Beruflich Dokumente

Kultur Dokumente

4.4 Research Procedures: 4.4.1. Get The Volcanic Rock Sample

Hochgeladen von

Claudio LoperaOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

4.4 Research Procedures: 4.4.1. Get The Volcanic Rock Sample

Hochgeladen von

Claudio LoperaCopyright:

Verfügbare Formate

1

4.4 Research Procedures

4.4.1. Get the volcanic rock sample.

4.4.2. Crush the volcanic rock sample according to the size of concrete aggregates.

4.4.3. Sieve the volcanic rock sample according the desired size and particle distribution. Use

sieve No.9

4.4.4

Mix the concrete ingredients using class A proportion.

Mixture Class: A

4.4.5 MOLDING SPECIMEN

Specimens molded on a level, rigid, horizontal surface, free from vibration and other

disturbances, and near as practicable to storage location.

Concrete placed in molds with scoop, blunted trowel, or shovel

Concrete remixed in mixing pan with shovel or trowel to prevent segregation during molding.

Scoop, trowel, or shovel moved around the perimeter of mold opening when adding concrete to

ensure even distribution of concrete. Specimens made in layers of approximately equal volumes

and rodded as follows.

Specimen Type and Size

CYLINDER

DIAMETER

4in

6in

9in

BEAMS

WIDTH

6 to 8in

>8in

Number of Layers of

Approximately Equal

Depth

Number of Roddings

per layer

2

3

4

25

25

50

2

3 or more equal depths, each

not exceeding 6 in

1 per 2in2 top surface area

1 per 2in2 top surface area

Final layer placed in an amount that will fill mold after compaction

Underfilled molds adjusted with representative concrete during consolidation of top layer

4.4.6. CONSOLIDATION RODDING

Each layer rodded with rounded end of tamping rod in accordance with table 2

Rodding distributed uniformly over cross section of mold

Bottom layer rodded throughout its depth

After each layer is rodded, mold is lightly tapped 10 to 15 times with open hand or mallet

FINISHING CYLINDERS

Excess concrete struck off from surface

Top surface finished by striking off with tamping rod where consistency of the concrete permits

or with wood float or trowel.

Finishing performed with minimum manipulation that produces a flat even surface level with

rim of mold.

Surface or concrete has no depression or projection larger than 1/8 in

4.4.7. CURING

Covering After Finishing To prevent evaporation of water from the unhardened concrete, the

specimen shall be covered immediately after finishing, preferably.

Initial Curing During the first 24 to 48 hours after molding, all the test specimens shall be

stored under the conditions representative of the concrete in the structure or pavement.

Following the period of initial cure, the specimens may be transported to the laboratory for

subsequent curing and testing. Laboratory curing shall consist of a minimum of 95% humidity

and temperature of 73.4 3o F (23 0.94o C)

4.4.8. Determination of Compressive Strength of Cylindrical

Concrete Specimen

1. Compression test on specimen shall be made as soon as practicable after removal from the

moist storage. A 28 day test shall be performed within the 20th day. Test specimen shall be kept

moist buy any convenient method during the period between removal from moist storage and

testing. They shall be tested in moist condition.

2. All test specimen for a given test age shall be broken within the permissible time tolerance

prescribed below.

Test Age

24 hours

3 days

7 days

28 days

90 days

Permissible Tolerance

0.5 hours or 2.1%

2 hours or 2.8%

6 hours or 3.6 %

20 hours 3.0%

2 days 2.2%

10

3. Rest the specimen on the lower extrusion controller, place the top extrusion controller on the

specimen, and check the spacing between the sides of the specimen and the extrusion controller

to ensure no contact between the cylinder and the steel. Slide the specimen and the extrusion

controller configuration into the center of the concentric circles of the lower bearing block.

Check the alignment of the upper bearing face after lowering it into position.

11

4. Apply the load until the specimen fails, and record the maximum load supported by the

specimen during the test .

5. Calculate the compressive strength of the specimen by dividing the maximum load carried by the

specimen during the test by the average cross-sectional area.

C = Q/ R2

s

WHERE:

Cs = Compressive Strength (psi)

Q = load at failure ( lb-force )

R = radius of specimen ( in )

For 6-inch ( 150mm ) diameter specimen = Q/28.274

4.4.9. COMPUTATION

Concrete Cylinder age 7 days

Sample No.

Q (kg)

1

20,000.00

2

3

21,000.00

21,000.00

12

Sample No.1

Cs =

Q

28.274

Cs =

20,000.00(2.2)

28.274

Cs = 1556.40 psi

Cs =

21,000.00(2.2)

28.274

Cs = 1634.24 psi

Cs =

24,000.00(2.2)

28.274

Cs = 1867.70 psi

Cs =

Q

28.274

Sample No.3

Sample No.3

Q

28.274

Cs = 1789.88 psi

Cs =

23,000.00(2.2)

28.274

Sample No.2

Sample No.2

Q

28.274

Q

28.274

21,000.00(2.2)

28.274

Q

28.274

25,000 (2.2)

28.274

Cs = 1945.52 psi

Cs = 1634.24 psi

Concrete Cylinder age 14days

Sample No.

Q (kg)

1

23,000.00

2

24,000.00

3

25,000.00

Concrete Cylinder age 28 days

Sample No.

Q (kg)

1

29,000.00

2

30,000.00

3

32,000.00

Sample No.1

Sample No.1

Q

Cs = 28.274

29,000.00( 2.2)

28.274

13

Cs = 2256.80 psi

Sample No.2

Cs =

Q

28.274

30,000.00(2.2)

28.274

Cs = 2334.62 psi

Sample No.3

Cs =

Q

28.274

32,000.00(2.2)

28.274

Cs = 2490.26 psi

4.4.10. Tabulated Data result of Compressive Strength of Cylinder Specimen

14

Sample

identification

Parts of sctructure

Date

sampled

Date

tested

Age in

Days

Compressive

strength(psi)

1

2

3

CONCRETE CYLINDER

09-19-14

09-19-14

-do-do-

-do-do-

7

7

7

1556.40

1634.24

1634.24

2130

1

2

3

CONCRETE CYLINDER

09-19-14

09-19-14

-do-do-

-do-do-

14

14

14

1789.88

1867.70

1945.52

2610

1

2

3

CONCRETE CYLINDER

09-19-14

09-19-14

-do-do-

-do-do-

28

28

28

2256.80

2334.62

2490.26

3000

-do-do-

-do-do-

-do-do-

7 days Specimen after

failure

14 days Specimen after

failure

Govt. std.

Specs

Rqd. (psi)

28 days Specimen after

failure

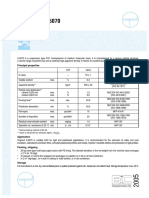

COMPRESSIVE STRENGTH OF CONCRETE AT VARIOUS AGES IN

PERCENT OF 28-DAYS STRENGTH

DAYS

PERCENT

DESIGN STRENGTH_28 DAY psi

4000

3500

3000

25000

2000

15

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

35

40

50

60

70

80

90

100

18

38

49

57

63

68

71

74

77

79

81

83

85

87

88

88.5

90

91.5

93

94

95

96

97

97.5

98

99

99.5

100

101

102

105

108

112

116

118

120

121

122

720

1520

1960

2280

2520

2720

2840

2960

3080

3160

3240

3320

3400

3480

3520

3540

3600

3660

3720

3760

3800

3840

3880

3900

3920

3960

3980

4000

4040

4080

4200

4320

4480

4640

4720

4800

4840

4880

630

1330

1750

1995

2205

2380

2485

2590

2695

2765

2835

2905

2975

3045

3080

3100

3150

3205

3255

3290

3325

3360

3395

3415

3430

3465

3485

3500

3535

3570

3675

3780

3920

4060

4130

4200

4235

4270

540

1140

1470

1710

1890

2040

2130

2220

2310

2370

2430

2490

2550

2610

2640

2655

2700

2745

2790

2820

2850

2880

2910

2925

2940

2970

2985

3000

3030

3060

3150

3240

3360

3480

3540

3600

3630

3660

4.4.11. Determination of Flexural Strength of Concrete

450

950

1225

1425

1575

1700

1775

1850

1925

1975

2025

2075

2125

2175

2200

2215

2250

2290

2325

2350

2375

2400

2425

2440

2450

2475

2490

2500

2525

2550

2625

2700

2800

2900

2950

3000

3025

3050

360

720

980

1140

1260

1360

1420

1480

1540

1580

1620

1660

1700

1740

1760

1770

1800

1830

1860

1880

1900

1920

1940

1950

1960

1980

1990

2000

2020

2040

2100

2160

2240

2320

2360

2400

2420

2440

16

4.4.12. MOLDING SPECIMEN

a) Specimens molded on a level, rigid, horizontal surface, free from vibration and other

disturbances, and near as practicable to storage location.

b) Concrete placed in molds with scoop, blunted trowel, or shovel

c) Concrete remixed in mixing pan with shovel or trowel to prevent segregation during

molding.

d) Scoop, trowel, or shovel moved around the perimeter of mold opening when adding

concrete to ensure even distribution of concrete. Specimens made in layers of

approximately equal volumes and rodded as follows.

Specimen Type and Size

BEAMS

WIDTH

6 to 8in

>8in

Number of Layers of

Approximately Equal

Depth

2

3 or more equal depths, each

not exceeding 6 in

Number of Roddings

per layer

1 per 2in2 top surface area

1 per 2in2 top surface area

e.) Final layer placed in an amount that will fill mold after compaction

f.) Under filledmolds adjusted with representative concrete during consolidation of top layer.

4.4.13 CONSOLIDATION RODDING

a.) Each layer rodded with rounded end of tamping rod in accordance with table 2

b.) Rodding distributed uniformly over cross section of mold

c.) Bottom layer rodded throughout its depth

17

d.) After each layer is rodded, mold is lightly tapped 10 to 15 times with open hand or mallet

4.4.14. CURING

a.) Covering After Finishing To prevent evaporation of water from the unhardened

concrete, the specimen shall be covered immediately after finishing, preferably.

b.) Initial Curing During the first 24 to 48 hours after molding, all the test specimens shall

be stored under the conditions representative of the concrete in the structure or pavement.

c.) Following the period of initial cure, the specimens may be transported to the laboratory

for subsequent curing and testing. Laboratory curing shall consist of a minimum of 95%

humidity and temperature of 73.4 3o F (23 0.94o C)

4.4.15. Determination of Flexural Strength of a concrete

a.) Put the specimen in the test machine. Center the loading apparatus in relation to the

applied axial force.

b.) Bring the load applying block in contact with the upper surface of the specimen at the

third points between the lower supports.

c.) If the fracture occurs in the tension surface ( the bottom surface ) outside the middle

third of the span length by more than 5% of the span length (about 1in)

Discard the result test

18

1.

Calculate the flexural strength, neglecting the beam weight, as follows:

a. When fracture initiates in the tension surface (i.e. The bottom surface) within the middle

third,

FS =

PL

2

bd

Where:

P = maximum load at failure in pounds

L = is the span length

d = is the depth of the beam

b = is the width of the beam

Note that all dimensions are in inches

b.

If fracture initiates in the tension surface (i.e.,the bottom surface )outside the middle third of

the beam by not more than 5% of the span length.

FS =

3 Pa

b d2

Where:

a = average distance, in inches, between the line of fracture and the nearest support measured

on the

tension surface of the beam.

19

4.4.16. COMPUTATIONS:

Concrete beam age 14 days

Sample No.

1

2

3

a = 10in

P (lb)

1980.00

1340.00

1930.00

a = 9.75in

Sample No.1

FS =

3 Pa

b d2

3 ( 1980 ) (12)

2

6(6 )

= 275.00 psi

a = 12in

Sample No.2

FS =

3 Pa

b d2

= 223.75 psi

3 ( 1340 ) (10)

6(6 2)

20

FS =

Sample No.3

3 Pa

2

bd

= 261.25 psi

3 ( 1980 ) (9.75)

2

6(6 )

4.4.17.Tabulated Data result of Flexural Strength of Beam Specimen

Sample

identificatio

n

1

Parts of

structure

CONCRETE

CYLINDER

Date

sampled

09-12-14

Date

tested

Age

in

Days

Compres

sive

strength(

psi)

09-26-14

14

275.00

-do-

-do-

-do-

14

223.75

-do-

-do-

-do-

14

261.25

Govt.

std.

Specs

Rqd.

(psi)

550

Relationship between Compressive and Flexural Strength

(28 days old)

Compressive

Strength

325

525

800

1025

1325

1700

2125

2600

3100

3625

4125

4700

5300

5900

6425

7000

7525

8125

9725

Flexural Strength

100

150

200

250

300

350

400

450

500

550

600

650

700

750

800

850

900

950

1000

Das könnte Ihnen auch gefallen

- Cube and Slump Test ReportDokument13 SeitenCube and Slump Test ReportZahir Solihin97% (29)

- C1140 PDFDokument3 SeitenC1140 PDFMyriam Carrera100% (2)

- Catia Training MaterialDokument523 SeitenCatia Training Materialnikhilcon100% (9)

- CMT Lab. 03Dokument5 SeitenCMT Lab. 03John Ceasar PascoNoch keine Bewertungen

- Concrete CubesDokument5 SeitenConcrete CubesDipti Ranjan Swain100% (1)

- Conducting A Compressive Strength TestDokument8 SeitenConducting A Compressive Strength TestCeleste Amor FactorNoch keine Bewertungen

- Modulus of RaptureDokument18 SeitenModulus of RaptureHitesh PatilNoch keine Bewertungen

- Slump TestDokument9 SeitenSlump TestCaroline MuthoniNoch keine Bewertungen

- Compressive Strength of Concrete: 1. ObjectiveDokument3 SeitenCompressive Strength of Concrete: 1. ObjectiveShahrukhNoch keine Bewertungen

- Splitting Tensile Strength of Cylindrical Concrete Specimens DetailedDokument4 SeitenSplitting Tensile Strength of Cylindrical Concrete Specimens DetailedYasirNoch keine Bewertungen

- 3 (D) Workability of Concrete - Flow Table TestDokument11 Seiten3 (D) Workability of Concrete - Flow Table TestFrank JohnNoch keine Bewertungen

- Institute of Engineering Department CivilDokument27 SeitenInstitute of Engineering Department CivilSabbir HossainNoch keine Bewertungen

- Compressive Strength of ConcreteDokument9 SeitenCompressive Strength of ConcreteAmos kiprutoNoch keine Bewertungen

- CT SMB Module 3Dokument31 SeitenCT SMB Module 3sankarsanasahoo690Noch keine Bewertungen

- Cube Compressive Strenght TestDokument6 SeitenCube Compressive Strenght TestMM tarasNoch keine Bewertungen

- Quality Control in Concrete ConstructionDokument66 SeitenQuality Control in Concrete ConstructionNerfzeeb0Noch keine Bewertungen

- Surface Hardness and Compressive Strength of ConcreteDokument20 SeitenSurface Hardness and Compressive Strength of ConcreteAmer FarkhanNoch keine Bewertungen

- Method Statement For Concrete CompressionDokument5 SeitenMethod Statement For Concrete CompressionResearcherNoch keine Bewertungen

- Cylinder Mould (100mm X 200mm or 150mm X 300mm or 300mm X 600mm) Bulled-Nosed Rod (16mm Diam. & 600mm Long) Steel FloatDokument3 SeitenCylinder Mould (100mm X 200mm or 150mm X 300mm or 300mm X 600mm) Bulled-Nosed Rod (16mm Diam. & 600mm Long) Steel FloatStain HecNoch keine Bewertungen

- Flexual Strength TestDokument3 SeitenFlexual Strength TestmercysouerNoch keine Bewertungen

- Basic Civil Engineering Lab-2-1Dokument8 SeitenBasic Civil Engineering Lab-2-1KUNDAN SHARMANoch keine Bewertungen

- Material-SLUMP TEST Zairi Azizi KamarudinDokument9 SeitenMaterial-SLUMP TEST Zairi Azizi KamarudinWHfamilyNoch keine Bewertungen

- Making Concrete Cylinders in The FieldDokument2 SeitenMaking Concrete Cylinders in The FieldaaNoch keine Bewertungen

- Bldg. Sanitation, Code & RulesDokument8 SeitenBldg. Sanitation, Code & RulesNick GeneseNoch keine Bewertungen

- CIP 34 - Making Concrete Cylinders in The FieldDokument2 SeitenCIP 34 - Making Concrete Cylinders in The FieldGreg YeeNoch keine Bewertungen

- 1716.2.3. Test Specimen and Sample Strength: Three Test Specimens Shall Be Made From EachDokument6 Seiten1716.2.3. Test Specimen and Sample Strength: Three Test Specimens Shall Be Made From EachSrikrishan singhNoch keine Bewertungen

- Portland (W/C 0.485) 242: (Air-Entraining Portland (W/C 0.460) 230 Non-Portland (As Required For Flow of 110) )Dokument3 SeitenPortland (W/C 0.485) 242: (Air-Entraining Portland (W/C 0.460) 230 Non-Portland (As Required For Flow of 110) )Anuradha RumeshNoch keine Bewertungen

- Flexural Strength TestDokument23 SeitenFlexural Strength TestJommel GonzalesNoch keine Bewertungen

- ACCEPT. Test For CONCRETEDokument53 SeitenACCEPT. Test For CONCRETEvijay100% (1)

- Compressive Strength of Concrete: 1. ObjectiveDokument6 SeitenCompressive Strength of Concrete: 1. ObjectivedavyordersNoch keine Bewertungen

- Compression TestDokument10 SeitenCompression TestRohan Singh SikarwarNoch keine Bewertungen

- High Strength Prestressed Concrete Cube Test ResultsDokument5 SeitenHigh Strength Prestressed Concrete Cube Test ResultsKumar Narmadeshwar Gupta0% (1)

- Pull Out TestDokument4 SeitenPull Out TestAjoy Mc100% (1)

- Reconfirmation Notice: AS 1012.3.2-1998 (Reconfirmed) 2014-10-24Dokument9 SeitenReconfirmation Notice: AS 1012.3.2-1998 (Reconfirmed) 2014-10-24heyh jdjNoch keine Bewertungen

- Compressive Strength of Lightweight Insulating Concrete: Standard Test Method ForDokument3 SeitenCompressive Strength of Lightweight Insulating Concrete: Standard Test Method ForibrahimNoch keine Bewertungen

- Compressive & Rebound G1Dokument13 SeitenCompressive & Rebound G1Amir AkmalNoch keine Bewertungen

- Compressive and Flexural Strength Test of Hydraulic Cement MortarDokument7 SeitenCompressive and Flexural Strength Test of Hydraulic Cement MortarMayolitesNoch keine Bewertungen

- Test Prcedure For ConcreteDokument57 SeitenTest Prcedure For Concreteneroshan1978100% (2)

- Compressive TestDokument9 SeitenCompressive TestDAVID JUDE CALLADONoch keine Bewertungen

- Determination of Slump of Portland Cement ConcreteDokument7 SeitenDetermination of Slump of Portland Cement Concreteayat1234Noch keine Bewertungen

- For My Students:: Always Treat Your Parents With Utmost Respect and KindnessDokument36 SeitenFor My Students:: Always Treat Your Parents With Utmost Respect and KindnessHefon MarketerNoch keine Bewertungen

- Lab Report 10 Making and Curing Concrete Test Specimen in The FieldDokument7 SeitenLab Report 10 Making and Curing Concrete Test Specimen in The FieldLeny Agrabio Alaro100% (1)

- Compressive Strength of Concrete - Cube Test Procedure ResultsDokument5 SeitenCompressive Strength of Concrete - Cube Test Procedure ResultsAriyan AriyanNoch keine Bewertungen

- Strength Test On ConcreteDokument23 SeitenStrength Test On ConcreteMukesh Kumar SamotaNoch keine Bewertungen

- Experiment No. 10 Compressive, Splitting, and Flexural Strength Test On ConcreteDokument8 SeitenExperiment No. 10 Compressive, Splitting, and Flexural Strength Test On ConcreteManuel John Contridas PallonesNoch keine Bewertungen

- Concrete TestingDokument1 SeiteConcrete TestingNadia IzzatiNoch keine Bewertungen

- Flexural Test On Concrete Based On The ASTM Standards Are ExplainedDokument9 SeitenFlexural Test On Concrete Based On The ASTM Standards Are ExplainedTesfayeNoch keine Bewertungen

- Compressive Strength of Concrete CubeDokument6 SeitenCompressive Strength of Concrete CubePawan PatilNoch keine Bewertungen

- Appendix A Communication Letter: Appendices - 55Dokument30 SeitenAppendix A Communication Letter: Appendices - 55Jaymark SorianoNoch keine Bewertungen

- Destructive TestDokument19 SeitenDestructive TestREALITY CNoch keine Bewertungen

- Standard Density For Hydraulic Cement Using ASTM C188Dokument7 SeitenStandard Density For Hydraulic Cement Using ASTM C188paTriciaNoch keine Bewertungen

- Sampling and Testing Concrete Masonry UnitsDokument10 SeitenSampling and Testing Concrete Masonry UnitsRegenir Macedo AlvesNoch keine Bewertungen

- Compressive Strength Test ProcedureDokument9 SeitenCompressive Strength Test ProcedureAnique Ur RehmanNoch keine Bewertungen

- Compressive Strength of Concrete 1Dokument6 SeitenCompressive Strength of Concrete 1Christabel AbbeyNoch keine Bewertungen

- Experiment No. 9:: Compressive Strength of Cylindrical Concrete SpecimenDokument5 SeitenExperiment No. 9:: Compressive Strength of Cylindrical Concrete SpecimencarloNoch keine Bewertungen

- Aggregate Crushing Value Test.Dokument2 SeitenAggregate Crushing Value Test.Rajesh SharmaNoch keine Bewertungen

- Thin Bed MortarDokument20 SeitenThin Bed Mortarrajeshji_000Noch keine Bewertungen

- The Design of Piled Foundations: Structures and Solid Body MechanicsVon EverandThe Design of Piled Foundations: Structures and Solid Body MechanicsBewertung: 4 von 5 Sternen4/5 (8)

- Sewage Disposal Works: Their Design and ConstructionVon EverandSewage Disposal Works: Their Design and ConstructionNoch keine Bewertungen

- Experiment and Calculation of Reinforced Concrete at Elevated TemperaturesVon EverandExperiment and Calculation of Reinforced Concrete at Elevated TemperaturesBewertung: 5 von 5 Sternen5/5 (2)

- Experimental Set-Up and Results of The Process of Co-Extruded Perforated Gun PropellantsDokument17 SeitenExperimental Set-Up and Results of The Process of Co-Extruded Perforated Gun PropellantsMarcelo MartinezNoch keine Bewertungen

- Paraloid km-334Dokument5 SeitenParaloid km-334Naseer MianNoch keine Bewertungen

- Thermoforming Design Guide (GE Plastics)Dokument57 SeitenThermoforming Design Guide (GE Plastics)Mario Daniel Conejo100% (2)

- Anantha PVC LTDDokument58 SeitenAnantha PVC LTDMaheshSrikakulam50% (2)

- Recostar DynamicDokument2 SeitenRecostar DynamicVijaya SimhaNoch keine Bewertungen

- General Specs and Steel and Aluminium WorksDokument10 SeitenGeneral Specs and Steel and Aluminium WorksPoojaNoch keine Bewertungen

- PVC PipesDokument35 SeitenPVC Pipespratikgarg03Noch keine Bewertungen

- Kabel - UNIWEMA Ainha de Alumínio HV GB 0501 - 1 PDFDokument8 SeitenKabel - UNIWEMA Ainha de Alumínio HV GB 0501 - 1 PDFIvenNoch keine Bewertungen

- Thomson Lifting Columns CatalogDokument15 SeitenThomson Lifting Columns CatalogElectromateNoch keine Bewertungen

- AcerosTabla GRAL BohlerDokument1 SeiteAcerosTabla GRAL BohlerFidel JhonatanNoch keine Bewertungen

- Catalogo Medidas ITMDokument358 SeitenCatalogo Medidas ITMerika isabel JUSTINIANONoch keine Bewertungen

- 07 Rupture Disk Data SheetDokument1 Seite07 Rupture Disk Data SheetPingu3Noch keine Bewertungen

- Formula Information For Process ManufacturingDokument21 SeitenFormula Information For Process ManufacturingDia SiriNoch keine Bewertungen

- GEA Power Cooler Brochure 2002Dokument12 SeitenGEA Power Cooler Brochure 2002Dory CanoNoch keine Bewertungen

- Total Workshop QuestionsDokument8 SeitenTotal Workshop QuestionsSanjeet KumarNoch keine Bewertungen

- MET-TECH - Product Data Sheet - EXTRUSION PRESS LINE - 2200 MT - 8"Dokument2 SeitenMET-TECH - Product Data Sheet - EXTRUSION PRESS LINE - 2200 MT - 8"Ângelo PereiraNoch keine Bewertungen

- REE AssignmentDokument14 SeitenREE AssignmentEmmanNoch keine Bewertungen

- Mesh Modeling AutoCAD 2010Dokument6 SeitenMesh Modeling AutoCAD 2010arutapub100% (1)

- Plastic Products LahoreDokument32 SeitenPlastic Products LahoreAbdul SattarNoch keine Bewertungen

- Ongrovil 5070Dokument1 SeiteOngrovil 5070Corina RomanNoch keine Bewertungen

- Aluminium CompaniesDokument4 SeitenAluminium CompaniesHumayun KhanNoch keine Bewertungen

- Bandera HDB FFS Eng v2 2016 FinalDokument29 SeitenBandera HDB FFS Eng v2 2016 FinaljomoncNoch keine Bewertungen

- Interior Sliding SystemsDokument24 SeitenInterior Sliding SystemsMohammed NadeemNoch keine Bewertungen

- Using A Map Sections and Polygons in 3D PVSOL 0.2Dokument9 SeitenUsing A Map Sections and Polygons in 3D PVSOL 0.2elmaturkovic01Noch keine Bewertungen

- Polymer Processing Design LaboratoryDokument38 SeitenPolymer Processing Design LaboratoryAbdul RahmanNoch keine Bewertungen

- EXTRUSION DIE DESIGN (Compatibility Mode)Dokument7 SeitenEXTRUSION DIE DESIGN (Compatibility Mode)Śaksham ŔathoreNoch keine Bewertungen

- Shaping Processes For Plastics - Chapter 13Dokument118 SeitenShaping Processes For Plastics - Chapter 13xharpreetx100% (1)

- Film ExtrusionDokument44 SeitenFilm Extrusionkhala1391@gmail.com100% (1)

- Rotary Friction Welding Review.Dokument24 SeitenRotary Friction Welding Review.senthil muruganNoch keine Bewertungen