Beruflich Dokumente

Kultur Dokumente

List of Equipments As Per Anna University R 2013

Hochgeladen von

Harsha0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

21 Ansichten7 SeitenList of Equipments as Per Anna University R 2013

Originaltitel

List of Equipments as Per Anna University R 2013

Copyright

© © All Rights Reserved

Verfügbare Formate

DOC, PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenList of Equipments as Per Anna University R 2013

Copyright:

© All Rights Reserved

Verfügbare Formate

Als DOC, PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

21 Ansichten7 SeitenList of Equipments As Per Anna University R 2013

Hochgeladen von

HarshaList of Equipments as Per Anna University R 2013

Copyright:

© All Rights Reserved

Verfügbare Formate

Als DOC, PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 7

CH6411 TECHNICAL ANALYSIS LABORATORY L T P C 0 0 4 2

OBJECTIVE:

To train the students on basic principles involved in estimation and

Characterization of industrially important materials.

LIST OF EXPERIMENTS

I Soap Analysis

a. Estimation of total fatty acid

b. Estimation of percentage alkali content

II. Oil Analysis

a. Estimation of free acid

b. Determination of Saponification value

c. Determination of iodine value

III. Cement Analysis

48

a. Estimation of Silica content

b. Estimation of mixed oxide content

c. Estimation of calcium oxide content

d. Estimation of calcium oxide by rapid method

IV. Coal Analysis

a. Estimation of Sulphur present in coal

b. Ultimate analysis of coal

c. Proximate analysis of coal

V. Analysis of Bleaching Powder

a. Estimation of available chlorine

VI. Analysis of Glycerol

a. Estimation of purity of glycerol

VII. Analysis of fuels

a. Flash point b. Fire point c. Cloud point d. Pour point e. Aniline point.

VIII. Determination of the molecular weight of the polymer by viscometry.

IX. Calorimetric measurements

X. Conductivity measurement of an electrolyte solution

XI. pH measurements

TOTAL : 45 PERIODS

OUTCOME:

At the end of this practical course, the student would have a thorough

understanding on the estimation and analysis of chemical compounds.

LIST OF EQUIPMENT FOR BATCH OF 30 STUDENTS

1. Silica Crucible

2. Heating Mantle

3. Muffle Furnace

4. Hot air oven

5. Desiccator

6. Vacuum pump

7. Condenser

8. Reflux Condenser

9. Pensky martens closed cup apparatus

10. Cleveland open cup apparatus

11. Cloud point apparatus

12. Aniline point apparatus

13. Saybolt Viscometer

14. Redwood viscometer

15. Bomb Calorimeter

16. Junkers gas Calorimeter

17. Conductivity meter

18. pH meter

CE6412 FLUID MECHANICS LABORATORY L T P C 0 0 3 2

OBJECTIVE:

To learn experimentally to calibrate flow meters, find pressure loss for fluid

flows and determine pump characteristics.

LIST OF EXPERIMENTS

1. Viscosity measurement of non Newtonian fluids

2. Calibration of constant and variable head meters

3. Calibration of weirs and notches

4. Open drum orifice and draining time

5. Flow through straight pipe

6. Flow through annular pipe

7. Flow through helical coil and spiral coil

8. Losses in pipe fittings and valves

9. Characteristic curves of pumps

10. Pressure drop studies in packed column

11. Hydrodynamics of fluidized bed

12. Drag coefficient of solid particle

TOTAL: 45 PERIODS

OUTCOME:

Practical knowledge on the measurement of Fluid Flow and their characteristics

at different operating conditions.

LIST OF EQUIPMENT FOR BATCH OF 30 STUDENTS

1. Viscometer

2. Venturi meter

3. Orifice meter

4. Rotameter

5. Weir

6. Open drum with orifice

7. Pipes and fittings

8. Helical and spiral coils

9. Centrifugal pump

10. Packed column

11. Fluidized bed

CH6512 MECHANICAL OPERATIONS LABORATORY L T P C 0 0 3 2

OBJECTIVE:

To enable the students to develop a sound working knowledge on different

types of crushing equipments and separation characteristics of different

mechanical operation separators.

LIST OF EXPERIMENTS

1. Sieve analysis

2. Batch filtration studies using a Leaf filter

3. Batch filtration studies using a Plate and Frame Filter press

4. Characteristics of batch Sedimentation

5. Reduction ratio in Jaw Crusher

6. Reduction ratio in Ball mill

7. Separation characteristics of Cyclone separator

8. Reduction ratio of Roll Crusher

59

9. Separation characteristics of Elutriator

10. Reduction ratio of Drop weight crusher

11. Size separation using Sub-Sieving

TOTAL : 45 PERIODS

OUTCOME:

Students would gain the practical knowledge and hands on various separation

Techniques like filtration, sedimentation, screening, elutriation, and

Centrifugation

LIST OF EQUIPMENT FOR BATCH OF 30 STUDENTS

1. Sieve shaker

2. Leaf filter

3. Plate and Frame Filter Press

4. Sedimentation Jar

5. Jaw Crusher

6. Ball Mill

7. Cyclone Separator

8. Roll Crusher

9. Elutriator

10. Drop Weight Crusher

11. Sieves.

CH6611 HEAT TRANSFER LABORATORY L T P C 0 0 3 2

OBJECTIVE:

To enable the students to develop a sound working knowledge on different

types of heat transfer equipments.

LIST OF EXPERIMENTS

1. Performance studies on Cooling Tower

2. Batch drying kinetics using Tray Dryer

3. Heat transfer in Open Pan Evaporator

4. Boiling Heat Transfer

5. Heat Transfer through Packed Bed

6. Heat Transfer in a Double Pipe Heat Exchanger

7. Heat Transfer in a Bare and Finned Tube Heat Exchanger

8. Heat Transfer in a Condenser

9. Heat Transfer in Helical Coils

65

10. Heat Transfer in Agitated Vessels

TOTAL : 45 PERIODS

OUTCOME:

Student would be able to calculate heat transfer by conduction, different types

of convection using classical models for these phenomena.

LIST OF EQUIPMENT FOR BATCH OF 30 STUDENTS

1. Cooling Tower

2. Tray Dryer

3. Open Pan Evaporator

4. Boiler

5. Packed Bed

6. Double Pipe Heat Exchanger

7. Bare and Finned Tube Heat Exchanger

8. Condenser

9. Helical Coil

10. Agitated Vessel

CH6613 MASS TRANSFER LABORATORY L T P C 0 0 3 2

OBJECTIVE:

To train the students to develop sound working knowledge on different types of

mass transfer equipments.

LIST OF EXPERIMENTS

1. Separation of binary mixture using Simple distillation

2. Separation of binary mixture using Steam distillation

3. Separation of binary mixture using Packed column distillation

4. Measurement of diffusivity

5. Liquid-liquid extraction

6. Drying characteristics of Vacuum Dryer

7. Drying characteristics of Tray dryer

8. Drying characteristics of Rotary dryer

9. Water purification using ion exchange columns

10. Mass transfer characteristics of Rotating disc contactor

11. Estimation of mass/heat transfer coefficient for cooling tower

12. Demonstration of Gas Liquid absorption

TOTAL : 45 PERIODS

OUTCOME:

Students would be able to determine important data for the design and

operation of the process equipments like distillation, extraction, diffusivity and

drying principles which are having wide applications in various industries

LIST OF EQUIPMENTS FOR BATCH OF 30 STUDENTS

1. Simple distillation setup

2. Steam distillation setup

3. Packed column

4. Liquid-liquid extractor

5. Vacuum Dryer

6. Tray dryer

7. Rotary dryer

8. Ion exchange column

9. Rotating disc contactor

10. Cooling tower

11. Absorption column

Minimum 10 experiments shall be offered

CH6711 CHEMICAL REACTION ENGINEERING LABORATORY L T P C 0 0 3 2

OBJECTIVE:

To impart knowledge on design of reactors.

LIST OF EXPERIMENTS

1. Kinetic studies in a Batch reactor

2. Kinetic studies in a Plug flow reactor

3. Kinetic studies in a CSTR

4. Kinetic studies in a Packed bed reactor

5. Kinetic studies in a PFR followed by a CSTR

6. RTD studies in a PFR

7. RTD studies in a Packed bed reactor

8. RTD studies in a CSTR

9. Studies on micellar catalysis

10. Study of temperature dependence of rate constant using CSTR.

11. Kinetic studies in Sono chemical reactor

12. Batch reactive distillation

13. Kinetics of photochemical reaction

14. Demonstration of heterogeneous catalytic reaction

15. Demonstration of gas-liquid reaction

TOTAL : 45 PERIODS

OUTCOME:

Students would get a sound working knowledge on different types of reactors.

LIST OF EQUIPMENT FOR BATCH OF 30 STUDENTS

1. Batch Reactor

2. Plug flow reactor

3. CSTR

4. Sono-chemical reactor

5. Photochemical reactor

6. Packed bed reactor

*Minimum 10 experiments shall be offered.

CH6713 PROCESS CONTROL LABORATORY L T P C 0 0 3 2

OBJECTIVE:

To determine experimentally the methods of controlling the processes including

Measurements using process simulation techniques.

LIST OF EXPERIMENTS

1. Response of first order system

2. Response of second order system

3. Response of Non-Interacting level System

4. Response of Interacting level System

5. Open loop study on a thermal system

6. Closed loop study on a level system

7. Closed loop study on a flow system

8. Closed loop study on a thermal system

9. Tuning of a level system

10. Tuning of a pressure system

11. Tuning of a thermal system

12. Flow co-efficient of control valves

13. Characteristics of different types of control valves

14. Closed loop study on a pressure system

15. Tuning of pressure system

16. Closed loop response of cascade control system

*Minimum 10 experiments shall be offered.

TOTAL : 45 PERIODS

OUTCOME:

Students would have knowledge on the development and use of right type of

control dynamics for process control under different operative conditions.

LIST OF EQUIPMENT FOR BATCH OF 30 STUDENTS

1. U tube manometer with controller

2. Interacting Tank

3. Non Interacting Tank

4. Open loop control system

5. Closed loop control system

6. ON/OFF controller

7. Control valve characteristics

8. Pressure Tuner

9. Temperature Tuner

10. Proportional Controller

11. Flow Transmitter

12. Level Transmitter

13. Cascade control system

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- Code of Ethics Multiple Choice QuestionsDokument4 SeitenCode of Ethics Multiple Choice QuestionsGideon P. Casas88% (24)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Pipe Flow Calculations PDFDokument12 SeitenPipe Flow Calculations PDFharrypop418Noch keine Bewertungen

- ECEN 160 Final Project Logisim Instrs and DecoderDokument2 SeitenECEN 160 Final Project Logisim Instrs and DecoderEvandro Fernandes LedemaNoch keine Bewertungen

- In-Film BrandingDokument27 SeitenIn-Film BrandingSantosh Parachuri0% (1)

- Assessment ParametersDokument1 SeiteAssessment ParametersHarshaNoch keine Bewertungen

- LorenaDokument22 SeitenLorenaVinay MPNoch keine Bewertungen

- Modeling, Simulating and Rendering Fluids: Thanks To Ron Fediw Et Al, Jos Stam, Henrik Jensen, RyanDokument47 SeitenModeling, Simulating and Rendering Fluids: Thanks To Ron Fediw Et Al, Jos Stam, Henrik Jensen, RyanvdertiNoch keine Bewertungen

- LorenaDokument22 SeitenLorenaVinay MPNoch keine Bewertungen

- AIChE 155fDokument26 SeitenAIChE 155fHarshaNoch keine Bewertungen

- Thomas Edgar C Se 022013Dokument1 SeiteThomas Edgar C Se 022013HarshaNoch keine Bewertungen

- Ecc 2001Dokument5 SeitenEcc 2001A MahmoodNoch keine Bewertungen

- Chegg SolutionsDokument9 SeitenChegg SolutionsRambabu R100% (1)

- AIChE 155fDokument26 SeitenAIChE 155fHarshaNoch keine Bewertungen

- Chemi Tech - 201801091549Dokument4 SeitenChemi Tech - 201801091549HarshaNoch keine Bewertungen

- AIChE 155fDokument26 SeitenAIChE 155fHarshaNoch keine Bewertungen

- Chem CadDokument3 SeitenChem CadHarshaNoch keine Bewertungen

- Read MeDokument1 SeiteRead MeHarshaNoch keine Bewertungen

- Understanding Particle SegDokument10 SeitenUnderstanding Particle SegHarshaNoch keine Bewertungen

- Savings With Uber/Ola: 3 Years CalculationDokument2 SeitenSavings With Uber/Ola: 3 Years CalculationHarshaNoch keine Bewertungen

- Following Is The Feed Back of System Engineer MRDokument1 SeiteFollowing Is The Feed Back of System Engineer MRHarshaNoch keine Bewertungen

- Go 78 PDFDokument22 SeitenGo 78 PDFHariragavaraj SadasivamNoch keine Bewertungen

- ATM List IndiaDokument210 SeitenATM List IndiaK MuruganNoch keine Bewertungen

- Itr2 2018 PR1.1Dokument98 SeitenItr2 2018 PR1.1HarshaNoch keine Bewertungen

- New Syllabus Chem Engg Deg STDDokument3 SeitenNew Syllabus Chem Engg Deg STDHarshaNoch keine Bewertungen

- Silo Failures PDFDokument15 SeitenSilo Failures PDFpalanipaaaaNoch keine Bewertungen

- Chemical Engineering SingleDokument2 SeitenChemical Engineering SinglenatrajNoch keine Bewertungen

- RingtonesDokument60 SeitenRingtonesHarshaNoch keine Bewertungen

- Crackers Standard Fireworks Price List 2017Dokument12 SeitenCrackers Standard Fireworks Price List 2017HarshaNoch keine Bewertungen

- Fluid SelecDokument5 SeitenFluid Selecnirmal_subudhiNoch keine Bewertungen

- Group II SyllabusDokument3 SeitenGroup II SyllabushemanthgaddamNoch keine Bewertungen

- Absorber TutoDokument36 SeitenAbsorber TutotutuncucananNoch keine Bewertungen

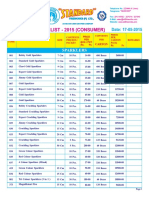

- Price List Ver12-2015 - Consumer81913 PDFDokument17 SeitenPrice List Ver12-2015 - Consumer81913 PDFHarshaNoch keine Bewertungen

- 1 s2.0 S0009250917304396 MainDokument10 Seiten1 s2.0 S0009250917304396 MainHarshaNoch keine Bewertungen

- Atex ExplainedDokument3 SeitenAtex ExplainedErica LindseyNoch keine Bewertungen

- Company of Heroes Opposing Fronts Manual PCDokument12 SeitenCompany of Heroes Opposing Fronts Manual PCMads JensenNoch keine Bewertungen

- Indian - Origin Girls Bag Google Science Honour - Yahoo! India EducationDokument3 SeitenIndian - Origin Girls Bag Google Science Honour - Yahoo! India EducationRiyaz RafiqueNoch keine Bewertungen

- User Mode I. System Support Processes: de Leon - Dolliente - Gayeta - Rondilla It201 - Platform Technology - TPDokument6 SeitenUser Mode I. System Support Processes: de Leon - Dolliente - Gayeta - Rondilla It201 - Platform Technology - TPCariza DollienteNoch keine Bewertungen

- CV - Oscar ChampionDokument3 SeitenCV - Oscar ChampionKarina Gamarra NinaNoch keine Bewertungen

- Belgian Overseas Chartering and Shipping NDokument2 SeitenBelgian Overseas Chartering and Shipping NMXKatNoch keine Bewertungen

- ION 900 Series Owners ManualDokument24 SeitenION 900 Series Owners ManualParosanu IonelNoch keine Bewertungen

- FEW Tapping Drill Sizes PDFDokument1 SeiteFEW Tapping Drill Sizes PDFrefaeNoch keine Bewertungen

- Mystique-1 Shark Bay Block Diagram: Project Code: 91.4LY01.001 PCB (Raw Card) : 12298-2Dokument80 SeitenMystique-1 Shark Bay Block Diagram: Project Code: 91.4LY01.001 PCB (Raw Card) : 12298-2Ion PetruscaNoch keine Bewertungen

- Accounting QuestionsDokument16 SeitenAccounting QuestionsPrachi ChananaNoch keine Bewertungen

- RBA Catalog Maltby GBR Aug 16 2023 NL NLDokument131 SeitenRBA Catalog Maltby GBR Aug 16 2023 NL NLKelvin FaneyteNoch keine Bewertungen

- Appendix: Dhuts-Phase Ii Dhaka Urban Transport Network Development Study-Phase IIDokument20 SeitenAppendix: Dhuts-Phase Ii Dhaka Urban Transport Network Development Study-Phase IIhhbeckNoch keine Bewertungen

- Pk-Kredit Finanzierung-Db International Opening A Bank Account For Foreign StudentsDokument19 SeitenPk-Kredit Finanzierung-Db International Opening A Bank Account For Foreign StudentsBoűmřãh FōüĀdNoch keine Bewertungen

- Communication To Offer-ContractsDokument20 SeitenCommunication To Offer-ContractsAarif Mohammad BilgramiNoch keine Bewertungen

- Fax Cross ReferenceDokument32 SeitenFax Cross ReferenceBranga CorneliuNoch keine Bewertungen

- Plewa2016 - Reputation in Higher Education: A Fuzzy Set Analysis of Resource ConfigurationsDokument9 SeitenPlewa2016 - Reputation in Higher Education: A Fuzzy Set Analysis of Resource ConfigurationsAlice ChenNoch keine Bewertungen

- Economic History of The PhilippinesDokument21 SeitenEconomic History of The PhilippinesBench AndayaNoch keine Bewertungen

- Avamar Backup Clients User Guide 19.3Dokument86 SeitenAvamar Backup Clients User Guide 19.3manish.puri.gcpNoch keine Bewertungen

- CH03 HKM Law Investigation and EthicsDokument32 SeitenCH03 HKM Law Investigation and Ethicsmilkikoo shiferaNoch keine Bewertungen

- ION Architecture & ION ModulesDokument512 SeitenION Architecture & ION ModulesAhmed RabaaNoch keine Bewertungen

- Optical Current TransformerDokument22 SeitenOptical Current TransformerchallaramcharanreddyNoch keine Bewertungen

- File 1379580604 PDFDokument9 SeitenFile 1379580604 PDFMuhammad Salik TaimuriNoch keine Bewertungen

- Case Studies Public LibraryDokument4 SeitenCase Studies Public LibraryHimalya Kaim83% (6)

- CS8792 CNS Unit5Dokument17 SeitenCS8792 CNS Unit5024CSE DHARSHINI.ANoch keine Bewertungen

- MT7605B DSDokument7 SeitenMT7605B DSVishal dtuNoch keine Bewertungen

- GSM Controlled RobotDokument33 SeitenGSM Controlled RobotAbhishek KunalNoch keine Bewertungen

- Best Evidence Rule CasesDokument5 SeitenBest Evidence Rule CasesRemy Rose AlegreNoch keine Bewertungen