Beruflich Dokumente

Kultur Dokumente

ECD-V5 Injection Pump System

Hochgeladen von

Vincentius NikimOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

ECD-V5 Injection Pump System

Hochgeladen von

Vincentius NikimCopyright:

Verfügbare Formate

ECD-V5 Injection Pump System

ECD-V5

Injection Pump System

NOTE: Some of the components of the ECD-V5 injection pump system are very similar in

design and operation to those of the NP-VE4 injection pump system. Therefore this

lesson only describes the components which are new or operate in a different way to

those in the NP-VE4 injection pump system.

Service Training

117

ECD-V5 Injection Pump System

Intake system

The construction and operation of the intake system is essentially carried over from that of

the NP-VE4 injection pump system except for the following:

Mass air flow sensor has been eliminated (only Euro 2 vehicles)

Turbocharger with variable geometry turbine has been adopted (only Euro 3 vehicles)

Variable swirl control valve has been adopted (only Euro 3 vehicles)

Parts location

1

2

3

4

5

6

118

Fresh-air duct

Resonance chamber

Air cleaner

Turbocharger

Charge air cooler

Intake manifold

7

8

9

10

11

12

VBC vacuum actuator

VBC check valve

VBC solenoid valve

VBC vacuum chamber

VSC vacuum actuator

VSC solenoid valve

Service Training

ECD-V5 Injection Pump System

Intake system (continued)

System overview

1

2

3

4

5

6

7

Fresh-air duct

Air cleaner

Turbocharger

Charge air cooler

Intake manifold

VBC vacuum actuator

VBC vacuum chamber

Service Training

8

9

10

11

12

13

14

VBC solenoid valve

VBC check valve

VSC vacuum actuator

VSC solenoid valve

Vacuum pump

To PCM

Vacuum chamber

119

ECD-V5 Injection Pump System

Turbocharger

Mazda vehicles with RF-T engine and Euro 3 emission standard feature a turbocharger with

VGT (Variable Geometry Turbine), which controls the boost pressure by adjusting guide

blades. The blades are located in the turbine housing and are driven by a vacuum actuator,

resulting in an increased power output and a reduced fuel consumption.

The guide blades vary the cross-section in front of the turbine and thus the passages that

duct the exhaust gas to the turbine. The position of the guide blades is controlled by the

PCM, which activates the VBC (Variable Boost Control) solenoid valve via a duty signal. As

a result, the boost pressure remains approximately the same over the entire engine speed

range.

1

2

3

120

Adjusting linkage

Vacuum actuator

Turbine

4

5

Guide blades

Compressor housing

Service Training

ECD-V5 Injection Pump System

Turbocharger (continued)

1

2

3

4

5

Turbocharger

VBC vacuum actuator

VBC vacuum chamber

VBC solenoid valve

Charge air cooler

6

7

8

9

Vacuum pump

VBC check valve

To PCM

Vacuum chamber

At low engine speeds the PCM controls the VBC solenoid valve with a large duty cycle, so

that vacuum is applied to the vacuum actuator. Due to this the guide blades move in the

closing direction and the passages that duct the exhaust gas to the turbine become narrow.

Thus the exhaust gas stream impinges with a high velocity and a small angle on the turbine,

resulting in a high boost pressure.

1

2

From PCM control relay

VBC solenoid valve

Service Training

PCM

121

ECD-V5 Injection Pump System

Turbocharger (continued)

High boost pressure

Low boost pressure

At high engine speeds the PCM controls the VBC solenoid valve with a small duty cycle, so

that atmosphere pressure is applied to the vacuum actuator. Due to this the guide blades

move in the opening direction and the passages that duct the exhaust gas to the turbine

become wide. Thus the exhaust gas stream impinges with a low velocity and a large angle

on the turbine, resulting in a low boost pressure.

NOTE: If the VBC system fails, the blades adopt in a parked position again in which only a

minimal boost pressure is produced.

The PCM controls the VBC solenoid valve by a duty signal between 012 V.

122

Service Training

ECD-V5 Injection Pump System

Turbocharger (continued)

Diagnostics

The turbocharger can be checked as following:

Monitoring the boost pressure via the PID MAP (Press/Volt)

Checking turbocharger (see NP-VE4 injection pump system)

Checking boost pressure (see NP-VE4 injection pump system)

Monitoring/Activating the blade adjustment via the PID VBCV# (Per)

Checking the voltage signal at the VBC solenoid valve

Checking blade adjustment

Checking blade adjustment

Connect a hand-operated vacuum pump to the VBC actuator and apply vacuum. Check,

whether the adjusting linkage moves easily, and returns to the parked position when the

system is vented.

NOTE: The blade adjustment system is a fixed part of a turbocharger. As turbochargers usually

cannot be repaired with the means available in workshops, they must be changed

complete.

Service Training

123

ECD-V5 Injection Pump System

Variable swirl control valve

Mazda vehicles with RF-T engine and Euro 3 emission standard are equipped with VSC

(Variable Swirl Control) valves in the intake manifold, reducing the exhaust emissions at low

engine speed. The VSC valves are driven by a vacuum actuator and vary the cross-section

of the manifold. Therefore the intake manifold features two inlet ports per each cylinder. The

swirl port induces the intake air tangentially into the combustion chamber, while the charge

port induces it vertically.

The shutter valves close or open the charge ports, influencing the passages that duct the

intake air into the cylinder. The position of the shutter valves is controlled by the PCM,

which activates the VSC solenoid valve by an ON/OFF signal.

1

2

124

VSC solenoid valve

VSC valve

VSC vacuum actuator

Service Training

ECD-V5 Injection Pump System

Variable swirl control valve (continued)

1

2

3

VSC vacuum actuator

VSC solenoid valve

Intake manifold

4

5

6

Vacuum pump

Vacuum chamber

To PCM

At an engine speed below 2300 min-1 the PCM energizes the VSC solenoid valve, so that

vacuum is applied to the vacuum actuator. Due to this the shutter valves close the charge

ports, decreasing the cross-section of the intake manifold. Thus the intake air enters the

cylinder only via the swirl port, creating a high air flow speed and a strong swirl. This

improves the mixture of the injected fuel with the air and hence the combustion.

1

2

From PCM control relay

VSC solenoid valve

Service Training

PCM

125

ECD-V5 Injection Pump System

Variable swirl control valve (continued)

1

2

3

4

VSC valve closed

VSC valve open

Charge port

Exhaust ports

5

6

7

Piston

VSC valve

Swirl port

At an engine speed above 2300 min-1 the PCM de-energizes the VSC solenoid valve, so

that atmosphere pressure is applied to the vacuum actuator. Due to this the shutter valves

open the charge port, making the complete cross-section of the intake manifold available.

Thus the intake air stream enters the cylinder via the swirl port and the charge port,

resulting in high air throughput and a good cylinder charging. This ensures, that the engine

delivers the required high power.

NOTE: If the VSC system fails, the shutter valves adopt in a parked position again in which no

swirl is produced.

Diagnostics

The VSC system can be checked as following:

Monitoring/Activating the shutter valve adjustment via the PID IMRC# (Mode)

Checking the voltage at the VSC solenoid valve

Checking shutter valve adjustment

Checking shutter valve adjustment

Connect a hand-operated vacuum pump to the VSC actuator and apply vacuum. Check,

whether the adjusting linkage moves easily, and returns to the parked position when the

system is vented.

126

Service Training

ECD-V5 Injection Pump System

Fuel system

The construction and operation of the fuel system is essentially carried over from that of the

NP-VE4 injection pump system except for the following:

High-pressure system has been modified

Injection amount control has been modified

Injection timing control has been modified

Parts location

1

2

Fuel filter

Injection pump

Service Training

Injector

127

ECD-V5 Injection Pump System

Fuel system (continued)

System overview

1

2

128

Fuel tank

Fuel filter

3

4

Injection pump

Injector

Service Training

ECD-V5 Injection Pump System

Fuel system (continued)

Injection pump

The ECD-V5 injection pump system features an axial-piston distributor pump manufactured

by Denso.

1

2

3

4

5

Spill valve

FLT sensor

TCV

Pump speed sensor

Overflow restrictor

Service Training

6

7

8

9

Roller ring

Toothed rotor

Cam plate

Distributor plunger

129

ECD-V5 Injection Pump System

High-pressure system

The design and operation of the high-pressure system is essentially carried over from the

NP-VE 4 injection pump system except for the following:

Axial-piston distributor pump with spill valve has been adopted

Two-spring injectors have been adopted

Axial-piston distributor pump

On the ECD-V5 injection pump system the axial-piston distributor pump features a spill

valve instead of transverse cut-off bore and control sleeve. The valve is located in an

additional passage, which bypasses the FSOV and connects the high-pressure chamber to

the pump chamber. According to the signals from the PCM the spill valve opens or closes

this additional passage.

1

2

3

4

130

Cam plate

Distributor plunger

Roller ring

From pump chamber

5

6

7

High-pressure chamber

To injector

Spill valve

Service Training

ECD-V5 Injection Pump System

High-pressure system (continued)

Axial-piston distributor pump (continued)

As the distributor plunger moves from TDC to BDC, the spill valve opens the additional

passage. Now fuel flows through the open inlet passage into the high-pressure chamber

(filling phase).

1

2

3

4

5

Pump chamber

Roller ring

Cam plate

Distributor plunger

Distribution slot

6

7

8

9

High-pressure chamber

Injector

Intake port

Spill valve open

At BDC the plungers rotating movement then closes the inlet passage and opens the

distributor slot for a certain outlet port. When the plunger moves from BDC to TDC (working

stroke), the spill valve closes the additional passage. Due to this, the fuel is compressed in

the high-pressure chamber (high-pressure phase). As the pressure rises in the highpressure chamber and in the outlet port passage, it suffices to open the delivery valve in

question and the fuel is forced through the high-pressure line to the injection nozzle.

1

2

Roller ring

Cam plate

Service Training

Spill valve closed

131

ECD-V5 Injection Pump System

High-pressure system (continued)

Axial-piston distributor pump (continued)

The working stroke is completed as soon as the spill valve opens the additional passage,

spilling the fuel into the pump interior (end of high-pressure phase). As the pressure in the

high-pressure chamber collapses, the delivery valve closes the high-pressure line and no

more fuel is delivered to the injector.

1

2

132

Roller ring

Cam plate

Spill valve open

Service Training

ECD-V5 Injection Pump System

High-pressure system (continued)

Injectors

On the ECD-V5 injection pump system two-spring injectors are used. The injectors consist

of nozzle body with nozzle needle, pressure pin, two springs and stop sleeve.

1

2

3

4

5

6

7

Nozzle body

Adjustment shim

Spring No.1

Pressure pin

Guide element

Spring No.2

Spring seat

Service Training

8

9

10

11

12

13

14

Intermediate element

Stop sleeve

Nozzle needle

Nozzle retaining nut

Nozzle

Initial stroke

Main stroke

133

ECD-V5 Injection Pump System

High-pressure system (continued)

Injectors (continued)

The two-spring injector injects the fuel in two stages into the combustion chamber. It

features two springs with different spring rates, which are located one behind the other.

During the injection process the needle is lifted against the force of spring No.1 (low spring

rate), until it reaches the stop sleeve. Due to this a small annular gap is opened, so that only

a small amount of fuel is injected with low-pressure (initial spray).

Since the injection pump delivers more fuel than can flow through the small gap, the

pressure in the injector rises. Due to this the needle and the stop sleeve are lifted further

against the force of spring No.2 (high spring rate). Now the spray orifice is widened, and the

major amount of fuel is injected with high-pressure (main spray). Since the pressure in the

combustion chamber rises less sharply, combustion in part-load range is smoother and

though quieter.

The injectors are equipped with a hole-type nozzle, which improves the atomization of the

fuel in the combustion chamber. The spray holes with 0.18 mm in diameter are located on

the circumference of the nozzle body. Depending on the emission level of the vehicle the

nozzle features 6 (Euro 3 vehicles) or 5 spray holes (Euro 2 vehicles).

1

2

3

Euro 3 vehicles

Euro 2 vehicles

Six fuel jets

4

5

Five fuel jets

Piston

For low HC emissions its highly important that the volume filled with fuel (residual volume)

between nozzle needle and nozzle body is kept to a minimum. Therefore the tip of the

nozzle needle is rounded off. Since the thin spray holes produce a good atomization at a

high pressure, power output as well as fuel consumption and exhaust emissions are

improved.

134

Service Training

ECD-V5 Injection Pump System

High-pressure system (continued)

Diagnostics

The high-pressure system can be checked as following:

Checking the start of fuel delivery

Checking the injectors

Checking the start of fuel delivery

Check whether the marks of the housing and the bracket of the injection pump are aligned.

If not as specified, slacken the high-pressure lines and the mounting nuts / bolts and adjust

the start of fuel delivery by turning the injection pump.

Injection pump

Injection pump bracket

Checking the injectors

The injectors can be checked as following:

1. Connect the injector to an injector tester and bleed the air by pumping the injector tester

handle several times.

2. To check the opening pressure of the injectors first stage slowly lower the handle and

note the pressure when injection starts.

3. If not as specified, replace the injector.

4. To check the injectors atomization lower the handle several times as quickly as

possible, so that a pulsating whistling noise is heard and inspect the atomization

pattern.

5. If not as specified, replace the injector.

6. To check the injector for leakage apply a certain pressure (see Workshop Manual) to the

injector and inspect for fuel leakage from the nozzle spray port.

7. If fuel leaks, replace the injector.

NOTE: As the pressure build-up of the injector tester is too slow, only the first stage of the twostage injector can be checked.

Service Training

135

ECD-V5 Injection Pump System

High-pressure system (continued)

Diagnostics (continued)

Checking the injectors (continued)

1

2

Normal spray

Spray angle incorrect

Poor misting

NOTE: If the diagnostic check reveals, that the concern indicates one or more faulty injectors,

this can be checked by releasing the high-pressure lines at the injectors while the engine

is running. When the high-pressure lines are released, check whether the engine running

changes and whether fuel escapes between the high-pressure line and the injector. If the

engine running is unchanged and fuel escapes, the injector concerned is faulty.

136

Service Training

ECD-V5 Injection Pump System

Injection amount control

The design and operation of the injection amount control is essentially is essentially carried

over from the NP-VE 4 injection pump system except for the following:

Spill valve has been adopted

Injector driver module has been adopted

Fuel shut-off valve has been modified

Spill valve

The ECD-V5 injection pump system features a SPV (Spill Valve) instead of an electronic

governor. The valve controls the high-pressure phase of the axial piston pump, so that the

fuel injection amount varies depending on the operating conditions. The SPV is located on

top of the distributor head and consists of a coil and a spring-loaded spool valve. The

position of the spool valve is controlled by the PCM, which drives the SPV via the injector

driver module.

1

2

3

Distributor plunger

To pump chamber

Spill ports

Service Training

4

5

Coil

Spool valve

137

ECD-V5 Injection Pump System

Injection amount control (continued)

Spill valve (continued)

When the SPV is energized by the IDM, the spool valve closes the additional passage

between high-pressure chamber and pump chamber. Due to this the high-pressure phase

starts, i.e. fuel is delivered to the injectors.

1

3

SPV closed

To high-pressure chamber

2

4

SPV open

To pump chamber

When the SPV is de-energized by the IDM, the spool valve opens the additional passage

and the fuel in the high-pressure chamber is spilled into the pump interior. Due to this the

high-pressure phase ends, i.e. no more fuel is delivered to the injectors. So the closing time

of the SPV determines the duration of the high-pressure phase, changing the injection

amount from zero to maximum.

NOTE: The SPV serves also to switch off the engine. When the ignition is switched off, the SPV

is de-energized by the IDM. The spring force causes the spool valve to adopt in a parked

position, setting the fuel injection amount to zero.

NOTE: When the SPV fails the spool valve adopts in a parked position and sets the fuel

injection amount to zero, i.e. the engine doesnt run anymore.

138

Service Training

ECD-V5 Injection Pump System

Injection amount control (continued)

Injector driver module

The IDM (Injector Driver Module) drives the SPV at high speed and high accuracy. It has a

high-voltage generator inside, which amplifies the battery voltage input from the SPV relay

into a high voltage of approx. 150 V and stores it in a capacitor. A control circuit outputs the

high voltage to the SPV as a drive signal. The IDM is controlled by the PCM via a duty

signal. Besides the PCM switches the power supply to the IDM with the aid of the SPV

relay.

1

2

3

4

From SPV relay

Injection signal

Injection confirmation signal

High voltage generator

Service Training

5

6

7

Control circuit

SPV

Connector

139

ECD-V5 Injection Pump System

Injection amount control (continued)

Injector driver module (continued)

The IDM energizes the SPV in two stages. When the injection signal is input from the PCM

to the IDM, the IDM actuates the SPV with a high voltage of approx. 150 V. Due to the high

pull-down current (approx. 12 A) the valve closes rapidly. After a certain time the IDM

reduces the actuating voltage to 12 V, resulting in a lower holding current (approx. 6 A).

Due to this the power loss in the IDM and in the SPV is minimized, avoiding unnecessary

heat in these components. While the SPV is closed the IDM detects the drive current and

outputs an injection confirmation signal (SPV operating status) to the PCM.

1

2

3

4

140

Injection confirmation signal

Injection signal

SPV drive current

Holding current switching time

5

6

7

8

Holding current

Pull-down current

Fail signal (High side)

Fail signal (Low side)

Service Training

ECD-V5 Injection Pump System

Injection amount control (continued)

Injector driver module (continued)

Service Training

141

ECD-V5 Injection Pump System

Injection amount control (continued)

Injector driver module (continued)

When the required injection amount is small, the PCM controls the IDM with a small duty

cycle, so that the drive signal outputted to the SPV has also a small duty cycle. Due to this

the closing time of the SPV is short, resulting in a short high-pressure phase and though in

a small injection amount.

1

2

3

4

Cam lift

SPV control

Injection amount

Start of injection

5

6

7

8

End of injection

Cam angle

Small injection amount

Large injection amount

When the required injection amount is large, the PCM controls the IDM with a large duty

cycle, so that the drive signal outputted to the SPV has also a large duty cycle. Due to this

the closing time of the SPV is long, resulting in a long high-pressure phase and though in a

large injection amount.

142

Service Training

ECD-V5 Injection Pump System

Injection amount control (continued)

Fuel shut-off valve

On the ECD-V5 injection pump system the FSOV is controlled by the PCM via a relay.

1

2

FSOV

FSOV relay

PCM

When the engine is started, the PCM energizes the FSOV relay, switching the power supply

to the FSOV. Due to this the passage between the interior of the pump and the highpressure chamber is opened and fuel is supplied the high-pressure chamber, enabling the

engine to start.

When the ignition is switched off, the PCM de-energizes the FSOV relay, cutting off the

power supply from the FSOV. Due to this the passage between the interior of the pump and

the high-pressure chamber is closed and the fuel supply to the high-pressure chamber is

shut off, stopping the engine.

Service Training

143

ECD-V5 Injection Pump System

Injection amount control (continued)

Diagnostics

The components of the injection amount control can be checked as following:

Checking the voltage signal of the SPV

Checking the resistance of the SPV

Checking the voltage at the SPV relay

Checking the voltage signal to the IDM

Monitoring the FLT sensor via the PID FLT/FLT V (Temp/Volt)

Checking the voltage of the FLT sensor

Checking the resistance of the FLT sensor

Monitoring the FSOV relay via the PID FSOV (Mode)

Checking the voltage at the FSOV relay

Checking the voltage at the FSOV

Checking the resistance of the FSOV

144

Service Training

ECD-V5 Injection Pump System

Injection timing control

The design and operation of the injection timing control is essentially is essentially carried

over from the NP-VE 4 injection pump system except for the following:

Timer device has been modified

Timer position sensor has been eliminated

Pump speed sensor has been modified

Timer device

On the Mazda vehicles with RF-T engine the TCV is located in a passage between the

pump chamber and the low-pressure side of the timer piston, varying the pressure on the

low-pressure side of the timer piston. An additional orifice in the passage to the suction side

of the feed pump serves to maintain a high pressure on the low-pressure side of the timer

piston.

1

2

3

4

TCV

To feed pump (suction side)

Roller ring

Pump chamber

5

6

7

8

High-pressure side

Low-pressure side

Timer piston

Orifice

At low engine speeds the PCM controls the TCV with a large duty cycle, so that the

solenoid valve opens and the pressure on the low-pressure side increases. Due to this the

spring force and the pressure on the low-pressure side overcome the pressure on the highpressure side and the piston moves away from the return spring. Thus the roller ring rotates

into the turning direction of the cam plate, retarding the injection timing.

Service Training

145

ECD-V5 Injection Pump System

Injection timing control (continued)

Timer device (continued)

At high engine speeds the PCM controls the TCV with a small duty cycle, so that the

solenoid valve closes and the pressure on the low-pressure side decreases. Due to this the

pressure on the high-pressure side overcomes the spring force and the pressure on the

low-pressure side and the piston moves into the direction of the return spring. Thus the

roller ring rotates against the turning direction of the cam plate, advancing the fuel injection

timing.

NOTE: When the TCV fails the solenoid valve adopts in a parked position, setting the injection

timing to advance position. This can be recognized by the increased engine noise at idle

(Diesel knocking).

Pump speed sensor

On the Denso ECD-V5 injection pump system the pump speed sensor is mounted on the

roller ring of the axial piston pump and scans a rotor with 52 teeth. According to the number

of cylinders the rotor has 4 tooth gaps spread evenly around the circumference. Due to the

elimination of the TPS the signal of the pump speed sensor is used to detect the position of

the timer device, giving a feedback about the actual injection timing to the PCM.

X

1

2

3

146

Time

Pump speed sensor

Timer piston

Toothed rotor

Y

4

5

6

Output voltage

Roller ring

Tooth gap

Output voltage characteristics

Service Training

ECD-V5 Injection Pump System

Injection timing control (continued)

Pump speed sensor (continued)

When the injection timing is altered by the timer device the roller ring and hence the sensor

is turned in the advance or retard direction, changing the position of the pump speed

sensor in relation to the rotor. Thus the position of the tooth gap on the rotor also changes

in relation to the TDC position of the engine. The PCM calculates the difference between

the signals from the pump speed sensor and the TDC sensor and compares it with a

reference value. As a result, the PCM determines an accurate position of the timer device.

Furthermore the PCM uses the pump speed sensor signal to detect the position of the

distributor plunger, determining the time at which the SPV is actuated. Actuation must take

place at precisely the correct angle so that both the closing and the opening of the SPV take

place in the appropriate position of the distributor plunger. This ensures that the start of fuel

injection and the fuel injection amount are correct.

NOTE: When the pump speed sensor fails, the engine doesnt run anymore.

The pump speed sensor supplies the PCM with an alternating voltage of approx. 29 V

(peak to peak).

Service Training

147

ECD-V5 Injection Pump System

Emission system

The construction and operation of the emission system is essentially carried over from the

NP-VE4 injection pump system except for the following:

Warm-up oxidation catalyst has been adopted (only Euro 3 vehicles)

EGR control solenoid valve has been eliminated

EGR valve position sensor has been eliminated (only Euro 3 vehicles)

EGR water cooler has been eliminated

Intake shutter valve has been eliminated (only Euro 2 vehicles)

Parts location

1

2

3

4

148

EGR valve

EGR ventilation solenoid valve

EGR vacuum solenoid valve

ISV vacuum actuator

5

6

7

8

ISV solenoid valve

Crankcase ventilation hose

Warm-up oxidation catalyst

Oxidation catalyst

Service Training

ECD-V5 Injection Pump System

Emission system (continued)

System overview

1

2

3

4

5

EGR valve

EGR ventilation solenoid valve

EGR vacuum solenoid valve

ISV vacuum actuator

ISV solenoid valve

Service Training

6

7

8

9

10

Crankcase ventilation hose

Warm-up oxidation catalyst

Oxidation catalyst

Vacuum pump

To PCM

149

ECD-V5 Injection Pump System

Warm-up oxidation catalyst

In addition to the oxidation catalyst equipped Euro 3 vehicles feature a warm-up oxidation

catalyst, which improves the emission performance of the cold engine. The warm-up

catalyst is located just behind the exhaust manifold, so that it reaches its operating

temperature quickly after cold start. As a result the HC and CO emissions of the cold engine

are reduced, meeting the requirements of the emission control legislation.

1 Warm-up oxidation catalyst

Oxidation catalyst

NOTE: The warm-up oxidation catalyst cant be cleaned or repaired. If necessary replace the

catalyst.

150

Service Training

ECD-V5 Injection Pump System

Control system

The construction and operation of the control system is essentially carried over from that of

the NP-VE4 injection pump system.

Parts location

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

PCM (incl. Barometric pressure sensor)

MAF sensor

IAT sensor

MAP sensor

Engine coolant temperature sensor

Crankshaft position sensor

Accelerator pedal position sensor

Idle switch

Clutch pedal position switch

FLT sensor

Pump speed sensor

Injection pump EPROM

TCV

VBC solenoid valve

VSC solenoid valve

Service Training

16

17

18

19

20

21

22

23

24

25

26

27

28

29

EGR ventilation solenoid valve

EGR vacuum solenoid valve

ISV solenoid valve

IDM

Glow plug relay

SPV relay

FSOV relay

PCM control relay

A/C relay

Condenser fan relay

Cooling fan relay

Data link connector

Battery

Park / Neutral position switch

151

ECD-V5 Injection Pump System

Control system (continued)

Block diagram

152

Service Training

ECD-V5 Injection Pump System

Control system (continued)

Block diagram (continued)

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

Injection amount control

Injection timing control

Idle speed control

Glow control

EGR control

VBC

VSC

Electrical fan control

A/C control (if equipped)

Immobilizer system

MAF sensor

Engine coolant temperature sensor

Accelerator pedal position sensor

Idle switch

IAT sensor

Pump speed sensor

FLT sensor

Injection pump EPROM

Crankshaft position sensor

MAP sensor

Park / Neutral position switch

Clutch pedal position switch

Vehicle speed sensor

Service Training

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

Refrigerant pressure switch (with A/C)

Immobilizer module

Battery

Data link connector

Starter (starter signal)

Barometric pressure sensor (in PCM)

VBC solenoid valve

VSC solenoid valve

TCV

EGR vacuum solenoid valve

EGR ventilation solenoid valve

SPV relay

FSOV relay

Glow indicator light

Glow plug relay

A/C relay (with A/C)

Cooling fan relay

Condenser fan relay (with A/C)

IDM

SPV

PCM

ISV

153

ECD-V5 Injection Pump System

Control system (continued)

Relationship chart

x: Applicable

MAF/IAT sensor

IAT sensor No.2

Pump speed sensor

FLT sensor

Injection pump EPROM

Crankshaft position sensor

Input

X

X

MAP sensor

Park / Neutral position switch

Clutch pedal position switch

Vehicle speed sensor

Barometric pressure sensor (integrated in PCM)

Refrigerant pressure switch (with A/C)

Immobilizer module

Battery voltage

DLC (TEN terminal)

Starter signal

X

X

VBC solenoid valve

TCV

EGR solenoid valve (vacuum, vent)

Output

X

X

VSC solenoid valve

Spill valve relay

FSOV relay

Glow indicator light

Glow plug relay

A/C relay

Cooling fan relay

Condenser fan relay (with A/C)

ISV solenoid valve

IDM

154

Immobilizer system

Idle switch

A/C control

Accelerator pedal position sensor

Electrical fan control

VSC

VBC

Idle speed control

EGR control

Injection timing control

Engine coolant temperature sensor

Device

Glow control

Injection amount control

Control item

X

X

Service Training

ECD-V5 Injection Pump System

Sensors

The design and operation of the sensors is essentially carried over from those of the NPVE4 injection pump system except for the following:

Crankshaft position sensor has been modified

Barometric pressure sensor has been eliminated (only Euro 2 vehicles)

Vehicle speed sensor has been eliminated

Crankshaft position sensor

Mazda vehicles with RF-T engine feature an inductive-type CKP sensor. The sensor

consists of a permanent magnet and a coil, which scan a rotor with one tooth.

1

2

Toothed rotor

CKP sensor

Output voltage characteristics

When the rotor passes the sensor, an alternating voltage is induced in the coil and input to

the PCM. The level of the alternating voltage depends on the distance between sensor and

rotor as well as on the speed of the crankshaft, i.e. the amplitude rises with decreasing

distance and increasing speed.

NOTE: When the CKP sensor fails, the TCV adopts in a parked position, setting the injection

timing to advance position. This can be recognized by the increased engine noise at idle

(Diesel knocking).

Service Training

155

ECD-V5 Injection Pump System

Sensors (continued)

Crankshaft position sensor (continued)

CKP sensor

PCM

The CKP sensor supplies the PCM with an alternating voltage between 618 V (peak to

peak).

Diagnostics

The CKP sensor can be checked as following:

Checking the voltage signal

Checking the resistance

156

Service Training

ECD-V5 Injection Pump System

Actuators

The design and operation of the actuators is essentially carried over from those of the NPVE4 injection pump system except for the following:

Electrical fan has been adopted

Immobilizer system has been modified

Electrical fan

On Mazda vehicles with RF-T engine the PCM controls the cooling fan and the condenser

fan (if equipped) via relays. When the engine coolant temperature reaches a given value

(approx. 100 C), the PCM energizes the cooling fan relay, switching the power supply to

the cooling fan motor. In addition the PCM activates the condenser fan relay, when the A/C

is switched on or when the coolant temperature reaches a given value (approx. 105 C),

supplying the condenser fan motor with power.

1

2

3

Cooling fan

Condenser fan

Cooling fan relay

4

5

6

Condenser fan relay

PCM

With A/C

NOTE: In order to prevent the engine from overheating when the ECT sensor is faulty, the PCM

activates the cooling and the condenser fan permanently. Furthermore both fans are

switched on, when the terminal TEN in the 17-pin data link connector is grounded and

the accelerator pedal is depressed.

Diagnostics

The function of the electrical fan can be checked as following:

Monitoring the engine coolant temperature via the PID ECT (Temp/Volt)

Monitoring / Activating the cooling and the condenser fan relay via the PID FAN2# /

FAN3# (Mode)

Checking the voltage at the cooling and the condenser fan relay

Checking the voltage at the cooling and the condenser fan

Service Training

157

ECD-V5 Injection Pump System

Actuators (continued)

Immobilizer System

On Mazda vehicles with RF-T engine the PCM deactivates the FSOV (via the FSOV relay)

and the IDM, when the vehicle is started with an invalid key. If the vehicle is equipped with a

starter relay, the immobilizer module disables the starter as well. As a result the engine

doesnt even crank.

When a vehicle without starter relay is started with an invalid key, the PCM allows the

engine to start but cuts off the fuel supply after approx. 2 s, stopping the engine. After three

attempts to start the engine with an invalid key the PCM permanently cuts off the fuel

supply. As a result the engine doesnt start at all.

NOTE: If a vehicle without starter relay starts and stalls after a short time or cranks and doesnt

start, verify that this concern isnt related to the immobilizer system by observing the

immobilizer warning light.

1

2

3

4

Immobilizer module

SPV relay

FSOV relay

IDM

5

6

7

SPV

FSOV

PCM

NOTE: For diagnosis on the immobilizer system refer to the workshop manual (section T

Immobilizer System).

158

Service Training

Das könnte Ihnen auch gefallen

- ECD V5 Injection Pump SystemDokument42 SeitenECD V5 Injection Pump SystemArtur Bujdoso78% (9)

- VP44 Service ManualDokument39 SeitenVP44 Service Manualhelder100% (5)

- Audi A3 2004 Workshop ManualDokument19 SeitenAudi A3 2004 Workshop ManualNatalie Jolly100% (3)

- Pinout-Schematic DiagramsDokument14 SeitenPinout-Schematic DiagramsIvan RdzNoch keine Bewertungen

- (Automotive) SAE - FSAE Suspension and Frame DesignDokument11 Seiten(Automotive) SAE - FSAE Suspension and Frame Designmarshall, of course100% (3)

- Army CH-47 Chinook HelicopterDokument714 SeitenArmy CH-47 Chinook HelicopterArmySGT100% (3)

- How Does The VNT WorksDokument3 SeitenHow Does The VNT WorksAyman Al ShabanahNoch keine Bewertungen

- Ackerman? Anti-Ackerman? or Parallel Steering?Dokument10 SeitenAckerman? Anti-Ackerman? or Parallel Steering?Alija SirotanovićNoch keine Bewertungen

- 2011 Jeep Liberty Limited 2011 Jeep Liberty Limited: Fig. 73: Transmission Control Output Wiring DiagramDokument7 Seiten2011 Jeep Liberty Limited 2011 Jeep Liberty Limited: Fig. 73: Transmission Control Output Wiring DiagramcarlosNoch keine Bewertungen

- Bosch Vp37 PumpsDokument32 SeitenBosch Vp37 PumpsLuís Fidalgo92% (13)

- CAN Bus TutorialDokument8 SeitenCAN Bus TutorialVincentius Nikim100% (1)

- 2 Variable Valve TimingDokument30 Seiten2 Variable Valve Timingadibazmi93100% (1)

- Berlingo Iii 9HF (Dv6dted) 1.6Dokument11 SeitenBerlingo Iii 9HF (Dv6dted) 1.6Fabian Carrasco NaulaNoch keine Bewertungen

- How To Diagnose Vp44 Fuel System IssuesDokument17 SeitenHow To Diagnose Vp44 Fuel System Issuesมนต์ชัย บุญธนลาภNoch keine Bewertungen

- Ergonomic Design GuideDokument66 SeitenErgonomic Design GuideAnonymous p2cFoXbjD100% (2)

- Denso CR - Hp2 NissanDokument31 SeitenDenso CR - Hp2 NissanMarcelo Diesel86% (7)

- ssp382 - Audi TT Coupé '07 Electrical and Infotainment SystemsDokument56 Seitenssp382 - Audi TT Coupé '07 Electrical and Infotainment Systemspsychoreality100% (1)

- MR419X6113B150 PDFDokument389 SeitenMR419X6113B150 PDFArchivo 0546Noch keine Bewertungen

- Variable Valve TimingDokument25 SeitenVariable Valve TimingCochintu Radu100% (1)

- Vp44 Installation InstructionsDokument4 SeitenVp44 Installation InstructionsDony SuthanNoch keine Bewertungen

- Velo Steering 09 10Dokument8 SeitenVelo Steering 09 10onezero111Noch keine Bewertungen

- CAN Bus Interface Description CANbus Pin Out, and Signal Names. Controller ADokument8 SeitenCAN Bus Interface Description CANbus Pin Out, and Signal Names. Controller AVincentius Nikim100% (1)

- Common RailDokument5 SeitenCommon RailPushkar Nath100% (3)

- High-Rise Standpipe SystemsDokument22 SeitenHigh-Rise Standpipe SystemsStory LoveNoch keine Bewertungen

- Kart Basic Chassis SetupDokument6 SeitenKart Basic Chassis SetupVincentius NikimNoch keine Bewertungen

- Denso Common Rail SystemDokument68 SeitenDenso Common Rail SystemAngeliNoch keine Bewertungen

- JSA - Shut Down and Tie in WorkDokument6 SeitenJSA - Shut Down and Tie in WorkNurul Hidayah67% (6)

- Structure AhmedabadDokument87 SeitenStructure AhmedabadNandpal Prashant100% (1)

- Bosch Edc17cp05 Irom TC1797 Ford PDFDokument6 SeitenBosch Edc17cp05 Irom TC1797 Ford PDFAlpine LeeNoch keine Bewertungen

- Electric EGR ValveDokument2 SeitenElectric EGR ValveLóránd Barta100% (1)

- 8d22de PDFDokument299 Seiten8d22de PDFA-t HectorNoch keine Bewertungen

- Electronic Engine Controls TDV6 2.7Dokument10 SeitenElectronic Engine Controls TDV6 2.7elisei sorinNoch keine Bewertungen

- NT Continental Siemens Vdo m3c Ducati 1033Dokument6 SeitenNT Continental Siemens Vdo m3c Ducati 1033Thanh Lâm PhanNoch keine Bewertungen

- C38 Operating Instructions PDFDokument71 SeitenC38 Operating Instructions PDFAnonymous OfU0JS100% (1)

- Ak TrainingDokument40 SeitenAk TrainingBatuhanÇetinGüven100% (1)

- Rolls-Royce M250-C20R SERIES OPERATION AND MAINTENANCE 720000 - 5Dokument32 SeitenRolls-Royce M250-C20R SERIES OPERATION AND MAINTENANCE 720000 - 5anony8103100% (1)

- Audi VW Maf DiagnosticsDokument2 SeitenAudi VW Maf DiagnosticsЧедомир Марина ЂошићNoch keine Bewertungen

- Glow Plug ControllerDokument2 SeitenGlow Plug ControllerVijay Mirje100% (1)

- Fit For The Future:: Everything For Diesel ServiceDokument68 SeitenFit For The Future:: Everything For Diesel Servicemihai37100% (2)

- 1996 Toyota Land Cruiser Prado, RJ Modification - All Pics, Specs, Parts andDokument4 Seiten1996 Toyota Land Cruiser Prado, RJ Modification - All Pics, Specs, Parts andVincentius NikimNoch keine Bewertungen

- Covec FDokument22 SeitenCovec FVictor Montesdeoca100% (1)

- Kalmar DRF 450 Load HandlingDokument174 SeitenKalmar DRF 450 Load Handlingtuấn anh nguyễnNoch keine Bewertungen

- TOYOTA - Ficha de Calibración Bomba de Inyección - 1KZ - TDokument102 SeitenTOYOTA - Ficha de Calibración Bomba de Inyección - 1KZ - TJuan Junior Asto Torres100% (1)

- Tarifas PVP Turbos Nuevos AutoTurboCHRA FINAL2 PDFDokument12 SeitenTarifas PVP Turbos Nuevos AutoTurboCHRA FINAL2 PDFbourbiaNoch keine Bewertungen

- Launch x431 Heavy Duty For Trucks Vehicle ListDokument85 SeitenLaunch x431 Heavy Duty For Trucks Vehicle ListARYNoch keine Bewertungen

- Index Catalogue Supplement Vehicle Equipment For Passenger CarsDokument137 SeitenIndex Catalogue Supplement Vehicle Equipment For Passenger CarsdavideNoch keine Bewertungen

- VVT GeelyDokument6 SeitenVVT GeelydokarusNoch keine Bewertungen

- Bosch ECI Injection - ECIDokument17 SeitenBosch ECI Injection - ECIBeTONoch keine Bewertungen

- Common Rail Injectors Repairing Table: MM Bar M M M NM NM NM NMDokument1 SeiteCommon Rail Injectors Repairing Table: MM Bar M M M NM NM NM NMakhmedNoch keine Bewertungen

- Delphi DCM Medium Duty Diesel Engine Controller Series: BenefitsDokument2 SeitenDelphi DCM Medium Duty Diesel Engine Controller Series: BenefitsAsif Shah100% (1)

- TCM InjectorSID05 7Dokument7 SeitenTCM InjectorSID05 7leather_nunNoch keine Bewertungen

- All Passenger Car Dealers/TascsDokument9 SeitenAll Passenger Car Dealers/TascssouravNoch keine Bewertungen

- Ref. No.: EG 4010 Date: Page: Jul., 2004Dokument80 SeitenRef. No.: EG 4010 Date: Page: Jul., 2004mpecha67% (3)

- Diesel Fuel Injector Pump: Factsheet Updated 3 October 2008Dokument8 SeitenDiesel Fuel Injector Pump: Factsheet Updated 3 October 2008anshel100% (1)

- Code P1693Dokument21 SeitenCode P1693احمدميدوNoch keine Bewertungen

- Nissan Almera P1251 Engine Trouble Code - Nissan Almera P1251 OBD-II Diagnostic Powertrain (P) Trouble Code For Nissan Almera PDFDokument2 SeitenNissan Almera P1251 Engine Trouble Code - Nissan Almera P1251 OBD-II Diagnostic Powertrain (P) Trouble Code For Nissan Almera PDFJoaquin Enrique Rivas HungNoch keine Bewertungen

- Opel Airbag Reset Manual PDFDokument7 SeitenOpel Airbag Reset Manual PDFSergio Gardeazabal100% (1)

- Component LocationDokument2 SeitenComponent LocationkallatisNoch keine Bewertungen

- K-Suite 1.89Dokument3 SeitenK-Suite 1.89Fabio JuniorNoch keine Bewertungen

- 93C86Dokument12 Seiten93C86francisco_siles_lunaNoch keine Bewertungen

- TroubleshootingWithCodes-NonTurbo Volvo 850Dokument18 SeitenTroubleshootingWithCodes-NonTurbo Volvo 850azaharNoch keine Bewertungen

- 08 Engine MechanicalDokument80 Seiten08 Engine MechanicalmadcostaNoch keine Bewertungen

- JLR 13 65 10 - 1E - Defender Puma 60th Anniversary Electric Wiring Diagrams - SupplementDokument24 SeitenJLR 13 65 10 - 1E - Defender Puma 60th Anniversary Electric Wiring Diagrams - SupplementRiahi RezegNoch keine Bewertungen

- P0045 34 Turbo Circuit PDFDokument11 SeitenP0045 34 Turbo Circuit PDFAung Kyaw Min0% (1)

- Bosch Edc17cp09 Xrom Tc1796 BMW 1033Dokument2 SeitenBosch Edc17cp09 Xrom Tc1796 BMW 1033ddf_dedoNoch keine Bewertungen

- ЭБУ в машинахDokument93 SeitenЭБУ в машинахАлександр КулаковNoch keine Bewertungen

- Relay Loc LCR 200Dokument40 SeitenRelay Loc LCR 200Yannick de WalqueNoch keine Bewertungen

- Interject Harry Tech Book EFISpares TipsDokument10 SeitenInterject Harry Tech Book EFISpares Tipsgolden68Noch keine Bewertungen

- BDMMPC5 XXDokument3 SeitenBDMMPC5 XXaupNoch keine Bewertungen

- Maxximo: Diagnostic Manual MAN-00129Dokument1 SeiteMaxximo: Diagnostic Manual MAN-00129LeelaNoch keine Bewertungen

- Daewoo Matiz 2000-2013 Wheel AlignmentDokument6 SeitenDaewoo Matiz 2000-2013 Wheel AlignmentOMARNoch keine Bewertungen

- DarshanDokument21 SeitenDarshanMandar Ambi100% (1)

- Cam Less EngineDokument18 SeitenCam Less EnginePushkar VermaNoch keine Bewertungen

- Variable Valve TimingDokument3 SeitenVariable Valve Timingsandesh ganigaNoch keine Bewertungen

- V V T I C E: Ariable Alve Iming in Nternal Ombustion NgineDokument21 SeitenV V T I C E: Ariable Alve Iming in Nternal Ombustion NgineSivaNoch keine Bewertungen

- 2 Variable Valve TimingDokument30 Seiten2 Variable Valve TimingAlex Mariei100% (1)

- CAN Bus Pin Out, and CANopen Pinout, With Signal NamesDokument4 SeitenCAN Bus Pin Out, and CANopen Pinout, With Signal NamesVincentius Nikim100% (1)

- 217 Mod 03 Differential Locks (IC TF OP) 2-07-03Dokument6 Seiten217 Mod 03 Differential Locks (IC TF OP) 2-07-03arkhom1Noch keine Bewertungen

- Vsi 06 Light Vehicle ModificationsDokument18 SeitenVsi 06 Light Vehicle ModificationsVincentius NikimNoch keine Bewertungen

- RCT Vehicle Handling and ControlDokument11 SeitenRCT Vehicle Handling and ControlVincentius NikimNoch keine Bewertungen

- AUTT 1050 Automotive Suspension and Steering Systems: Master Course SyllabusDokument5 SeitenAUTT 1050 Automotive Suspension and Steering Systems: Master Course SyllabusVincentius NikimNoch keine Bewertungen

- A814Dokument5 SeitenA814Vincentius NikimNoch keine Bewertungen

- EML2322L Wheel Hub DesignDokument5 SeitenEML2322L Wheel Hub DesignVincentius NikimNoch keine Bewertungen

- Intro To Steering LinkageDokument25 SeitenIntro To Steering LinkageVincentius NikimNoch keine Bewertungen

- AUTT 1050 Automotive Suspension and Steering Systems: Master Course SyllabusDokument5 SeitenAUTT 1050 Automotive Suspension and Steering Systems: Master Course SyllabusVincentius NikimNoch keine Bewertungen

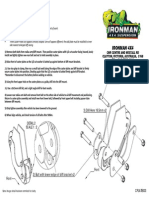

- Ironman 4X4: GQ, GU Series With Coil Springs 5 Degree Caster Plates For 130mm - 170mm LiftsDokument1 SeiteIronman 4X4: GQ, GU Series With Coil Springs 5 Degree Caster Plates For 130mm - 170mm LiftsVincentius NikimNoch keine Bewertungen

- Intro To Air SuspensionsDokument6 SeitenIntro To Air SuspensionsGyanendra Kumar PadhiNoch keine Bewertungen

- McLaren F1Dokument9 SeitenMcLaren F1Vincentius NikimNoch keine Bewertungen

- Simple Car DynamicsDokument16 SeitenSimple Car DynamicsVincentius NikimNoch keine Bewertungen

- Suspension BasicDokument7 SeitenSuspension BasicVincentius NikimNoch keine Bewertungen

- Steering MechanismDokument18 SeitenSteering MechanismVincentius NikimNoch keine Bewertungen

- Suspension 001Dokument26 SeitenSuspension 001Vincentius NikimNoch keine Bewertungen

- Alignment 001Dokument18 SeitenAlignment 001Vincentius NikimNoch keine Bewertungen

- Mechanisms With Lower PairsDokument43 SeitenMechanisms With Lower PairsVincentius NikimNoch keine Bewertungen

- Chapter 67 AlignmentDokument25 SeitenChapter 67 AlignmentVincentius NikimNoch keine Bewertungen

- Regulador 1800B2Dokument16 SeitenRegulador 1800B2DavidNoch keine Bewertungen

- 1126-20 Scanvent Type 2376 IMO2 Rev 1Dokument14 Seiten1126-20 Scanvent Type 2376 IMO2 Rev 1Ivaylo IvanovNoch keine Bewertungen

- Control Valves and Their Principles of OperationDokument5 SeitenControl Valves and Their Principles of Operationgroshan20Noch keine Bewertungen

- Valves For Cryogenic ServiceDokument1 SeiteValves For Cryogenic ServiceAnnamalai Ram JGCNoch keine Bewertungen

- Factors Influencing Compaction Test ResultsDokument105 SeitenFactors Influencing Compaction Test ResultsJonathan Carlos CallacaNoch keine Bewertungen

- EH-SolutionsLibrary 999902104 1Dokument16 SeitenEH-SolutionsLibrary 999902104 1Alfonso Lopez toroNoch keine Bewertungen

- Sulfinert Treated Sample CylinderDokument4 SeitenSulfinert Treated Sample Cylindervipequi50Noch keine Bewertungen

- Manual of Spray Dryer No.3 - Feeding PumpDokument8 SeitenManual of Spray Dryer No.3 - Feeding PumpM BJNoch keine Bewertungen

- Hotstart - Model OCLA or OCLE - Oil and Coolant Circulating Heating System Hazardous LocationDokument16 SeitenHotstart - Model OCLA or OCLE - Oil and Coolant Circulating Heating System Hazardous Locationdiego106Noch keine Bewertungen

- Whirlpool Cabrio Washer Fault CodesDokument7 SeitenWhirlpool Cabrio Washer Fault CodesqweezyNoch keine Bewertungen

- Volvo Cars Skövde Zhangjiakou Spezification v1.5 2022-01 ENDokument41 SeitenVolvo Cars Skövde Zhangjiakou Spezification v1.5 2022-01 ENMohamed DaHaBNoch keine Bewertungen

- Apollo Model 610F Gate ValveDokument2 SeitenApollo Model 610F Gate ValveDGWNoch keine Bewertungen

- Liebert Pexcw User ManualDokument109 SeitenLiebert Pexcw User ManualLe Thai vinh thinhNoch keine Bewertungen

- High Speed Printing Machine - 240215 - 044513Dokument19 SeitenHigh Speed Printing Machine - 240215 - 044513Murali AgencyNoch keine Bewertungen

- GIP2 IPFSIL-EXE-RTSB (TASB) - 000-INC-TDS-0002 - RevB (Datasheet) (1) - 4Dokument1 SeiteGIP2 IPFSIL-EXE-RTSB (TASB) - 000-INC-TDS-0002 - RevB (Datasheet) (1) - 4Kacip BolaNoch keine Bewertungen

- FK 4161Dokument8 SeitenFK 4161Nguyen KhaNoch keine Bewertungen

- Rebuilding A Cast Iron K Jetronic Fuel DistributorDokument13 SeitenRebuilding A Cast Iron K Jetronic Fuel DistributorPrudencioTeodosioNoch keine Bewertungen

- Domestic Pressure CookerDokument26 SeitenDomestic Pressure CookerDivyansh SharmaNoch keine Bewertungen

- Ifm International Short-Catalogue GB 05Dokument29 SeitenIfm International Short-Catalogue GB 05cesar luis gonzalez rodriguez100% (1)

- Fabrication of Pneumatic Auto Feed Drilling MachineDokument47 SeitenFabrication of Pneumatic Auto Feed Drilling MachineOnkar Chakkarwar100% (14)

- Reducteurs DRRP Bosch Rexroth Hydraulique BDokument4 SeitenReducteurs DRRP Bosch Rexroth Hydraulique BNguyễn Minh NhấtNoch keine Bewertungen

- PULSATRON A Plus طلمبات حقن الكيماويات الكهربائيةDokument8 SeitenPULSATRON A Plus طلمبات حقن الكيماويات الكهربائيةRheoserve Industrial SolutionsNoch keine Bewertungen

- Hydraulic Test Bench Circuit Construction Testing and AnalysisDokument12 SeitenHydraulic Test Bench Circuit Construction Testing and Analysisarmando desoyoNoch keine Bewertungen