Beruflich Dokumente

Kultur Dokumente

Reactivos Cytec Cu Oxidado

Hochgeladen von

Jorge Alberto Añazco EscobarCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Reactivos Cytec Cu Oxidado

Hochgeladen von

Jorge Alberto Añazco EscobarCopyright:

Verfügbare Formate

M i n e r a l P ro c e s s i n g

TECHNOLOGY NOTE

Application of AERO XD900 and AERO XD902

Promoters for Flotation of Copper Oxide Ores

Summary

This Technology Note has been prepared to offer

suggestions for the effective application of AERO

XD900 and XD902 promoters for use in copper

oxide flotation. The work suggests that there may

be some synergy in using these two products following sulfidization. All of the work has been

done on African mixed sulfide/oxide ores, and the

results could potentially have application in all

copper oxide ores where the oxide minerals are

discrete, rather than low Cu content minerals

such as cupriferous goethite (Ref 1).

It has been demonstrated that use of AERO

XD900 promoter on its own can be effective but

tends to require very high dosage. In addition to

cost considerations, higher dosages of AERO

XD900 promoter have the disadvantage that they

can create excessive foaming and an over-stable

froth (excessive foaming can be minimized with

the use of AERO XD903 promoter). Concentrate

filtration also tends to be very difficult. Application of AERO XD900 promoter following CPS

(controlled potential sulfidization Ref 2) allows

a major reduction in dosage and tends to result

in improved recovery and superior concentrate

grade. Use of xanthate alongside NaSH and

AERO XD900 promoter and AERO XD902

promoter also appears beneficial.

Test Work Procedure

The bulk of this work involved taking the rougher

tails after flotation of sulfides from a mixed sulfide/oxide ore at two African customers. Slurry

samples were screened to remove trash and

+500m material, then split into charges using a

rotary splitter. Tests were done using both 2.5l

and 4.5l cells on a Denver D12 machine. Tests

were conducted at natural pH (typically pH 8.0

pH 8.5) after test work at pH 9.0 and pH 9.5

(with NaOH) showed no advantage. Flotation

times up to 24 minutes were investigated, but

the bulk of the work used a flotation time of 12

minutes.

Only the test work for Customer 1 was conducted

on ore milled in the laboratory. In this case, bulk

sulfide/oxide rougher concentrates were produced.

Concentrates and tails were filtered, dried,

weighed and prepared. Most assays were performed by an international met lab.

In the final sets of work, tails assays were done in

duplicate, sending the second sample under different nomenclature. Further repeats were conducted

when these did not match.

One of the two customers has two ores which

feed separate lines in the plant. These are underground ore, often referred to as LOB (lower ore

body) and the open pit ore.

Notes:

AS Cu = acid soluble copper. For most of this

work, acid was 5% H2SO4, agitated at room

temperature for 20 minutes.

AI Cu is acid (as above) insoluble copper which

generally refers to the sulfides, metallic Cu and

low solubility minerals such as chrysocolla. AI Cu

www.cytec.com

can be determined by aqua regia dissolution of the

residue from AS Cu dissolution, but is more often

determined by difference, TCu ASCu.

T Cu is total copper, usually analyzed following

dissolution with boiling aqua regia.

1) Performance of AERO XD900 promoter

on its own, versus with NaSH

One of the African operations treats a mixed sulfide/oxide ore, although sulfides tend to dominate.

AS Cu tends to vary between 0.2% and 0.5%. On

the day this test work was done, AS Cu levels were

at their minimum.

In this case, minimal AS Cu was achieved with

dosages of AERO XD902 promoter between 48

g/t and 170 g/t. Only by using 320 g/t of AERO

XD902 promoter, on its own, did we start to

achieve respectable AS Cu grade/recovery. The

addition of 30 g/t SiPX alongside low dosages of

AERO XD902 promoter did not improve performance. Much better performance was seen

when the reagent was used after sulfidization,

with and without xanthate.

In a second series of tests on the second customer

underground ore, higher dosages of AERO

XD902 promoter were used.

Second Customer Underground Sulfide Tails Flotation

AS Cu Grade vs Recovery

70

Flotation of First Customer Sulfide Rougher Tails

AS Cu Grade vs Recovery

70

129 g/t S-8881

40

245 g/t NaSH, 33 g/t A343, 33 g/t S-888

30

238 g/t NaSH, 32 g/t A343, 64 g/t S-888

20

10

0

0.0

0.5

1.0

1.5

2.0

2.5

244 g/t NaSH 32 g/t A343

Standard

244 g/t NaSH 32 g/t A343

Standard

3.0

AS Cu grade (%)

Results show superior AS Cu grade/recovery at

two dosage levels when Reagent S-8881 (an early

AERO XD900 promoter) was used alongside 245

g/t NaSH + 33 g/t SiPX.

Continuing the work at the other African

Concentrator (Ref 3), where AS Cu levels are

significantly higher, the series of tests shown below

was run on underground ore.

African Customer Underground, Flotation

of Sulfide Rougher Tails AS Cu Grade vs Recovery

AS Cu recovery (%)

50

40

30

20

10

0

0

AS Cu grade (%)

10

11 12 13 14

550 g/t AERO XD902

170 g/t NaSH, 230 g/t AERO XD902

40

370 g/t NaSH, 240 g/t AERO XD902

350 g/t NaSH, 230 g/t AERO XD902

30

560 g/t NaSH, 220 g/t AERO XD902

20

320 g/t NaSH 40 g/t A343

48 g/t AERO XD902

100 g/t AERO XD902

170 g/t AERO XD902

320 g/t AERO XD902

30 g/t A343, 50 g/t

AERO XD902

30 g/t A343, 100 g/t

AERO XD902

360 g/t NaSH, 29 g/t A343,

48 g/t AERO XD902

400 g/t NaSH, 30 g/t A343,

100 g/t AERO XD902

420 g/t NaSH, 100 g/t

AERO XD902

380 g/t NaSH 30 g/t A343

Standard

380 g/t NaSH 30 g/t A343

420 g/t NaSH 60 g/t A343

Head 1.16% AS Cu

Standard

10

Head 1.24% AS Cu

0

0

Head 0.21% AS Cu

60

AS Cu recovery (%)

AS Cu recovery (%)

64 g/t S-8881

50

350 g/t AERO XD902

50

34 g/t S-8881

60

213 g/t AERO XD902

60

10

AS Cu grade (%)

This time, high AS Cu grade/recovery was only

achieved using 550 g/t AERO XD902 promoter,

with 350 g/t only achieving 22% AS Cu recovery.

The performance of 550 g/t AERO XD902 alone

was matched using 370 g/t NaSH + 250 g/t

AERO XD902 and by 550 g/t NaSH + 230 g/t

AERO XD902. There was an outlier, however, in

the repeat of the test using 350 g/t NaSH + 230

g/t AERO XD902.

A subsequent set of tests was run on a second

African open pit ore. The objective was to look at

NaSH, PAX and AERO XD900 promoter

requirements. Results for AS Cu recovery and AS

Cu grade have been plotted as AERO XD900

promoter dosage versus NaSH dosage.

This set of results appeared to be quite a setback

as it seemed that use of NaSH + PAX alone could

achieve high AS Cu recovery. Use of AERO

XD900 promoter managed to yield small increases

Second Customer AS Copper Recovery vs AERO XD900 Dosage

80

0 g/t NaSH, 0 g/t PAX

AS Cu recovery (%)

60

16

700 g/t NaSH, 0 g/t PAX

1400 g/t NaSH, 0 g/t PAX

14

1400 g/t NaSH, 0 g/t PAX

12

700 g/t NaSH, 105 g/t PAX

10

1400 g/t NaSH, 105 g/t PAX

50

700 g/t NaSH, 105 g/t PAX

40

1400 g/t NaSH, 105 g/t PAX

30

700 g/t NaSH, 170 g/t PAX

20

1400 g/t NaSH, 170 g/t PAX

20

40

60

80

100

120

1400 g/t NaSH, 170 g/t PAX

Second Customer Flotation of Sulfide Tails AS Cu Grade vs Recovery

100

Collector to Rghr 1

90

PAX

80

Rghr

none

AERO XD900 condition

4 min

none

70

60

50

40

PAX

NaSH + XD900

PAX

XD900

AERO XD900 + PAX condition

4 min

none

30

20

All tests 700 g/t NaSH to head

10

Head - 0.90% AS Cu

0

4

10

12

20

40

60

80

100

120

PAX was added to the first rougher. High AS Cu

grade concentrate was produced at high grade in

the first rougher but little additional AS Cu recovery was achieved in the second rougher. Repeating

the test (PAX only to first rougher) but adding 70

g/t AERO XD900 promoter (black line) or an

additional 200 g/t NaSH + 70 g/t AERO XD900

promoter (pink line) both brought about an additional 15%-20% AS Cu recovery gain to final

conc. Use of 70 g/t AERO XD900 promoter (no

PAX) gave superior results to the PAX only test

but optimum results were seen when both PAX

and AERO XD900 promoter were added to the

first rougher. Unfortunately no test was run where

PAX was added to first and second roughers.

As the previous tests had demonstrated the value

in having NaSH and PAX present, the following

set of tests was run on the second customers open

pit ore to determine if AERO XD900 promoter

added any value when used in conjunction with

these products.

Head = 0.90% AS Cu

0

AERO XD900 Dosage (g/t)

in recovery but with a major drop in concentrate

grade. Looking more closely at the results, however, it was seen that NaSH + PAX appeared to hit a

maximum at 50% AS Cu recovery. Increasing

NaSH from 700 g/t to 1400 g/t and PAX from

105 g/t to 170 g/t did not improve AS Cu recovery. In the tests without PAX, at both 700 g/t and

1400 g/t NaSH, increasing the dosage of AERO

XD900 promoter from 75 g/t to 120 g/t did

achieve significantly higher AS Cu recovery at

equivalent concentrate grade. It was again clearly

demonstrated that little AS Cu recovery could be

achieved with low dosages of AERO XD900

promoter alone.

AS Cu Recovery (%)

700 g/t NaSH, 170 g/t PAX

Head = 0.90% AS Cu

AERO XD900 Dosage (g/t)

10

0

0 g/t NaSH, 0 g/t PAX

18

700 g/t NaSH, 0 g/t PAX

AS Cu Grade (%)

Note: four tests with same

recovery obscure each other

70

Second Customer AS Copper Grade vs AERO XD900 Dosage

20

14

16

AS Cu Grade

In all tests 700 g/t NaSH was added and conditioned for four minutes prior to addition of the

collector. Duplicate tests were run where 100 g/t

At the request of the first customer plant, a series

of tests were run to demonstrate the effectiveness

of AERO XD900 promoter at recovering oxide.

The first customer treats a high grade ore at typically 3.8% AI Cu and 0.8% AS Cu. They normally achieve >90% recovery of AI Cu but <30%

recovery of AS Cu. In this work, xanthate dosage

was held constant at 30 g/t SiPX + 30 g/t PAX.

This work differs from previously shown results,

in that a bulk sulfide/oxide conc is produced

rather than floating an oxide conc following sulfide flotation. Hence, the surface responses for T

Cu and AS Cu have been included. The test work

was done over a period of two days, with a significant change in ore quality between days, so it will

be seen that the effect of different day is highly

significant.

Combined Roughers T Cu Grade

100

1 4.2

1 4.4

1 4.61 4.8 1 5

1 5.2

Summary of Fit

1 5.4 1 5 .6

AERO XD900 dosage

80

RSquare

0.923682

RSquare Adj

0.8321

Root Mean Square Error

1.068849

Mean of Response

15.15915

Observations (or Sum Wgts)

12

60

Effect Tests

Source

40

20

1 5.8

0

0

1 5.8

16

1 00

2 00

3 00

4 00

1 5.6 1 5.4

5 00

6 00

Nparm

DF

Sum of Squares

F Ratio

Prob > F

Day

25.146189

22.0110

0.0054

NaSH dosage

0.403250

0.3530

0.5783

AERO XD900 dosage

0.110098

0.0964

0.7688

NaSH dosage* AERO XD900

dosage

1.515640

1.3267

0.3015

NaSH dosage* AERO XD900

dosage

0.857460

0.7506

0.4259

Cytec OREPREP frother

dosage

1.001504

0.8766

0.3921

Sum of Squares

F Ratio

Prob > F

N aS H d os ag e

Combined Roughers T Cu Grade

100

1 4.2

1 4.4

1 4.61 4.8 1 5

1 5.2

Summary of Fit

1 5.4 1 5 .6

AERO XD900 dosage

80

60

RSquare

0.934278

RSquare Adj

0.856401

Root Mean Square Error

2.179624

Mean of Response

81.93862

Observations (or Sum Wgts)

12

Effect Tests

Source

40

20

1 5.8

1 5.8

16

1 5.6 1 5.4

Nparm

DF

Day

78.75451

16.5772

0.0096

NaSH dosage

100.60553

21.1767

0.0058

AERO XD900 dosage

2.53455

0.5335

0.4979

NaSH dosage* AERO XD900

dosage

3.00296

0.6321

0.4626

NaSH dosage* AERO XD900

dosage

29.30725

6.1690

0.0556

2.53544

0.5337

0.4978

1 00

2 00

3 00

4 00

5 00

6 00

Cytec OREPREP frother

dosage

N aS H d os ag e

* Not all effects, particularly grade, show statistical significance to >90%, so a degree of caution should be used rather than taking

all contours too literally. Even so, particularly for AS Cu recovery, the effects of NaSH dosage and AERO XD900 promoter

dosage do appear strong.

Combined Roughers AS Cu Grade

Summary of Fit

100

RSquare

0.949601

RSquare Adj

0.889123

Root Mean Square Error

0.347484

3 .1

Mean of Response

2.486433

Observations (or Sum Wgts)

12

3 .3

3 .2

AERO XD900 dosage

80

60

2 .9

Nparm

DF

Sum of Squares

F Ratio

Prob > F

Day

7.2047480

56.6689

0.0006

NaSH dosage

0.2259616

1.8714

0.2296

2 .6

AERO XD900 dosage

0.2325667

1.9261

0.2239

2 .5

NaSH dosage* AERO XD900

dosage

0.2391924

1.9810

0.2183

2 .4

NaSH dosage* AERO XD900

dosage

0.0004016

0.0033

0.9562

Cytec OREPREP frother

dosage

0.0606608

0.5024

0.5101

2 .8

40

2 .7

20

2 .3

0

1 00

2 00

3 00

4 00

5 00

Effect Tests

Source

6 00

N aS H d o s ag e

Combined Roughers AS Cu Recovery

Summary of Fit

100

80

80

AERO XD900 dosage

75

RSquare

0.939374

RSquare Adj

0.866622

Root Mean Square Error

4.85165

Mean of Response

56.68738

Observations (or Sum Wgts)

12

60

70

Effect Tests

Source

40

65

20

60

55

40

0

45

1 00

50

2 00

3 00

N a S H d o s ag e

4 00

5 00

6 00

Nparm

DF

Sum of Squares

F Ratio

Prob > F

Day

269.95274

11.4686

0.0195

NaSH dosage

877.75608

37.2902

0.0017

AERO XD900 dosage

240.72351

10.2268

0.0241

NaSH dosage* AERO XD900

dosage

68.40509

2.9061

0.1490

NaSH dosage* AERO XD900

dosage

96.65026

4.1060

0.0986

1.25839

0.0535

0.8263

Cytec OREPREP frother

dosage

Second Customer Open Pit Sulfide Tails

Flotation AS Cu Grade vs Recovery

2) Effect of AERO XD900 promoter and

AERO XD902 promoter Conditioning

Time

Second Customer Flotation of Sulfide Tails AS Cu Grade vs Recovery

100

Rghr 2

90

XD900 + PAX condition 1 min

none

XD900 + PAX condition 4 min

none

80

800 g/t NaSH, 100 g/t

AERO XD902

50

800 g/t NaSH, 100 g/t

AS Cu Recovery (%)

40

800 g/t NaSH, 100 g/t

AS Cu Recovery (%)

30

20

10

Head 1.14% AS Cu

0

0

10

12

14

AS CuGrade (%)

3.2 Use of CYQUEST 3223 dispersant

It was thought that use of CYQUEST 3223

dispersant might aid the use of AERO XD900

promoter by blocking adsorption on to surface of

slimes and dispersing slimes from the surface of

the oxide copper. Two sets of test work were run

using CYQUEST 3223 dispersant and in neither

set was any advantage seen.

0

XD900 + PAX condition 12 min none

60

50

40

XD900 condition 1 min

none

XD900 condition 4 min

none

XD900 condition 12 min

none

Flotation of First Customer Sulfide

Rougher Tails AS Cu Grade vs Recovery

70

30

34 g/t Reagent S8881

20

All tests 700 g/t NaSH to head

10

Head - 0.90%

0

0

10

12

14

AS Cu

16

AS Cu Grade

Use of PAX alongside this relatively low dosage of

AERO XD900 promoter proved beneficial.

Conditioning for 12 minutes was deleterious to

performance, with superior performance being

achieved at one minute and four minutes conditioning.

AS Cu Recovery (%)

60

64 g/t Reagent S8881

50

129 g/t Reagent S8881

40

129 g/t CYQUEST 3223, 64 g/t

Reagent S8881

30

330 g/t CYQUEST 3223, 64 g/t

Reagent S8881

20

10

Head 0.21% AS Cu

0

0.0

0.5

1.0

1.5

2.0

2.5

3.0

AS Cu grade (%)

Second Customer Underground Flotation of Sulfide

Rougher Tails AS Cu Grade vs Recovery

50

48 g/t AERO XD902

3) What Did Not Prove So Effective

3.1 Emulsification

It was thought that because the AERO XD900

promoter and AERO XD902 promoter molecules

were relatively water insoluble, use of an emulsifier

might aid its distribution through the pulp

(Cytecs Reagent S-9947).

As can be seen from the plot of duplicate tests,

there appears to be no metallurgical advantage to

adding an emulsifier. It would appear that the

AERO XD902 promoter disperses adequately on

its own.

100 g/t AERO XD902

AS Cu Recovery (%)

AS Cu Recovery (%)

70

AS Cu Recovery (%)

60

Since high energy conditioning is necessary for use

of AERO XD900 promoter and similar formulations in Kaolin processing, the question arose as to

whether additional conditioning time might

improve its effectiveness for oxide copper flotation. Tests were run on second customers open pit

ore using 70 g/t AERO XD900 promoter at three

conditioning times: one minute, four minutes and

12 minutes in 1) tests with only 700 g/t NaSH

added, 2) tests with 700 g/t NaSH then 100 g/t

PAX.

Collector to Rghr 1

800 g/t NaSH, 100 g/t

AERO XD902

70

40

170 g/t AERO XD902

320 g/t AERO XD902

30

50 g/t CYQUEST 3223,

100 g/t AERO XD902

100 g/t CYQUEST 3223,

100 g/t AERO XD902

300 g/t CYQUEST 3223,

100 g/t AERO XD902

.

20

10

Head 1.16% AS Cu

0

0

10

AS Cu grade (%)

This may have been because a dispersant was not

necessary on this ore, or it may have been due to

CYQUEST 3223 depressing the AS Cu to some

degree as a result of the high dosage.

3.3 Ammonium sulfate

In a paper by David Bastin of Liege University,

Belgium (Ref 4) it was suggested that use of ammonium sulfate significantly boosted AS Cu recovery in

CPS with xanthate. Looking again at the paper,

higher recoveries were achieved but at very poor

grades (relative to feed grade). The idea may have

come from the much older paper (Ref 5), which

describes use of ammonium sulfate as a means of

controlling the harmful effect of overdose of

sulfidizer.

Flotation of First Customer Sulfide

Rougher Tails AS Cu Grade vs Recovery

70

34 g/t Reagent S8881

AS Cu Recovery (%)

60

References

Ref 1: Lee J.S, Nagaraj D.R. and Coe J.E., 1998,

Practical Aspects of Oxide Copper Recovery with

Alkyl Hydroxamates, Minerals Engineering Vol 11

No 10 p929939.

64 g/t Reagent S8881

50

129 g/t Reagent S8881

40

129 g/t CYQUEST 3223, 64 g/t

Reagent S8881

30

330 g/t CYQUEST 3223, 64 g/t

Reagent S8881

20

10

Head 0.21% AS Cu

0

0.0

To maintain Cu recovery through cleaning, it is

necessary to maintain the cleaning stages at similar

potentials to the roughing stage.

For a mixed copper sulfide/oxide ore, it may be

valuable (when feasible) to clean the sulfide and

oxide concentrates separately, as kinetics of oxide

flotation are likely to be slower.

0.5

1.0

1.5

2.0

2.5

Ref 2: Nagaraj D.R. and Gorken A., 1991, Potential

controlled flotation and depression of copper sulfides

and oxides using hydrosulfide in nonxanthate systems, Canadian Metall. Quarterly Vol 30 No 2 pp

7986.

3.0

AS Cu grade (%)

In this work it can be seen that use of ammonium

sulfate had a negative impact on flotation performance. This may be because the levels of NaSH used

were below the threshold level where ammonium

salts start to show an advantage by control of excess

hydrosulfide.

Recommendations

As AERO XD900 and XD902 promoters tend to

solidify at lower temperatures (<17C), try to do

test work at the temperature of the plant pulp.

Adequate conditioning after NaSH addition is necessary to avoid excessive frothing.

Use of xanthate (PAX or NaBX), in addition to

sulfidization, and AERO XD900 promoter and

AERO XD902 promoter can aid recovery.

Very slimy ores can make use of AERO XD900

and XD902 promoters difficult, due to generation

of an over-stable froth. Look at either de-sliming or

use of polyphosphate type dispersants.

Experiment with conditioning time of AERO

XD900 and XD902 promoters, but 1-3 minutes is

a good starting point.

Ref 3: Kasanda J.K., Mpashi P. and Mumba C.,

1998, Laboratory Optimisation of the Underground

Copper Ore Flotation Recovery at Second customer

Concentrator, 100th AGM of the CIM, Montreal.

Ref 4: Bastin D., Frenay J. and Philippart P., 2003,

Ammonium Sulfate as Promoting Agent of the

Sulfidization Process of Cu-Co Oxide Ores From

The Luiswishi Deposit (DRC), Handout from Poster

session at XXII IMPC Cape Town 2003.

Ref 5: Zhang W. and Poling G.W., 1987,

Ammonium Sulfate as Activator in Sulpidized

Xanthate Flotation of malachite, unknown.

References not mentioned in the main text which

may be of value to enthusiastic oxide floaters:

Hallimond tube only

Salmon-Vega S., Herrera-Urbina R., SanchezCorrales V.M., Robles-Vega A., 2003, Floatability

of oxidised copper, oxidised chalcocite and copper

slag using octyl hydroxamate as a collector, 2003,

Cobre 2003 Volume III.

On use of ammonium sulfide

Kongolo K., Kipoka M., Minanga K. and Mpoyo

M., 2003, Improving the efficiency of oxide copper-cobalt ores flotation by combination of sulfidisers, Minerals Engineering 16, pp 10231026.

An early paper on use of sulfidization,

xanthate + AERO XD900 promoter and

AERO XD902 promoter

Evrard L. and De Cuyper J., 1975, Flotation of

copper-cobalt oxide ores with alkyl hydroxamates,

Proc 11th IMPC Cagliari.

Suggested use of imidazolines for malachite

flotation

Ackerman P.K., Harris G.H., Klimpel R.R. and

Aplan F.F., 1999, Use of Chelating Agents as

Collectors in the Flotation of Copper Sulfides and

Pyrite, Minerals and Metallurgical processing Vol

16, No 1.

Potential use of aldoximes for oxide copper

flotation

Das K.K., Pradip and Suresh B., 1995, Role of

Molecular Architecture and Chain Length in the

Flotation-Separation of Oxidised Copper-LeadZinc Minerals Using Salicylaldoxime derivatives,

XIX IMPC.

Email: custinfo@cytec.com

Worldwide Contact Info: www.cytec.com

US Toll Free 800-652-6013

Cytec Industries Inc. in its own name and on behalf of its affiliated companies (collectively, "Cytec") decline any liability with respect to the

use made by anyone of the information contained herein. The information contained herein represents Cytec's best knowledge thereon without constituting any express or implied guarantee or warranty of any kind (including, but not limited to, regarding the accuracy, the completeness or relevance of the data set out herein). Cytec is the sole owner or authorized user of the intellectual property rights relating to

the information communicated. The information relating to the use of the products is given for information purposes only. No guarantee or

warranty is provided that the product is adapted for any specific use. The user or purchaser should perform its own tests to determine the

suitability for a particular purpose. The final choice of use of a product remains the sole responsibility of the user.

2010 Cytec Industries Inc. All rights reserved.

Tel 973-357-3193

TRADEMARK NOTICE: The indicates a Registered

Trademark in the United States and the or *

indicates a Trademark in the United States. The mark

may also be registered, the subject of an application

for registration or a trademark in other countries.

MCT-1107-V2

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Lecture 2 Electrodeposition of CoatingDokument23 SeitenLecture 2 Electrodeposition of Coatingชนพัทธ์ คงพ่วงNoch keine Bewertungen

- Marine Corrosion in Tropical EnvironmentsDokument314 SeitenMarine Corrosion in Tropical Environmentsleocastarlenas75% (4)

- Application Datasheet: Standard Designation For Wrought Copper AlloysDokument72 SeitenApplication Datasheet: Standard Designation For Wrought Copper AlloysQuality teamNoch keine Bewertungen

- Welding Rod Selection 2 PDFDokument1 SeiteWelding Rod Selection 2 PDFPrior Drake89% (9)

- Testing Precious Metals (Printer Friendly)Dokument47 SeitenTesting Precious Metals (Printer Friendly)CoM - MúsicaNoch keine Bewertungen

- 1-Bimetal Technology PDFDokument32 Seiten1-Bimetal Technology PDFUdit SharmaNoch keine Bewertungen

- Project Report On Inner Grooved Copper TubeDokument8 SeitenProject Report On Inner Grooved Copper TubeEIRI Board of Consultants and Publishers0% (1)

- Production of Copper Powder by AtomizationDokument5 SeitenProduction of Copper Powder by AtomizationJavo BarrelNoch keine Bewertungen

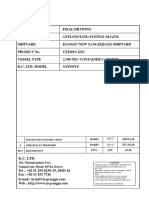

- K.C. LTD.: 165, Mieumsandan 3-Ro, Gangseo-Gu, Busan 46744, KoreaDokument23 SeitenK.C. LTD.: 165, Mieumsandan 3-Ro, Gangseo-Gu, Busan 46744, Koreamarine Shanghai100% (2)

- Talisman of NapoleonDokument17 SeitenTalisman of NapoleonEmanuel DaGloriaNoch keine Bewertungen

- Coherence and UnityDokument1 SeiteCoherence and UnitySighdz ManalansanNoch keine Bewertungen

- Metals & Non-Metals Lesson PlanDokument6 SeitenMetals & Non-Metals Lesson Plansunita mishraNoch keine Bewertungen

- MetalsDokument24 SeitenMetals4D-31 WONG YUEN TSZNoch keine Bewertungen

- Section T: Signage Works: @hakcipta JKR MalaysiaDokument5 SeitenSection T: Signage Works: @hakcipta JKR MalaysialordcasioNoch keine Bewertungen

- Characterization of Low Cost P-Cu2On-CuO JunctionDokument6 SeitenCharacterization of Low Cost P-Cu2On-CuO JunctionbongtongNoch keine Bewertungen

- Ferrer-2012-The Mechanical Properties of 16th Century Transport Jars From Panama and Seville-1Dokument496 SeitenFerrer-2012-The Mechanical Properties of 16th Century Transport Jars From Panama and Seville-1Samantha G. FerrerNoch keine Bewertungen

- Mineral Tolerances of AnimalsDokument7 SeitenMineral Tolerances of AnimalsJuliana YagualNoch keine Bewertungen

- Chem Unit 5 Quantitative QuestionsDokument27 SeitenChem Unit 5 Quantitative QuestionsRizam UmerNoch keine Bewertungen

- Cooling Water TreatmentDokument47 SeitenCooling Water Treatmentfurrano yonandaNoch keine Bewertungen

- October 2016 2Dokument16 SeitenOctober 2016 2Tanvika AroraNoch keine Bewertungen

- Aluminum The Wiring Material of The FutureDokument7 SeitenAluminum The Wiring Material of The FuturevkmsNoch keine Bewertungen

- Expansión Termica PascoDokument14 SeitenExpansión Termica PascoJorge GamezNoch keine Bewertungen

- Copper and Copper Alloy Clad Steel Plate: Standard Specification ForDokument6 SeitenCopper and Copper Alloy Clad Steel Plate: Standard Specification ForAdnan KhanNoch keine Bewertungen

- B 111-2018 Standard Specification For Copper and Copper-Alloy Seamless Condenser TubesDokument12 SeitenB 111-2018 Standard Specification For Copper and Copper-Alloy Seamless Condenser TubesnileshNoch keine Bewertungen

- FinalDokument74 SeitenFinalRaj NarulaNoch keine Bewertungen

- Report (Sculpture Materials)Dokument32 SeitenReport (Sculpture Materials)triziasisonNoch keine Bewertungen

- Lab Report-Elle Necole QuimadaDokument5 SeitenLab Report-Elle Necole QuimadaElleNoch keine Bewertungen

- Copper and Tin in Steel Scrap RecyclingDokument15 SeitenCopper and Tin in Steel Scrap RecyclingakshukNoch keine Bewertungen

- Scheme of Testing and Inspection For Certification of Carbon Steel Cast Billet Ingots Billets Blooms and Slabs For Re Rolling Into Seel For General Structural Purpose PDFDokument6 SeitenScheme of Testing and Inspection For Certification of Carbon Steel Cast Billet Ingots Billets Blooms and Slabs For Re Rolling Into Seel For General Structural Purpose PDFbipinagarwalNoch keine Bewertungen

- Mining Heritage of Co WicklowDokument50 SeitenMining Heritage of Co Wicklow345678923Noch keine Bewertungen