Beruflich Dokumente

Kultur Dokumente

Modelling and Analysis of The Simple Water Heater System

Hochgeladen von

Johandi PatriaOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Modelling and Analysis of The Simple Water Heater System

Hochgeladen von

Johandi PatriaCopyright:

Verfügbare Formate

International Journal of Electrical and Computer Engineering (IJECE)

Vol.1, No.1, September 2011, pp. 49~52

ISSN: 2088-8708

49

Modelling and Analysis of the Simple Water Heater System

Haresh A. Suthar, Dr. Jagrut J. Gadit

E&C Engineering Department, Parul Instutute of Engineering & Technology

Limda, Vadodara, India.

Telp:+91-9825718654

e-mail: hareshsuthar@rediffmail.com

Electrical Engineering Department, Faculty of Engineering & Technology, M.S.U of Baroda.

Vadodara, India.

e-mail: jagrut_gadit@yahoo.co.in

Abstract

Modelling is nothing but converting physical information in to mathematical form. Mathematical model plays vital

role for identification and analysis of the system. In this paper simple water heater system was taken as test bench. Considering

system parameters mathematical model of first order with time delayed was derived. Model was simulated in the simulation tool

MATLAB and systems response has been studied by changing various parameters like static gain, time constant, delay time and

noise, for applied step input.Response of the simulated system was analysed and compare with the actual real time system

parameters.

Keywords: Modelling, Analysis, MATLAB, Water heater system.

1.

Introduction

Modelling and analysis play fundamental roles in the field of automatic control, since it is not possible to

perform a control system design without having a model describing the dynamics of the process to be controlled.

Mathematical models are key elements in the field of automatic control. They are required for simulation as well as

design in a typical control system development. Models cannot represent every aspect of reality and hence

assumptions must be made in order to use them for control purposes [1]. The basic aim here is to have simulation

analysis of system parameters considering simple water heater system using tool MATLAB and comparision with

real time parameters.

The idea to change properties of the system and immediately being able to see the effects of the changes is

very powerful both for learning and for designing.Effect of the system response can be observed straight forward in

the grapgh and further information can be derived for the system behavior for both analysis and contro purpose[2].

The paper is organized as follows. In Section 2, the dynamic model of simple water heater system is

presented, Simulation and analysis is presented in Section 3, and a few real time comparision s are given in Section

4. The paper ends with references.

2.

Modelling of simple water heater system[3]

Consider a mathematical model (differential equation) for the simple water heater system which describes its

dynamics. The different signals and components needed to derive a mathematical model for the thermal system are

shown in Figureure 1.

Figureure 1. Thermal system

Received Jul 29th, 2011; Revised Aug 26th, 2011; Accepted Sep 14th, 2011

50

ISSN: 2088-8708

Where, V= Voltage applied to the heater (input), T= Temperature of water, (output), Ta= Ambient temperature,

Qh=Energy supplied by heater, Qs=Energy stored by liquid, QL=Energy lost to the surrounding environment by

conduction. The differential equation is obtained by applying heat balance equation. Energy supplied by the heater

(Qh) = Energy stored by water (Qs) + Energy lost to the surrounding environment by conduction (QL)

i.e. Qh = Qs + QL.

k*V = C*(dT/dt) + (T-Ta)/R

(1)

Where, k is a constant provided by the heater manufacturer ,C is a thermal capacitance of the liquid, R is the thermal

resistance of the tank wall (heat conduction) and t is the time. Equation (1) is the differential equation that describes

the dynamics of the thermal system. Taking Laplace transform at both the side of equation (1) and rearranging in the

transfer function form.

k*V(s) = C*s*T(s) +1/R *(T(s))

(2)

T(s)/V(s) = k/(C*s+1/R)

(3)

Equation (3) is a First order system with the time constant C*R. k*R can be treated as system static gain. if we add

more complexity in the system by adding time delay in the system and substituting system parameters, its transfer

function is derived , which is shown in following Figure 2.at the MATLAB command window.

Figure 2. MATLAB Command window.

3.

Simulation and Analysis

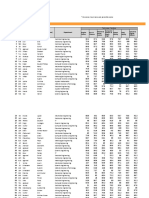

Consider Open loop system having the system parameters as under. Input applied is step function having

unity amplitude. System gain =1, Time constant =1, and Time delay = 1, the system dynamic behaviors for the

above conditions are shown in the following Figure.3.

3.1. Response open loop system

Figure 3 Step response of system.

Signal with color MAGENTA is applied step input and response of the system is YELLOW. As shown in the graph

Figure.3. step input is applied at 1 s and time delay is 0.3 s , so response will start at 1.3s and it stabilized at

amplitude 1 because system static gain is unity and step input is having final value '1'. If there is change in static

gain to '2' without changing other parameters in the system, the response will be stabilized at amplitude '2' instead of

IJECE Vol. 1, No. 1, September 2011 : 49 52

IJECE

ISSN: 2088-8708

51

'1'.on the contrary by changing final value of the step input to '2' and considering same transfer function without

changing system gain system will have same response as shown in the graph Figure.3.

3.2. Change in static gain of the system.

Figure.3 Change in static gain.

3.3. Change in Delay time.

Changing delay of the system from 0.3s to 0.6s keeping rest of the parameters unchanged. The system

response shows that system having higher time delay takes more time to change parameters though; both the

responses reached the final value at the same time approximately 7s shown in Figure.4.

Figure.4 Change in delay time of system.

3.4. Change in Time constant

Changing system time constant from 1s to 2s keeping rest of the parameters unchanged. The system

response shows that system having higher time constant takes more time to reach final value i.e 7s and 13s

respectively Figure.5.

Figure.5 Step response with change in time constant of system.

3.5. Adding white Noise

Adding white Gaussian noise having amplitude 0.001, sample time 0.1s keeping rest of the parameters

unchanged. Effect on the signal can be easily observed in the signal marked with YELLOW color.

Modelling and Analysis of the Simple Water Heater System (Haresh A. Suthar)

52

ISSN: 2088-8708

Figure.6 Step response with white noise.

4.

Conclusion

Various conditions for the first order system have been observed and can be taken as reference with the

response of real time system. The various conditions can be correlated as under.

1. Response of the open loop system can be used to study the behavior of the plant. Various methods like Reaction

curve and relay feedback can be used to find PID parameters.

2. Static gain of the system can be easily correlated with proportional gain of the PID controller.

3. Time delay can be correlated with the sensor position, location of the sensor in the system decides the time delay

in the system. Tip of the sensor in directly contact with the actual process gives fast response compared to

placing far away from the actual process.

4. Effect of the noise can be correlated with the chattering of the contactor and switching of the other devices in the

system.

Analysis carried out using tool MATLAB can be useful to compare the results of the real time system where

temperature is being controlled with simple heater system.It can be useful to derive control strategy for the system.

References

[1]

[2]

[3]

[4]

J.L. Guzman ,K.J.Astrom,S. Dormido,T. Hagglund ,Y. Piguet, M. Berenguel , Interactive Learning Learning

Module: Basic Modelling and Identification Concepts. Proceedings of the 17th World Congress The International

Federation of Automatic Control Seoul, Korea, July 6-11, 2008.

K.J. Astrom and T. Hagglund. Advanced PID Control. ISA - The Instrumentation, Systems, and Automation Society,

Research Triangle Park, NC 27709, 2005.

http://homepage.mac.com/sami_ashhab/courses/control/lectures/lecture_3/Lecture_3.html.

MATLAB Software tool 2009R.

Bibliography of authors

Haresh A.Suthar

He is Reader and Head of the E&C Engineering Department at Parul Institute of Engineering and

Technolgy,Vadodara.He got his BE-Electronics and Master in Autmatic Control & Robotics from

M.S.U of Baroda.

Dr. Jagrut J. Gadit

He is Reader in Electrical Engineering Department at Faculty of Technology & Engineering, M.S.U of

Baroda.He received his BE-Electrical and Master in Automatic Control and Robotics.He is Phd in the

area of control system.

IJECE Vol. 1, No. 1, September 2011 : 49 52

Das könnte Ihnen auch gefallen

- Earthing (Check-1) PDFDokument4 SeitenEarthing (Check-1) PDFZin BoNoch keine Bewertungen

- Recognition of Tokens: The Question Is How To Recognize The Tokens?Dokument15 SeitenRecognition of Tokens: The Question Is How To Recognize The Tokens?Shyam KaranthNoch keine Bewertungen

- Analog Vs Digital TransmissionDokument2 SeitenAnalog Vs Digital TransmissionFaizan AhmadNoch keine Bewertungen

- 01 Basic SignalDokument13 Seiten01 Basic SignalNk KushalNoch keine Bewertungen

- Signal SummaryDokument11 SeitenSignal Summaryaryaman58Noch keine Bewertungen

- Digital Over Analog Signal ProcessingDokument2 SeitenDigital Over Analog Signal ProcessingHayeon Lee100% (1)

- Loops - Do Until - Do While - Do - Access All in OneDokument5 SeitenLoops - Do Until - Do While - Do - Access All in Onehnoor6Noch keine Bewertungen

- Analog To Digital ConverterDokument8 SeitenAnalog To Digital ConverterNarendra SinhaNoch keine Bewertungen

- How Does A Nuclear Power Plant Work?Dokument4 SeitenHow Does A Nuclear Power Plant Work?Cherry ObiasNoch keine Bewertungen

- Research Definition: Martyn ShuttleworthDokument9 SeitenResearch Definition: Martyn ShuttleworthErica Joyce HerreraNoch keine Bewertungen

- Energy and Power Ib2Dokument24 SeitenEnergy and Power Ib2Gkid GkidNoch keine Bewertungen

- Signal Energy and PowerDokument6 SeitenSignal Energy and PowersandeepNoch keine Bewertungen

- ESC TerminologyDokument7 SeitenESC Terminologyapi-26045568Noch keine Bewertungen

- Machine Learning Solution 3Dokument5 SeitenMachine Learning Solution 3MRizqiSholahuddinNoch keine Bewertungen

- Tutorial I Basics of State Variable ModelingDokument11 SeitenTutorial I Basics of State Variable ModelingRebecca GrayNoch keine Bewertungen

- Unit 5: Advanced Optimization Techniques (M.Tech)Dokument10 SeitenUnit 5: Advanced Optimization Techniques (M.Tech)tsnrao30Noch keine Bewertungen

- Dec - Practical ResearchDokument5 SeitenDec - Practical ResearchJaimee Mojica TaligonNoch keine Bewertungen

- Smallmodel DC - DC ConverterDokument9 SeitenSmallmodel DC - DC ConverterAnnamalai ArumugamNoch keine Bewertungen

- Being Critical: Useful Language Introducing Questions, Problems and Limitations (Theory)Dokument2 SeitenBeing Critical: Useful Language Introducing Questions, Problems and Limitations (Theory)CristinaCrisNoch keine Bewertungen

- Signal Generation and PreprocessingDokument15 SeitenSignal Generation and Preprocessingkarthik2055Noch keine Bewertungen

- USB Relay Control - Relay Controller FC 1204 UDokument1 SeiteUSB Relay Control - Relay Controller FC 1204 Uintelligent ApplianceNoch keine Bewertungen

- Quant IzationDokument9 SeitenQuant IzationStephen KempNoch keine Bewertungen

- Battery DC Generator Electric Power Voltage: NextDokument13 SeitenBattery DC Generator Electric Power Voltage: NextHussam GujjarNoch keine Bewertungen

- Acoustic Noise CancellationDokument21 SeitenAcoustic Noise CancellationNESEGANoch keine Bewertungen

- Design DC-DC Converter Topology Full-Bridge 24/400 V 300 W 100Khz With Zero Voltage Switching Phase Shift PWM MethodDokument6 SeitenDesign DC-DC Converter Topology Full-Bridge 24/400 V 300 W 100Khz With Zero Voltage Switching Phase Shift PWM MethodtriwahonoNoch keine Bewertungen

- Data Acquisition HandbookDokument145 SeitenData Acquisition HandbookHan BeibeiNoch keine Bewertungen

- Electronic PID Controller Design ReportDokument19 SeitenElectronic PID Controller Design ReportRatoka LekhemaNoch keine Bewertungen

- Tutorial 6 - CT Fourier Transform: Linearity Property: C, we have that ¯αDokument2 SeitenTutorial 6 - CT Fourier Transform: Linearity Property: C, we have that ¯αPaola Avila100% (1)

- How To Calculate Maximum Sampling Rate of An Analog MuxDokument4 SeitenHow To Calculate Maximum Sampling Rate of An Analog MuxmaysquaredNoch keine Bewertungen

- Complete Overview of Lightning Arresters Part 2Dokument5 SeitenComplete Overview of Lightning Arresters Part 2hafizgNoch keine Bewertungen

- Experiment 5 State Variable ModelsDokument6 SeitenExperiment 5 State Variable Modelsalia khanNoch keine Bewertungen

- Time - Frequency Domain Representation of SignalsDokument9 SeitenTime - Frequency Domain Representation of SignalsSuyog KulkarniNoch keine Bewertungen

- Ee2303 Transmission and DistributionDokument2 SeitenEe2303 Transmission and DistributionMuruga RajNoch keine Bewertungen

- Chapter 2 Sampling and MeasurementDokument10 SeitenChapter 2 Sampling and MeasurementPhillipBattistaNoch keine Bewertungen

- Slide 1-14+ Backpropagation (BP) AlgorithmDokument8 SeitenSlide 1-14+ Backpropagation (BP) AlgorithmMatt MedrosoNoch keine Bewertungen

- Literature 4Dokument4 SeitenLiterature 4virnaNoch keine Bewertungen

- Thesis Poster FinalDokument1 SeiteThesis Poster Finalapi-371237588Noch keine Bewertungen

- Ac Signal GeneratorDokument5 SeitenAc Signal GeneratorSohaib Ahmed100% (1)

- Power Electronic DevicesDokument148 SeitenPower Electronic DevicesArpit AgarwalNoch keine Bewertungen

- Get Start of SysnoiseDokument231 SeitenGet Start of Sysnoisevaninho75% (8)

- To Convert Continuous Time Signal To Discrete Time Signal Using SamplingDokument3 SeitenTo Convert Continuous Time Signal To Discrete Time Signal Using SamplingNiriNoch keine Bewertungen

- Digital Control Engineering Chapter 1Dokument8 SeitenDigital Control Engineering Chapter 1Ishmayne Shawarrma100% (1)

- Analog and Digital Signals Are Used To Transmit InformationDokument49 SeitenAnalog and Digital Signals Are Used To Transmit Informationniiks119Noch keine Bewertungen

- Anfis Controller For Solar Powered Cascade Multilevel InverterDokument7 SeitenAnfis Controller For Solar Powered Cascade Multilevel InverterIAEME PublicationNoch keine Bewertungen

- QQ F R F F F: ! Electric! Current!Dokument4 SeitenQQ F R F F F: ! Electric! Current!metin100% (1)

- Hardware Implementation of Speech Enhancement AlgorithmsDokument3 SeitenHardware Implementation of Speech Enhancement AlgorithmsijsretNoch keine Bewertungen

- Power ConverterDokument26 SeitenPower Converterhardih123Noch keine Bewertungen

- L C R C L A e Y: Grounding SystemDokument45 SeitenL C R C L A e Y: Grounding SystemAnonymous Jy6ASdQ45JNoch keine Bewertungen

- Algorithm Speech EnhancementDokument15 SeitenAlgorithm Speech Enhancementreza100% (2)

- Phased Arrays of Microphones - Sound LocalizationDokument117 SeitenPhased Arrays of Microphones - Sound LocalizationZia UrRehmanNoch keine Bewertungen

- Smart MeterDokument2 SeitenSmart MeterBittuNoch keine Bewertungen

- Review - 3 - Load Forecasting PDFDokument25 SeitenReview - 3 - Load Forecasting PDFhabte gebreial shrashrNoch keine Bewertungen

- Chapter 3 - Signal Conditioning PDFDokument13 SeitenChapter 3 - Signal Conditioning PDFAzrinshah Abu BakarNoch keine Bewertungen

- HETT208 Signal Processing Test 2Dokument3 SeitenHETT208 Signal Processing Test 2Shawn Moyo100% (1)

- Speech RecognitionDokument576 SeitenSpeech RecognitionNadoc100% (4)

- Modern Digital Analog Communications Lathi Pg1-75Dokument75 SeitenModern Digital Analog Communications Lathi Pg1-75Sean WaitheNoch keine Bewertungen

- Basic Tutorials - Charge Controllers For Solar Energy SystemsDokument3 SeitenBasic Tutorials - Charge Controllers For Solar Energy SystemsGeroldo 'Rollie' L. QuerijeroNoch keine Bewertungen

- EECE 301 Note Set 10 CT ConvolutionDokument11 SeitenEECE 301 Note Set 10 CT ConvolutionrodriguesvascoNoch keine Bewertungen

- Journal of Electrical Engineering & Technology (JEET) : ©iaemeDokument8 SeitenJournal of Electrical Engineering & Technology (JEET) : ©iaemeIAEME PublicationNoch keine Bewertungen

- ISA Transactions: Rames C. Panda, V. Vijayan, V. Sujatha, P. Deepa, D. Manamali, A.B. MandalDokument9 SeitenISA Transactions: Rames C. Panda, V. Vijayan, V. Sujatha, P. Deepa, D. Manamali, A.B. MandalAnonymous WkbmWCa8MNoch keine Bewertungen

- HC-SR04 User ManualDokument10 SeitenHC-SR04 User ManualJohandi PatriaNoch keine Bewertungen

- CY3271 Kit GuideDokument106 SeitenCY3271 Kit GuideJohandi PatriaNoch keine Bewertungen

- CY3271 Release NotesDokument3 SeitenCY3271 Release NotesJohandi PatriaNoch keine Bewertungen

- LicenseDokument1 SeiteLicenseLudwig TapiaNoch keine Bewertungen

- Unity FlowchartDokument1 SeiteUnity Flowchartcippolippo123Noch keine Bewertungen

- Lab ManualDokument69 SeitenLab ManualPradeepNoch keine Bewertungen

- Physics WebpackDokument129 SeitenPhysics Webpackapi-333910330Noch keine Bewertungen

- 3D CL Correction S1223RTLDokument7 Seiten3D CL Correction S1223RTLakatsuki.exeNoch keine Bewertungen

- Organisational B.Dokument62 SeitenOrganisational B.Viktoria MolnarNoch keine Bewertungen

- Probability Form 4Dokument10 SeitenProbability Form 4Deen ZakariaNoch keine Bewertungen

- Derrida, Declarations of Independence PDFDokument7 SeitenDerrida, Declarations of Independence PDFMichael Litwack100% (1)

- Gary Molander Syllabus 2014Dokument3 SeitenGary Molander Syllabus 2014AlexGeorgeNoch keine Bewertungen

- Maria Bolboaca - Lucrare de LicentaDokument68 SeitenMaria Bolboaca - Lucrare de LicentaBucurei Ion-AlinNoch keine Bewertungen

- IMS - General MBA - Interview QuestionsDokument2 SeitenIMS - General MBA - Interview QuestionsRahulSatputeNoch keine Bewertungen

- The FlirterDokument2 SeitenThe Flirterdddbbb7Noch keine Bewertungen

- Hawk RoostingDokument11 SeitenHawk RoostingMOKIBUL ISLAM MOKIPSNoch keine Bewertungen

- Youtube Poop: Subverting Art OnlineDokument14 SeitenYoutube Poop: Subverting Art OnlineWill KurlinkusNoch keine Bewertungen

- Bayan Ko Linis Ko ProgramDokument43 SeitenBayan Ko Linis Ko ProgramCymagne Donna Aquino DelarosaNoch keine Bewertungen

- 1) Two Vectors A, B Are Orthogonal IfDokument9 Seiten1) Two Vectors A, B Are Orthogonal IfRamesh MallaiNoch keine Bewertungen

- ESL BOOKS - IELTS Academic Writing Task 1 Vocabulary by ESL Fluency - PreviewDokument7 SeitenESL BOOKS - IELTS Academic Writing Task 1 Vocabulary by ESL Fluency - Previewanirudh modhalavalasaNoch keine Bewertungen

- Seminar WorkshopDokument3 SeitenSeminar Workshopsir_mhickoNoch keine Bewertungen

- Edci 67200 Abby Carlin Case Study FacilitationDokument9 SeitenEdci 67200 Abby Carlin Case Study Facilitationapi-265670845Noch keine Bewertungen

- Water TableDokument5 SeitenWater TableJay DoshiNoch keine Bewertungen

- Innoventure List of Short Listed CandidatesDokument69 SeitenInnoventure List of Short Listed CandidatesgovindmalhotraNoch keine Bewertungen

- Expanding UNIT 1 For 2º ESO.-the History of Music NotationDokument1 SeiteExpanding UNIT 1 For 2º ESO.-the History of Music NotationEwerton CândidoNoch keine Bewertungen

- Things To Remember When Writing Your Conference Proposal AbstractDokument2 SeitenThings To Remember When Writing Your Conference Proposal AbstractBalizkoa BadaezpadakoaNoch keine Bewertungen

- TGC 121 505558shubham AggarwalDokument4 SeitenTGC 121 505558shubham Aggarwalshubham.aggarwalNoch keine Bewertungen

- A Sourcebook in Chinese LongevityDokument34 SeitenA Sourcebook in Chinese Longevitytanpausing67% (3)

- Ubd Food ChainDokument5 SeitenUbd Food Chainapi-313687749Noch keine Bewertungen

- Daily Lesson Log: Department of EducationDokument10 SeitenDaily Lesson Log: Department of EducationStevenson Libranda BarrettoNoch keine Bewertungen

- Critical Incident Stress DebriefingDokument20 SeitenCritical Incident Stress DebriefingatenampNoch keine Bewertungen

- PV Quick StartDokument61 SeitenPV Quick StartMayur PatelNoch keine Bewertungen

- Certification of Anti-Seismic Devices According To The European Standard EN 15129:2009: Tasks For Manufacturers and Notified BodiesDokument9 SeitenCertification of Anti-Seismic Devices According To The European Standard EN 15129:2009: Tasks For Manufacturers and Notified BodiesRobby PermataNoch keine Bewertungen