Beruflich Dokumente

Kultur Dokumente

Ijetae 0614 121

Hochgeladen von

Lawrence CainOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Ijetae 0614 121

Hochgeladen von

Lawrence CainCopyright:

Verfügbare Formate

International Journal of Emerging Technology and Advanced Engineering

Website: www.ijetae.com (ISSN 2250-2459, ISO 9001:2008 Certified Journal, Volume 4, Issue 6, June 2014)

Modification in Pump Piping to Comply with Nozzle Allowable

Harshal M Ghule1, S. B. Belkar2

1

PG Student PREC Loni, India.

HOD Mechanical dept. PREC Loni India.

But this resulting in significant increase in project

execution time, which, in turn, increases project costs. This

delay in project execution is further worsened in recent

years by increased operating pressures and temperatures in

order to increase plant output; increased operating

pressures increase pipe wall thicknesses, which, in turn,

increase piping stiffness's further. Such increased operating

temperatures applied on stiffer systems increase pipe

thermal stresses and support loads. So, it is all the more

important to make the piping layout flexible at the time of

routing.

Many researchers were worked on modification of pump

piping. Peng et.al. [1] Identified that the current allowable

for piping loads on rotating equipment nozzle imposed by

the equipment manufacturers are too low. William et.al.

[2] studied the pump reliability problem which is

responsible for the large amount of maintainence budget

and lost opportunitycost at chemical plants, refinaryies, and

many electric utilities. James et.al. [3] had studies the

Horizontal process Pump modification to comply with API610.sixth edition forces and moments. James et.al. [4]

Worked on the API 610 Base plate and Nozzle loading

criteria. The base plate and nozzle loading criteria in the

December 1985 draft version of API610 7th Edition is

substantially different from the criteria found in the 6th

Edition. Takio Simizu et.al. [5] senior research engineer

in Ebara research company studied "The analysis of nozzle

load for process pump." Also discussed shaft end

displacement of centerlines mounted pump under nozzle

loads. L.C. Peng et.al.[6]had studied the "Equipment

reliability improvement through reduced pipe stress ". The

loads and stress imposed from a connecting piping system

can greatly affect the reliability of equipment. Charles

et.al. [7] Proposed various aspects for pump piping. They

studied "Design and Operation of Pump for Hot standby

service.Peng et.al. [8] Found piping system is designed

based on the piping code created for each individual

industry. Peng,et.al. [9] Studied the "Treatment of support

friction in piping stress analysis".

It is always studied that how to overcome with this low

nozzle allowable provided by manufactures. So in this

research they have focused the various methods and

approach to comply this low allowable, without increasing

the project time, material and cost.

Abstract The load and stress imposed from a connecting

piping system can greatly affect the reliability of an

equipment; these loads either from expansion of a pipe or

from other source can cause shaft misalignment as well as

shell deformation interfering with the internal moving parts.

Therefore it is important to design the piping system to

impose a little stress as possible on the equipment, ideally, it is

not possible.

This project work is focused on to stress analysis of a pump

piping system as per process piping codes B31.3 by CAESARII and rethinking the nozzle allowable loads provided by the

pump manufacture, to optimize the design and reduced the

design, material as well as manufacturing cost. To achieve

this, implement various methods. The loads which are

imposed on the pump nozzle can be reduced by possible rerouting the piping system with less modification. But this rerouting of a piping has its practical & layout limitation, so as

to overcome this difficulty, explores the methods for setting a

higher allowable loads without changing pump manufacturer

design consideration and size of pump. A more realistic

allowable should be established as per API 610 standard to

better balance equipment cost against piping engineering.

I. INTRODUCTION

It is common practice worldwide for piping designers to

route pump piping by considering mainly space, process

and flow constraints (such as pressure drop) and other

requirements arising from constructability, operability and

reparability.

Unfortunately,

pipe

stress

analysis

requirements are often not sufficiently considered while

routing and supporting piping systems, especially in

providing adequate flexibility to absorb expansion

contraction of pipes due to thermal loads. So, when as

designed piping systems are handed-off to pipe stress

engineers for detailed analysis, they soon realize that the

systems are stiff and loads on nozzles is to high to

comply with manufactures allowable so as suggest routing

changes to make the systems more flexible and to reduced

the nozzle loads. The piping designers, in turn, make

changes to routing and send the revised layout to the pipe

stress engineers to check for compliance again. Such back

and forth design iterations between layout and stress

departments continue until a suitable layout and support

scheme is arrived.

784

International Journal of Emerging Technology and Advanced Engineering

Website: www.ijetae.com (ISSN 2250-2459, ISO 9001:2008 Certified Journal, Volume 3, Issue 4, April 2013)

Literature of past work does not adequately clarify the

proper innovative design of pump system and routine

modification in pump piping and Latest edition requirement

of API 610. So there is a need to modification in piping as

well as support friction factor consideration to reduce the

loads on piping nozzles.

Process layout of system

II. DESIGN BASIS FOR STRESS ANALYSIS.

The applicable edition of the codes and standards shall

be that in effect on the contract date.

A] Codes:-Comply with all applicable Codes including,

ASME, B31.3, Section VII, B16.5.

B] Standards:-Comply with the following applicable

Standards: API, API 610, WRC, WRC 107, WRC 297,

ASCE-7-05, EJMA

C] Basic Data for Analysis:-For analysis of stress it is

required to find out pressure,wight and temperature of the

fluid ,along with this loading type is important factor which

is to be consider while analysis.

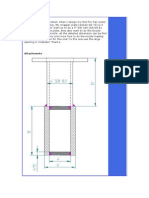

Piping designer and Layout engineer route piping as per

design requirement by considering various access ways,

maintenance requirement and process requirement as

shown in below fig

Project Specification And Pump Piping Design

Parameters:- Lines which are connected to the deethaniser

centrifugal pump in propylene recovery unit has below

listed properties.

Suction Line No14"-1630-P-400-31174XR

Equipment - 1630-D-007

(Reflux Drum )

Density of Fluid - .0004270

kg./cu.cm.

Operating Temperature - 49

Discharge Line No8"-1630-P-013-31174XR

Equipment-1630-G-004A/B

(Reflux Pump)

Pressure Rating 300

Design Temperature - 87

Design Pressure -32.65 bars

Mill Tolerance-12.5

Corrosion Allowance-3.00mm

Piping Code-B 31.3

Test Pressure = 48.98 bars

Piping Material- A333 6

Equipment Standard-API610

Operating Pressure -18.2 bars

Caesar model formation is based on the initial routine

and possible support location shared by Piping Dept.

Design parameters is as per project design basis.

Caesar model is as shown in below Fig.

785

International Journal of Emerging Technology and Advanced Engineering

Website: www.ijetae.com (ISSN 2250-2459, ISO 9001:2008 Certified Journal, Volume 3, Issue 4, April 2013)

Nozzle check with Initial Piping.

It is found that the nozzles are not qualified in the

existing routine as the initial system is very stiff. Even if

the nozzle is not passed in two times of allowable in API

610 then we will suggest possible route modification in

existing routine at clouded potion.

Forces

Check

Ma

N.m.

Mb

N.m.

Mc

N.m.

Moments

Check

Remark

13998

2609

2879

2528

-846

0.218

0.221

0.214

0.385

20899

-530

-612

-376

-323

13799

-547

-831

-392

-498

19599

1760

1856

2056

20

0.09

0.095

0.105

0.036

Qualify

Qualify

Qualify

Qualify

3781

2188

311

1995

-363

3114

-1139

-1154

-1262

-446

0.916

0.371

0.833

0.143

2576

-499

-845

-123

-411

3525

-1041

-764

-1491

-104

1762

-3258

-1091

-2890

337

1.849

0.619

1.64

0.191

Qualify

Qualify

Qualify

Qualify

4893

-5298

-4998

-1221

39

3781

3095

2911

1721

-330

3114

1938

1719

1450

283

1.083

1.021

0.466

0.091

2576

1360

937

1613

361

3525

2854

2496

1440

-275

1762

-5094

-4735

-3947

266

2.89

2.687

2.24

0.151

Fail

Fail

Fail

Qualify

Limits

2(OPE)

3(OPE)

4(OPE)

11(SUS)

3114

223

955

223

962

2491

1402

65

1429

-184

2046

1321

301

1350

7

0.645

0.307

0.66

0.309

1762

-188

-194

-195

-112

2305

510

108

522

-16

1180

-291

108

-293

126

0.247

0.11

0.249

0.107

Qualify

Qualify

Qualify

Qualify

Limits

2(OPE)

3(OPE)

4(OPE)

11(SUS)

3114

98

96

968

962

2491

716

809

-426

-202

2046

743

820

-405

-32

0.363

0.401

0.311

0.309

1762

147

120

60

-99

2305

150

193

-202

-31

1180

-443

-443

111

127

0.375

0.376

0.094

0.107

Qualify

Qualify

Qualify

Qualify

NODE

Fa N.

Fb N.

Fc N.

Limits

2(OPE)

3(OPE)

4(OPE)

11(SUS)

24299

5297

5366

5204

9347

23401

921

921

1138

-1094

Limits

2(OPE)

3(OPE)

4(OPE)

11(SUS)

4893

-4480

38

-4075

34

Limits

2(OPE)

3(OPE)

4(OPE)

11(SUS)

Piping Caesar-II model with route modification :As the Piping has rerouted the piping needs to be again

update the Caesar model as per latest routine which is as

shown in Fig.

In Stress analysis to reduced the nozzle loads due to

friction effect of support use 0.1 as a friction factor.

70

500

750

2130

2530

The Caesar-II model shows various temperature

consideration i.e. Pump standby, which as shown in Fig

In piping routine change some loop will apply to

increase flexibility and piping 3D model is as shown in Fig.

786

International Journal of Emerging Technology and Advanced Engineering

Website: www.ijetae.com (ISSN 2250-2459, ISO 9001:2008 Certified Journal, Volume 3, Issue 4, April 2013)

Maximum Stresses in piping system

Fig.Pump Piping Caesar-II Model with Pump B Operating and A

stand by

Fig.4.8 Pump Piping Caesar-II Model with Pump A Operating and B

stand by

III. CAESAR-II OUTPUT. NODE DISPLACEMENT IN SUS

CASE

In sustain case the displacement in Y direction i.e. in

vertical downward, should not be more that the specific

value in design basis . In this design basis in sustain case

sagging should not be more than 8 mm.As the sagging is

more than 8 mm then its shows that restrain which is

provided is not sufficient. even if the system is passed in

sustain stress. so Piping stress Engineer to check sagging

and needs to provide supports accordingly.

By using Caesar-II software, analysis of system is

carried out and result is tabulated below

787

11 (SUS) W+P1

Code stress Check

Highest Stresses: (N./sq.mm)

Code Stress Ratio (%):

Code Stress:

Axial Stress:

Bending Stress:

Torsion Stress:

Hoop Stress:

3D Max Intensity:

Load Case

Passed

16 (OCC) L16=L12+L11

Code stress Check

Highest Stresses: (N./sq.mm)

Code Stress Ratio (%):

Code Stress:

Axial Stress:

Bending Stress:

Torsion Stress:

Hoop Stress:

3D Max Intensity:

Load Case

Passed

17 (OCC) L17=L13+L11

Code stress Check

Highest Stresses: (N./sq.mm)

Code Stress Ratio (%):

Code Stress:

Axial Stress:

Bending Stress:

Torsion Stress:

Hoop Stress:

3D Max Intensity:

Load Case

Passed

18 (OCC) L18=L13+L11

Code stress Check

Highest Stresses: (N./sq.mm)

Code Stress Ratio (%):

Code Stress:

Axial Stress:

Bending Stress:

Torsion Stress:

Hoop Stress:

3D Max Intensity:

Load Case

Passed

19 (OCC) L19=L14+L11

Code stress Check

Highest Stresses: (N./sq.mm)

Code Stress Ratio (%):

Code Stress:

Axial Stress:

Bending Stress:

Torsion Stress:

Hoop Stress:

3D Max Intensity:

Load Case

Passed

20 (EXP) L20=L2-L11

Code stress Check

Highest Stresses: (N./sq.mm)

Code Stress Ratio (%):

Code Stress:

Axial Stress:

Bending Stress:

Load Case

Passed

49.7

67.1

66.6

36.4

1.8

134.7

139.7

43

78.8

66.6

46.7

4.2

134.7

139.7

43

78.8

66.6

46.7

2.4

134.7

139.7

43

78.8

66.6

46.7

2.4

134.7

139.7

41.6

76.2

66.6

44.1

2.1

134.7

139.7

12.9

26.6

2

26.6

@Node

Allowable

@Node

@Node

@Node

@Node

@Node

20

134.8

30

1720

1760

30

30

@Node

Allowable

@Node

@Node

@Node

@Node

@Node

1720

183.4

30

1720

1750

30

30

@Node

Allowable

@Node

@Node

@Node

@Node

@Node

1720

183.4

30

1720

1750

30

30

@Node

Allowable

@Node

@Node

@Node

@Node

@Node

1720

183.4

30

1720

1750

30

30

@Node

Allowable

@Node

@Node

@Node

@Node

@Node

1720

183.4

30

1720

1759

30

50

@Node

Allowable

@Node

@Node

1360

206.8

1360

1360

International Journal of Emerging Technology and Advanced Engineering

Website: www.ijetae.com (ISSN 2250-2459, ISO 9001:2008 Certified Journal, Volume 3, Issue 4, April 2013)

Torsion Stress:

Hoop Stress:

3D Max Intensity:

3.9

0

43.4

21 (EXP) L21=L3-L11

Code stress Check

Highest Stresses: (N./sq.mm)

Code Stress Ratio (%):

Code Stress:

Axial Stress:

Bending Stress:

Torsion Stress:

Hoop Stress:

3D Max Intensity:

Load Case

Passed

22 (EXP) L22=L4-L11

Code stress Check

Highest Stresses: (N./sq.mm)

Code Stress Ratio (%):

Code Stress:

Axial Stress:

Bending Stress:

Torsion Stress:

Hoop Stress:

3D Max Intensity:

Load Case

Passed

23 (EXP) L23=L5-L11

Code stress Check

Highest Stresses: (N./sq.mm)

Code Stress Ratio (%):

Code Stress:

Axial Stress:

Bending Stress:

Torsion Stress:

Hoop Stress:

3D Max Intensity:

Load Case

Passed

24 (EXP) L24=L6-L11

Code stress Check

Highest Stresses: (N./sq.mm)

Code Stress Ratio (%):

Code Stress:

Axial Stress:

Bending Stress:

Torsion Stress:

Hoop Stress:

3D Max Intensity:

Load Case

Passed

25 (EXP) L25=L5-L6

Code stress Check

Highest Stresses: (N./sq.mm)

Code Stress Ratio (%):

Code Stress:

Axial Stress:

Bending Stress:

Torsion Stress:

Hoop Stress:

3D Max Intensity:

Load Case

Passed

12.9

26.6

2

26.6

3.4

0

43.4

12.9

26.7

2

26.7

3.7

0

43.5

21.6

44.6

3.7

44.6

8.3

0

65.4

36.3

62.6

4.6

62.6

5.9

0

101.9

47.2

97.6

8.3

97.6

13.9

0

160.7

@Node

@Node

@Node

320

30

1360

@Node

Allowable

@Node

@Node

@Node

@Node

@Node

1360

206.8

1360

1360

570

30

1360

@Node

Allowable

@Node

@Node

@Node

@Node

@Node

1360

206.8

1360

1360

320

30

1360

@Node

Allowable

@Node

@Node

@Node

@Node

@Node

370

206.8

1360

370

320

30

1350

@Node

Allowable

@Node

@Node

@Node

@Node

@Node

1360

172.4

1360

1360

570

30

1360

@Node

Allowable

@Node

@Node

@Node

@Node

@Node

1360

206.8

1360

1360

320

30

1360

PipingNozzleCheck.

Nozzle Check Criteria By API-610.

If we considered nozzle allowable 2times of the API

then we have to comply "Annex F".

Annex F (Horizontal pumps):

F.1.1 Acceptable piping configurations should not cause

excessive misalignment between the pump and driver.

Piping configurations that produce component nozzle loads

lying within the ranges specified in Table 4 limit casing

distortion to one-half the pump vendors design criterion

(see 5.3.3) and ensure pump shaft displacement of less than

250 m (0,010 in). [13 3]

F.1.2 Piping configurations that produce loads outside

the ranges specified in Table 4 are also acceptable without

consultation with the pump vendor if the conditions

specified in F.1.2 a) through .1.2 c) below are satisfied.

Satisfying these conditions ensures that any pump casing

distortion will be within the vendor's design criteria and

that the displacement of the pump shaft will be less than

380 m (0,015 in).

788

International Journal of Emerging Technology and Advanced Engineering

Website: www.ijetae.com (ISSN 2250-2459, ISO 9001:2008 Certified Journal, Volume 3, Issue 4, April 2013)

a) The individual component forces and moments acting

on each pump nozzle flange shall not exceed the

range specified in Table 4 (T4) by a factor of more

than 2.

b) The resultant applied force (FRSA, FRDA) and the

resultant applied moment (MRSA, MRDA) acting on

each pump nozzle flange shall satisfy the appropriate

interaction equations below.

IV. RESULT AND DISSCUSION

Condition 1- Nozzle Load with initial routine

EQUIPMENT NO: 1630-G-004 A/B

NOZZLE NO: N1 Suction nozzle

RATING: 300 #

NOZZLE SIZE: 219 NB (8")

SCH THICK : XS (12.7 mm)

SPEC : 31174XR

SYSTEM DISCRIPTION: DEETHANISER REFLUX PUMP

DESIGN CONDITION :

PRESSURE: 33.8 kgf/cm square

TEMPRATURE: 87 C

Forces In N

Moment N-m

Node No Nozzel Discription

Type of Loads

Fx = Fc Fy = Fa Fz = Fb Mx = Mc My-Ma Mz = Mb

750 8" RFFE 300 # / N1/A 1938 3095 5298 5094 1613 2854

Operating Load

500 8" RFFE 300 # / N1/B 1262 4480 2188 3258 845

1491

Operating Load

3114 4893 3781 1762 2576 3525

Allowabel Load

[FRSA/(1,5FRST4)]+[MRSA/(1,5MRST4)] 2.......(F.1)

[FRDA/(1,5FRDT4)]+[MRDA/(1,5MRDT4)] 2....(F.2)

c) The applied component forces and moments acting on

each pump nozzle flange shall be translated to the

centre of the pump. The magnitude of the resultant

applied force (FRCA), the resultant applied moment

(MRCA), and the applied moment shall be limited by

Equation (F.3), Equation (F.4) and Equation (F.5) (the

sign convention shown in Figure 20 through Figure

24 and the right-hand rule should be used in

evaluating these equations). [13 3]

SPEC : 31174XR

SYSTEM Discription: DEETHANISER REFLUX PUMP

OPERATING CONDITION :

PRESSURE:

TEMPRATURE:

Forces In N

Moment N-m

Node No Nozzel Discription

Type of Loads

Fx = Fc Fy = Fa Fz = Fb Mx = Mc My-Ma Mz = Mb

2130 6" RFFE 300 # / N2/A 1350 962 1429 293

195

522

Operating Load

2530 6" RFFE 300 # / N2/B 820

968

809

443

147

202

Operating Load

2046 3114 2491 1180 1762 2305

Allowabel Load

Remark

System Fail

System Fail

As Per API 610

EQUIPMENT NO: 1630-G-004 A/B

NOZZLE NO: N2 Discharge Nozzle

RATING: 300 #

NOZZLE SIZE: 219 NB (6")

SCH THICK : XS (12.7 mm)

FRCA<1.5(FRST4+FRDT4).......................................(F.3)

Condition 2- Nozzle Load After route modification.

|MYCA|<2,0(MYST4+MYDT4)...............................(F.4)

EQUIPMENT NO: 1630-G-004 A/B

NOZZLE NO: N1 Suction nozzle

RATING: 300 #

NOZZLE SIZE: 219 NB (8")

SCH THICK : XS (12.7 mm)

Remark

System Pass

System Pass

As Per 2 API 610

SPEC : 31174XR

SYSTEM DISCRIPTION: DEETHANISER REFLUX PUMP

DESIGN CONDITION :

PRESSURE: 33.8 kgf/cm square

TEMPRATURE: 87 C

Forces In N

Moment N-m

Node No Nozzel Discription

Type of Loads

Remark

Fx = Fc Fy = Fa Fz = Fb Mx = Mc My-Ma Mz = Mb

750 8" RFFE 300 # / N1/A 505 8501 2347 3191 352 2066

Operating Load

System PASS

500 8" RFFE 300 # / N1/B 360 9524 2516 3447 342 1666

Operating Load

System PASS

6228 9786 7562 3524 5152 7050

Allowabel Load As Per 2 API 610

MRCA<1,5(MRST4+MRDT4)..................................(F.5)

EQUIPMENT NO: 1630-G-004 A/B

NOZZLE NO: N2 Discharge Nozzle

RATING: 300 #

NOZZLE SIZE: 219 NB (6")

SCH THICK : XS (12.7 mm)

SPEC : 31174XR

SYSTEM Discription: DEETHANISER REFLUX PUMP

OPERATING CONDITION :

PRESSURE:

TEMPRATURE:

Forces In N

Moment N-m

Node No Nozzel Discription

Type of Loads

Fx = Fc Fy = Fa Fz = Fb Mx = Mc My-Ma Mz = Mb

2130 6" RFFE 300 # / N2/A 1350 962 1429 293

195

522

Operating Load

2530 6" RFFE 300 # / N2/B 820 968

809

443

147

202

Operating Load

2046 3114 2491 1180 1762 2305

Allowabel Load

Remark

System Pass

System Pass

As Per API 610

V. DISSCUSION

To comply with nozzle allowable we will try to compare

the result before route modification and after route

modification as Condition-1 it is cleared that the external

load on pump nozzle is higher than the allowable given by

the API 610 standards or Vendor.

789

International Journal of Emerging Technology and Advanced Engineering

Website: www.ijetae.com (ISSN 2250-2459, ISO 9001:2008 Certified Journal, Volume 3, Issue 4, April 2013)

So to overcome this difficulties we will plan to route

modification in existing routine and also increase the

nozzle allowable for the same nozzle by complying API

610 Conditions Condition-2. In route modification we

increase the flexibility of pump piping by adding extra

elbows and loops. which reduced the circumferential

movement. In above nozzle loading chart the nozzle

allowable loads is considered to be 2 times of API 610 and

comply all condition of API 610

REFERENCES

[1 ] L. C. Peng and A.O. Medellin " Rethinking the allowable pipe load

on rotating equipment nozzle " pp

[2 ] William D Marscher "Avoiding Failures in centrifugal

Pumps"(1999).

[3 ] James E Steiger "Horizontal process pump modifications to comply

with API-610 sixth edition force and moments"(1981)

[4 ] James E Steiger "API 610,Baseplate and nozzle loading

criteria"(1981).

[5 ] Tokio Shimizu and Hironori Teshiba "Analysis of nozzle load for

process pump".

[6 ] L.C.Peng "Equipment Reliability Improvement through Reduced

Pipe Stress"(1993).

[7 ] Charles C.Head & David G.Penry ."Design and operation of pumps

for hot standby services".

[8 ] L.C Peng "Understanding piping Code stress evaluation paradoxes

and ASME B31.3 Appendix P".(2013). pp 6-13.

[9 ] L.C. Peng "Treatment of support friction in Piping stress analysis".

[10 ] L.C. Peng "The Art of designing Piping Support System".

[11 ] "Code Piping Stress Analysis Seminar Notes". pp 8-50

[12 ] Code ASME B31.3 2004 .pp 1-38.

[13 ] Standard API 610. 10th Edition 2004. pp 110-113

VI. CONCLUSION

By following the proper guideline of pump piping &

support philosophy, the forces & moments which is on the

nozzles are kept within allowable as per API 610.and

ASME section VIII DIV-1/2. Also increase the nozzle

allowable loads to reduces the design cost by complying

with allowable standards,

The low equipment allowable nozzle loads forced piping

engineers to use excessive pipe loops coupled with

complex restraint arrangement to meet the requirements.

This not only increase capital expenditure but also increase

potential operational problems. Vibration, cavitations, and

loss of net positive suction head (NPSH) are some of the

common operating problem resulting from excessive piping

loops To overcome the above difficulties, we have increase

the Pump allowable loads than the vendor without violating

API 610 standard.

790

Das könnte Ihnen auch gefallen

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (894)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- Hydraulic - Calculations VERY GOODDokument210 SeitenHydraulic - Calculations VERY GOODpn100% (1)

- Pile Cap Design ExamplesDokument70 SeitenPile Cap Design Examplest_solanki200160% (5)

- Braithwaite Type Pressed Steel Water Storage TankDokument2 SeitenBraithwaite Type Pressed Steel Water Storage TankLawrence CainNoch keine Bewertungen

- Braithwaite Type Pressed Steel Water Storage TankDokument2 SeitenBraithwaite Type Pressed Steel Water Storage TankLawrence CainNoch keine Bewertungen

- Vibration TechnologyDokument18 SeitenVibration TechnologySakthimgsNoch keine Bewertungen

- Vortex SheddingDokument3 SeitenVortex SheddingMaheshNoch keine Bewertungen

- ASME B31 3 Calculator V2Dokument11 SeitenASME B31 3 Calculator V2gerrydimayuga100% (3)

- Steel Bridge Design Handbook - Bridge Steels - Mech - Properties - Vol - 01Dokument59 SeitenSteel Bridge Design Handbook - Bridge Steels - Mech - Properties - Vol - 01Cyril VomáčkaNoch keine Bewertungen

- Power Piping LinesDokument9 SeitenPower Piping LinesArar gargeNoch keine Bewertungen

- Fabricators' and Erectors' Guide To Welded Steel Construction - 1999 (Structural Welding)Dokument58 SeitenFabricators' and Erectors' Guide To Welded Steel Construction - 1999 (Structural Welding)johnknight000Noch keine Bewertungen

- Moody DiagramDokument1 SeiteMoody Diagramjkl. lkjNoch keine Bewertungen

- Understanding INSTRUCALC For Valve Sizing & Orifice - M Agha Hutama SDokument5 SeitenUnderstanding INSTRUCALC For Valve Sizing & Orifice - M Agha Hutama SMuhammad Agha Hutama Syukron100% (1)

- Marine Piping Diagram Graphical SymbolsDokument18 SeitenMarine Piping Diagram Graphical SymbolsRudyGunawan100% (2)

- Repair Pa Rts Sheet P - 3 9 1, 1004 / P-392, 1 0 0 5Dokument2 SeitenRepair Pa Rts Sheet P - 3 9 1, 1004 / P-392, 1 0 0 5JPJFNoch keine Bewertungen

- Plate Heat Exchanger Design in ExcelDokument6 SeitenPlate Heat Exchanger Design in Excelamitkray67% (12)

- Ansi - Asme B 16.5Dokument2 SeitenAnsi - Asme B 16.5gdwivedi100% (4)

- Experiment 01 The Hydraulic BenchDokument2 SeitenExperiment 01 The Hydraulic BenchSafi Ullah Warraich100% (2)

- Hydraulic PDFDokument19 SeitenHydraulic PDFLeslie CooperNoch keine Bewertungen

- LM AN INFO 0106 E Tutorial Vibration Analysis PDFDokument4 SeitenLM AN INFO 0106 E Tutorial Vibration Analysis PDFjeyaselvanmNoch keine Bewertungen

- Nozzle in Flat PlateDokument11 SeitenNozzle in Flat PlateLawrence CainNoch keine Bewertungen

- Artikel Fisika Bahasa Inggris Tentang Vibration-1Dokument10 SeitenArtikel Fisika Bahasa Inggris Tentang Vibration-1Xerxes Xanthe XyzaNoch keine Bewertungen

- Methods For Design of Hoppers, Silo's, Bins & BunkersDokument10 SeitenMethods For Design of Hoppers, Silo's, Bins & BunkersJaco KotzeNoch keine Bewertungen

- Application of WRC Bulletins 107, 297, 368Dokument3 SeitenApplication of WRC Bulletins 107, 297, 368shivabtowin3301100% (3)

- Active Force on Retaining Wall Supporting Φ Backfill Considering Curvilinear Rupture SurfaceDokument10 SeitenActive Force on Retaining Wall Supporting Φ Backfill Considering Curvilinear Rupture SurfaceLawrence CainNoch keine Bewertungen

- WRC107 297Dokument4 SeitenWRC107 297enjoygurujiNoch keine Bewertungen

- Comparative Study Manufacturing Cost Between EN13445 and ASMEDokument32 SeitenComparative Study Manufacturing Cost Between EN13445 and ASMEDries VandezandeNoch keine Bewertungen

- Design of Tallbuidings Preliminra DesignDokument20 SeitenDesign of Tallbuidings Preliminra DesignMuhammed SabahNoch keine Bewertungen

- Ivc Valves PDFDokument4 SeitenIvc Valves PDFNaveen ReddyNoch keine Bewertungen

- Punch ListDokument8 SeitenPunch ListJamal BakhtNoch keine Bewertungen

- Lec4. Practical Applications of Bernoulli Equation By. Engr - Wendhel Q.LDokument5 SeitenLec4. Practical Applications of Bernoulli Equation By. Engr - Wendhel Q.Ljames PrincipeNoch keine Bewertungen

- Fuild Mechanics Unit 5Dokument47 SeitenFuild Mechanics Unit 5KeerthiBalanNoch keine Bewertungen

- Thermal Expansion in Piping SystemsDokument50 SeitenThermal Expansion in Piping SystemsmehdiNoch keine Bewertungen

- Valve Drawing VSG2 PDFDokument1 SeiteValve Drawing VSG2 PDFGỗ MộcNoch keine Bewertungen

- Industrial hydraulic pressure relief valve specification sheetDokument88 SeitenIndustrial hydraulic pressure relief valve specification sheetRS Rajib sarkerNoch keine Bewertungen

- Study boiler mountings and accessoriesDokument10 SeitenStudy boiler mountings and accessoriesShahedNoch keine Bewertungen

- Hydraulic Turbine Governing System RequirementsDokument15 SeitenHydraulic Turbine Governing System Requirementsjdwhite9Noch keine Bewertungen

- Reasonable Velocities For Fluid Flow Through Pipes-SteamDokument4 SeitenReasonable Velocities For Fluid Flow Through Pipes-SteamRaj KamalNoch keine Bewertungen

- REYNOLDS NUMBER EXPERIMENT PREDICTS FLUID FLOW TYPESDokument21 SeitenREYNOLDS NUMBER EXPERIMENT PREDICTS FLUID FLOW TYPESMervin PerezNoch keine Bewertungen

- Bib Cock-10.04.2017Dokument4 SeitenBib Cock-10.04.2017Mahesh DewaniNoch keine Bewertungen

- Keystone Butterfly Valve ParaSeal RangeDokument16 SeitenKeystone Butterfly Valve ParaSeal RangetungNoch keine Bewertungen

- Dorot S300Dokument13 SeitenDorot S300Jaime RiveraNoch keine Bewertungen

- Sebapo Stock Material DrillcoDokument7 SeitenSebapo Stock Material Drillcogandhi_wirawanNoch keine Bewertungen

- Procedure PipeDokument4 SeitenProcedure PipejoeknotNoch keine Bewertungen

- Standart WeldingDokument68 SeitenStandart WeldingEko Wahyu QrakerNoch keine Bewertungen

- Каталог - запчастей ecoTEC pro 24, 28 - R1 - R2Dokument24 SeitenКаталог - запчастей ecoTEC pro 24, 28 - R1 - R2ЗеновийNoch keine Bewertungen

- Catalog 4204 PSG ProcessDokument32 SeitenCatalog 4204 PSG Processsugiarto MarpaungNoch keine Bewertungen