, and wyes (and particularly those with reducedsize branches), the designer should consider for optimum design, layout, and installation

the use of fabricated outlet pipe, tangential outlet pipe, and lateral outlets as explained

in Sec. 7.

6-3

AMERICAN Ductile Iron Flanged Fittings

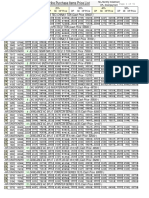

ANSI/AWWA C110/A21.10, C111/A21.11 or C153/A21.53

Flange Details O.D.

Table No. 6-1

Size

in.

3

4

6

8

10

12

14

16

18

20

24

30

36

42

48

54

60

**64

O.D.

in.

B.C.

in.

7.50

9.00

11.00

13.50

16.00

19.00

21.00

23.50

25.00

27.50

32.00

38.75

46.00

53.00

59.50

66.25

73.00

80.00

6.00

7.50

9.50

11.75

14.25

17.00

18.75

21.25

22.75

25.00

29.50

36.00

42.75

49.50

56.00

62.75

69.25

76.00

T

in.

.75

.94

1.00

1.12

1.19

1.25

1.38

1.44

1.56

1.69

1.88

2.12

2.38

2.62

2.75

3.00

3.12

3.38

Bolt

Hole

Diameter

in.

/4

/4

7

/8

7

/8

5

1 /8

11

11/8

11/8

11/4

11/4

13/8

13/8

15/8

15/8

15/8

21

21

21

3

3

Bolts

No. Per

Joint

Size

in.

14

18

18

18

12

12

12

16

16

20

20

28

32

36

44

44

52

52

15/8 x 21/2

5

/8 x 3

13/4 x 31/2

13/4 x 31/2

7

/8 x 4

7

/8 x 4

11 x 41/2

11 x 41/2

11/8 x 5

11/8 x 5

11/4 x 51/2

11/4 x 61/2

11/2 x 71

11/2 x 71/2

11/2 x 8

13/4 x 81/2

13/4 x 9

13/4 x 9

**The dimensions of 64 flange correspond with applicable dimensions of 66 Class E in ANSI/AWWA C207, and 64 ductile iron flanges

can be connected to those flanges.

FACING: Flanges are plain faced and are finished smooth or with shallow serrations (AMERICANs option).

BACK FACING: Flanges may be back faced or spot faced, AMERICANs option, for compliance with the flange thickness tolerance.

FLANGES: The flanges shown above are adequate for water service of 250 psi working pressure and should not be confused with

Class 250 flanges per ANSI B16.1. The bolt circle and the bolt holes match those of ANSI B16.1 Class 125. If flanges are required to be made in

accordance with other ratings or other standards, this must be specified on the purchase order. 24 and smaller flanges are rated equal to the

fittings to which they are attached and are adequate for water service of greater than 350 psi only with the use of AMERICANs Toruseal

gaskets.

Drilling of flanges can be rotated when required; for those sizes with an even number of bolt holes in each quadrant, fitting can be rotated

45 with standard drilling.

AMERICAN recommends AMERICAN Toruseal gaskets shown on page 621 be used for normal water service.

See Section 8, Table No. 83 for information on bolts and studs.

See General Notes on page 62.

6-4

6-5

Taps are made directly into the wall of the flanged fitting. Tap diameter depends on the fitting wall thickness and will vary on the diameter of the fitting.

In the designation of the openings of reducing fittings, they should be read in the order indicated by the sequence of the numbers 1, 2, 3 and 4 as shown. Maximum tap diameter depends on the

fitting wall thickness.

Note that numbering sequence for wye ends differs from that shown in ANSI B16.1 standard (for gray cast iron flanged items).

Method of Designating Location of Tapped Holes and Sequence of Openings

AMERICAN Standard

AMERICAN Ductile Iron Flanged Fittings

6-6

AMERICAN Ductile Iron Flanged Fittings

Dimensions for above fittings are given in Table No. 62.

Some of the above fittings are not listed in AWWA C110 but do meet applicable requirements of AWWA C110.

The largest opening establishes the basic size of a reducing fitting. The largest opening is named first, except for bullhead tees and double branch bends where both branches are

reducing; in these two cases, the largest opening is named last.

In the designation of the openings of reducing fittings, they should be read in the order indicated by the sequence of the numbers 1, 2, 3 and 4 as shown.

In describing tees reducing on the branch only, the first size applies to both outlets on the run. Similarly, for crosses with the same size for both run outlets and the same size for

both branch outlets, it is necessary to indicate only two sizes. For example: for an 8 x 6 tee or wye, it is not necessary to show 8 x 8 x 6; for an 8 x 6 cross, it is not necessary to show

8 x 8 x 6 x 6.

Flanged Fitting Dimensions and Designation of Outlets

ANSI/AWWAC110/A21.10, C153/A21.53, or AMERICAN Standard

6-7

5.5

6.5

8.0

9.0

11.0

12.0

14.0

15.0

16.5

18.0

22.0

25.0

28.0

31.0

34.0

39.0

43.0

48.0

7.75

9.00

11.50

14.00

16.50

19.00

21.50

24.00

26.50

29.00

34.00

41.50

49.00

56.50

64.00

D**

E**

3.0

10.0 3.0

4.0

12.0 3.0

5.0

14.5 3.5

5.5

17.5 4.5

6.5

20.5 5.0

7.5

24.5 5.5

7.5

27.0 6.0

8.0

30.0 6.5

8.5

32.0 7.0

9.5

35.0 8.0

11.0

40.5 9.0

15.0

See Table

18.0

No. 6-8

21.0

24.0

20.5

23.5

25.0

16

17

19

11

12

14

16

18

19

20

24

30

36

42

48

4.88

5.50

7.00

8.38

9.75

11.25

12.50

13.75

15.00

16.00

18.50

23.00

26.00

30.00

34.00

38.00

42.00

44.00

Dimensions in Inches Reducing Tees

5.00

6.00

7.00

9.00

9.00

11.00

11.00

11.00

13.50

13.50

13.50

16.00

19.00

23.50

25.00

27.50

32.00

38.75

S

(Dia.)

.56

.62

.69

.94

.94

1.00

1.00

1.00

1.12

1.12

1.12

1.19

1.25

1.44

1.56

1.69

1.88

2.12

.50

.50

.62

.88

.88

1.00

1.00

1.00

1.12

1.12

1.12

1.15

1.15

1.28

1.42

1.55

1.75

1.75

12

14

16

20

24

24

30

Size

of

Branches

and

Smaller

***

13

14

15

18

20

23

26

15.5

17.0

19.0

23.0

26.0

30.0

34.0

Reducing Tees

and Crosses

Flanged Fittings Dimensions

*AWWA C110 and C153 do not include data on wyes of any size.

**See footnote to Table No. 68.

***For larger branches, use A dimensions.

For these smaller diameter reducing tees and crosses, the A dimension applies as shown in cut of standard tee and cross.

For these smaller diameter reducing wyes, the D and E dimensions apply as shown in cut of standard wye.

See General Notes on page 62.

F dimensions for 5464 reducers vary with diameters of reduction.

H and J dimensions for 5464 tees and crosses vary with diameters of reduction.

13

14

16

18

10

12

14

16

18

20

24

30

36

42

48

54

60

64

Size

in.

Table No. 6-2

AMERICAN Ductile Iron Flanged Fittings

8

10

12

Size

of

Branches

and

Smaller

ANSI/AWWAC110/A21.10, C153/A21.53, or AMERICAN Standard

25.0

27.0

40.5

See Table

No. 6-8

1.00

1.00

9.00

Reducing Wyes*

27.5

29.5

40.5

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5795)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Sans 1200 HDokument3 SeitenSans 1200 HfilipeNoch keine Bewertungen

- Operation and Maintenance Manual Casing Hydraulic Tong Eckel 20 - STDDokument56 SeitenOperation and Maintenance Manual Casing Hydraulic Tong Eckel 20 - STDAli Ali100% (4)

- Ansys Motion in MechanicalDokument35 SeitenAnsys Motion in MechanicalKyon EsdelleNoch keine Bewertungen

- Pipeline Design Construction p1 PDFDokument309 SeitenPipeline Design Construction p1 PDFDavid BerríoNoch keine Bewertungen

- Whirlpool Duet Washer Component TestingDokument6 SeitenWhirlpool Duet Washer Component TestingSamurai Appliance Repair Man50% (2)

- Docslide - Us - Gate MFG Latest PDFDokument210 SeitenDocslide - Us - Gate MFG Latest PDFAnonymous Zx7EG1PaNoch keine Bewertungen

- Docslide - Us - Gate MFG Latest PDFDokument210 SeitenDocslide - Us - Gate MFG Latest PDFAnonymous Zx7EG1PaNoch keine Bewertungen

- 2011 Coh Design Manual Submersible Lift StationsDokument200 Seiten2011 Coh Design Manual Submersible Lift StationsDavid Berrío100% (1)

- Heatcraft Engineering ManualDokument44 SeitenHeatcraft Engineering ManualAbdiel Martínez100% (2)

- Rock Permeability: Reservoir Rock Properties LabDokument12 SeitenRock Permeability: Reservoir Rock Properties LabhashoNoch keine Bewertungen

- Arc Welding Process PDFDokument12 SeitenArc Welding Process PDFBiswanath RoulNoch keine Bewertungen

- HPDokument51 SeitenHPKhan Basit KhanNoch keine Bewertungen

- Metallic Medical Bone Screws: Standard Specification and Test Methods ForDokument18 SeitenMetallic Medical Bone Screws: Standard Specification and Test Methods ForDiego MarchioriNoch keine Bewertungen

- E3Dokument300 SeitenE3JuinNoch keine Bewertungen

- Theorem of Three Moments - Wikipedia, The Free EncyclopediaDokument3 SeitenTheorem of Three Moments - Wikipedia, The Free EncyclopediasoulsellNoch keine Bewertungen

- Worksheet 2Dokument3 SeitenWorksheet 2Harsh SinghNoch keine Bewertungen

- Grav Fields A2 M4Dokument55 SeitenGrav Fields A2 M4aby251188Noch keine Bewertungen

- Kaplan - Expt No. 3Dokument14 SeitenKaplan - Expt No. 3ruikar manojNoch keine Bewertungen

- Marksman Housing PDFDokument2 SeitenMarksman Housing PDFAyahKenzieNoch keine Bewertungen

- A Master's Guide To Ship's Piping 2nd EditionDokument42 SeitenA Master's Guide To Ship's Piping 2nd Editiondassi99100% (1)

- Dumper Caterpillar 772Dokument32 SeitenDumper Caterpillar 772Foromaquinas100% (2)

- Lifting Tongs: Solving Material Handling ProblemsDokument4 SeitenLifting Tongs: Solving Material Handling Problemsmohsen123100% (1)

- Vent Master Cam C InjeccionDokument2 SeitenVent Master Cam C InjeccionFreddy VeraNoch keine Bewertungen

- Example 3: Concrete Pile, ECH, Tension Stress Check: GRLWEAP Standard ExamplesDokument2 SeitenExample 3: Concrete Pile, ECH, Tension Stress Check: GRLWEAP Standard ExamplesbozarromegustaNoch keine Bewertungen

- Fisher GX Globe Valve d103171x012Dokument30 SeitenFisher GX Globe Valve d103171x012arun_tulsianeyNoch keine Bewertungen

- JCB JS145W+JS160WTechnical DataDokument36 SeitenJCB JS145W+JS160WTechnical DataMoataz SamiNoch keine Bewertungen

- Grasso Screw Compressor Package Pi - tcm11 38504Dokument84 SeitenGrasso Screw Compressor Package Pi - tcm11 38504Twfeek AhmedNoch keine Bewertungen

- Mechanical Properties of Stainless SteelDokument8 SeitenMechanical Properties of Stainless SteelFahrul Nur ArifinNoch keine Bewertungen

- Aircraft Materials and Processes - 2017 PDFDokument36 SeitenAircraft Materials and Processes - 2017 PDFDan Keith Mina DuadNoch keine Bewertungen

- L-1 Butterfly Valve InstallDokument9 SeitenL-1 Butterfly Valve InstallgerardtrNoch keine Bewertungen

- Flow Types: - Base of SpillwayDokument6 SeitenFlow Types: - Base of Spillwaygizem cenikNoch keine Bewertungen

- WCTE 2018 Conference Paper Stoner FinalVerDokument7 SeitenWCTE 2018 Conference Paper Stoner FinalVerMichael StonerNoch keine Bewertungen

- Clutch Damper ChangeDokument6 SeitenClutch Damper ChangeAaron StaubNoch keine Bewertungen

- Enerpac PullerDokument14 SeitenEnerpac PullerantonioNoch keine Bewertungen