Beruflich Dokumente

Kultur Dokumente

Iso Grid Spec

Hochgeladen von

onspsnonsOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Iso Grid Spec

Hochgeladen von

onspsnonsCopyright:

Verfügbare Formate

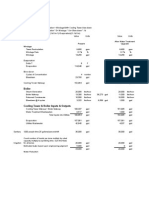

IsoGrid Sound Isolation Clip Specifications

Part 1 General

1.01 Work Included

A. Furnish all labor, materials, tools, and equipment to install sound isolated ceilings.

Construct ceiling composite using the quick connect ceiling hanger where shown on

contract drawings.

1.02 System Description

A. Gypsum board shall be attached to the resiliently supported ceiling grid to isolate the

material from the wall or ceiling structure thereby reducing sound and impact transmission

through the ceiling.

1.03 Quality Assurance

A. The quick connect ceiling hanger shall be designed and fabricated at the facilities of a

manufacturer having a minimum of five years experience in furnishing similar sound

control products.

1.04 Submittals

A. Submit product data

1. Catalog cut sheet.

2. Sound Transmission Loss Test Report per ASTM E90 documenting a minimum

STC 63 floor/ceiling assembly for a 6 in. concrete slab with 2 layers of gypsum board

suspended 6 in. below the bottom of the concrete slab and fiber glass batts in the

cavity.

3. Impact Insulation Test Report per ASTM E413 documenting a minimum IIC 50

floor/ceiling assembly for a bare 6 in. concrete slab with 2 layers of gypsum board

suspended 6 in. below the bottom of the concrete slab and fiber glass batts in the

cavity.

3. Test reports must be from an independent laboratory accredited by the National

Institute of Standards and Technology (NIST) under the National Voluntary Laboratory

Accreditation Program (NVLAP) or from the Institute for Research in Construction

(IRC) of the National Research Council of Canada (NRC-C)

IsoGrid Quick Connect Ceiling Hanger Specifications

Page 2

Part 2.00 Product

2.01 Materials

A. Sound isolation clips specified shall be designed and manufactured by Kinetics Noise

Control, Dublin, Ohio. Product shall be Model IsoGrid Quick Connect Ceiling Hanger.

B. Vertical Load capacity. Ceiling hangers shall have sufficient capacity to support ceiling

weights as constructed. In a vertical load test comparable to a ceiling installation, the

ceiling hanger shall have a minimum design load capacity of 160 lbs. Design Load

capacity shall be based on a minimum safety factor of 5 as compared to load to failure.

Anchors for attachment of the clips to the substructure shall be selected to support ceiling

weights at each hanger.

C. The isolation clips shall consist of a dual deflection rubber element which supports the

hanger bracket on the hanger sleeve insert.

D. The isolation clip is attached to the floor/ceiling framing or other structural deck substrate

through the hanger sleeve insert running through the rubber element. The bracket and

insert shall be of sufficient strength to carry the ceiling weight without bending or failure.

Part 3.00 Execution

3.01 Installation

A. General Install work in accordance with the manufacturers approved product

installation procedures.

1/18/2015

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (890)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- 1 s2.0 0379711283900218 Main PDFDokument8 Seiten1 s2.0 0379711283900218 Main PDFBam DrogbaNoch keine Bewertungen

- Vibration in Pumps PDFDokument5 SeitenVibration in Pumps PDFonspsnonsNoch keine Bewertungen

- TACO Hydronics Step by StepDokument45 SeitenTACO Hydronics Step by Stepminiongsky100% (4)

- The Gift - Joel Edgerton - May 2014Dokument116 SeitenThe Gift - Joel Edgerton - May 2014Michael50% (2)

- PH House: by Norm ArchitectsDokument14 SeitenPH House: by Norm ArchitectsMax PigaNoch keine Bewertungen

- Villa Savoye Case StudyDokument14 SeitenVilla Savoye Case StudyJaspreet Singh100% (1)

- Marvel Studios Fantastic Four 07-10-15Dokument91 SeitenMarvel Studios Fantastic Four 07-10-15Robert Garlen100% (1)

- 0014-Cpr-001 Concept Phase Report 170409bDokument15 Seiten0014-Cpr-001 Concept Phase Report 170409bonspsnonsNoch keine Bewertungen

- SPEC For Chilled Water Pipework and FittingsDokument4 SeitenSPEC For Chilled Water Pipework and FittingsonspsnonsNoch keine Bewertungen

- Pipe Wall Thickness (ASME B31.3)Dokument12 SeitenPipe Wall Thickness (ASME B31.3)Rachmad HidayatNoch keine Bewertungen

- Basics of Refrigeration CycleDokument2 SeitenBasics of Refrigeration CyclePradeep SukumaranNoch keine Bewertungen

- Ahu 01 (STD)Dokument5 SeitenAhu 01 (STD)onspsnonsNoch keine Bewertungen

- Fire Damper Installation DetailsDokument1 SeiteFire Damper Installation DetailsonspsnonsNoch keine Bewertungen

- Air Distribution Basics and Duct DesignDokument46 SeitenAir Distribution Basics and Duct DesignVali GheorghisorNoch keine Bewertungen

- Ashraed2830120060711Dokument6 SeitenAshraed2830120060711kabardeyNoch keine Bewertungen

- A O Smith Residential Water Heater CatalogDokument24 SeitenA O Smith Residential Water Heater CatalogonspsnonsNoch keine Bewertungen

- 00 BLANK - Hot and Cold Water LU Calculation SheetDokument17 Seiten00 BLANK - Hot and Cold Water LU Calculation SheetmaxmorekNoch keine Bewertungen

- WaStop SS - PVC - PE International Version 2014Dokument2 SeitenWaStop SS - PVC - PE International Version 2014onspsnonsNoch keine Bewertungen

- PDO SMO Buildings - Site Visit ReportDokument9 SeitenPDO SMO Buildings - Site Visit ReportonspsnonsNoch keine Bewertungen

- Balancing and Vibration LimitsDokument3 SeitenBalancing and Vibration Limitsramamoorthy_sNoch keine Bewertungen

- Inline Check Valve SpecificationDokument1 SeiteInline Check Valve SpecificationonspsnonsNoch keine Bewertungen

- CalculationsDokument2 SeitenCalculationsAliAliNoch keine Bewertungen

- Cooling Tower ArticleDokument7 SeitenCooling Tower ArticleAudrey Patrick KallaNoch keine Bewertungen

- Chiller Barrier Wall SpecificationDokument2 SeitenChiller Barrier Wall SpecificationonspsnonsNoch keine Bewertungen

- Cib HDokument1 SeiteCib HonspsnonsNoch keine Bewertungen

- Drainge&Waste WaterDokument43 SeitenDrainge&Waste WatermohdnazirNoch keine Bewertungen

- ECO V - CatalogueDokument5 SeitenECO V - CatalogueonspsnonsNoch keine Bewertungen

- Commercial STL HTL Panels SpecificationDokument4 SeitenCommercial STL HTL Panels SpecificationonspsnonsNoch keine Bewertungen

- Barrier Wall SystemsDokument2 SeitenBarrier Wall SystemsonspsnonsNoch keine Bewertungen

- FDS B 4 - CoilDokument1 SeiteFDS B 4 - CoilonspsnonsNoch keine Bewertungen

- Icw SpecDokument3 SeitenIcw SpeconspsnonsNoch keine Bewertungen

- FLM SpecificationsDokument2 SeitenFLM SpecificationsonspsnonsNoch keine Bewertungen

- Icc SpecDokument2 SeitenIcc SpeconspsnonsNoch keine Bewertungen

- High TonesDokument2 SeitenHigh TonesonspsnonsNoch keine Bewertungen

- Hard Side Cloud SystemDokument2 SeitenHard Side Cloud SystemonspsnonsNoch keine Bewertungen

- High Impact HardSide Panels Acoustics ControlDokument2 SeitenHigh Impact HardSide Panels Acoustics ControlonspsnonsNoch keine Bewertungen

- Guestroom CleaningDokument115 SeitenGuestroom CleaningSrivalli Krishnan0% (1)

- Building Utilities Steel Reinforcement Bars SpecificationsDokument28 SeitenBuilding Utilities Steel Reinforcement Bars Specifications1004.100% (1)

- Area of Luna Wood Façade WorkDokument6 SeitenArea of Luna Wood Façade WorkGokul NathNoch keine Bewertungen

- Erich MendelsohnDokument35 SeitenErich Mendelsohnhs24march100% (4)

- Net Case StudyDokument17 SeitenNet Case StudyGandharapu SatishNoch keine Bewertungen

- Kotharis GRP Portable Cabin QuotationDokument3 SeitenKotharis GRP Portable Cabin Quotationsharma.hansrajNoch keine Bewertungen

- GMS9 Installation InstructionsDokument36 SeitenGMS9 Installation Instructionsradikmike8838Noch keine Bewertungen

- Gropius HouseDokument24 SeitenGropius Housealexmihai00100% (1)

- Betrayal Traitor TomeDokument54 SeitenBetrayal Traitor TomegrimbblesNoch keine Bewertungen

- Cooler Catalogue 2016Dokument11 SeitenCooler Catalogue 2016Jitu Kumar SahooNoch keine Bewertungen

- Code Review MatrixDokument7 SeitenCode Review MatrixAndrei GrigoreNoch keine Bewertungen

- CME - Estimate Sample 1Dokument34 SeitenCME - Estimate Sample 1erwin sarmientoNoch keine Bewertungen

- Cocena June Month Quotation For Civil WorksDokument5 SeitenCocena June Month Quotation For Civil WorksVgRoshanNoch keine Bewertungen

- Volume Zero: Documentary On Charles CorreaDokument7 SeitenVolume Zero: Documentary On Charles Correasailee gosaviNoch keine Bewertungen

- Arkerryhill PDFDokument2 SeitenArkerryhill PDFVuTienAnNoch keine Bewertungen

- Natural Ventilation Strategies in Tropical ClimateDokument50 SeitenNatural Ventilation Strategies in Tropical ClimateFirrdhaus Sahabuddin100% (3)

- AULT 2005, Housing The PoorDokument11 SeitenAULT 2005, Housing The Poorgordianknot2020Noch keine Bewertungen

- Multi Storey Car ParksDokument6 SeitenMulti Storey Car ParksRifat Türkkan0% (1)

- Feati-Civil Engineering Department 1994-2007 - Feati University-Civil Engineering Department Thesis 1997-2007Dokument11 SeitenFeati-Civil Engineering Department 1994-2007 - Feati University-Civil Engineering Department Thesis 1997-2007Paulo ParenasNoch keine Bewertungen

- JZHCHDokument1 SeiteJZHCHJohn AndersonNoch keine Bewertungen

- Uttarakhand PWD Schedule of RateDokument20 SeitenUttarakhand PWD Schedule of RateBIJAY KRISHNA DAS33% (3)

- Nizwa HvacDokument35 SeitenNizwa HvaczfrlNoch keine Bewertungen

- Residential Building For Mr. Satish Rao Chitpady, Udupi, KarnatakaDokument12 SeitenResidential Building For Mr. Satish Rao Chitpady, Udupi, Karnatakapratheek DasNoch keine Bewertungen

- 11 Ards0112 - Floor PlanDokument35 Seiten11 Ards0112 - Floor PlanCHELSIE KAITLYN DE GUZMANNoch keine Bewertungen