Beruflich Dokumente

Kultur Dokumente

Uplift With Moment Calculation

Hochgeladen von

dennykvgOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Uplift With Moment Calculation

Hochgeladen von

dennykvgCopyright:

Verfügbare Formate

Tedds Calc

Project

Job Ref.

Section

Sheet no./rev.

1

Calc. by

Date

1/6/2012

Chk'd by

Date

App'd by

Date

COLUMN BASE PLATE DESIGN (AISC360-05)

AISC 360-10

TEDDS calculation version 2.0.07;

Bolt diameter - 1.0"

Bolt embedment - 10.0"

Flange/base weld - 0.3"

Web/base weld - 0.3"

2.0"

15.0"

W 12x96

50.0 kips

325.0 kip_in

2.0"

46.0 kips

1.75"

1.75"

4.0 kips

15.5"

Plan on baseplate

Elevation on baseplate

Design forces and moments

Axial force;

Pu = -50.0 kips; (Tension)

Bending moment;

Mu = 325.0 kip_in

Shear force;

Fv = 0.0 kips

Eccentricity;

e = ABS(Mu / Pu) = 6.500 in

Anchor bolt to center of plate;

f = N/2 - e1 = 7.750 in

Column details

Column section;

W 12x96

Depth;

d = 12.700 in

Breadth;

bf = 12.200 in

Flange thickness;

tf = 0.900 in

Web thickness;

tw = 0.550 in

Baseplate details

Depth;

N = 19.000 in

Breadth;

B = 19.000 in

Thickness;

tp = 1.250 in

Design strength;

Fy = 36.0 ksi

Foundation geometry

Member thickness;

ha = 20.000 in

Dist center of baseplate to left edge foundation;

xce1 = 30.000 in

Dist center of baseplate to right edge foundation;

xce2 = 30.000 in

Dist center of baseplate to bot edge foundation;

yce1 = 30.000 in

Dist center of baseplate to top edge foundation;

yce2 = 30.000 in

Holding down bolt and anchor plate details

Total number of bolts;

Nbolt = 4

Bolt diameter;

do = 1.000 in

Bolt spacing;

sbolt = 15.000 in

Tedds Calc

Project

Job Ref.

Section

Sheet no./rev.

2

Calc. by

Date

1/6/2012

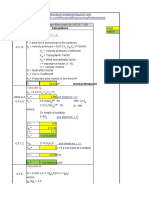

Edge distance;

e1 = 1.750 in

Minimum tensile strength of steel;

Fy = 36 ksi

Compressive strength of concrete;

fc = 3 ksi

Chk'd by

Date

App'd by

Date

Strength reduction factors

Compression;

c = 0.65

Flexure;

b = 0.90

Weld shear;

v = 0.75

Compression force in concrete;

fp,max = 0 ksi

Tension force in one half of bolts (max);

Tu,max = Mu / (N - 2 e1) - Pu / 2 = 46.0 kips

Tension force in other half of bolts (min);

Tu,min = -(Mu / (N - 2 e1) + Pu / 2) = 4.0 kips

Max tensile force in single bolt;

Trod = Tu,max / Nbolty = 23.0 kips

Base plate yielding

Bolts are located outside the section so distribute bolt forces to the flanges

Effective width for bending with 45deg distribution; beff = 2 ((N - d)/2 - e1) = 2.800 in

Bending moment in plate;

Mup = (Tu,max / Nbolty) (beff / 2) = 32.18 kip_in

Thickness of plate required;

tp,req = ((4 Mup) / (beff b Fy))0.5 = 1.191 in

PASS - Thickness of plate exceeds required thickness

Flange weld

Flange weld leg length;

tfw = 0.3125 in

Tension capacity of flange;

Ptf = bf tf Fy = 395.3 kips

Force in tension flange;

Ftf = Mu / (d - tf) - Pu (bf tf) / Acol = 47.0 kips

Critical force in flange;

Ff = min(Ptf, max(Ftf, 0kips)) = 47.0 kips

Flange weld force per in;

Rwf = Ff / (2 bf - tw) = 2.0 kips/in

Electrode classification number;

FEXX = 70.0 ksi

Nominal weld stress;

Fw = v 0.60 FEXX (1.0 + 0.5 (sin(90deg))1.5) = 47.250ksi

Design strength of weld per in;

Rnf = Fw twf / (2) = 10.4 kips/in

PASS - Available strength of flange weld exceeds force in flange weld

Transverse web weld

tww = 0.3125 in

Web weld leg length;

Effective width for bending with 45deg distribution; beff = 2 ((N - d)/2 - e1) = 2.800 in

Web weld force;

Ftw = abs(Pu) (Acol - 2 bf tf) / Acol = 11.064 kips

Web weld force per in;

Rwt = Ftw / (2 (d - 2 tf)) = 0.508 kips/in

Electrode classification number;

FEXX = 70.0 ksi

Nominal weld stress;

Fw = v 0.60 FEXX (1.0 + 0.5 (sin(90deg))1.5) = 47.250ksi

Design strength of weld per in;

Rnt = Fw tww / (2) = 10.4 kips/in

PASS - Available strength of transverse web weld exceeds force in transverse web weld

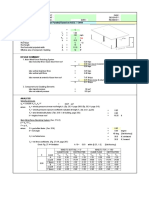

ANCHOR BOLT DESIGN (ACI318-08)

TEDDS calculation version 2.0.07

Anchor bolt geometry

Type of anchor bolt;

Cast-in headed end bolt anchor

Diameter of anchor bolt;

da = 1 in

Number of bolts in x direction;

Nboltx = 2

Number of bolts in y direction;

Nbolty = 2

Tedds Calc

Project

Job Ref.

Section

Sheet no./rev.

3

Calc. by

Date

1/6/2012

Chk'd by

Date

Total number of bolts;

ntotal = (Nboltx 2) + (Nbolty - 2) 2 = 4

Total number of bolts in tension;

ntens = (NboltN 2) + (Nbolty - 2) 2 = 4

Spacing of bolts in x direction;

sboltx = 15.5 in

App'd by

Spacing of bolts in y direction;

sbolty = 15 in

Number of threads per inch;

nt = 8

Effective cross-sectional area of anchor;

Ase = / 4 (da - 0.9743 in / nt)2 = 0.606 in2

Embedded depth of each anchor bolt;

hef = 10 in

Date

Material details

fya = 36 ksi

Minimum yield strength of steel;

Nominal tensile strength of steel;

futa = 68.4 ksi

Compressive strength of concrete;

fc = 3 ksi

Concrete modification factor;

= 1.00

Strength reduction factors

Tension of steel element;

t,s = 0.75

Shear of steel element;

v,s = 0.70

Concrete tension;

t,c = 0.65

Concrete shear;

v,c = 0.70

Concrete tension for pullout;

t,cB = 0.70

Concrete shear for pryout;

v,cB = 0.70

Steel strength of anchor in tension (D.5.1)

Nominal strength of anchor in tension;

Nsa = Ase futa = 41.43 kips

Steel strength of anchor in tension;

Nsa = t,s Nsa = 31.07 kips

PASS - Steel strength of anchor exceeds max tension in single bolt

1' 10.5"

Check concrete breakout strength of anchor bolt in tension (D.5.2)

1' 10.3"

1' 3.5"

10"

1' 8"

1' 10.5"

1' 3.0"

50 kips

1' 10.3"

5'

Plan on foundation

Section A-A

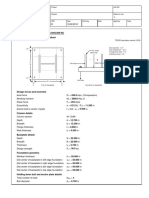

Concrete breakout - tension

Stength reduction factor;

t = 0.65

Coeff for basic breakout strength in tension;

kc = 24

Breakout strength for single anchor in tension;

Nb = kc (f'c 1 psi) hef1.5 1 in0.5 = 41.57 kips

Projected area for groups of anchors;

ANc = 2047.5 in2

Projected area of a single anchor;

ANco = 9 hef2 = 900 in2

Min dist center of anchor to edge of concrete;

ca,min = 22.25 in

Tedds Calc

Project

Job Ref.

Section

Sheet no./rev.

4

Calc. by

Date

1/6/2012

Chk'd by

Date

App'd by

Mod factor for groups loaded eccentrically;

ec,N = min(1 / (1 + ((2 e'N) / (3 hef))), 1) = 0.698

Modification factor for edge effects;

ed,N = 1.0 = 1.000

Date

Modification factor for no cracking at service loads; c,N = 1.250

Modification factor for uncracked concrete;

cp,N = 1.000

Nominal concrete breakout strength;

Ncbg = ANc/ ANco ec,N ed,N c,N cp,N Nb = 82.47 kips

Concrete breakout strength;

Ncbg = t,c Ncbg = 53.61 kips

PASS - Breakout strength exceeds tension in bolts

Pullout strength (D.5.3)

Net bearing area of the head of anchor;

Abrg = 1 in2

Mod factor for no cracking at service loads;

c,P = 1.400

Pullout strength for single anchor;

Np = 8 Abrg f'c = 24.00 kips

Nominal pullout strength of single anchor;

Npn = c,P Np = 33.60 kips

Pullout strength of single anchor;

Npn = t,cB Npn = 23.52 kips

PASS - Pullout strength of single anchor exceeds maximum axial force in single bolt

Side face blowout strength (D.5.4)

As hef <= 2.5 min(ca1, ca2) the edge distance is considered to be far from an edge and blowout strength need not be

considered

Das könnte Ihnen auch gefallen

- Rean'S Building 5/24/2002 Angle Plate Design: Framed Beam ConnectionDokument11 SeitenRean'S Building 5/24/2002 Angle Plate Design: Framed Beam Connectionmhel_almoNoch keine Bewertungen

- Wind LoadDokument5 SeitenWind LoadPATEL JIGARNoch keine Bewertungen

- WIND LOADING ANALYSIS - Roof Components and CladdingDokument3 SeitenWIND LOADING ANALYSIS - Roof Components and CladdingdantevariasNoch keine Bewertungen

- 247 SDC As Per Adibc Seismic For Abu DhabiDokument10 Seiten247 SDC As Per Adibc Seismic For Abu DhabiAlaaBadwyNoch keine Bewertungen

- Wind Analysis For Circular Structure Based On ASCE 7-16 Input DataDokument2 SeitenWind Analysis For Circular Structure Based On ASCE 7-16 Input DatarymacNoch keine Bewertungen

- ASCE 7-05 Wind LoadsDokument31 SeitenASCE 7-05 Wind LoadsSebastián Ignacio Pajarito VillalobosNoch keine Bewertungen

- "Footings" - Spread Footing Analysis: Program DescriptionDokument22 Seiten"Footings" - Spread Footing Analysis: Program Descriptionmuh2006Noch keine Bewertungen

- Wind Analysis For Low-Rise Building, Based On ASCE 7-05 / IBC 2006 / CBC 2007 Input DataDokument5 SeitenWind Analysis For Low-Rise Building, Based On ASCE 7-05 / IBC 2006 / CBC 2007 Input DataNAVEED AHMAD NAZNoch keine Bewertungen

- Wind Loads Calculations by ASCE7 05 For Any BuildingDokument13 SeitenWind Loads Calculations by ASCE7 05 For Any BuildingDaren ModestoNoch keine Bewertungen

- Filled Composite ColumnDokument1 SeiteFilled Composite ColumnAlphaNoch keine Bewertungen

- Software Verification: AISC-360-16 Example 004Dokument4 SeitenSoftware Verification: AISC-360-16 Example 004alejandro mantillaNoch keine Bewertungen

- AISC Connection-2nd Edition - (3+3) Anchor Rod-FixedDokument14 SeitenAISC Connection-2nd Edition - (3+3) Anchor Rod-FixedTuấnThanhNoch keine Bewertungen

- Anchor Calculation - Case 2Dokument10 SeitenAnchor Calculation - Case 2MdShahbazAhmedNoch keine Bewertungen

- Wind ASCE 7-10 V 1.02-2Dokument188 SeitenWind ASCE 7-10 V 1.02-2Dass DassNoch keine Bewertungen

- Wind Analysis For Low-Rise Building, Based On ASCE 7-98: Q 0.00256 K K K V IDokument5 SeitenWind Analysis For Low-Rise Building, Based On ASCE 7-98: Q 0.00256 K K K V ILivian TeddyNoch keine Bewertungen

- Angle Flex SeatDokument3 SeitenAngle Flex Seatitissa INGENIERIANoch keine Bewertungen

- Foundation Design For Dynamic Equipment Based On ACI 351.3 & ACI 318-19Dokument12 SeitenFoundation Design For Dynamic Equipment Based On ACI 351.3 & ACI 318-19ZuzarNoch keine Bewertungen

- Anchor Bolt - StrengthDokument2 SeitenAnchor Bolt - StrengthSana UllahNoch keine Bewertungen

- Software Verification: AISC-360-16 Example 003Dokument5 SeitenSoftware Verification: AISC-360-16 Example 003alejandro mantillaNoch keine Bewertungen

- Design of Base Plate by EurocodeDokument13 SeitenDesign of Base Plate by EurocodeBharati MajlekarNoch keine Bewertungen

- Wind Loading Based On EC 1991-4Dokument4 SeitenWind Loading Based On EC 1991-4janethNoch keine Bewertungen

- Mathcad - Clip Angle ConnectionDokument8 SeitenMathcad - Clip Angle ConnectionShobanBaabu ArumugamNoch keine Bewertungen

- Base Plate Design Metric Units PDFDokument8 SeitenBase Plate Design Metric Units PDFVinayak PatilNoch keine Bewertungen

- BasePlate 1 Check 46.8TDokument63 SeitenBasePlate 1 Check 46.8TrustamriyadiNoch keine Bewertungen

- Wind Load Analysis: Sustain Wind Pressure For 15' HeightDokument4 SeitenWind Load Analysis: Sustain Wind Pressure For 15' HeightSumon RoyNoch keine Bewertungen

- Wind - Load - ASCE 7-05Dokument3 SeitenWind - Load - ASCE 7-05Siva ShankarNoch keine Bewertungen

- Base Plate 2Dokument5 SeitenBase Plate 2Bunkun15Noch keine Bewertungen

- Clipconn All Bolt 13Dokument22 SeitenClipconn All Bolt 13NEONoch keine Bewertungen

- Wind Load CalcsDokument10 SeitenWind Load CalcsUmange RanasingheNoch keine Bewertungen

- Pedestal DesignDokument2 SeitenPedestal DesignRamadanNoch keine Bewertungen

- Open Structure WindDokument6 SeitenOpen Structure WindjamalNoch keine Bewertungen

- Wind Load Calculation Sample NSCP 2015 - Google SearchDokument4 SeitenWind Load Calculation Sample NSCP 2015 - Google Searchgodofredo dumaliNoch keine Bewertungen

- Wind Load CalculationsDokument1 SeiteWind Load CalculationsAnkesh MundraNoch keine Bewertungen

- Rectangular Spread Footing DesignDokument42 SeitenRectangular Spread Footing DesignJedidiah MelakuNoch keine Bewertungen

- Daniel Tian Li: Circular Column Design Based On ACI 318-05Dokument1 SeiteDaniel Tian Li: Circular Column Design Based On ACI 318-05OswardMorenoNoch keine Bewertungen

- Wind Analysis For Freestanding Wall & Sign Based On ASCE 7-05 Input DataDokument2 SeitenWind Analysis For Freestanding Wall & Sign Based On ASCE 7-05 Input Datavpvipin93Noch keine Bewertungen

- 8 Wind LoadDokument16 Seiten8 Wind LoadTuanQuachNoch keine Bewertungen

- Bracing ConnectionDokument15 SeitenBracing ConnectionrajedmaglinteNoch keine Bewertungen

- Corbel BS8110Dokument3 SeitenCorbel BS8110Nugraha BintangNoch keine Bewertungen

- Typical Beam To Beam Connection Design Calcultion - Fin PLTDokument122 SeitenTypical Beam To Beam Connection Design Calcultion - Fin PLTAsaru DeenNoch keine Bewertungen

- Anchor BoltDokument93 SeitenAnchor BoltAnand.5Noch keine Bewertungen

- Wind Speed Calculation As Per SP-1275Dokument7 SeitenWind Speed Calculation As Per SP-1275Siva baalanNoch keine Bewertungen

- Aisc Chevron BraceDokument42 SeitenAisc Chevron Bracegvlanusha100% (1)

- Wind Load Reaction Force Due To Wind Action From Stack Acting On The Fan DeckDokument3 SeitenWind Load Reaction Force Due To Wind Action From Stack Acting On The Fan Deckikanyu79Noch keine Bewertungen

- Knee ConnectionsDokument13 SeitenKnee ConnectionsNag RajNoch keine Bewertungen

- Bracing Connection EC3Dokument9 SeitenBracing Connection EC3Mustafa AyşeNoch keine Bewertungen

- ANCHOR - REINFORCEMENT (Metric)Dokument10 SeitenANCHOR - REINFORCEMENT (Metric)Tarek AbulailNoch keine Bewertungen

- EC3 WeldsDokument6 SeitenEC3 WeldsSixmonNoch keine Bewertungen

- Moment Connection Design For Beam To Weak Axis Column Based On AISC 360-10/16Dokument4 SeitenMoment Connection Design For Beam To Weak Axis Column Based On AISC 360-10/16gyanwapiNoch keine Bewertungen

- Evo Design - Structural Design: Calculation SheetDokument4 SeitenEvo Design - Structural Design: Calculation SheetVij Vaibhav VermaNoch keine Bewertungen

- Members With Combined Bending and Axial ForceDokument32 SeitenMembers With Combined Bending and Axial ForceJohn RomanusNoch keine Bewertungen

- Design of End Plate ConnectionDokument2 SeitenDesign of End Plate ConnectionAndro RebuyasNoch keine Bewertungen

- Seismic Load Analysis Per Asce 7-02 Aisc-08Dokument3 SeitenSeismic Load Analysis Per Asce 7-02 Aisc-08intimate4lifeNoch keine Bewertungen

- Concrete Anchor Foundation Bolt Design Calculations With Example As Per ACI 318 Appendix D-Part2-Breakout Strength in TensionDokument6 SeitenConcrete Anchor Foundation Bolt Design Calculations With Example As Per ACI 318 Appendix D-Part2-Breakout Strength in TensionVenu GopalNoch keine Bewertungen

- Side Girt Design-RwphDokument23 SeitenSide Girt Design-Rwphasvenk309100% (1)

- Base Plate FixedDokument4 SeitenBase Plate FixedssikhaNoch keine Bewertungen

- Large Moment ExampleDokument5 SeitenLarge Moment ExampleAmro Ahmad AliNoch keine Bewertungen

- Bolted Cover Plate Splice Connection B1Dokument4 SeitenBolted Cover Plate Splice Connection B1ikanyu79Noch keine Bewertungen

- Column Base Plate Design (Bs5950-1:2000) : Project Job RefDokument4 SeitenColumn Base Plate Design (Bs5950-1:2000) : Project Job RefronyNoch keine Bewertungen

- 8 - Welding of Stainless Steels and Nickel AlloysDokument61 Seiten8 - Welding of Stainless Steels and Nickel AlloysdennykvgNoch keine Bewertungen

- 7 - Material Selection For Urea ServiceDokument17 Seiten7 - Material Selection For Urea ServicedennykvgNoch keine Bewertungen

- 6 - Materials Selection For Processing EquipmentDokument50 Seiten6 - Materials Selection For Processing EquipmentdennykvgNoch keine Bewertungen

- 5 - Duplex Stainless Steels and Nickel AlloysDokument44 Seiten5 - Duplex Stainless Steels and Nickel AlloysdennykvgNoch keine Bewertungen

- 3 - High Temperature CorrosionDokument35 Seiten3 - High Temperature CorrosiondennykvgNoch keine Bewertungen

- 1 - IntroductionDokument15 Seiten1 - Introductionkeyur1109Noch keine Bewertungen

- 4 - Stainless Steels - Wrought and CastDokument24 Seiten4 - Stainless Steels - Wrought and CastdennykvgNoch keine Bewertungen

- 2 - Low Temperature CorrosionDokument65 Seiten2 - Low Temperature CorrosiondennykvgNoch keine Bewertungen

- BPC-2017-PRS-15-2017-V1 Workshop - Taking AWP To The Next LevelDokument20 SeitenBPC-2017-PRS-15-2017-V1 Workshop - Taking AWP To The Next Levelcrescente galendezNoch keine Bewertungen

- Workface Planning Infrastructure: Document Number: Cop-Wfp-Spd-04-2013-VDokument5 SeitenWorkface Planning Infrastructure: Document Number: Cop-Wfp-Spd-04-2013-VdennykvgNoch keine Bewertungen

- WFP FaqDokument4 SeitenWFP FaqdennykvgNoch keine Bewertungen

- 3 Kammprofile PDFDokument4 Seiten3 Kammprofile PDFsalunkheclNoch keine Bewertungen

- Iwp Cable Tray Installation Checklist: Appendix - 9Dokument3 SeitenIwp Cable Tray Installation Checklist: Appendix - 9dennykvg0% (1)

- Best Practices Awards Nomination Form: This Submission Is For (Please Check One) : Use Separate Form For Each SubmissionDokument16 SeitenBest Practices Awards Nomination Form: This Submission Is For (Please Check One) : Use Separate Form For Each SubmissiondennykvgNoch keine Bewertungen

- Advanced Work Packaging SummaryDokument6 SeitenAdvanced Work Packaging SummarydennykvgNoch keine Bewertungen

- 3.0 Workface Planning Procedure Insight AWP 2017Dokument31 Seiten3.0 Workface Planning Procedure Insight AWP 2017dennykvgNoch keine Bewertungen

- Workface Planning Prerequisites: Document Number: Cop-Wfp-Spd-05-2013-V1Dokument5 SeitenWorkface Planning Prerequisites: Document Number: Cop-Wfp-Spd-05-2013-V1dennykvgNoch keine Bewertungen

- Best Practice Award To JacobsDokument10 SeitenBest Practice Award To JacobsdennykvgNoch keine Bewertungen

- WFP Fundamentals - The Build Simulation DetailsDokument39 SeitenWFP Fundamentals - The Build Simulation DetailsdennykvgNoch keine Bewertungen

- Measuring The Impacts of Advanced Work Packaging (Awp) and Workface Planning (WFP) On Work Package and Project PerformanceDokument38 SeitenMeasuring The Impacts of Advanced Work Packaging (Awp) and Workface Planning (WFP) On Work Package and Project Performancecrescente galendezNoch keine Bewertungen

- PTFE Lip Seal Design Guide: Catalog EPS 5340/USADokument170 SeitenPTFE Lip Seal Design Guide: Catalog EPS 5340/USAdtr17Noch keine Bewertungen

- O Rings HandbookDokument292 SeitenO Rings HandbookleocastarlenasNoch keine Bewertungen

- Seal & Seat Matrix-Floating-LatestDokument5 SeitenSeal & Seat Matrix-Floating-LatestdennykvgNoch keine Bewertungen

- Selection of MaterialsDokument4 SeitenSelection of MaterialsdennykvgNoch keine Bewertungen

- Customer Guide Vol8Dokument148 SeitenCustomer Guide Vol8dennykvgNoch keine Bewertungen

- Lesson LearntDokument16 SeitenLesson LearntdennykvgNoch keine Bewertungen

- Simpler Shear ConnectionsDokument3 SeitenSimpler Shear ConnectionsAnil K Vishwa100% (1)

- Product CatalogueDokument116 SeitenProduct CatalogueSrishti SonkarNoch keine Bewertungen

- Jaquar Plumber Guide Editable1Dokument52 SeitenJaquar Plumber Guide Editable1sandeep0975Noch keine Bewertungen

- Whitehall Free-Standing SwivetteDokument2 SeitenWhitehall Free-Standing Swivettecvl1983Noch keine Bewertungen

- PPT FastenerDokument96 SeitenPPT FastenerjoNoch keine Bewertungen

- 08 Push in Fittings For PneumaticDokument20 Seiten08 Push in Fittings For PneumaticNilesh MistryNoch keine Bewertungen

- The Effect of Using Coconut Fibre To Concrete AsphaltDokument13 SeitenThe Effect of Using Coconut Fibre To Concrete AsphaltLembaga Pendidikan100% (2)

- AOT 4-1/2" & 5-1/2" "TS-100" MANUAL SPIDER: Aot# Description # REQ. WTDokument1 SeiteAOT 4-1/2" & 5-1/2" "TS-100" MANUAL SPIDER: Aot# Description # REQ. WTRICHARDNoch keine Bewertungen

- Plumbing Questions. ProprofsDokument33 SeitenPlumbing Questions. ProprofsChristine Joyce RoseteNoch keine Bewertungen

- Boq InteriorDokument3 SeitenBoq InteriorDavid WebNoch keine Bewertungen

- On BondsDokument18 SeitenOn BondsMahesh Ramteke100% (1)

- Radiography Examination Report: PT. Rekayasa Penta AsiaDokument2 SeitenRadiography Examination Report: PT. Rekayasa Penta AsiaSyafi'i SongoNoch keine Bewertungen

- Astm 795Dokument7 SeitenAstm 795djfreditoNoch keine Bewertungen

- Your Guide To Shaker Furniture: 3 Classic ProjectsDokument25 SeitenYour Guide To Shaker Furniture: 3 Classic Projectsjpl.guedes6842100% (1)

- Indian Standards List For Civil-2020Dokument185 SeitenIndian Standards List For Civil-2020SRINIVASAN T100% (1)

- Bainite in SteelsDokument479 SeitenBainite in SteelsCharlie Chong100% (7)

- Pressure-Reducing Valves For Steam ServiceDokument8 SeitenPressure-Reducing Valves For Steam ServiceDarwin DarmawanNoch keine Bewertungen

- APPENDIX B: Weights of Building MaterialsDokument5 SeitenAPPENDIX B: Weights of Building MaterialsnickNoch keine Bewertungen

- The World Standard in Quality Flow Management Products and ServiceDokument8 SeitenThe World Standard in Quality Flow Management Products and ServiceCarlos Alberto Aguilera MendezNoch keine Bewertungen

- Sensitization of AISI 304 and Reversing of Corrosion 2012Dokument13 SeitenSensitization of AISI 304 and Reversing of Corrosion 2012Adnan SaadiNoch keine Bewertungen

- Definitions and Related Materials: Stahliją or Stakhlijan (Made of Steel), Stahliją (Standing Firm)Dokument5 SeitenDefinitions and Related Materials: Stahliją or Stakhlijan (Made of Steel), Stahliją (Standing Firm)kingNoch keine Bewertungen

- Civ 1164 HWDokument2 SeitenCiv 1164 HWpilsenscribdNoch keine Bewertungen

- Sect TPR MatrlDokument5 SeitenSect TPR MatrlcanhizNoch keine Bewertungen

- Modernization and Mechanisation of Foundry PDFDokument105 SeitenModernization and Mechanisation of Foundry PDFpratik g100% (1)

- Milling Process: IE 337: Materials and Manufacturing Processes Lab # 4Dokument4 SeitenMilling Process: IE 337: Materials and Manufacturing Processes Lab # 4Revanth ViswanadhaNoch keine Bewertungen

- Truss CalculationsDokument16 SeitenTruss CalculationsAnkit SuriNoch keine Bewertungen

- Chapter 6 Brick WorkDokument17 SeitenChapter 6 Brick WorkFaisal KhanNoch keine Bewertungen

- 004 - GRP Instrument SheildDokument1 Seite004 - GRP Instrument SheildVishnuNoch keine Bewertungen

- Plain and Steel-Laminated Elastomeric Bearings For BridgesDokument1 SeitePlain and Steel-Laminated Elastomeric Bearings For BridgesMirza SakibNoch keine Bewertungen

- Astm A36 2019 PDFDokument3 SeitenAstm A36 2019 PDFrahmath nawaz100% (1)

- Approved Supplier ListDokument6 SeitenApproved Supplier ListRohith KommuNoch keine Bewertungen

- Tata Steel - SlimdekDokument36 SeitenTata Steel - SlimdekdevgrpNoch keine Bewertungen