Beruflich Dokumente

Kultur Dokumente

EPM 451/3 Computer Integrated Manufacturing

Hochgeladen von

Joash Mock Kar WaiOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

EPM 451/3 Computer Integrated Manufacturing

Hochgeladen von

Joash Mock Kar WaiCopyright:

Verfügbare Formate

EPM 451/3

COMPUTER INTEGRATED

MANUFACTURING

INIVIDUAL ASSIGNMENT

AUTOMATIC IDENTIFICATION AND DATA CAPTURE

Name: Mock Kar Wai

No. Matric: 111879

Lecturer: Assoc. Prof. Dr Shahrul Kamaruddin

MANUFACTURING ENGINEERING WITH

MANAGEMENT

AUTOMATIC IDENTIFICATION AND DATA CAPTURE (AIDC)

Definition: Technologies that capture data for computer entry without

keyboard which require no human involvement.

Applications:

Material handling: shipping, picking, receiving and storage

Retail sales, Mail and parcels

Distributions, Inventory control

Medical

Banking

Advantages of AIDC:

Reduces error in data collection and entry. AIDC reduces or eliminate

human factor and improves accuracy.

Reduces time in data entry. AIDC captures data in a shorter time than

manual entry.

Reduces labor cost. AIDC removes the need of full human attention.

3 Steps of AIDC:

Data Encoder

Set code

Generate

machinereadable code

Attach to item

Scanner

Reads the

encoded data

Data Decoder

Process and

transform read

data

AIDC Technologies:

1. Optical: use graphical symbols interpretable by optical scanners.

2. Electromagnetic: use electromagnetic waves to transmit data to

3.

4.

5.

6.

receiver/scanner.

Magnetic: use magnetic data encoding. E.g. Credit card Magnetic strip

Smart Card: small microchip-embedded cards.

Touch techniques: touch screens and buttons.

Biometric: uses voice, fingerprint, retina-scans and etc.

Bar Code (Linear):

Optical AIDC technology that read data by a linear sweep from scanner. Two

types:

1. Width-modulated which consist of bars and space of different width.

2. Height-modulated which consist of evenly spaced bars with different

height.

Bar Code Reader:

1.

2.

3.

4.

Contact: portable, battery-powered with memory for data storage.

Noncontact: use focused light beam to read bar code.

Fixed beam: Stationary as product pass for scanning

Moving beam: rotating mirror to scan barcode in any orientation. High

scan rate.

Bar Code Printer:

1. Ink-jet

2. Direct Thermal: heat-sensitive chemical coated paper printed by heat

3. Thermal transfer: Similar to Direct Thermal but printable on normal

paper

4. Laser printing

5. Laser Etching: use laser to mark barcodes on metal parts

Bar Code (Two Dimensional):

1. Stacked Bar Code: similar to linear barcode but several linear bar

codes are stacked vertically to store more data.

2. Matrix Symbologies: 2D pattern normally in square. More data than

Stacked bar code but more complicated to generate and require

special equipment to read.

Radio Frequency Identification (RFID):

RFID uses ID tag containing electronically encoded data. Tag made of IC

chip and small antenna. Reader is brought near to tag (or vice-versa), a RF

signal is sent to tags antenna. The tag replies with encoded data. Reader

decodes, confirms the signal before transmitting to computer. Two types of

tags:

1. Passive: no internal power source. Uses power from received signal.

Shorter range but cheaper, durable and smaller

2. Active: comes with power pack. Longer range.

Advantages of RFID:

1. No physical contact or direct line of sight required

2. Higher data capacity

3. Data rewritable. Tag reusable.

Disadvantage: Expensive, only suitable for environment, which optical

method is not suitable.

Das könnte Ihnen auch gefallen

- Barcode Technology Guide: A Complete Look at History, Types, Reading & MoreDokument16 SeitenBarcode Technology Guide: A Complete Look at History, Types, Reading & MoreChidgana HegdeNoch keine Bewertungen

- Radiologist in DelhiDokument9 SeitenRadiologist in DelhishahulNoch keine Bewertungen

- Suresh AadharDokument1 SeiteSuresh AadharApcare14Noch keine Bewertungen

- Practical Data Acquisition for Instrumentation and Control SystemsVon EverandPractical Data Acquisition for Instrumentation and Control SystemsNoch keine Bewertungen

- Creditcardrush JSONDokument31 SeitenCreditcardrush JSONStaceyNoch keine Bewertungen

- PPTDokument69 SeitenPPTAjit MishraNoch keine Bewertungen

- Rfid Project ReportDokument65 SeitenRfid Project Reportgsrawat123Noch keine Bewertungen

- RFID Shrinkage in Supply ChainDokument198 SeitenRFID Shrinkage in Supply ChainAN101Noch keine Bewertungen

- Rfid Based Car Parking Security System Using Microcontroller Ic89c52 IJERTV4IS031045Dokument5 SeitenRfid Based Car Parking Security System Using Microcontroller Ic89c52 IJERTV4IS031045Tummuri ShanmukNoch keine Bewertungen

- Creditcardrush JSON 2Dokument31 SeitenCreditcardrush JSON 2grand theftNoch keine Bewertungen

- Credit Card Transactions by Brand and Masked NumberDokument1.094 SeitenCredit Card Transactions by Brand and Masked NumberAngelo GzoNoch keine Bewertungen

- Rfid Access Control SystemDokument16 SeitenRfid Access Control SystemManjeet SinghNoch keine Bewertungen

- M M M MM MDokument28 SeitenM M M MM Mraj_behraNoch keine Bewertungen

- AIDC Technologies Optimize Supply Chain OperationsDokument4 SeitenAIDC Technologies Optimize Supply Chain OperationsShiba Narayan SahuNoch keine Bewertungen

- Unit 10 Automatic IdentificationDokument21 SeitenUnit 10 Automatic IdentificationKirandeep GandhamNoch keine Bewertungen

- Automatic Data CaptureDokument5 SeitenAutomatic Data CapturePrathamesh NaikNoch keine Bewertungen

- Automatic Identification and Data CaptureDokument31 SeitenAutomatic Identification and Data Capture13311A0341 S SHIVA SAI KIRANNoch keine Bewertungen

- Lecture 13Dokument28 SeitenLecture 13Philani XabaNoch keine Bewertungen

- Automatic Identification and Data CapturingDokument24 SeitenAutomatic Identification and Data CapturinghabtamuNoch keine Bewertungen

- Department of Electronics & Telecommunication: Project Guide DR N.S. AmbatkarDokument16 SeitenDepartment of Electronics & Telecommunication: Project Guide DR N.S. AmbatkarRaj BhargavNoch keine Bewertungen

- Automatic Data Capture CIMDokument10 SeitenAutomatic Data Capture CIMsohorabatscribdNoch keine Bewertungen

- Automated Data Collection: Priya SharmaDokument17 SeitenAutomated Data Collection: Priya SharmaSumanAgarwalNoch keine Bewertungen

- Barcode System DocumentationDokument27 SeitenBarcode System DocumentationYogi BhimaniNoch keine Bewertungen

- Automatic Identification and Data Capture - Automation - CIM - GrooverDokument16 SeitenAutomatic Identification and Data Capture - Automation - CIM - GrooverRabianur KalemNoch keine Bewertungen

- Barcode Reading Glossary EN PDFDokument6 SeitenBarcode Reading Glossary EN PDFSơn Nguyễn VănNoch keine Bewertungen

- Automatic Identification and Data Capture TechnologyDokument17 SeitenAutomatic Identification and Data Capture TechnologyPaspulati LeelaramNoch keine Bewertungen

- Automatic Identification and Data CaptureDokument16 SeitenAutomatic Identification and Data CaptureROHIT VERMANoch keine Bewertungen

- RFID Based Smart Lock Implementation: Computer Engineering Department, College of Engineering, Al-Iraqia University, IraqDokument5 SeitenRFID Based Smart Lock Implementation: Computer Engineering Department, College of Engineering, Al-Iraqia University, IraqAliNoch keine Bewertungen

- Web Based Solution For Thermal Printing of Bar Code: Manpreet Singh, Baljinder SinghDokument3 SeitenWeb Based Solution For Thermal Printing of Bar Code: Manpreet Singh, Baljinder SinghInternational Organization of Scientific Research (IOSR)Noch keine Bewertungen

- Barcode System Conceptual FrameworkDokument20 SeitenBarcode System Conceptual Frameworkgireesh_mouliNoch keine Bewertungen

- RFID e-passport journal articleDokument4 SeitenRFID e-passport journal articleakashlogicNoch keine Bewertungen

- Volume 1number 2PP 492 496Dokument5 SeitenVolume 1number 2PP 492 496Akbar AfridiNoch keine Bewertungen

- ICT Revision WorksheetDokument11 SeitenICT Revision WorksheetJuan RanjuNoch keine Bewertungen

- RFID vs. Barcode (ICA Assignment) - Muddasir Ali Soomro: Bar CodeDokument4 SeitenRFID vs. Barcode (ICA Assignment) - Muddasir Ali Soomro: Bar CodeSalman KhalidNoch keine Bewertungen

- Radio Frequency Identification (RFID)Dokument11 SeitenRadio Frequency Identification (RFID)Priyesh KumarNoch keine Bewertungen

- Barcode Reader Using CameraDokument25 SeitenBarcode Reader Using CameraApoorva JoshiNoch keine Bewertungen

- Groover, Mikell P - Automation, Production Systems, and Computer-Integrated Manufacturing-Pearson (2014 - 2019) - 355-368Dokument14 SeitenGroover, Mikell P - Automation, Production Systems, and Computer-Integrated Manufacturing-Pearson (2014 - 2019) - 355-368Mileva Hayes-AleksandrovNoch keine Bewertungen

- RFID Based Security SystemDokument3 SeitenRFID Based Security SystemBedanshu Shekhar MishraNoch keine Bewertungen

- 6893-Article Text-12642-1-10-20210519Dokument6 Seiten6893-Article Text-12642-1-10-20210519abesalok123Noch keine Bewertungen

- 5.chapter 1Dokument4 Seiten5.chapter 1thethtet87Noch keine Bewertungen

- Bar Codes and RFID Technology Use To University Library ManagementDokument5 SeitenBar Codes and RFID Technology Use To University Library ManagementerpublicationNoch keine Bewertungen

- (Automatic Identification and Data Capture) : I 1 e OpicDokument3 Seiten(Automatic Identification and Data Capture) : I 1 e OpicKilangNoch keine Bewertungen

- RFID Based Smart Attendance Monitoring System Using IoTDokument4 SeitenRFID Based Smart Attendance Monitoring System Using IoTInternational Journal of Innovative Science and Research TechnologyNoch keine Bewertungen

- Minor ReportFinalDokument34 SeitenMinor ReportFinalPawan VishnoiNoch keine Bewertungen

- Attendance System Using RfidDokument5 SeitenAttendance System Using RfidKethavath Sakrunaik KNoch keine Bewertungen

- On Rfid Based Attendance System: Internet of Things Project ReportDokument36 SeitenOn Rfid Based Attendance System: Internet of Things Project ReportNaveen KumarNoch keine Bewertungen

- ARM-7 Based GSM Control of Home Lighting Devices With RFID Identification and Current Detection of OutletsDokument4 SeitenARM-7 Based GSM Control of Home Lighting Devices With RFID Identification and Current Detection of OutletsAmeem Ahmed KhanNoch keine Bewertungen

- RFID Based Security and Access Control System Using ARDUINODokument3 SeitenRFID Based Security and Access Control System Using ARDUINOJangkrik GengGongNoch keine Bewertungen

- Terminals and Scanning Devices - Chapter #1Dokument4 SeitenTerminals and Scanning Devices - Chapter #1Wasif QaziNoch keine Bewertungen

- Attendance Marking System With RF Id - Contact Less & Face IndicatorDokument3 SeitenAttendance Marking System With RF Id - Contact Less & Face IndicatorkarunamoorthiNoch keine Bewertungen

- Parcel Tracking System in 40 CharactersDokument2 SeitenParcel Tracking System in 40 CharactersSameer NandanNoch keine Bewertungen

- RFID Based Attendance SystemDokument7 SeitenRFID Based Attendance SystemAdvanced Research PublicationsNoch keine Bewertungen

- AUTOMATED ATTENDANCE SYSTEM ' Is Designed To Collect and Manage Student'sDokument5 SeitenAUTOMATED ATTENDANCE SYSTEM ' Is Designed To Collect and Manage Student'spankhuri3737Noch keine Bewertungen

- CMR Engineering College: "Barcode"Dokument14 SeitenCMR Engineering College: "Barcode"Madhu SravaniNoch keine Bewertungen

- Automated Attendance SystemDokument5 SeitenAutomated Attendance SystembalabooksNoch keine Bewertungen

- IRJET RFID Based Petrol Pump AutomationDokument3 SeitenIRJET RFID Based Petrol Pump AutomationKiranNoch keine Bewertungen

- JKMDokument78 SeitenJKMShaanu ShaanNoch keine Bewertungen

- RFID Based Security and Access Control System Using ARDUINODokument3 SeitenRFID Based Security and Access Control System Using ARDUINOIJMTST-Online Journal100% (1)

- RFID Modules & Guideline For Selecting Appropriate RFID Module For IndustriesDokument4 SeitenRFID Modules & Guideline For Selecting Appropriate RFID Module For IndustriesInternational Journal of Application or Innovation in Engineering & ManagementNoch keine Bewertungen

- RFID Based Attendance SystemDokument5 SeitenRFID Based Attendance SystemNyashadzashe ChikarakaraNoch keine Bewertungen

- Biometric Smart Card Polling SystemDokument9 SeitenBiometric Smart Card Polling SystemVasudev DeshpandeNoch keine Bewertungen

- Security System Using RFID: A Project ReportDokument30 SeitenSecurity System Using RFID: A Project Reportdnadar881Noch keine Bewertungen

- On The Creation of Automatic Identification and Data Capture Infrastructure Via RFIDDokument19 SeitenOn The Creation of Automatic Identification and Data Capture Infrastructure Via RFIDhamzeecoNoch keine Bewertungen

- Research Review of Related LiteratureDokument9 SeitenResearch Review of Related LiteratureBless beljNoch keine Bewertungen

- AbstractDokument5 SeitenAbstractpayalwaniNoch keine Bewertungen

- YHD-M800D Default User Manual V1.3Dokument16 SeitenYHD-M800D Default User Manual V1.3Aadil FerozeNoch keine Bewertungen

- GKH 2011 OverviewDokument13 SeitenGKH 2011 OverviewSayed HashemNoch keine Bewertungen

- EDI - Kurs 20190410Dokument151 SeitenEDI - Kurs 20190410Tom ChanNoch keine Bewertungen

- Comparing Classic Bluetooth and Bluetooth Low Energy (BLE) TechnologiesDokument5 SeitenComparing Classic Bluetooth and Bluetooth Low Energy (BLE) TechnologiesfdsfsdfrgeNoch keine Bewertungen

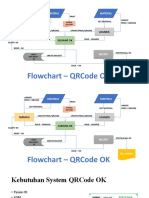

- Alur - Qrcode - OkDokument3 SeitenAlur - Qrcode - OkMadheSatyawanNoch keine Bewertungen

- 300x Netflix USA by Jonathan OpDokument11 Seiten300x Netflix USA by Jonathan Op27999703210jNoch keine Bewertungen

- Glossary of Fingerprint TermsDokument4 SeitenGlossary of Fingerprint Termsroncarl29Noch keine Bewertungen

- Digital Marketing & Social Media PeshawarLibrary PDFDokument483 SeitenDigital Marketing & Social Media PeshawarLibrary PDFFazal AminNoch keine Bewertungen

- AADHAAR LEH BABULON INKUNGKAIHNA - Writen By-Tey TmaxDokument11 SeitenAADHAAR LEH BABULON INKUNGKAIHNA - Writen By-Tey TmaxTey T-maxNoch keine Bewertungen

- AnshdeepDokument1 SeiteAnshdeeppradeep.gov99Noch keine Bewertungen

- Effective Wagon Tracking Using RFIDDokument76 SeitenEffective Wagon Tracking Using RFIDankur1540% (1)

- TechTarget IT AcronymsDokument91 SeitenTechTarget IT AcronymsTaha ShahzadNoch keine Bewertungen

- Licence Plate No. Tag Seria L No. Toll Amount (RS.)Dokument2 SeitenLicence Plate No. Tag Seria L No. Toll Amount (RS.)Anonymous YS4aqs1SNoch keine Bewertungen

- RFID Soft SkillsDokument6 SeitenRFID Soft SkillsTanya Naman SarafNoch keine Bewertungen

- Fingerprint Biometric Attendance System ProposalDokument8 SeitenFingerprint Biometric Attendance System Proposalエリカ ジョイNoch keine Bewertungen

- Rfid Based Banking System: Software: Embedded C, Keil, ProloadDokument2 SeitenRfid Based Banking System: Software: Embedded C, Keil, ProloadsomeshwartNoch keine Bewertungen

- Biometrics Security TechnologiesDokument2 SeitenBiometrics Security TechnologiesAmy RiceNoch keine Bewertungen

- SKODA Transponder CatalogDokument2 SeitenSKODA Transponder CatalogKIMI GOKU YTNoch keine Bewertungen

- Logistic in Value Chain Hadout (Cha-1&2) PDFDokument26 SeitenLogistic in Value Chain Hadout (Cha-1&2) PDFbanitessew82Noch keine Bewertungen

- 1.3 Hardware and SoftwareDokument229 Seiten1.3 Hardware and SoftwarehussainNoch keine Bewertungen

- FingerprintDokument34 SeitenFingerprintSumanta KarNoch keine Bewertungen

- HMIS Project ProposalDokument17 SeitenHMIS Project ProposalManal KhanNoch keine Bewertungen

- Livescan-List-10 02 2020Dokument250 SeitenLivescan-List-10 02 2020Susan KunkleNoch keine Bewertungen

- Dell Store Hi-Tech Mall - 14 Januari 2021Dokument22 SeitenDell Store Hi-Tech Mall - 14 Januari 2021EndraNoch keine Bewertungen