Beruflich Dokumente

Kultur Dokumente

Electrical Brooder

Hochgeladen von

andisurtiOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Electrical Brooder

Hochgeladen von

andisurtiCopyright:

Verfügbare Formate

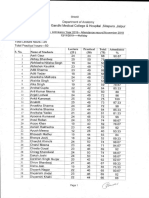

GPFPP Note No 01

International Network for Family Poultry Development

Rseau International pour le Dveloppement de l'Aviculture

Familiale

Red Internacional Para El Desarrollo de la Avicultura Familiar

www.fao.org/ag/againfo/themes/en/infpd/home.html

http://www.infpd.net/

Good Practices for Family Poultry Production

Hay Box Brooder: A Milestone to Increase Rural

Households Poultry Production

by

Professor Solomon Demeke

Country: Ethiopia

Hay Box Brooder: A milestone to Increase Rural Households Poultry Production

Author

Solomon Demeke is a Professor in the Department of Animal Sciences, Jimma

University College of Agriculture and Veterinary Medicine (JUCAVM), P.O.Box

307, Jimma, Ethiopia

Cell Phone 251 917 804430

Office 251471112659

email: solomondemeke2000@gmail.com

solomon.demeke@ju.edu.et

Recommended Citation

Solomon Demeke. 2012. Hay Box Brooder: A Milestone to Increase Rural

Households Poultry Production. INFPD Good Practices of Family Poultry

Production Note No 01.

Keywords

Hay Box, brooder, rural poultry

Date of publication:

October 2012

The designations employed and the presentation of material in this information

product do not imply the expression of any opinion whatsoever on the part of

the Food and Agriculture Organization of the United Nations (FAO) or the

International Fund for Agricultural Development of the United Nations (IFAD)

concerning the legal or development status of any country, territory, city or area

or of its authorities, or concerning the delimitation of its frontiers or boundaries.

The mention of specific companies or products of manufacturers, whether or not

these have been patented, does not imply that these have been endorsed or

recommended by FAO or IFAD in preference to others of a similar nature that

are not mentioned. The views expressed in this information product are those of

the author(s) and do not necessarily reflect the views of FAO or IFAD.

Hay Box Brooder: A milestone to Increase Rural Households Poultry Production

Acknowledgements

The purpose of the International Network for Family Poultry Development

(INFPD) is to share information about poultry production among scientists,

researchers, policy makers, educationists, students and development workers

and to promote the cause of family poultry production.

Good Practices of Family Poultry Production (GPFPP) are "practices that

address environmental, economic and social sustainability for on-farm

processes, and result in safe and quality food and non-food agricultural

products" (FAO COAG 2003 GAP paper). Sharing information about Good

Practices for Family Poultry Production that are successfully implemented in

countries, regions or development projects is an important objective of the

INFPD so that these practices can be replicated in different region based on the

farmers demand.

Dr. Md. A. Saleque, the coordinator of the FAO/IFAD/INFPD project Support

for Smallholder Poultry Development formulated guidelines for the

documentation of GPFPP based on experience for the documentation of good

practices by other institutions, including the South Asia Pro Poor Livestock

Policy Programme (SA PPLPP). Special thanks are due to Dr. Fallou Gueye

(FAO), Dr. Olaf Thieme (FAO), Professor Dr. E. B Sonaiya (Obafemi Awolowo

University, Nigeria), Dr. Robyn Alders (Kyeema Foundation) and Mr. Antonio

Rota (IFAD) for their continuous efforts to finalize the guidelines. The INFPD

encourages all members to collect and document GPFPP and to make

knowledge of them available to a wide audience.

The GPFPP about Hay Box Brooder: A Milestone to Increase Rural Households

Poultry Production was prepared by Prof. Solomon Demeke based on his

works and experiences in Ethiopia. It was reviewed and edited by Dr. Md. A.

Saleque and Auvijit Saha Apu from Bangladesh and Dr. Olaf Thieme (FAO).

Their valuable comments helped to finalize this note.

Hay Box Brooder: A milestone to Increase Rural Households Poultry Production

1. Introduction

Chick brooding refers to the early periods of growth (0-8 weeks), when young

chicks are unable to maintain their normal body temperature without the aid

of supplementary heat. Unlike most other small animals, baby chicks are

unable to live for any length of time without an additional source of heat other

than their own bodies. Under natural condition, broody hens lay and brood

their eggs until they hatch. After hatching she continues rearing the chicks

through provision of the needed warmth and protection against predators.

Artificial brooding refers to some type of heated enclosure for raising baby

chicks and artificial brooders include a heat lamp, provision of food and water

and bedding materials.

Different artificial chick brooders exist of every conceivable type and size,

heated by oil, coal, wood, water, gas and electricity. With the exception of the

electric brooders, all other methods are difficult to operate with local skills in

rural areas. They do not maintain constant brooding temperature, require

foreign currency for importation and are expensive in size of less than 1000

chick capacity. On the contrary electric brooders are economically feasible,

could safely and easily be constructed and maintain the desired constant

brooding temperature. Unfortunately however, it is difficult to adopt electric

brooders by the African rural household poultry producers owing to the

unavailability of electric power, numbers of chicks to be raised and remote

locations of the farm sites (Solomon, 2007).

It is by natural brooding that the indigenous baby chicks are raised all over

rural Africa including Ethiopia. The broody hen is rearing and protecting few

chicks and ceases laying during the entire incubation and brooding periods of

up to 81 days. Yet the success of the brooding process depends on the

maternal instinct of the broody hen and the prevalence of predators such as

birds of prey, pets and some wild animals, all of which are listed as the major

causes of premature death of chicks (Solomon, 1999). Natural brooding as it is

practiced in different parts of rural Africa is characterized by high chick

mortality. The average survival rate of baby chicks to an age of 3-months

reared under natural brooding condition in Ethiopia is about 40 percent

(AACMC, 1984; Hoyle, 1992; Ethiopian Statistical Authority,1985-1996), and

the other parts of rural Africa are not exception to this situation. The general

observation is that broody hens cease egg laying for 2.7 months for the purpose

of rearing 2.8 chicks to an age of 3 months (Solomon, 2010). Mortality will be

reduced if an artificial chick brooding system is adopted. Moreover, artificial

brooding will relieve the hen from the long broody period and the hen would

come into lay again within a short period and hence increase rural poultry

production in the villages.

Some of the African countries developed their own national poultry extension

package based on the above described local conditions. For instance the

Hay Box Brooder: A milestone to Increase Rural Households Poultry Production

initiation of the Ethiopian national poultry extension package goes back to the

early 1950s and comprised of the distributions of three months old exotic

pullets and cockerels. This aimed at promoting small scale exotic poultry

production within the rural farming population and up-grading of the

indigenous chickens by crossing with exotic males (Alemu Sida, 1987). The

Ministry of Agriculture (MoA), being responsible for the Ethiopian national

poultry extension package, established several poultry multiplication and

breeding centers in different parts of the country to be used as a source of

breeding stock and management information. MoA was also reported to have a

plan of establishing about 57 satellite brooder houses that would have received

day-old chicks from the breeding and multiplication centers, rear them to 3

months of age and supply pullets and cockerels to farmers in their respective

zones (Alemu and Tadelle, 1997).

The supply of improved pullets and cockerels from the government poultry

multiplication and breeding centers however was not adequate for the demand.

Hence, the MoA cannot claim to have had a sustainable and measurable

impact on the rural communities that it was expected to serve in the area of

poultry production. It seems difficult to expect rapid and positive change

through the supply of 3 months old pullets and cockerels from the government

poultry multiplication centers. Although these centers have adequate hatching

capacity they cannot meet the huge demand for brooding facilities. Brooding

chicks by using the hay-box chick brooding technology, that was developed at

Jimma University College of Agriculture and Veterinary Medicine (JUCAVM)

seems promising in bridging this gap (Nigussie et al, 2003).

2. Practice of Hay-Box Brooder

2.1 Construction and Specifications

The hay-box chick brooder which is not using any artificial heat is an ESTC

(Ethiopian Science and Technology Commission) award winning technology

developed by Prof. Solomon Demeke at Jimma University College of Agriculture

and Veterinary Medicine (JUCAVM) (Solomon, 2003). Unlike other brooders,

this device does not require coal, oil, or electricity for heating. The brooder

comprises of a simple square box made of four outer framing wooden boards, a

door, small ventilation holes, a wooden or wire-mesh floor, a central nest, a

roof (top cover) and wire mesh enclosing a chick run (Figure 1). The walls of the

brooder could be made of 4 outer framing boards, each being 30 cm high and 2

cm thick. Four small ventilation holes of 2.5 cm diameter are drilled at the

upper side of each frame board (making it a total of 16 holes). A door of

appropriate dimension, depending on the size of the box, is made at the center

of one of the four frame boards. The floor of the hay-box brooder should be

made durable, smooth and easy to clean and disinfect.

Hay Box Brooder: A milestone to Increase Rural Households Poultry Production

Figure 1 Construction design of the hay-box and run.

1= frame board, 2 = Ventilation hole, 3 = mesh-wire floor, 4 = door, 5 = central nest, 6 =

stuffed hay, 7 = stick, 8 = sack filled with hay, 9 = run frame board, 10 = mesh-wire, 11 = run

door, 12 = box and run arrangement.

Cheap (soft) wood and/or half inch wire-mesh tightly stretched to prevent

sagging could be used for the construction of the floor. The central nest is

made up of a central circle of wire-mesh netting with an opening to the door

that is arranged to lead directly into the run, leaving no open space between

the nest and door. Insulation material (hay or straw) is stuffed very loosely into

the space between the central nest and the sides of the box. Depending on

climatic conditions the roof or top of the hay-box is made of either a single or

double layered sack filled with an insulation material. The run is made of 4wooden frame boards, each of them 30 cm high and 2 cm thick (similar in

height and width to the frame boards of the hay-box brooder) covered by wire

mesh.

The suggestions for the minimum and maximum number of chicks that could

be conveniently raised with the use of the hay-box chick brooding technology

under the rural/village conditions of Africa are based on experiences in

Ethiopia with respect to housing and feeding. It has been shown that the

fabrication of hay-boxes for less than 10 chicks is expensive and urban

dwellers and rural farmers participating in its introduction were reluctant to

accept the offer of hay box brooder of that size. On the other side, retarded

growth and high chick mortality were observed among chicks raised in hay-box

brooders for more than 70 chicks. Most of the observations made and the

results of a series of on-station and on-farm trails indicate that for the hay-box

chick brooding technology a capacity of 10 to 70 is the most appropriate size

under the present Ethiopian small holder conditions (Solomon, 1999). The

Hay Box Brooder: A milestone to Increase Rural Households Poultry Production

specifications for different size hay-box chick brooders in the range for 10-70

chicks of egg type breeds are shown in Table 1 (Solomon, 2001).

Table 1 Specifications of the hay-boxes for 10-70 chicks

No chicks

10

20

30

Box dimension (cm)

30 x 26 x 26

30 x 37 x 37

30 x 45 x 45

Run dimension (cm)

30 x 56 x 56

30 x 80 x 80

30 x 98 x 98

40

60

30 x 52 x 52

30 x 63 x 63

30 x 113 x 113

30 x 139 x 139

70

30 x 68 x 68

30 x 150 x 150

2.2 Management

Feed and water are always provided in the run and not in the brooder box. Very

close attention is required during the first week of brooding and the chicks

should be moved out of the box 4 to 5 times/day for feeding and watering in

the run. Two to three hours after feeding and watering they should be gently

pushed back into the box and the door closed behind them. After the first week

of brooding, the chicks will know their way about and will freely run in and out

of the box, when the door of the box to the run is left open during daytime.

Changing the position of the box and run frequently (for provision of fresh

pasture) and closing of the chicks into the box at night are the major

managerial practices required after the first week of brooding.

2.3 Brooding Temperature and Space

One of the critical requirements of successful chick brooding is regulation of

brooding temperature and provision of adequate space. As chicks grow and

mature, the need for supplemental heat is less important whereas, the need for

adequate space becomes critical. Generally there is no agreement among

poultry men as to the exact brooding temperature of baby chicks, just

transferred from an incubator. The initial brooding temperature below the

hover should be 35C at 5 cm from the floor and this initial brooding

temperature should be reduced by approximately 3C per week until 21C is

reached (Amanda, 2007). A brooding temperature of about 34-39C is achieved

in the hay-box brooders during the first week of brooding if the specified design

and the dimension of the technology are maintained. The brooding temperature

of the hay-box brooders could be reduced by at least 3C weekly, to the desired

level by reducing the amount of hay stuffed between the sides of the box and

the central nest. There is thus gradual increase in the available space with the

proportional reduction of the amount of hay stuffed between the sides of the

box and the central nest. The central nest will thus have to be enlarged and

adjusted each time the insulation material is reduced (Solomon, 2007).

Hay Box Brooder: A milestone to Increase Rural Households Poultry Production

2.4 Ventilation

The ventilation needs of the hay-box brooder depend on the climatic conditions

and chick density and are ensured by the 16 small ventilation holes drilled on

the top of the outer frame boards of the hay box-brooder. The omission or

blockage of these ventilation holes results in high brooding temperature,

suffocation and chick death. The floor of the hay-box may also provide

considerable additional air circulation depending on the type of constructional

materials used. A wire-mesh floor would provide the best ventilation in addition

to the continuous supply of fresh air through the sack covering the top.

2.5 Feed and Water

Adequate commercial or homemade feed and clean water need to be available

in the run permanently during daytime. Additionally the practice of thinly

spreading of household scraps, green leafy materials and by-products of yellow

vegetables such as carrots, mango, papaya etc into the chick run is advisable.

The consumption of very cold water early in the morning makes baby chicks

uncomfortably cold and results in bunching, crowding and smothering in the

run accompanied by high mortality. Therefore it is advisable to provide warm

water in the run immediately after the chicks are moved out of the box early in

the morning.

2.6 Parasitism

The Hay-box brooding technology involves the use of fibrous and bulky dry

organic substance (hay and straw) as insulation materials for the conservation

of the metabolic heat of the chicks. Unfortunately however, these insulation

materials and the top covering sack may harbor external parasites such as lice,

mites, and bed bugs. Heavy infestation by these blood sucking parasites could

be encountered under rural household conditions resulting in stunted and

retarded growth of chicks. It is important therefore to change and renew the

insulation materials and to clean the hay-box and the run with boiling water

on a regular basis.

2.7 Ant Attack

The technology offer safety against predators such as birds of prey, pets and

wild animals. Unfortunately however, it could easily be attacked by ants which

could result in total loss of chicks. Close attention (supervision) and fast

reaction to sound signals are required in areas where there is high prevalence

of ants such as south, west and southwest of Ethiopia.

3. Key Components of the Good Practice

The hay box chick brooding technology utilizes simple and locally available

materials. The major principles of this simple technique are brooding chicks by

conserving the metabolic heat produced by the chicks and thus keeping them

Hay Box Brooder: A milestone to Increase Rural Households Poultry Production

warm. It was assumed that the use of the hay box brooder could alleviate the

burden of the breeding and multiplication centers of the Ethiopian Ministry of

Agriculture and develop the capacity and success of the national poultry

extension services. Under village conditions using the hay box brooder also has

the advantage of providing protection to chicks against predator attack and

reducing the risk of exposure to disease through confinement. Another

potential benefit of this technique is that it could enable farmers to isolate

chicks from their mother at a very early age and raise them separately so that

the hens could resume egg laying in short period of time (Nigussie et al., 2003).

The hay box brooder is a low-input technology that releases the mother hen

from brooding so that it may return to laying early. This would increase small

scale poultry production in general and egg productivity in particular. The

brooder is easy to construct, use and modify with the use of locally available

skills and materials (Photos 1-2).

The advantages and significance of the hay-box chick brooding technology

compared to natural brooding are the better performance in terms of number of

chicks raised at a time and their survival rate, earlier start of egg laying by the

hen and protection of chicks from predators such as birds of prey, pets and

wild animals. It also better fits a market oriented production system, since

batches of up to 70 chicks could be reared at a time. Compared to electric

brooders the advantages and significance of the hay- box chick brooding

technology are that:

It is as productive as the electric brooder in any size of < 70 chicks.

No artificial heat is employed in the hay-box and hence brooding costs

are saved.

It is portable and exposes the chicks to natural vegetation.

It is simple and could successfully be operated and managed without

high level specialized training.

It can be modified by local skills to the local situation of climate and

available type of construction materials.

It is applicable to different agro-ecological conditions and a wide range of

changing circumstances.

The construction and management of the hay-box brooder have been well

conceived, operationalized and monitored. In 2010, the Food and Agriculture

Organization of the United Nations (FAO) provided funds to the Jimma

University College of Agriculture and Veterinary Medicine (JUCAVM), for field

testing of the hay box brooder in Poultry Sector 4 farms in Ethiopia, Kenya and

Tanzania. The activities included fabricating different sizes of the hay box

brooders and producing an English manual how to manufacture and use the

hay box brooder. The English and Amharic (local language) version of the

operational

manuals

are

now

available

from

JUCAVM

Hay Box Brooder: A milestone to Increase Rural Households Poultry Production

(solomondemeke2000@gmail.com or solomon.demeke@ju.edu.et) or through

the Ethiopian Agricultural Portal .

Photos 1-2 Construction of the hay-box brooding technology at JUCAVM

4. Effectiveness and Impact of Hay Box Brooder

Hay box brooders maintain a temperature of 34-39C during the first week of

brooding, which can later be adjusted by reducing the amount of hay used for

insulation as the chicks grow and depend less on external heat. All the series of

on station and on farm trials conducted at different locations all over Ethiopia

clearly showed that batches of 10-70 day old chicks could successfully be

reared with the use of the hay-box brooder except during the heavy rainy

season in the months of June, July and August (Solomon, 2003). With few

exception most of the trials conducted in different parts of Ethiopia reported

chick survival rates to an age of 3 months in the range of 85 percent to 95

percent. This is very high compared to the results from natural brooding as it is

practiced in different parts of Ethiopia.

With the support of an agricultural sustainability project funded by CIDA

(The Canadian International Development Agency), the hay- box brooder was

extended to hundreds of farmers in the Jimma Zone. The project funds were

provided from 2005 to 2009 to build and distribute brooder boxes, day old

chicks of improved breeds and starters ration formula and to deliver short

companion training program. This has proved to be an additional source of

food and income for rural and peri-urban people in the region. A number of

additional success stories are attributed to the hay box brooder. A large

number of female headed families have become self sufficient in the purchase

of essential household food items (sugar, salt, cooking oil, kerosene etc)

through the sale of poultry product raised with the use of hay box brooder.

JUCAVM students get to practice community development skills by assisting in

hay box brooder construction (Photos 3-8). This technology is a great example

of how small amounts of money can go a long way in helping to improve the

livelihood of the needy people (Solomon, 2010). The hay box chick brooding

10

Hay Box Brooder: A milestone to Increase Rural Households Poultry Production

technology has proved a success in diverse locations across the country and

batches of 10-70 baby chicks have been successfully raised in different regions

of Ethiopia. With joint work by ESTC and UNHCR, the development of the

technology was extended to all the regional states of Ethiopia, including

Gambella and Asossa. The demand for the technology expressed from

individual farmers to governmental and non-governmental organization is very

high. The supply of exotic baby chicks from the government poultry breeding

and multiplication center, along with the constructional design of the hay box

chick brooding technology attracts regions of Ethiopia where there is no

electricity (ESAP, 2003).

Photos 3-8. Training and distributions of hay-box brooders and related deliverables in

Jimma

Sponsored by FAO, the hay box brooder is made available in Kenya and

Tanzania and it is reported to have effectively helped poultry farmers solve the

problem of high chick mortality rates within the first 8 weeks caused by

disease, predation, harsh weather and physical injury. The cost for preparation

of the brooder is just Ksh100 (1) spore.cta.int/en/component/content/1150?task=view.

5. Acceptability, Repeatability and Sustainability

Natural brooding does not fit market oriented poultry production system. It is

also difficult to adopt electric chick brooders by rural household poultry

producers in Africa owing to the unavailability of electricity, the number of

chicks to be raised and the remote location of the household farm sites. The

hay box chick brooding technology is environment friendly because there is no

toxic discharge and emission from the technology.

11

Hay Box Brooder: A milestone to Increase Rural Households Poultry Production

The information about the hay box brooder was published as news article of

the International Ag-sieve Newsletter, Rodale Institute, USA in 1991, and in the

Spore Bulletin of CTA in 1988 and 2010, as a result of which the

constructional design and the other informations requested were

communicated to a wide range of beneficiaries. The technology can be modified

by local skills to the local situation with respect to climate and type of

construction materials available (Photos 9-10) and is applicable (acceptable) to

different agro-ecological conditions and a wide range of changing

circumstances.

Photo 9-10. Modified hay box-brooder and run, Machenko, Kenya

5.1 Seasonal Variability

A significantly higher rate of mortality (as high as 40%) compared to electric

brooding was recorded from the hay-box groups during the main rainy season

which lasts in the Ethiopian high lands, from June to August. The use of haybox chick brooding technology may be severely affected by heavy rains as the

chicks will seldom move outside into the run for feeding, watering and foraging.

During the heavy rains, the chicks get wet and are chilled causing them to

crowd and huddle together leading to smothering and death.

5.2 Rate of Chick Growth

The growth performance of chicks reared in the hay-box brooders is slower

during the first 4-6 weeks of brooding than of those chicks reared by electric

brooders. This could be attributed to the fact that the chicks in the hay-box

brooders are only fed during daytime since they are closed in the box at night.

Contrary chicks in the electric brooders are fed to appetite both day and night.

However, comparatively faster growth rate is obtained from the chicks reared in

hay-box brooders after the first four weeks of brooding during which time they

double their body weight and compensate the slow growth they experienced at

the early phase of brooding. They also acclimatize faster than the chicks from

electric brooder groups when they are transferred to the growers houses.

12

Hay Box Brooder: A milestone to Increase Rural Households Poultry Production

6. Conclusion and lessons learnt

It is by natural incubation and brooding that chicks are hatched and raised all

over rural Ethiopia. Almost all the rural household poultry producers are not

aware of the existence of artificial brooding methods applicable to indigenous

baby chicks. The available experiences indicate that locally constructed

portable hay-box brooders in which no artificial heat is employed can be the

brooder of choice for the promotion of household poultry in rural Africa but the

drawbacks (2.5, 2.6, 2.7 & 5.1) of the technology need to be considered. The

conventional Ethiopian poultry extension package envisaged the distribution of

exotic pullets and cockerels to the farming population at 3 months of age to

maximize survival rate under rural household conditions. However, there were

no such cases in which exotic chickens of even 60-89 days of age were

distributed from the government poultry breeding and multiplication centers.

Fortunately it has been learnt that distribution of day old exotic chicks could

be done successfully if they were reared with the use of the good practice of the

hay box brooder. Moreover the use of this good practice alleviated the burden

of government poultry breeding and multiplication centers in raising the chicks

to an age of 3-months. While normally chick brooding refers to raising of chicks

for the first eight weeks of life the chicks raised in the hay box brooder could be

transferred to their rearing places at an age of 5-6 weeks. This can be

attributed to better acclimatization capacity. After introduction of the good

practice farmers started incubating eggs with the use of many broody hens at

the same time and by raising the resulting indigenous chicks with the help of

hay box brooder. Thus the farmer learnt to isolate indigenous chicks from their

mothers at a very early age and to raise them separately so that the hens could

resume laying.

Traditionally the productivity of scavenging hens was considered to be low

because of their low egg production potential and poor management. This was

also due to their long reproductive cycle (attributed to natural incubation and

brooding) and high chick mortality caused by disease condition and predations.

Mean survival rate to an age of 3-months of baby chicks reared under natural

brooding condition in Ethiopia is said to be about 40%. On the contrary, with

few exception most of the trials conducted in different parts of Ethiopia, Kenya

and Tanzania with the use of hay box brooders reported chick survival rates to

an age of 3 months in the range of 85 to 95 percent.

References

Alemu Sida 1987. Small scale poultry production In: The proceedings of the

first National Livestock Improvement conference in Ethiopia. Institute of

Agricultural Research. Addis Ababa, Ethiopia.

Alemu Yami and Tadelle Dessie 1997. The status of poultry research and

development in Ethiopia. In: The proceedings of the fifth National

13

Hay Box Brooder: A milestone to Increase Rural Households Poultry Production

Conference of the Ethiopian Society of Animal Production. The Ethiopian

Society of Animal Production (ESAP), Addis Ababa, Ethiopia.

Amanda B 2007. General brooding and rearing fact sheet. Introduction to

Poultry Production in Saskatchewan (http://www.agriculture.gov.sk.ca)

ESAP 2003. Hay box chick brooding technology hailed a success. Ethiopian

Society of Animal Production, Newsletter Issue No 9. Addis Ababa,

Ethiopian.

Ethiopian Statistical Authority 1985-1996. Livestock, poultry and beehives

population. Agricultural sample survey. Ethiopian Central Statistics

Authority, Addis Ababa, Ethiopia

Hoyle E 1992 Small scale poultry keeping in Welaita, North Omo region.

Farmers Research Project. Technical Pamphlet No 3, Farm Africa, Addis

Ababa, Ethiopia

Nigussie D, Alemu Y, Tadelle D and Samual W Hana 2003. On station and onfarm evaluation of the hay-box chick brooder using different insulation

materials at the Debre Zeit Agricultural Research Center and Denbi

Village, Adaa Wereda. Proceedings of the 10th Annual Conference of the

Ethiopian Society of Animal Production. Addis Ababa, Ethiopia

Australian Agricultural Consulting and Management Company (AACMC) 1984.

The Ethiopian livestock sub-sector review. Volume 2 Annex 5. Addis

Ababa, Ethiopia

Solomon Demeke, 1988. Homemade hay box chick brooder. News article of

Spore, CTA Bimonthly bulletin.

Solomon Demeke, 1991. A better brooder box. News article of the International

Ag-sieve Newsletter. Rodale Institute. .

Solomon Demeke,1999. Suitability of homemade hay-box chick brooder to the

Ethiopian household poultry production system. Proceedings of the 7th

annual Conference of the Ethiopian Society of Animal Production. Addis

Ababa, Ethiopia

Solomon Demeke, 2001. Suitability of homemade hay box chick brooder to the

Jimma and Bedele areas of Oromia Region. Ethiopian.J.Agri.Sci.

Solomon Demeke, 2003.Hay-box chick brooding technology: construction,

operation and management Manuel. Jimma College of Agriculture.

Jimma, Ethiopia

Solomon Demeke, 2007: Suitability of hay-box brooding technology to rural

household poultry production system. Livestock Research for Rural

Development. Volume 19, Article #3. Retrieved August 31, 2011, from

http://www.lrrd.org/lrrd19/1/deme19003.htm

14

Hay Box Brooder: A milestone to Increase Rural Households Poultry Production

Solomon Demeke, 2010. Chick Brooder. News article of Spore, CTA. Bimonthly

bulletin No.145.

Solomon Demeke, 2010. Hay-box Chick Brooder- a low cost technology for

rural farmers. Beyond Borders. NSAC-International. Nova Scotia,

Canada.

http://nsac.ca/international/resources/documents/beyond_bordersApr

2010.pdf

15

Das könnte Ihnen auch gefallen

- The Ancient Quail Farming Tricks: How To Raise Highly Productive Quail BirdsVon EverandThe Ancient Quail Farming Tricks: How To Raise Highly Productive Quail BirdsNoch keine Bewertungen

- The Poultry Industry: Dr. Michael SmithDokument27 SeitenThe Poultry Industry: Dr. Michael SmithRahul AroraNoch keine Bewertungen

- Producing Broilers and Fryers - An Instructional Article on Raising ChickensVon EverandProducing Broilers and Fryers - An Instructional Article on Raising ChickensNoch keine Bewertungen

- Broiler & ManagmentDokument8 SeitenBroiler & ManagmentrajeevknpNoch keine Bewertungen

- Cattle and Sheep - A Practical Manual about Breeds and Breeding, Foods and Feeding and General ManagementVon EverandCattle and Sheep - A Practical Manual about Breeds and Breeding, Foods and Feeding and General ManagementNoch keine Bewertungen

- 2009 Lebas KAZAN Production of RabbitDokument67 Seiten2009 Lebas KAZAN Production of RabbitKamarulazwa MuhammadNoch keine Bewertungen

- Egg Incubation for the Poultry Keeper - A Collection of Articles on the Methods and Equipment of Natural and Artificial IncubationVon EverandEgg Incubation for the Poultry Keeper - A Collection of Articles on the Methods and Equipment of Natural and Artificial IncubationNoch keine Bewertungen

- Basic Manual For Free Range Colored Broilers Production PDFDokument12 SeitenBasic Manual For Free Range Colored Broilers Production PDFAndy LimNoch keine Bewertungen

- Goat Production ManualDokument32 SeitenGoat Production ManualctamilNoch keine Bewertungen

- CVB Table Booklet Feeding of Poultry - Website VersionDokument34 SeitenCVB Table Booklet Feeding of Poultry - Website Versionsanjay_lingot80% (5)

- Starting a Duck Farm - A Collection of Articles on Stock Selection, Rearing, Economics and Other Aspects of Duck FarmingVon EverandStarting a Duck Farm - A Collection of Articles on Stock Selection, Rearing, Economics and Other Aspects of Duck FarmingNoch keine Bewertungen

- Rabbit Housing 08-02Dokument3 SeitenRabbit Housing 08-02jetgreenbulldogNoch keine Bewertungen

- Quail Farming for Beginners: All The Vital Details You Must KnowVon EverandQuail Farming for Beginners: All The Vital Details You Must KnowNoch keine Bewertungen

- Creep Feeding GoatDokument4 SeitenCreep Feeding GoatqfarmsNoch keine Bewertungen

- Quail Farming Mastery: Expert Insights and Solutions to Common ChallengesVon EverandQuail Farming Mastery: Expert Insights and Solutions to Common ChallengesNoch keine Bewertungen

- The Dollar Hen by Hastings, Milo M. (Milo Milton), 1884-1957Dokument139 SeitenThe Dollar Hen by Hastings, Milo M. (Milo Milton), 1884-1957Gutenberg.orgNoch keine Bewertungen

- AZOLLADokument22 SeitenAZOLLAKambaska Kumar BeheraNoch keine Bewertungen

- Turkey Farming in Kenya ZasDokument9 SeitenTurkey Farming in Kenya ZasDoRo ThyNoch keine Bewertungen

- Quail Diseases: The Most Comprehensive Guide On Diagnosis, Treatment And PreventionVon EverandQuail Diseases: The Most Comprehensive Guide On Diagnosis, Treatment And PreventionNoch keine Bewertungen

- A Guide On Goat Farming in SikkimDokument15 SeitenA Guide On Goat Farming in Sikkimchandradeep123Noch keine Bewertungen

- Broiler Farming Broiler Farming: Government of SikkimDokument20 SeitenBroiler Farming Broiler Farming: Government of Sikkimmicheal kaggwaNoch keine Bewertungen

- Selecting Meat GoatsDokument11 SeitenSelecting Meat GoatsqfarmsNoch keine Bewertungen

- Treat Yourself With Quail EggsDokument3 SeitenTreat Yourself With Quail EggsFrancis Kamwati0% (1)

- Poultry Husbandry ManualDokument40 SeitenPoultry Husbandry Manualmodibedi100% (1)

- Methods of BreedingDokument28 SeitenMethods of BreedingNicole RichardsonNoch keine Bewertungen

- Rural Backyard Poultry FarmingDokument15 SeitenRural Backyard Poultry FarmingSuman HalderNoch keine Bewertungen

- Basic Management of Poultry in Developing CommunitiesDokument138 SeitenBasic Management of Poultry in Developing Communitiesridwan muntheNoch keine Bewertungen

- Commercial Rabbit Production PDFDokument13 SeitenCommercial Rabbit Production PDFRobert D. Beasley100% (2)

- Do Roosters Have A Penis - Cackle HatcheryDokument16 SeitenDo Roosters Have A Penis - Cackle HatcheryMaddy SjiicroNoch keine Bewertungen

- ACF 2010 Subsistence Fish Farming in AfricaDokument294 SeitenACF 2010 Subsistence Fish Farming in AfricaAcción Contra el HambreNoch keine Bewertungen

- How To Begin and Survive A Commercial Gamebird Farm: "Those Who Want To Make Money Raising Gamebirds"Dokument33 SeitenHow To Begin and Survive A Commercial Gamebird Farm: "Those Who Want To Make Money Raising Gamebirds"laboraetoraNoch keine Bewertungen

- Chicken TerminologyDokument3 SeitenChicken TerminologyGrowel Agrovet Private Limited.100% (1)

- Basic Beekeeping ManualDokument71 SeitenBasic Beekeeping ManualTanja Ješovnik67% (3)

- (1850) The American Poultry Yard: Comprising The Origin, History, Description of The Different Breeds of Domestic PoultryDokument350 Seiten(1850) The American Poultry Yard: Comprising The Origin, History, Description of The Different Breeds of Domestic PoultryHerbert Hillary Booker 2nd100% (1)

- 5 PoultryPiggery Sheep HousingDokument59 Seiten5 PoultryPiggery Sheep HousingSANDEEPNoch keine Bewertungen

- General Guidelines For Feeding Sheep and GoatsDokument7 SeitenGeneral Guidelines For Feeding Sheep and GoatsFernando AlcantaraNoch keine Bewertungen

- (1918) Chicks: Hatching and Rearing: A Manual of Dependable InstructionDokument136 Seiten(1918) Chicks: Hatching and Rearing: A Manual of Dependable InstructionHerbert Hillary Booker 2nd100% (1)

- Rabbit Nutrition and Feed IngredientsDokument43 SeitenRabbit Nutrition and Feed IngredientsKen KellyNoch keine Bewertungen

- Diseases of Backyard ChickensDokument4 SeitenDiseases of Backyard ChickensKathryn BaxNoch keine Bewertungen

- Facilities & Equipmemt in SwineDokument29 SeitenFacilities & Equipmemt in SwineAlliah Dela RosaNoch keine Bewertungen

- A Guide On GoataryDokument15 SeitenA Guide On Goataryksm256Noch keine Bewertungen

- Breeding Snails in AustraliaDokument51 SeitenBreeding Snails in Australialiridonq83Noch keine Bewertungen

- Animal Breeding Geneticst6Dokument4 SeitenAnimal Breeding Geneticst6Nadzirah YusopNoch keine Bewertungen

- Hamster Biology HusbandryDokument39 SeitenHamster Biology HusbandryKulenović Zlatan100% (1)

- Disease / Condition Symptom Treatment: Abortions See Details AcidosisDokument13 SeitenDisease / Condition Symptom Treatment: Abortions See Details Acidosisreurri100% (2)

- Rabbit Housing ManualDokument25 SeitenRabbit Housing ManualGlenn Dixon100% (2)

- Raising Goats For Meat and MilkDokument136 SeitenRaising Goats For Meat and MilkLstock14100% (1)

- Module 4 LivestockDokument37 SeitenModule 4 LivestockDeejay BeekayNoch keine Bewertungen

- Quail Farming & Quail Parasites. By: Basit Sohail (2019-Ag-397)Dokument7 SeitenQuail Farming & Quail Parasites. By: Basit Sohail (2019-Ag-397)Zohaib Saeed AhmadNoch keine Bewertungen

- Fiji Honey HarvestingDokument26 SeitenFiji Honey HarvestingJohnCaldeiraNoch keine Bewertungen

- Dominant Final HybridDokument26 SeitenDominant Final HybridKonrad Neil III100% (1)

- 4h Rabbit RGDokument57 Seiten4h Rabbit RGPatty AusejoNoch keine Bewertungen

- Dairy Cattle HousingDokument4 SeitenDairy Cattle Housingrengachen50% (2)

- ANSC3101 Animal NutritionDokument3 SeitenANSC3101 Animal NutritionAbery AuNoch keine Bewertungen

- Press Release For The Small Scale Poultry FlocDokument2 SeitenPress Release For The Small Scale Poultry FlocChelsea Green PublishingNoch keine Bewertungen

- Prepared by D.sirag Al-Hamadi Tripoli University Dental FacultyDokument59 SeitenPrepared by D.sirag Al-Hamadi Tripoli University Dental Facultypepe_074Noch keine Bewertungen

- Case Study About Cervical CancerDokument11 SeitenCase Study About Cervical CancerJisel-Apple Bulan100% (1)

- Anatomical TermsDokument12 SeitenAnatomical TermsZeo12opsNoch keine Bewertungen

- Comparative Anatomy of The Horse, Ox, and Dog-The Brain and Associated VesselsDokument11 SeitenComparative Anatomy of The Horse, Ox, and Dog-The Brain and Associated VesselsmichiparisNoch keine Bewertungen

- The Dystopian NovelDokument17 SeitenThe Dystopian NovelafiNoch keine Bewertungen

- L1 - BB LecDokument11 SeitenL1 - BB LecJUDEA WILCH ORJENoch keine Bewertungen

- I Want To Eat Your Pancreas Omnibus (2019) (Digital) (Danke-Empire)Dokument433 SeitenI Want To Eat Your Pancreas Omnibus (2019) (Digital) (Danke-Empire)Ghanishtha SharmaNoch keine Bewertungen

- Make Money With VestigeDokument46 SeitenMake Money With Vestigejameser123100% (1)

- A French Reader Aldrich and Foster 1903Dokument324 SeitenA French Reader Aldrich and Foster 1903sandrabbit100% (1)

- Objectives:: Lesson Plan: The Digestive System Class: Biology (Grade: 10)Dokument7 SeitenObjectives:: Lesson Plan: The Digestive System Class: Biology (Grade: 10)Ederlina Bentilanon FagtananNoch keine Bewertungen

- Answer Keys of Comedk Pget-2008Dokument23 SeitenAnswer Keys of Comedk Pget-2008mobiled2Noch keine Bewertungen

- Physiology of Mammalian IngestionDokument6 SeitenPhysiology of Mammalian IngestionEbooks For YouNoch keine Bewertungen

- Diaphragmatic Breathing: The Foundation of Core StabilityDokument7 SeitenDiaphragmatic Breathing: The Foundation of Core StabilityLevyNoch keine Bewertungen

- SDOFM Viscerosomatic Reflex Pocket ChartDokument2 SeitenSDOFM Viscerosomatic Reflex Pocket ChartRohit NalamasuNoch keine Bewertungen

- Gibberish WordsDokument4 SeitenGibberish WordsDaniel PopaNoch keine Bewertungen

- Cheat Sheet 2Dokument2 SeitenCheat Sheet 2oushaNoch keine Bewertungen

- Interpretasi Foto DadaDokument137 SeitenInterpretasi Foto DadaRofi Irman100% (1)

- Role of Homeopathy Medicine in Veterinary PracticeDokument30 SeitenRole of Homeopathy Medicine in Veterinary PracticeDr.Jibachha Sah,Vet.physician,author, & motivatorNoch keine Bewertungen

- Science Illustrated July-August 2008Dokument79 SeitenScience Illustrated July-August 2008lelo2k30% (1)

- (Tham Khảo) Tài Liệu Ngoại Ngữ Y2Dokument55 Seiten(Tham Khảo) Tài Liệu Ngoại Ngữ Y2Nam TruongNoch keine Bewertungen

- King G., Custance D. - Colour Atlas of Vertebrate Anatomy - An Integrated Text and Dissection GuideDokument130 SeitenKing G., Custance D. - Colour Atlas of Vertebrate Anatomy - An Integrated Text and Dissection Guidenozomi n.nNoch keine Bewertungen

- PharmacologyDokument162 SeitenPharmacologyManuNoch keine Bewertungen

- Chapter 2 - Respiratory SystemDokument43 SeitenChapter 2 - Respiratory SystemSYAZWANINoch keine Bewertungen

- The ElephantDokument5 SeitenThe ElephantvenumeNoch keine Bewertungen

- Practice Prelim 3-KeyDokument3 SeitenPractice Prelim 3-KeyLauren PriscoNoch keine Bewertungen

- Agglutination ReactionsDokument28 SeitenAgglutination ReactionscyrhenmieNoch keine Bewertungen

- Inevitable AbortionDokument21 SeitenInevitable AbortionJaysonPangilinanAbanNoch keine Bewertungen

- Pulmo Physio-Transport 2Dokument35 SeitenPulmo Physio-Transport 2Mich Therese AbejeroNoch keine Bewertungen

- Animales en La Cultura YorubaDokument9 SeitenAnimales en La Cultura Yorubaaganju999Noch keine Bewertungen

- PNS - Bafs 267.2019 Code of Good Animal Husbandry Practice For SwineDokument20 SeitenPNS - Bafs 267.2019 Code of Good Animal Husbandry Practice For Swinejoriz klenz sabeteNoch keine Bewertungen

- Arizona, Utah & New Mexico: A Guide to the State & National ParksVon EverandArizona, Utah & New Mexico: A Guide to the State & National ParksBewertung: 4 von 5 Sternen4/5 (1)

- Japanese Gardens Revealed and Explained: Things To Know About The Worlds Most Beautiful GardensVon EverandJapanese Gardens Revealed and Explained: Things To Know About The Worlds Most Beautiful GardensNoch keine Bewertungen

- The Bahamas a Taste of the Islands ExcerptVon EverandThe Bahamas a Taste of the Islands ExcerptBewertung: 4 von 5 Sternen4/5 (1)

- New York & New Jersey: A Guide to the State & National ParksVon EverandNew York & New Jersey: A Guide to the State & National ParksNoch keine Bewertungen

- South Central Alaska a Guide to the Hiking & Canoeing Trails ExcerptVon EverandSouth Central Alaska a Guide to the Hiking & Canoeing Trails ExcerptBewertung: 5 von 5 Sternen5/5 (1)

- Naples, Sorrento & the Amalfi Coast Adventure Guide: Capri, Ischia, Pompeii & PositanoVon EverandNaples, Sorrento & the Amalfi Coast Adventure Guide: Capri, Ischia, Pompeii & PositanoBewertung: 5 von 5 Sternen5/5 (1)