Beruflich Dokumente

Kultur Dokumente

CornerDesk DrawerCabinet

Hochgeladen von

ZRomulus73Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

CornerDesk DrawerCabinet

Hochgeladen von

ZRomulus73Copyright:

Verfügbare Formate

www.BobsPlans.

com

Corner Computer Desk

&

Four Drawer Cabinet

Here's the perfect computer desk for people who like lots of space. The top is not only large, it wraps

around you providing a convenient surface to rest your elbows while you work. It's made of oak veneered

plywood with a small amount of solid oak for the lap drawer and trim. Plus, it's an easy project. Check out

these features:

Convenient lap drawer.

Plenty of space below for the CPU tower and a large chair.

A swivel caster on the rear leg for easy positioning in a corner.

Easily disassembles for moving.

The top measures 48" by 48" and the height is 30".

Four Drawer Cabinet may be placed on either side.

Tools You Will Need: Table Saw, Drill, Pocket Hole Jig, Router

Copyright 2009 by Robert E. Reedy

All rights reserved

Release Date: 02/27/2009

Corner Computer Desk Plans

Table of Contents

Materials List ................................................................................................................................. 1

Top Dimensions ............................................................................................................................. 2

End Panels Dimensions ................................................................................................................. 3

Edge Trim Dimensions .................................................................................................................. 4

Leg Dimensions ............................................................................................................................. 5

Lap Drawer Dimensions ................................................................................................................ 6

Stiffener Dimensions ..................................................................................................................... 7

Gusset & Leg Mount Dimensions ................................................................................................. 8

Stiffener Pocket Holes ................................................................................................................... 9

Stiffener A Screw Holes .............................................................................................................. 10

End Panel Mount Holes ............................................................................................................... 11

Gusset Holes - End Panel ............................................................................................................ 12

Leg Mount Holes ......................................................................................................................... 13

Leg Holes ..................................................................................................................................... 14

Attach Top Edge Trim ................................................................................................................. 15

Attach End Panel Edge Trim ....................................................................................................... 16

Round Over Edges ....................................................................................................................... 17

Attach Stiffeners A & Gusset B ................................................................................................... 18

Assemble Stiffeners C, D, & E .................................................................................................... 19

Attach Stiffeners CDE, & F ......................................................................................................... 20

Attach Gussets G, H, & I ............................................................................................................. 21

Attach Stiffeners J ........................................................................................................................ 22

Attach End Panel Mounts ............................................................................................................ 23

Assemble Leg A ....................................................................................................................... 24

Assemble Leg B ........................................................................................................................ 25

Assemble Leg C ........................................................................................................................ 26

Attach Leg Mount ........................................................................................................................ 27

Drawer Parts Slots .................................................................................................................... 28

Assemble The Drawer Step 1 ................................................................................................... 29

Assemble The Drawer Step 2 ................................................................................................... 30

Complete the Drawer ................................................................................................................... 31

Assemble the Desk ...................................................................................................................... 32

Stiffener Layout ........................................................................................................................... 33

Plywood Cutout Diagram ............................................................................................................ 34

Working with Veneered plywood ................................................................................................ 35

Router Guide plates ..................................................................................................................... 36

Making the Top ............................................................................................................................ 37

Copyright 2009 by Robert E. Reedy, Vandalia, Ohio

All Rights Reserved

Corner Computer Desk

Materials You Will Need

One sheet of oak veneer plywood ........................................................................... see cutout diagram.

Less than 1/4 sheet of Oak Veneer Plywood or other material ........................... drawer sides and back.

Less than 1/4 sheet of hardboard or thinner material ................................................... drawer bottom.

One 5 by 6 by solid oak board .............................. for the drawer front & stiffeners C, & edge trim.

One sets of 18 drawer slides (may be closer to 17 ) .................................. available in hardware stores.

Box of 100 pocket hole face frame screws 1 ........................................................ (youll need about 65)

Seven Hex head bolts with flat washers, & lock washers ............................... (1/4 by 20 threads per inch).

Seven T-Nuts .................................................................................................. (1/4 by 20 threads per inch).

Item List

Item Name

Top

End Panels

Top End Trim

Top Middle Trim

Top Intermediate Trim

End Panel Trim

Size

Material

Qty

Oak Veneer Plywood

Oak Veneer Plywood

Solid Oak

47 /8 by 47 /8

29 by 21 /8

1

24 by by /8

5

22 /8 by by /8

1

Solid Oak

Solid Oak

Solid Oak

Oak Veneer Plywood

8 /8 by by /8

29 by by /8

Stiffener A

44 by 3

Stiffener B

3 by by

Solid Oak

Stiffener C

8 by 3 by

Solid Oak

Stiffener D

18 by 3

Oak Veneer Plywood

Stiffener E

5 by 3

Oak Veneer Plywood

Stiffener F

37 /8 by 3

Oak Veneer Plywood

Gusset G

4 by 3

Oak Veneer Plywood

Gusset H

4 by 3

Oak Veneer Plywood

Gusset I

4 by 3

Oak Veneer Plywood

Stiffener J

20 by 3

Oak Veneer Plywood

End Panel Mount

20 by 3

Oak Veneer Plywood

Leg Mount K

5 by 5

Oak Veneer Plywood

Leg Top L

5 by 5

Oak Veneer Plywood

Leg Side M

26 by 5

Oak Veneer Plywood

Leg Side N

26 by 5

Oak Veneer Plywood

Leg Foot O

2 by 2

Oak Veneer Plywood

Solid Oak

Drawer Front

Drawer Front Filler

Drawer Side

Drawer Back

22 by 2 /8 by

7

2 /8 by /16 by /8

Solid Oak

Oak Plywood

Oak Plywood

16 /8 by 2 /8

20 /8 by 2 /8

2 Swivel Caster

1

Copyright 2009 by Robert E. Reedy

All Rights Reserved

Notes About T-Track

Rockler Universal T-Track

For accurate work, your workpiece must be securely clamped to your workbench. With

T-Track, hold down clamps, and a little imagination, you can clamp just about anything

from very small, very large, and even irregularly shaped workpieces for consistently

accurately work.

www.rockler.com

Most T-Track is designed to use either 1/4 hex head bolts or 5/16 T- bolts. T-bolts

have rounded flat oval shaped heads that slide though the track smoothly. 1/4 hex

head bolts are more readily available in a wide variety of lengths but the corners of the

head make it more difficult to slide the hold down clamps along track.

End View

With most T-Track manufacturers, you only have one choice but Rockler's Universal Ttrack enables you to have the beat of both types. The bottom of their universal track is

the correct width to accept 1/4 hex heads and the middle section allows you to use

the smoother sliding oval head T-bolts.

Universal T-Track Kit

www.rockler.com

Hold Down Clamps

www.rockler.com

This kit includes a 48" length of

Rockler's new anodized aluminum

Universal T-track that can be cut to

length. Plus an assortment of knobs

and easy to slide T-bolts.

Pocket Hole Joinery

This workbench uses pocket hole joinery for

assembling many of the parts. Pocket holes are one of

the easiest, quickest, and strongest ways to join two

pieces of wood. You simply drill a pocket hole in one

piece. Apply glue to the mating surfaces, clamp and

insert the pocket hole screw.

This kit includes a 48" length of

Rockler's new Universal T-track that

can be cut to length. Plus two hold

down clamps, 3'' T-bolts, and 5-star

knobs) good for material up to 2-1/2''

thick.

Casters

I recommend using total lock casters on one

end of your workbench and rigid casters on the

other end. This provides easy mobility and

enables you to lock the workbench securely in

place. Total lock means the swivel mechanism

and the wheel are locked when the brake is

applied. Use a minimum of 3 wheel dia.

The screw draws the joint tightly together and remains

in the joint permanently. Th combination of the screw

and glue provides an extremely strong joint.

Kreg Jig K3

www.rockler.com

Kreg Jig K3

www.rockler.com

Casters

www.rockler.com

Corner Computer Desk

Top Dimensions

Page 2

23 7/8"

Note: The top is made of 3/4" thick

material. The 47 7/8" and 23 7/8

dimensions will become 48" and

24" after the 1/8" edge trim is

added.

23 7/8"

47 7/8"

8"

47 7/8"

90

Cut an opening from the rear corner as

shown to the left. This opening is for

computer cables. (This opening is

optional. If you prefer, you can leave the

corner square.)

23 7/8"

8"

90

2"

2"

Copyright

2009 by Robert E. Reedy, Vandalia, Ohio

23 7/8"

Corner Computer Desk

End Panel Dimensions

Page 3

21 3/8"

End Panel

Wood Grain

29 1/4"

(2 Required)

Copyright

2009 by Robert E. Reedy, Vandalia, Ohio

Corner Computer Desk

Edge Trim Dimensions

Page 4

Make all Edge Trim pieces from solid oak 3/4" wide by 1/8" thick.

Note: The red circle are to pinit out corners tha require miter cuts

Top End Trim (2 Required)

Side View

3/4"

24"

45

90

Top View

1/8"

24"

Top Middle Trim (1 Required)

Side View

3/4"

22 5/8"

67.5

67.5

Top View

22 5/8"

Top Intermdeiate Trim (2 Required)

3/4"

Side View

8 1/8"

45

Top View

67.5

8 1/8"

End Panel Trim (2 Required)

Side View

3/4"

29 1/4"

90

Top View

29 1/4"

Copyright

2009 by Robert E. Reedy, Vandalia, Ohio

90

Corner Computer Desk

Leg Dimensions

Page 5

5 3/4"

5"

3"

Cut a 3/4" by 3" section from

M. This provides clearance for

Gusset B.

N

3/4"

2 1/2"

2 1/2"

26"

30"

29 1/4"

26"

26"

2 1/2"

2"

3/4"

1 1/4"

The length of Leg sections M & N are given as 26". This based on the wheel being 2 1/2" from the

floor to the top of the mounting plate. If your wheel is a little higher, you need to subtract the

difference from the lengths of sections M & N. The total length of the leg and wheel must be 29

1/4".

Example: If your wheel is 2 9/16" high, you should make M & N 1/16" shorter than 26". Remove

the difference from the bottoms of M & N.

Copyright

2009 by Robert E. Reedy, Vandalia, Ohio

Corner Computer Desk

Lap Drawer Dimensions

Page 6

2 7/8"

Drawer Front

22 1/2"

The Drawer Front is made of 3/4" thick solid oak.

Drawer Front Trim

Drawer Side (2 Required)

2 7/8"

2 5/8"

(2 Required)

7/16"

16 3/8"

2 5/8"

The Drawer Sides are made of 1/2" thick material of your choice. Drawer Front Trim is made of 3/8" thick

solid oak.

Drawer Back (1 Required)

20 5/8"

15 7/8"

The Drawer Back is made of 1/2" thick material of your choice.

Drawer Bottom (1 Required)

21"

The Drawer Bottom may be made of 1/4" thick material or thinner if you choose.

Copyright

2009 by Robert E. Reedy, Vandalia, Ohio

Corner Computer Desk

Stiffeners Dimensions

Page 7

Note: Parts "C" are made of solid

hardwood. You can use veneered

plywood but you will need to make them

1/8" shorter and cover the exposed end

with 1/8" thick trim as you did with the

exposed edges on the top. The end you

cut at 45 will NOT be exposed.

Note: Parts "C", "D", & "E" require a

45 angle on one end!

45

45

F (1 Required)

18 3/4"

8 3/4"

Edge View

D (2 Required)

Edge View

Copyright

45

5"

Edge View

(2 Required)

Edge View

3"

20 3/4"

J - Panel Mounts (4 Required)

44 3/4"

Edge View

A (2 Required)

3"

2009 by Robert E. Reedy, Vandalia, Ohio

Edge View

3"

3"

37 1/8"

3"

C (2 Required)

3"

Corner Computer Desk

Gussets and Leg Mount Dimensions

Page 8

G, H, & I - (8 Required)

B - (1 Required)

3/4"

3"

G, H, & I

K & L - (2 Required)

5"

KL

Copyright

5"

4"

Edge View

3"

2009 by Robert E. Reedy, Vandalia, Ohio

Corner Computer Desk

Stiffener Pocket Holes

Page 9

Drill pocket holes in stiffeners according to the drawings below.

2"

2"

2"

1 1/2"

"1 1/2

5/16" Dia.

2"

5/16" Dia.

3"

3"

In addition to the pocket holes, drill two 5/16"

dia. holes through Stiffener "J" as shown above.

Stiffeners "A", "D", and "F" have pocket holes on both sides.

2"

2"

A (1st Side)

A (2nd Side)

15"

15"

2"

2"

F (1st Side)

F (2ndSide)

13"

13"

2"

2"

D (1st Side)

D (2nd Side)

6"

Copyright

6"

2009 by Robert E. Reedy, Vandalia, Ohio

Corner Computer Desk

Stiffener A Holes

Page 10

Drill and countersink holes for #6 flathead screws in the ends of the Stiffeners A as shown in

the drawings below. Note that the holes in the left and right stiffeners have the holes in

different positions from the top and bottom. This is so the screws will not interfere with each

other when attaching them to the Corner Gusset B.

Position the stiffener with the pocket holes down when determining the position of these holes.

1 1/8"

Left Stiffener A

Left Stiffener A

3/8"

Enlarged View

1/2"

Right Stiffener A

"1/2

3/8"

Right Stiffener A

1 1/8"

Enlarged View

Copyright

2009 by Robert E. Reedy, Vandalia, Ohio

Corner Computer Desk

End Panel Mount Holes

Page 11

Drill and countersink three 9/64" holes in the End Panel Mounts as shown below.

These will be used to attach the End Panel Mounts to the End Panels

End Panel Mount (Front Side)

1"

1"

1 1/2"

10 3/8"

Turn the End panel mount over and drill two 3/4" diameter by 1/8" deep flat bottom holes

in back side of each End Panel Mount as shown below. T-Nuts will be used in these holes

so they need to be drilled with a bit that leaves a flat bottom. A forstner, brad point, or

spade type bit will work. The reason for the 1/8" depth is so the T-Nut will be recessed

below the surface of the wood.

End Panel Mount (Rear Side)

3/4" Dia.

1 1/2"

5/16" Dia.

3/4" Dia.

1 1/2"

2"

2"

5/16" Dia.

Next, drill a 5/16" diameter hole completely through the center of each of the 3/4"

holes you just drilled. These are for the threaded section of the T-Nuts.

Place a T-Nut in each hole and tap with a hammer to make marks where the teeth contact

the wood. Then, drill a 1/8" dia. hole about 3/8" deep for each tooth. Apply some glue to

each tooth and insert the T-Nuts in place. Insert a 1/4" bolt with a flat washer through the

Leg Mount and tighten it to draw the T-Nuts fully into place. (This ensures the T-Nut is

aligned correctly.) Remove the bolt. The back side of the End Panel Mount should look

like the drawing to the right.

End Panel Mount (Rear Side)

Copyright

2009 by Robert E. Reedy, Vandalia, Ohio

Corner Computer Desk

End Panel Gusset Holes

Page 12

Six gussets are required for re-enforcing the End Panel Stiffeners. The hole

arrangement differs depending on the mounting location of each.You'll see what I mean

when you view the drawing for attaching these gussets to the Top.

Drill two 9/64" holes in Gussets "I" for mounting to their

respective stiffeners with 1 1/4" #6 screws. If you use

flathead screws, you should countersink these holes.

A single pocket hole is required for each gusset for securing

it to the End Panel Stillener. Drill the pocket hole 3/4" from

the top. Note that the pocket hole is on the left for Gussets

"I".

I

(2 Required)

1"

Drill a pocket hole and two 9/64"

holes in Gussets "G" as with Gussets

"I".

Note that the pocket hole is on the

right for Gussets "G".

1 1/2"

G

(2 Required)

"1

"1

Gussets "H" will be mounted to the

top between Gussets "G" and "I" and

also beside the Leg Mount. These are

mounted to the Top with two pocket

hole screws and to The Stiffeners

with a single screw like Gussets "I"

and "G".

Copyright

1"

1 1/2"

2009 by Robert E. Reedy, Vandalia, Ohio

H

(4 Required)

1"

1"

Corner Computer Desk

Leg Mount Holes

Page 13

Leg Mount (Front Side)

1 1/4"

3/4"

3/4"

Drill and countersink three 9/64" holes in the Leg Mount as shown to

the right These will be used to attach the Leg Mount to the Top.

3/4"

K

3/4"

1 1/4"

Leg Mount (Rear Side)

Turn the Leg Mount over and drill three 3/4" diameter by 1/8" deep

flat bottom holes in back side. T-Nuts will be used in these holes so

they need to be drilled with a bit that leaves a flat bottom. A forstner,

brad point, or spade type bit will work. The reason for the 1/8" depth

is so the T-Nut will be recessed below the surface of the wood.

1 1/2"

1 1/2"

1 3/4"

3/4" Dia.

5/16" Dia.

1 3/4"

Next, drill a 5/16" diameter hole completely through the center of each

of the 3/4" holes you just drilled. These are for the threaded section of

the T-Nuts.

Leg Mount (Rear Side)

Place a T-Nut in each hole and tap with a hammer to make marks

where the teeth contact the wood. Then, drill a 1/8" dia. hole about

3/8" deep for each tooth. Apply some glue to each tooth and insert the

T-Nuts in place. Insert a 1/4" bolt with a flat washer through the Leg

Mount and tighten it to draw the T-Nuts fully into place. (This ensures

the T-Nut is aligned correctly.) Remove the bolt. The back side of the

Leg Mount should look like the drawing to the right.

Copyright

2009 by Robert E. Reedy, Vandalia, Ohio

Corner Computer Desk

Leg Holes

Page 14

Drill and countersink two 9/64"

holes through Leg Section "N"

as shown below.

Drill and countersink two 9/64"

holes through foot "O" as

shown below.

5"

1 3/8"

5/8"

1 3/8"

5/8"

6 1/2"

1 1/4"

1 1/8"

1 1/2"

6 1/2"

Drill four pocket holes

in N as shown to the

right.

Drill three 5/16" holes through

L as shown below.

1 1/2"

6"

1 1/2"

1 1/8"

1 3/4"

1 3/4"

1 1/2"

1 1/4"

Drill and countersink two 9/64"

holes through Leg Section "M"

as shown above.

Copyright

2009 by Robert E. Reedy, Vandalia, Ohio

Corner Computer Desk

Attache Top Edge Trim

Page 15

Apply contact cement to the mating surfaces of the Top and Edge Trim and allow it to dry as per the

instruction on the container. When the contact cement is dry, attach the edge trim to the edges of the Top

as shown in the drawings below. Be sure it is positioned correctly the first time. It will be very difficult

to remove the trim without damaging it after it is pressed in place.

First, carefully position the Front Edge trim so it is flush with the top and bottom surfaces of the

Top and is lined up correctly in the corners. When it is positioned correctly, press it against the

Top with your fingers.

End Edge trim

End Edge trim

Front Edge trim

Next, carefully attach the two pieces of Front Edge trim and press them in place. Then, attach the

two pieces of End Edge trim and press them in place. Finally, use a roller or edge clamp to apply

pressure allong the length of all the trim.

Copyright

2009 by Robert E. Reedy, Vandalia, Ohio

Corner Computer Desk

Attach End Panel Edge Trim

Page 16

p

To

l

ne

a

P

nd

E

ft

Le

Choose the side with the best looking grain and attach the End Panel Edge Trim to the side as

shown above with contact cement as you did with the top trim. This will be the left End panel.

To

p

Rig

ht

E

nd

P

an

el

Again, choose the best looking side and attach the End Panel Edge Trim to the second End

panel with contact cement as shown above. This will be the Right End panel.

Copyright

2009 by Robert E. Reedy, Vandalia, Ohio

Corner Computer Desk

Round Over Edges

Page 17

Using a 1/8" radius roundover bit, round over the indicated edges on the Top, The End Panels,

Stiffeners C, and the Drawer Front.

Round over both the top and bottom edges of the Top on the indicated edges. (These are the edges

that have the 1/8" thick edge trim.)

n

ft E

Le

Rig

ht

En

d

el

an

dP

Pa

ne

l

Round over both the top and bottom edges of the End Panels on the indicated edges. (These are

the edges that have the 1/8" thick edge trim.)

Drawer Front

C

Round over only the bottom edges of pieces C.

Copyright

Round over all four front edges of the Drawer front.

2009 by Robert E. Reedy, Vandalia, Ohio

Corner Computer Desk

Attach Stiffeners "A" and Gusset "B"

Page 18

Apply glue to mating surfaces and postion the Left and Right Stiffeners "A" to the underside of the

Top as shown in the drawings below. Secure with pocket hole screws. Remember, there are pocket

holes on both sides of each Stiffener "A".

ht)

Rig

(

A

A(

Le

ft)

Apply glue to mating surfaces and attach Gusset "B" to the inside corner of the Stiffeners with

1 1/4" #6 flathead screws as shown above.

Top View

1 3/4"

3/4"

3/4"

3/4"

H

3/4"

NOTICE! The stiffeners go on the bottom! Determine

which side of the plywood has the most attractive grain

and use the least attractive side for the bottom.Do not over

tighten screws!

1 3/4"

Copyright

2009 by Robert E. Reedy, Vandalia, Ohio

Corner Computer Desk

Assemble Stiffeners C, D, & E

Page 19

Apply glue to mating surfaces and assemble stiffeners C, D, and E as showns below. Secure with

1 1/4" #6 screws.

D

E

3/4"

1/4"

1/4"

Mount a drawer slide on each piece D as shown above and secure with the screws provided with

the slide. Self closing drawer slides typically have a slope starting about 2 1/2" from the end.

Make sure the straight portion of the slide is 1/4" from the bottom of piece D.

Copyright

2009 by Robert E. Reedy, Vandalia, Ohio

Corner Computer Desk

Attach Stiffeners CDE, & F

Page 20

Apply glue to mating surfaces and position the pre-assembled stiffeners C, D, and E to the underside of the

Top as shown in the drawings below. Secure with pocket hole screws.

Next, apply glue and position stiffener F as show in the drawings and secure with pocket hole screws.

Remember, there are pocket holes on both sides of each stiffeners D and F.

C, D, & E

C, D, & E

C

F

ht)

Rig

A(

A(

Le

ft)

1"

1"

1"

1"

22 5/8"

22 5/8"

6 1/2"

6 1/2"

D

1"

Copyright

2009 by Robert E. Reedy, Vandalia, Ohio

1"

Corner Computer Desk

Attach Gussets G, H, & I

Page 21

Apply glue to mating surfaces and postion the Stiffeners G, H, and I to the underside of the Top

as shown in the drawings below.

G and I are secured to Stiffeners C and A with 1 1/4" #6 screws.

H is secured to the Top with pocket hole screws.

I

A

I

A

G

H

F

ht)

Rig

(

A

1/

4

"

1/

4"

A(

Le

ft)

"

1/

4

1/

4"

1/

4"

4"

1/

H

3

4"

1/

Copyright

2009 by Robert E. Reedy, Vandalia, Ohio

4"

1/

Corner Computer Desk

Attach Stiffeners J

Page 22

Apply glue to mating surfaces where stiffeners J contact stiffeners G, H, and I and the underside of

the Top as shown. Secure the stiffeners J with pocket hole screws.

J

IC

C

G

JJ

H

F

A(

Le

ft)

1/

4

"

1/

4"

ft)

Le

A(

"

1/

4

1/

4"

1/

4"

4"

1/

H

3

4"

1/

Copyright

2009 by Robert E. Reedy, Vandalia, Ohio

4"

1/

Corner Computer Desk

Attach End Panel Mounts

Page 23

These edges are flush.

Apply glue to mating surfaces and attach the End Panel Mounts to the End Panels

with 1 1/4" #6 flathead screws.

Copyright

2009 by Robert E. Reedy, Vandalia, Ohio

Corner Computer Desk

Leg Assembly - A

Page 24

Apply glue to mating surfaces and attach the leg

sections M and N with pocket hole screws as

shown below.

Copyright

N

N

2009 by Robert E. Reedy, Vandalia, Ohio

Corner Computer Desk

Leg Assembly - B

Page 25

L

K

Place the assembled pieces M & N on a flat

surface as shown above and place piece K in the

inside corner. Do not apply glue to K. It is only

being used to establish the correct position of

piece L.

Insert piece L fully into the corner as shown

above (pocket holes down). While holding the

pieces in place, insert the nail through each

screw hole and tap with a hammer to mark the

position of the pilot holes.

L

Drill four 7/64" pilot holes about 1/2"

deep in the edges of section L using the

points you made with the nail as shown

above.

N

M

N

Apply glue to the mating edges of L and secure

L in place with 1 1/4" #6 flathead screws.

Remove piece K (K will be attached to the Top

later.).

Copyright

Next, insert two pocket hole screws as shown

above to add extra strength.

2009 by Robert E. Reedy, Vandalia, Ohio

Corner Computer Desk

Leg Assembly - C

Page 26

Apply glue to mating surfaces and position piece

"O" so it extends equally over the leg pieces M

& N. Secure with 1 1/4" #6 flathead screws.

Attach the Wheel as as shown below. If screws

did not come with the wheel, 3/4" #6 panheads

will work fine.

Copyright

2009 by Robert E. Reedy, Vandalia, Ohio

Corner Computer Desk

Attach Leg Mount

Page 27

Position the two remaining Gussets H in the

corner to server as spacers as shown to the right.

The Gussets H should be made of material the

same thickness as the Leg pieces M & N. This

will ensure the ends of the Leg fits behind the

Leg Mount. Do not appy glue as these will be

removed after the Leg Mount is attached.

K

H

Apply glue to mating surfaces of Leg Mount K and

the Top. Then, position Leg Mount K against the

Gussets H as shown to the left. Secure Gusset K to the

Top with 1 1/4" #6 flathead screws. . The side of the

Leg Mount with T-Nuts goes against the Top.

Remove the two Gussets H and wipe any excess

glue from around the edges of The Leg Mount K.

E( R

igh

)

eft

E(L

t)

Apply glue to mating surfaces and secure Gussets H to the Stiffeners A and the Top with pocket hole screws

as shown below. Be sure the Gussets H provide enough room for the Leg Assembly to sit flat against Leg

Mount K.

A(

Rig

ht)

ft)

Le

(

A

Copyright

2009 by Robert E. Reedy, Vandalia, Ohio

Corner Computer Desk

Drawer Parts - Slots

Page 28

Drawer Front

1/2"

Step 1. Cut a slot for the Drawer Bottom in the Drawer Front as shown above.

The slot is 1/2" from the bottom of the Drawer Front and 3/16" deep. The

width of the slot should be just wide enough for the Drawer Bottom to slide in

it easily.

"15/16

15/16"

20 5/8"

3/8"

"3/8

Top View

Drawer Front

1/4"

2 5/8"

Step 2. Cut a 15/16" wide by 3/8" deep rabbet on each end of the

Drawer front as shown above. This should leave a section in the

center that is 20 5/8" long (the same as the length of the Drawer

Back.

Drawer Side (2 Required)

Drawer Back (1 Required)

1/4"

Step 3. Cut a slot for the Drawer Bottom in each Drawer Side and the Drawer

Back. These slots are only 1/4" from the bottom and 3/16" deep. The width of

the slot should be the same as with the slot in the Drawer Front.

1/2"

7/8"

3/16"

"3/16

Drawer Side (2 Required)

"1/2

"7/8

Step 4. Drill two 1/16" holes through each end of both Drawer Sides. These

hole will ensure the 1" brads will be in the correct position when assembling

the drawer.

Copyright

2009 by Robert E. Reedy, Vandalia, Ohio

Corner Computer Desk

Assemble the Drawer Step 1

Page 29

Step 1. Apply glue to the mating surfaces and attach the First Drawer Side to the

Drawer Front and Back as shown below. Make sure the slots for the Bottom are

alligned correctly (The Front, Sides, and Back will be flush at the top.) Secure with

1 1/4" finishing nails using the 1/16" holes already drilled. (You made need help

holding the assembly in place.)

First Drawer Side

Drawer Front

Drawer Back

Front

Support Block

Second Drawer Side

Use a 3/4" thick piece of wood as a support block so

the Front is not touching the workbench.

Copyright

2009 by Robert E. Reedy, Vandalia, Ohio

Corner Computer Desk

Assemble the Drawer Step 2

Page 30

Step 2. Turn the assembly over and insert the bottom into the

slots. Apply glue to the mating surfaces and secure with 1 1/4"

finishing nails. Do not glue the bottom in plaace, it should be free

to expand and contract.

Second Drawer Side

Drawer Bottom

Copyright

2009 by Robert E. Reedy, Vandalia, Ohio

Corner Computer Desk

Complete the Drawer

Page 31

Apply glue to the mating surfaces and position the Drawer Front Trim flush

against the Drawer Front and the Drawer Side as shown above. Repeat for

the other side. Clamp in place until glue dries.

Position the drawer slide flush against the

Drawer front as shown.

Drawer slide extends past the end of the

drawer.

Using the screws provided with the drawer slides, attach a drawer slide to each side of

the drawer as shown above. The drawer slides will protrude past the end of the drawer.

This is necessary so the drawer can be removed and installed.

This completes the drawer.

Copyright

2009 by Robert E. Reedy, Vandalia, Ohio

Corner Computer Desk

Assemble the Desk

Page 32

Attach the End Panels to the Stiffeners J

with 1 1/2" long bolts (1/4" dia. by 20

threads per inch), lock washers and flat

washers as shown below.

Do not use glue. You may want to

disassemble the desk to move it.

IC

C

G

JJ

H

F

A(

Le

ft)

ft)

Le

A(

ft)

Le

A(

Attach the Leg Assembly to the Leg

Mount with three 1 1/2" long bolts

(1/4" dia. by 20 threads per inch), lock

washers and flat washers as shown

above.

F

A(

Rig

h

t)

Again, do not use glue.

J

Copyright

2009 by Robert E. Reedy, Vandalia, Ohio

Corner Computer Desk

Stiffener Layout

Page 33

This drawing shows the layout and positions of the stiffeners.The edge trim should

already be attached at this point or else the dimensions will be incorrect.

3/4"

3/4"

A

I

2 1/2"

6

2

1/

3/4"

"

H

J

37

18

"

9 1/4"

22

2 1/2"

1/

8"

5/

8"

E

1"

1"

6

2

1/

"

22

5/

"

"

18

3/4"

9 1/4"

J

Copyright

2009 by Robert E. Reedy, Vandalia, Ohio

1"

G

C

Corner Computer Desk

Plywood Cutout Diagram

Page 34

Top

96"

J

End Panel Mount

End Panel Mount

A

A

End Panel

F

End Panel

48"

Copyright

2009 by Robert E. Reedy, Vandalia, Ohio

Corner Computer Desk

Working With Veneered Plywood

Page 35

Working with Veneered Plywood

When building projects that require large panels, veneered plywood is usually a great choice.

It is just as attractive as solid wood, is less likely warp and split, and its less expensive.

While it offers some excellent benefits over solid wood, veneered plywood presents some

challenges that need to be considered.

1. First, the edges that will be visible need to be covered with some type of edge trim.

With this project, I chose to make 1/8 thick edge trim from solid oak boards and glue

it to the edges with contact cement. To finish off the edges, use a 1/8 radius rounding

over router bit. This is the reason the trim needs to be 1/8 thick.

2. The second issue is tearout. A saw blade presses fibers toward the wood when it

enters the work piece (which is good) but it tears fibers loose when it leaves the work

piece. This can leave a terrible looking edge that cannot be corrected. Tearout occurs

on solid wood too but its worse with plywood.

You can prevent tearout by placing a piece of hardboard like Masonite or thin

MDF board between the saw and the work piece. This sacrificial board will hold the

fibers against the wood and prevent tearout.

I strongly recommend that you use this technique to prevent tearout when cutting the

Top and End Panels. The stiffeners and gussets wont be visible and a little tearout

wont matter so much with them.

3. The third issue is that the veneer is very thin and you cannot sand out defects without

sanding through the veneered surface. If you do, you will have an unsightly blotch that

will ruin the appearance of your project.

For this reason, you need to be careful not to drive the pocket hole screws too deep

when attaching the stiffeners and gussets to the bottom surface of the desk top. If you

over tighten the screws, you will have an unsightly bump on the top surface. The

illustrations below show you how to prevent this.

4. When the project is completed and youre ready to finish it. You can sand the surface

with 220 grit sandpaper. Only sand enough to get a smooth finish. Dont over do it.

The depth of the pocket hole

is determined by how far the

drill goes into the jig. Use a

stop collar on your drill bit to

adjust the depth of the hole so

no more than half the screw

protrudes.

Use a screwdriver

instead of an electric

drill driver so you can

be sure not to over

tighten the pocket hole

screws.

Good

Copyright

2009 by Robert E. Reedy, Vandalia, Ohio

If you over tighten the

screw and it crushes the

wood under the screw

head, you will have a

bump on the surface of

your desk top.

Over tightened

Corner Computer Desk

Router Guide Plates

Page 36

8"

2"

45

67.5

Intermediate Router Guide (1Required)

22 5/8"

2"

67.5

2"

90

Middle Router Guide (1Required)

End Router Guide (2Required)

67.5

45

23 7/8"

Make the router guide plates out of scrap material as shown above. The

thickness of the plates may be anywhere from 1/4" to 3/4". These are used

in the next step when you make the Top. Be sure the edges are straight and

smooth so the router will leave a straight smooth edge.

Copyright

2009 by Robert E. Reedy, Vandalia, Ohio

Corner Computer Desk

Making the Top

Page 37

Next, select the best looking side for the top surface

and being careful not to scratch the surface, turn the

work piece so the best looking side is down. Place

masking tape around the edges as shown below and

layout your cut lines on the masking tape according to

the dimensions given. The cut lines should be about

1/16" from the edges. Remember, this side will be the

bottom surface of the finished Top.

First, cut the Top about 1/16" larger than the 47 7/8

and the 23 7/8 dimensions shown in the drawings. You

will use your router and straight edges to remove this

extra 1/16". The router will provide a nice smooth

edge suitable for applying the edge trim. Because of

the shape of the Top, you will need to use a jig saw for

this cut. Be sure to place a sacrifical board under the

jig saw to prevent tearout.

47

7/8

"47

"

7/8

Bottom Side

47

"23

7/8

"

"47

7/8

7/8

23

"8

7/8

"

8"

Bottom Side

Attach the router guide plates along the cut marks and secure to the workpiece with small

brads as shown above. Select brads that are long enough to penetrate about 1/2" into the Top.

Be sure the brads are flush with the surface so the router doesn't hang up on them. Use a 5/16"

flush trim bit in your router to trim the edges of the workpiece flush to the guide plates.

The two inside corners will be slightly rounded. With the guide plates still in place, use a file

to clean up the corners so the edges are straight all the way to the corners.

Copyright

2009 by Robert E. Reedy, Vandalia, Ohio

www.BobsPlans.com

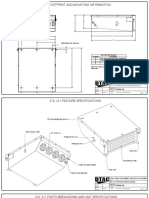

Four Drawer Cabinet

A computer desk is not complete without a matching drawer cabinet. This cabinet is designed

to compliment our Corner Computer Desk plans. Features an 18 by 24 top and the height is

30.

Like the Corner Computer Desk, it's made of oak veneered plywood with solid oak for the

drawer fronts and trim. Self closing drawer slides are easy to install, provide smooth operation,

and facilitates easy drawer removal. Check out these features:

The 18 by 24 top is perfect for your printer or scanner.

Shallow top drawer for pens, pencils, paper clips, and other small items.

The second drawer is large enough for a stapler, hole punch and other mid sized items.

The third drawer is large enough to hold CD jewel cases and envelopes.

The bottom drawer is for regular size file folders.

Tools You Will Need: Table Saw, Drill, Pocket Hole Jig, Router

Copyright 2009 by Robert E. Reedy

All rights reserved

Release Date: 01/23/2009

Four Drawer Cabinet Plans

Table of Contents

Materials List ................................................................................................................................. 1

Top & Side Panel Dimensions ....................................................................................................... 2

Trim, Drawer Dividers, & Gusset Dimensions .............................................................................. 3

Trim, Drawer Dividers, & Gusset Holes ....................................................................................... 4

Drawer Parts .................................................................................................................................. 5

Drawer Fronts ................................................................................................................................ 6

Attach Side Trim ............................................................................................................................ 7

Attach Drawer Slides to Right Panel ............................................................................................. 8

Attach Drawer Slides to Left Panel ............................................................................................... 9

Assemble Cabinet - 1.................................................................................................................... 10

Assemble Cabinet - 2 ................................................................................................................... 11

Assemble Cabinet - 3 ................................................................................................................... 12

Assemble Cabinet - 4 ................................................................................................................... 13

Assemble Cabinet - 5 ................................................................................................................... 14

Drawer Slots ................................................................................................................................ 15

Drawer Front Slots - A ................................................................................................................ 16

Drawer Front Slots - B ................................................................................................................. 17

Assemble the Drawers ................................................................................................................. 18

Attach Drawer Slides ................................................................................................................... 19

Cabinet Cutouts ........................................................................................................................... 20

Drawer Cutouts ............................................................................................................................ 21

Copyright 2009 by Robert E. Reedy, Vandalia, Ohio

All Rights Reserved

Four Drawer Cabinet

Materials You Will Need

One half sheet (48 by 48) of oak veneer plywood ............................................... see cutout diagram.

One quarter sheet of Oak Veneer Plywood or other material .............................. drawer sides and back.

Less than 1/4 sheet of hardboard or thinner material ................................................... drawer bottom.

One 7 by 8 by solid oak board ..................................... for the drawer fronts, dividers, & edge trim.

Four sets of 18 drawer slides (may be closer to 17 ) ................................. available in hardware stores.

Box of pocket hole face frame screws 1 ............................................................... (youll need about 65)

Item List

Item Name

Top

Side Panels

Top Side Trim

Top Front Trim

Size

Material

Qty

Oak Veneer Plywood

Oak Veneer Plywood

24 by by /8

18 by 23 /8

29 by 22 /8

1

/8 Thick Solid Oak

18 by by /8

/8 Thick Solid Oak

Side Panel Trim

29 by by /8

Front Top Gusset

15 by 3

Solid Oak

Rear Top Gusset

15 by 3

Oak Veneer Plywood

Drawer Dividers

15 by 2

Solid Oak

/8 Thick Solid Oak

Bottom Trim

15 by 1 /8

Oak Veneer Plywood

Side Gussets

16 by 1

Oak Veneer Plywood

Rear Gussets

15 by 5

Oak Veneer Plywood

File Folder Slide Support

13 by 1

Thick Wood (Any Type)

Top Drawer Back

Oak Veneer Plywood

nd

13 by 3 "

Oak Veneer Plywood

rd

3 Drawer Back

13 by 6

Oak Veneer Plywood

Bottom Drawer Back

13 by 10

2 Drawer Back

Top Drawer Side

nd

2 Drawer Side

rd

3 Drawer Side

Bottom Drawer Side

Top Drawer Front

13 by 2

3/8

16

3/8

Oak Veneer Plywood

Oak Veneer Plywood

16

3/8

by 3

Oak Veneer Plywood

16

3/8

Oak Veneer Plywood

16

3/8

Oak Veneer Plywood

3/8

by 2

by 6

by 10

3

15 by 3 /8

Solid Oak

nd

15 by 4

Solid Oak

rd

3 Drawer Front

15 by 7

Solid Oak

Bottom Drawer Front

15 by 11 34

Solid Oak

Steel Bar

2 Drawer Front Filler

File Folder Slide

15 by by

1/8

Copyright 2009 by Robert E. Reedy

All Rights Reserved

Four Drawer Cabinet

Top & Side Panel Dimensions

Page 2

22 1/8"

Side Panel

(1 Required)

Top

Wood Grain

23 7/8"

Wood Grain

29 1/4"

(2 Required)

18 1/4"

(All Trim is 1/8" thick solid oak)

29 1/4"

3/4"

Side Panel Trim (2 Required)

24"

3/4"

Top Side Trim (2 Required)

18 1/2"

3/4"

Top Front Trim (1 Required)

Copyright

2009 by Robert E. Reedy, Vandalia, Ohio

Four Drawer Cabinet

Trim, Drawers Dividers, & Gussets

Page 3

15"

3"

Front & Rear Top Gusset

(2 Required)

Note: The Front Gusset is solid oak, the Rear Gusset is 3/4" plywood

15"

Drawer Dividers

2"

(3 Required)

15"

Bottom Trim

1 7/8"

(1 Required)

15"

Rear Gussets

5"

(2 Required)

16 1/4"

Side Gussets (2 Required)

1 1/2"

Copyright

2009 by Robert E. Reedy, Vandalia, Ohio

Corner Computer Desk

Trim, Dividers, & Gussets Holes

Page 4

Drill four pocket holes and two 3/16"diameter holes through the Top Gussets as shown below.

2"

2"

3/4"

1/2"

"1/2

Top Gussets

3/4"

Drill two pocket holes on each end of the Drawer Dividers as shown below.

1/2"

Drawer Dividers

1/2"

Drill two pocket holes on each end of the Bottom Trim as shown below.

Note: Choose the best looking of the Bottom trim for the front. Drill pocket holes on back side.

1/2"

Bottom Trim

1/2"

Drill two pocket holes on each end of the Rear Gussets as shown below.

3/4"

Rear Gussets

3/4"

Drill two 3/16" dia. holes through the edge and two through the wide surface of the Top Mounts as shown below.

2"

2"

Top Mounts

3/8"

1"

3/8"

1"

Copyright

2009 by Robert E. Reedy, Vandalia, Ohio

Four Drawer Cabinet

Drawer Parts

Page 5

16"

Drawer sides, backs, and file folder slide supports are

made of 1'2" thick material,

Drawer bottoms are made of 1/4" thick material but

3/16" material will work just as well. If you use

material less than 1/4", cut the slots just wide enough

for the bottoms to fit without binding.

13 1/2"

Drawer bottom (4 Required)

13"

File Folder Slide Support (2 Required)

1"

All drawer backs are 13" wide and all drawer sides are

16 3/8" long.

2 3/8"

2 3/8"

Top Drawer Side (2 Required)

2nd Drawer Back (1 required)

3 1/4"

2nd Drawer Side (2 Required)

3rd Drawer Back (1 required)

6"

3rd Drawer Side (2 Required)

Bottom Drawer Back (1 required)

Bottom Drawer Side (2 Required)

10 3/4"

10 3/4"

Top Drawer Back (1 required)

3 1/4"

16 3/8"

6"

13"

2009 by Robert E. Reedy, Vandalia, Ohio

Four Drawer Cabinet

Drawer Fronts

Page 6

Drawer fronts are made of solid oak.

All drawer fronts are 15 1/2" wide.

3 3/8"

Top Drawer Front

4 1/4"

15 1/2"

2nd Drawer Front

(1 Required)

(1 Required)

11 3/4"

7"

3rd Drawer Front

(1 Required)

Bottom Drawer Front

(1 Required)

E. Reedy, Vandalia, Ohio

2009 by Robert Copyright

Corner Computer Desk

Attach SideTrim

Page 07

Attach the End Panel Edge Trim to each End Panel with contact cement as shown above.

Choose the most attractive side and round over the edge with a 1/8" radius rounding over bit.

Only the outside edge should be rounded over.

Copyright

2009 by Robert E. Reedy, Vandalia, Ohio

Four Drawer Cabinet

Attach Drawer Slides to Right Panel

Page 8

Rig

ht

Sid

eP

/8

35

/2 "

41

ane

l

/4 "

71

12

"

Oak Trim

Attach the drawer slides to the right panel with screws that were

provided with the slides as shown above. If no screws were

provided, use 1/2" long #6 flathead screws. Be sure the middle

section of each slide is parallel to the top and bottom of the panels.

Copyright

2009 by Robert E. Reedy, Vandalia, Ohio

Four Drawer Cabinet

Attach Drawer Slides to Left Panel

Page 9

35

/8

"4

1/2

"7

ide

S

ft

Le

1/4

el

n

a

P

"12

Oak Trim

Attach the drawer slides to the left panel.

Copyright

2009 by Robert E. Reedy, Vandalia, Ohio

Four Drawer Cabinet

Assemble Cabinet - 1

Page 10

Rear Gusset

All three pieces should be flush with the top of the side

panel.

Bottom Trim

h

Rig

id

tS

nel

a

P

To

pM

oun

t

Apply glue to mating surfaces and attach a Rear Gusset

and the Front Trim to the Right Side with pocket hole

screws as shown to above.

The Rear Gusset and Front Trim should be flush with the

bottom of the side panel.

Copyright

2009 by Robert E. Reedy, Vandalia, Ohio

Top Gusset

Top Gusset

Apply glue to mating surfaces and attach the Top Gussets

and a Top Mount to the top Right Side as shown below.

Use pocket hole screws for the gussets and 2" screws for

the Top Mount.

Four Drawer Cabinet

Assemble Cabinet - 2

Page 11

Apply glue to mating surfaces and place the assembled

Right Side with the parts that are already attached to it on

the Left Side as shown below.

To

pM

oun

t

id

S

t

f

Le

nel

a

P

Top Gusset

Top Gusset

h

Rig

ide

S

t

el

n

a

P

Copyright

2009 by Robert E. Reedy, Vandalia, Ohio

Bottom Trim

Rear Gusset

Make sure all joints are flush at the corners and edges

before attaching with screws as with the previous step.

Four Drawer Cabinet

Assemble Cabinet - 3

Rear Gusset

Page 12

To

pM

oun

t

Bottom Trim

Drawer Dividers

Drawer Dividers

id

S

t

f

Le

nel

a

P

Drawer Dividers

To

pM

oun

t

Top Gusset

Top Gusset

h

Rig

ide

S

t

el

n

a

P

Third

Second

First

Pocket holes go toward the bottom of the cabinet and the oak trim is on the front.

Each Drawer Divider must be secured with pocket hole screws on both ends before

starting the next one. (This is because when the second divider is in place, you won't

have room to drive the screws in the previous one.)

Starting with the top Drawer Divider, apply glue to mating surfaces and position the

Drawer Dividers as shown in the drawing. Position the Drawer Dividers against the

bottom of the drawer slides and flush with the front edge of the cabinet.

Copyright

2009 by Robert E. Reedy, Vandalia, Ohio

Four Drawer Cabinet

Assemble Cabinet - 4

Top Gusset

To

pM

oun

t

Rear Gusset

Apply glue to the mating surfaces and position the remaining Rear Gusset about one

inch from the Top Gusset and flush with the back. Secure with pocket hole screws. The

reason for the one inch distance from the Top Gusset is so you have room to drive the

screws.

Copyright

2009 by Robert E. Reedy, Vandalia, Ohio

Top Gusset

Rear Gusset

Drawer Dividers

Drawer Dividers

h

Rig

id

tS

nel

a

P

Bottom Trim

Drawer Dividers

Page 13

Four Drawer Cabinet

Assemble Cabinet - 4

Page 14

t

se

us

et

uss

G

p

To

m

tto

Bo

a

Dr

To

p

M

ou

nt

Right Side Panel

Left Side Panel

G

ar

Re

a

Dr

T ri

rs

id e

Div

r

we

rs

id e

Div

r

we

3/4"

a

Dr

ivid

rD

we

ers

1"

et

uss

G

p

To

1"

Round over all four edges of the top (both top and bottom sides) with a 1/8" round over bit before attaching

it to the cabinet.

Place the best looking surface of the Top down and position the cabinet on the least attractive surface as

shown above. There should be a one inch overhang on both sides and one inch on the front (3/4" on the

back).

Secure with 1 1/4" #6 screws using the 3/16" holes in the Top Gussets and Top Mounts. If you are sure you

will never want to remove the top you can use glue. But it will be strong enough without glue.

Copyright

2009 by Robert E. Reedy, Vandalia, Ohio

Four Drawer Cabinet

Drawer Slots

Page 15

Cut a slot 1/4" deep and 3/8" from the bottom of each side and back as shown in

the drawing to the right. The width of the slot should be the thickness of the

material you use for the drawer bottoms. Just wide enough so the bottom slides in

it.

3/8"

Top Drawer Side

back

TopDrawer

DrawerBack

Top

2nd Drawer Side

2nd Drawer Back

Envelope Drawer back

3rd Drawer Back

3rd Drawer Side

Bottom Drawer Side

Bottom Drawer Side

Bottom Drawer Back

Drill 1/16" dia. holes in each side as indicated by the red arrows above. All holes

are 1/4" from the end of the sides. The holes at the top should be 3/4" from the

top. The bottom holes are 7/8" from the bottom. For the two larger drawers,

placea holes aproximately centered from top to bottom.

Copyright

2008 by Robert E. Reedy, Vandalia, Ohio

Four Drawer Cabinet

Drawer Front Slots - A

Page 16

7"

Side View

You can use either the table saw or router to make these cuts. We use the 3rd drawer front as an

example in these drawings. But since the same procedure applies to all the drawers, you should

make the cuts on all four drawer fronts while you have the fence set in the correct position for

each cut.

3rd Drawer Front

7/8"

Step 1.

The first step is to cut the slot for the drawer bottom. The width of the slot should be just

slightly wider than the thickness of the drawer bottoms. This allows for movement in case

for expansion or contraction. The above drawing provides the location of the slots

measured from the bottom of each Drawer Front.

3/8"

Step 2. Cut a 3/8" by 1/2" rabbet along the top edge as shown below.

1/2"

3rd Drawer Front

1/2"

3/8"

Step 3. Cut a 3/8" by 1/2" rabbet along the bottom as shown above.

Copyright

2009 by Robert E. Reedy, Vandalia, Ohio

Four Drawer Cabinet

Drawer Front Slots - B

Page 17

3/8"

3/8"

Top View

1 1/4"

"1 1/4

FrontFront

3rd Drawer

3rd Drawer

Step 4. Cut a 1 1/4" wide by 3/8" deep rabbet along each end as shown above.

Step 5. Round over all four edges on the front side with a 1/8" round over bit.

Step 6. The last step is to drill the holes for the drawer pulls or knobs. Since there are different sizes and

types of drawer pulls and knobs, I cannot provide specific locations for the holes.

You'll need to determine the location of the holes based on whether you use knobs with a single screw or

handles with two screws. Either way, you'll need to position the holes so the handle is centered from side

to side and top to bottom.

Copyright

2009 by Robert E. Reedy, Vandalia, Ohio

Four Drawer Cabinet

File Drawer Slide Supports

Page 18

5/16

Cut a 1/8" wide slot 5/16" from each end of the File Drawer Slide

Supports as shown below. The depth of the slots should be the same as

the width of the File Folder Slide.

5/16

File Folder Slide Support

Drill two 3/16"dia. holes through each of the File Folder Slide Supports as shown

above. These holes are 1" from each end and centered from top to bottom.

File Folder Slide

File Folder Slide Support

File Folder Slide Support

3rd Drawer Front

Bottom Drawer Front

Bottom Drawer Back

Mount one of the File Folder Slide Supports to the Bottom Drawer Front and the other to the

Bottom Drawer Back with 1 1/4" #6 screws as shown above. The File Slide Supports should be

5/8" from the top of the drawer back and 5/8" from the top of the inner surface of the frawer front.

I reccomend you do not use glue as you may want to remove the supports if your needs change in

the future.

When the Bottom Drawer is completed, insert the File Folder Slides in the slots and you're ready

to hang your file folders.

Copyright

2009 by Robert E. Reedy, Vandalia, Ohio

Four Drawer Cabinet

Assemble the Drawers

Page 19

Step 1. Apply glue to the mating

surfaces and support the drawer front,

one side, and the back as shown to the

right. Be sure the slots for the bottom

are alligned with each other in all three

pieces. Secure with 1 1/4" finishing

nails.

Step 2. Turn the assembly over and

insert the bottom into the slots. Apply

glue to the mating surfaces and secure

the second side with 1 1/4" finishing

nails. Do not glue the bottom in plaace,

it should be free to expand and contract.

2009 by Robert E. Reedy, Vandalia, Ohio

Four Drawer Cabinet

Attach Drawer Slides

Page 20

Attach the drawers slides with the screws provided with the slides as

shown above. The end of the slide without the roller is flush with the

inside surface of the drawer front. The end with the roller protrudes past

the other end of the drawer. This is makes it easier to insert and remove

the drawers. Repeat for the opposite side.

This completes the drawer assembly.

2009 by Robert E. Reedy, Vandalia, Ohio

(1 Required)

Top

Copyright

48"

2009 by Robert E. Reedy, Vandalia, Ohio

Side Gussets (2 Required)

48"

(1 required)

Bottom Trim

(2 Required)

Side Gussets (2 Required)

Side Panel

(2 Required)

(3 Required)

Wood Grain

Side Panel

Rear Gussets

(3 Required)

Rear Gussets

(3 Required)

Rear Gussets

(1 Required)

Rear Top Gusset

Wood Grain

Four Drawer Cabinet

Cabinet Cutouts

Page 21

3/4" Oak Veneered Plywood

Four Drawer Cabinet

Drawer Cutouts

(3 required)

Top Drawer Back (1 required)

Top Drawer Side (2 Required)

Top Drawer Side (2 Required)

2nd Drawer Back (1 required)

2nd Drawer Side (2 Required)

2nd Drawer Side (2 Required)

3rd Drawer Back (1 required)

3rd Drawer Side (2 Required)

3rd Drawer Side (2 Required)

Bottom Drawer Back (1 required)

Bottom Drawer Side (2 Required)

Bottom Drawer Side (2 Required)

24"

Drawer Dividers

1/2" Oak Veneered Plywood

Side Panel Trim

(3 required)

Drawer Dividers

(1 Required)

(1 Required)

(1 Required)

48"

Drawer bottom (4 Required)

Drawer bottom (4 Required)

Drawer bottom (4 Required)

48"

(3 required)

Drawer Dividers

Drawer bottom (4 Required)

(Upper Section - 1 Required)

Bottom Drawer Front

(Lower Section - 1 Required)

3/16" or 1/4" Thick Material

(1 Required)

Top Drawer Front

Bottom Drawer Front

Solid Oak - 1 by 8 by 8

2nd Drawer Front

3rd Drawer Front

Front Gusset

Page 22

48"

Copyright

2009 by Robert E. Reedy, Vandalia, Ohio

Das könnte Ihnen auch gefallen

- Traditional Picnic TableDokument14 SeitenTraditional Picnic TableZRomulus73100% (2)

- Skills Builder For Flyers 1 PDFDokument140 SeitenSkills Builder For Flyers 1 PDFEhcrem Saveuc0% (1)

- F 22 Construction Guide ScratchbuildDokument26 SeitenF 22 Construction Guide ScratchbuildZRomulus73Noch keine Bewertungen

- Desk CNC ManualDokument63 SeitenDesk CNC ManualsaddlemanNoch keine Bewertungen

- Dolls House 1Dokument13 SeitenDolls House 1ZRomulus73Noch keine Bewertungen

- Gripen Park Jet Parts Template TiledDokument16 SeitenGripen Park Jet Parts Template TiledZRomulus73Noch keine Bewertungen

- Router TableDokument24 SeitenRouter TableZRomulus73Noch keine Bewertungen

- Bco Carp Robust BenchDokument6 SeitenBco Carp Robust BenchFabio Fernando FigaroNoch keine Bewertungen

- Minimalist Router Table Free PlanDokument2 SeitenMinimalist Router Table Free PlanslavikpNoch keine Bewertungen

- DulapDokument19 SeitenDulapZRomulus73Noch keine Bewertungen

- Epson Stylus SX235W Brochures 1Dokument2 SeitenEpson Stylus SX235W Brochures 1Peltan AndrasNoch keine Bewertungen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (120)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Operator'S Manual 72633-D: 35 LB DrumDokument4 SeitenOperator'S Manual 72633-D: 35 LB DrumSaul PerezNoch keine Bewertungen

- BRNO CZ 452 ManualDokument15 SeitenBRNO CZ 452 ManualTim JNoch keine Bewertungen

- Heating, Ventilation, and Air Conditioning-20230116013328Dokument48 SeitenHeating, Ventilation, and Air Conditioning-20230116013328EDUARDO ALCANTARA JRNoch keine Bewertungen

- Thread CalculatorDokument2 SeitenThread Calculatorrakesh.parmar100% (1)

- Beaba Catalogue Imbex 2021Dokument12 SeitenBeaba Catalogue Imbex 2021Sari SarbiniNoch keine Bewertungen

- DrawingsDokument4 SeitenDrawingsRoque ValenciaNoch keine Bewertungen

- Process Valves Pneumatic Actuators Engineering Consultants: Flowtorq Engineering (India) Pvt. LTDDokument4 SeitenProcess Valves Pneumatic Actuators Engineering Consultants: Flowtorq Engineering (India) Pvt. LTDAbdullah Areeb AnsariNoch keine Bewertungen

- 2021 Flow Binding Change SnaplockDokument1 Seite2021 Flow Binding Change SnaplockLeNoch keine Bewertungen

- Activity 1Dokument2 SeitenActivity 1GLYDEL JOYCE UBAYNoch keine Bewertungen

- Spirit Levels - Block LevelsDokument4 SeitenSpirit Levels - Block LevelsGia Minh Tieu Tu100% (1)

- 2020-21 Fee Due ListDokument10 Seiten2020-21 Fee Due Listamarapalli uday kumarNoch keine Bewertungen

- Air Pistol/ Rifle Instruction ManualDokument10 SeitenAir Pistol/ Rifle Instruction ManualJustinNoch keine Bewertungen

- Tools and Equipment For The BakeshopDokument13 SeitenTools and Equipment For The Bakeshopanthony anggotNoch keine Bewertungen

- Calibrare Tool Eye MazakDokument1 SeiteCalibrare Tool Eye MazakqdarioNoch keine Bewertungen

- Lay Out New PL Press QltyDokument68 SeitenLay Out New PL Press QltyDadan Hendra KurniawanNoch keine Bewertungen

- Accessory User Guide: Bit Kit Removable Bit Driver Bit Driver ExtenderDokument2 SeitenAccessory User Guide: Bit Kit Removable Bit Driver Bit Driver ExtenderScube DiveNoch keine Bewertungen

- Massage Chair: Electric OvenDokument3 SeitenMassage Chair: Electric OvenLoraine May GamisNoch keine Bewertungen

- Calibration MethodDokument4 SeitenCalibration MethodevanNoch keine Bewertungen

- Storage Heaters Containing AsbestosDokument9 SeitenStorage Heaters Containing AsbestosandresNoch keine Bewertungen

- Ga - TM1404 35 U003 - U004 - A22-32 - PMS22 - STD - Iec160m - Plan54 - AfcDokument1 SeiteGa - TM1404 35 U003 - U004 - A22-32 - PMS22 - STD - Iec160m - Plan54 - AfcMuhammad ANoch keine Bewertungen

- Ags 30Dokument1 SeiteAgs 30Anonymous jIzz7woS60% (1)

- Ingersoll 2008 Pak Promo USDokument12 SeitenIngersoll 2008 Pak Promo USLegend211Noch keine Bewertungen

- Victor Welding HeatingDokument10 SeitenVictor Welding HeatingjpolancosNoch keine Bewertungen

- BALLISTICSDokument48 SeitenBALLISTICSAngelika Unarce SuelenNoch keine Bewertungen

- Ian Kirby Marking ToolsDokument6 SeitenIan Kirby Marking ToolsGiovanni Cenci100% (1)

- Ww2 PenetrationDokument33 SeitenWw2 Penetrationskarbyhistorii100% (1)

- Atlas Copco Shank AdaptorsDokument4 SeitenAtlas Copco Shank AdaptorsAntonis GogosNoch keine Bewertungen

- Manufacturer Name Item ID Manufacturers Part Number Part Description QuantityDokument1 SeiteManufacturer Name Item ID Manufacturers Part Number Part Description QuantityIndustrial Garage SalesNoch keine Bewertungen

- Handbook PDFDokument168 SeitenHandbook PDFrajan_2002eeeNoch keine Bewertungen

- Basic Components of Ahu and Fcu, Fan and Duct SystemsDokument113 SeitenBasic Components of Ahu and Fcu, Fan and Duct SystemsSka dooshNoch keine Bewertungen