Beruflich Dokumente

Kultur Dokumente

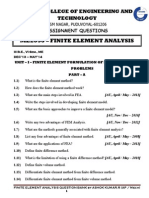

Stress-Strain Analysis of Trusses and Planar Structures

Hochgeladen von

Jim SullivanOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Stress-Strain Analysis of Trusses and Planar Structures

Hochgeladen von

Jim SullivanCopyright:

Verfügbare Formate

CHAP 1.

STRESSSTRAIN ANALYSIS

1. A vertical force F is applied to a two-bar truss as shown in the figure. Let crosssectional areas of the members 1 and 2 be A1 and A2, respectively. Determine the

area ratio A1/A2 in order to have the same magnitude of stress in both members.

A

45

l

F

Solution:

From force equilibrium at B,

f1

45

Fy

f1 sin 45 F 0

f1

2F

Fx

f2 f1 cos 45 0

f2

2F

1

2

Since truss is two-force member, f1 A11 and f2 A22 . Thus,

f1

f2

A

A

2F

1 1 1 ( 1 2 ) ,

F

A22

A2

A1

A2

19

f2

20

Finite Element Analysis and Design

2. The stress at a point P is given below. The direction cosines of the normal n to a

plane that passes through P have the ratio nx:ny:nz = 3:4:12. Determine (a) the

traction vector T(n); (b) the magnitude T of T(n); (c) the normal stress n; (d) the shear

stress n; and (e) the angle between T(n) and n.

Hint: Use nx2 ny2 nz2 1 .

13 13

0

[ ] 13 26 13

0 13 39

Solution:

(a) First, we need unit normal vector n:

3

0.2308

4 0.3077

32 42 122

12

0.9231

Then, the traction vector on this plane becomes

(n )

13 13

0

0.2308

7

n 13 26 13 0.3077 1

0 13 39

0.9231

40

(b) Since T(n) is a vector, its magnitude can be obtained using the norm as

T (n ) Tx(n )2 Ty(n )2 Tz(n )2

(c)

(d)

(e)

(n )

n T

T(n)

72 (1)2 (40)2 40.6202

0.2308

n 7 1 40 0.3077

35.6154

0.9231

n 2

40.62022 (35.6154)2 19.5331

n T(n) n T(n) cos

n

(n )

T

cos

2.64 151.30

CHAP 1 Stress-Strain Analysis

21

3. At a point P in a body, Cartesian stress components are given by xx = 80 MPa, yy =

40 MPa, zz = 40 MPa, and xy = yz = zx = 80 MPa. Determine the traction vector,

its normal component, and its shear component on a plane that is equally inclined to

all three coordinate axes.

Hint: When a plane is equally inclined to all three coordinate axes, the direction

cosines of the normal are equal to each other.

Solution:

The unit normal in this case is:

0.577

1

n 1 0.577

3

1

0.577

The traction vector in this direction becomes

T(n )

80 80

80 0.577 138.56

n 80 40 80 0.577 69.28 MPa

80 80 40 0.577 69.28

The normal component of the traction vector is

(n )

n T

0.577

n 138.56 69.28 69.28 0.577

160 MPa

0.577

The shear component of the traction vector is:

n

T(n)

n 2

169.712 1602 56.58 MPa

22

Finite Element Analysis and Design

4. If xx = 90 MPa, yy = 45 MPa, xy = 30 MPa, and zz = xz = yz = 0, compute the

surface traction T(n) on the plane shown in the figure, which makes an angle of =

40 with the vertical axis. What are the normal and shear components of stress on

this plane?

yy

xy

n

xx

xy

xy

xy

xx

yy

Solution:

Unit normal vector:

Traction vector: T(n)

Normal stress:

Shear stress:

nT cos(40) sin(40) 0

90 30 0

.776

88.23

[ ] n 30 45 0 .643 5.94

MPa

0

0

0

0

n T(n) n 63.77MPa

n

T(n)

n2 61.27MPa

CHAP 1 Stress-Strain Analysis

23

5. Find the principal stresses and the corresponding principal stress directions for the

following cases of plane stress.

(a) xx = 40 MPa,

yy = 0 MPa,

xy = 80 MPa

(b) xx = 140 MPa,

yy = 20 MPa,

xy = 60 MPa

(c) xx = 120 MPa,

yy = 50 MPa,

xy = 100 MPa

Solution:

(a) The stress matrix becomes

xx

xy

40 80

xy

80 0 MPa

yy

To find the principal stresses, the standard eigen value problem can be written as

I n 0

The above problem will have non-trivial solution when the determinant of the coefficient

matrix becomes zero:

xx

xy

40

80

0

xy

yy

80

0

The equation of the determinant becomes:

40 80 80 2 40 6400 0

The above quadratic equation yields two principal stresses, as

1 102.46 MPa and 2 62.46 MPa .

To determine the orientation of the first principal stresses, substitute 1 in the original

eigen value problem to obtain

40 102.46

80

0

nx

n 0

80

0

102.46

Since the determinant is zero, two equations are not independent

62.46 nx 80 ny and 80 nx 102.46 ny .

Thus, we can only get the relation between nx and ny. Then using the condition |n| = 1 we

obtain

24

Finite Element Analysis and Design

nx

(1)

0.788

n

0.615

y

To determine the orientation of the second principal stress, substitute 2 in the original

eigen value problem to obtain

40 62.46

80

0

nx

80

0

62.46

n

0

y

102.46 nx 80 ny and 80 nx 62.46 ny .

Using similar procedures as above, the eigen vector of 2 can be obtained as

(2)

nx

0.615

0.788

y

Note that if n is a principal direction, n is also a principal direction

(b) Repeat the procedure in (a) to obtain

1 164.85 MPa and 2 4.85 MPa .

nx

(1)

0.924

nx

(2)

0.383

and

n

0.383

n

0.924

(c) Repeat the procedure in (a) to obtain

1 96.24 MPa and 2 166.24 MPa .

(1)

(2)

nx

0.420

nx

0.908

and

n

0.908

n

0.420

y

Note that for the case of plane stress 3=0 is also a principal stress and the corresponding

principal stress direction is given by n(3) =(0,0,1)

CHAP 1 Stress-Strain Analysis

25

6. If the minimum principal stress is 7 MPa, find xx and the angle that the principal

stress axes make with the x and y axes for the case of plane stress illustrated

21 MN/m2

y

xx

x

56 MN/m2

Solution:

With unknown x-component, the eigen value problem can be written as

xx 56

0

nx

56

21

n

0

y

The principal stresses can be determined by making the determinant zero

xx 56

0

56

21

(xx )(21 ) 562 0

Since 7 MPa is one of the roots of the above equation, we can find xx by substituting

in the above equation as

(xx 7)(21 7) 562 0

By solving the above equation, we can get xx 105 MPa . Then, the other principal

stress can be found from the original determinant, as

1 133 MPa

2 7 MPa

Principal direction for the first principal stress: From the original eigen value

problem,

(105 133)nx1 56ny1 0

56nx1 (21 133)ny1 0

The solution of the above equations is not unique. By putting |n1| = 1, we have

n1 {0.8944, 0.4472} , which is principal direction corresponding to 1

Principal direction for the second principal stress: From the original eigen value

problem,

26

Finite Element Analysis and Design

(105 7)nx2 56ny2 0

56nx2 (21 7)ny2 0

The solution of above equations is n2 {0.4472, 0.8944} , which is principal

direction corresponding to 2 . Two principal directions are plotted on the following

graph. Note that the two principal directions are perpendicular each other.

y

n1'

n2

135.43o

x

-26.57o

n1

n2'

CHAP 1 Stress-Strain Analysis

27

7. Determine the principal stresses and their associated directions, when the stress

matrix at a point is given by

1 1 1

[ ] 1 1 2 MPa

1 2 1

Solution:

Use the Eq. (0.46) of Chapter 0 with the coefficients of I1=3, I2= 3, and I3 = 1,

3 3 2 3 1 0

By solving the above cubic equation using the method described in Section 0.4,

1 3.73 MPa,

2 0.268 MPa,

3 1.00 MPa

(a) Principal direction corresponding to 1:

(1 3.7321)nx1 ny1 nz1 0

nx1 (1 3.7321)ny1 2nz1 0

nx1 2ny1 (1 3.7321)nz1 0

Solving the above equations with |n1| = 1 yields

n1 {0.4597, 0.6280, 0.6280}

(b) Principal direction corresponding to 2:

(1 0.2679)nx1 ny1 nz1 0

nx2 (1 0.2679)ny2 2nz2 0

nx2 2ny2 (1 0.2679)nz2 0

Solving the above equations with |n2| = 1 yields

n2 {0.8881, 0.3251, 0.3251}

(c) Principal direction corresponding to 3:

(1 1)nx3 ny3 nz3 0

nx3 (1 1)ny3 2nz3 0

nx3 2ny3 (1 1)nz3 0

Solving the above equations with |n2| = 1 yields

28

Finite Element Analysis and Design

n3 {0, 0.7071, 0.7071}

CHAP 1 Stress-Strain Analysis

29

8. Let xyz coordinate system be defined using the three principal directions obtained

from Problem 7. Determine the transformed stress matrix []xyz in the new

coordinates system.

Solution:

The three principal directions in Problem 6 can be used for the coordinate transformation

matrix:

n (1) n (2) n (3)

0.460 0.888

0

x

x

x

N ny(1) ny(2) ny(3) 0.628 0.325

0.707

(1)

0.628 0.325 0.707

nz

nz(2) nz(3)

To determine the stress components in the new coordinates we use Eq. (1.30):

x y z

1 0

0

N N 0 .268

0

0

0

3.732

Note that the transformed stress matrix is a diagonal matrix with the original principal

stresses on the diagonal.

30

Finite Element Analysis and Design

9. For the stress matrix below, the two principal stresses are given as 3 = 3 and 1 = 2,

respectively. In addition, the two principal stress directions corresponding to the two

principal stresses are also given below.

2

1

1 0 2

5

5

[ ] 0 1 0 , n1 0 and n 3 0

2 0 2

2

1

5

5

(a) What is the normal and shear stress on a plane whose normal vector is parallel to

(2, 1, 2)?

(b) Calculate the missing principal stress 2 and the principal direction n2.

(c) Write stress matrix in the new coordinates system that is aligned with n1, n2, and

n3.

Solution:

nT 13 {2 1 2}

(a) Normal vector:

Traction vector

T(n)

n 3

The normal component of the stress vector on the plane can be calculated

n T(n) n 1.4444

n

T(n)

n2 1.4229

(b) Using Eq. (0.46) of Chapter 0, the eigen values are governed by

3 I12 I 2 I 3 0

We can find the coefficients of the above cubic equation from Eq. (0.47) by I1 = 0, I2 =

7, and I3 = 6. Thus, we have

3 7 6 ( 1)(2 6) 0

Thus, the missing principal stress is 2 1 .

Since three principal directions are mutually orthogonal, the third principal direction

can be calculated using the cross product. To establish a defined sign convention for the

principal axes, we require them to form a right-handed triad. If n1 and n3 are unit vectors

that define the directions of the first and third principal axes, then the unit vector n2 for

the second principal axis is determined by the right-hand rule of the vector multiplication.

Thus we have

CHAP 1 Stress-Strain Analysis

n2 n 3 n1 {0 1 0}T

(c) Coordinate transformation matrix can be obtained from three principal directions as

N n1

n2

3

n

2

5

0

1

5

1

5

1 0

0

5

0

The stress matrix at the transformed coordinates becomes

N T N

2

5

0

1

5

2

1

1 0 2

5

5

1 0 0 1 0 0

2 2 0 2 1

0

5

5

0

1

2 0 0

5

1 0 0 1 0

0 0 3

2

0

5

0

31

32

Finite Element Analysis and Design

10. With respect to the coordinate system xyz, the state of stress at a point P in a solid is

20 0 0

[ ] 0

50 0 MPa

0

0 50

z

m3

m2

y

m1

(a) m1, m2 and m3 are three mutually perpendicular vectors such that m1 makes 45

with both x- and y-axes and m3 is aligned with the z-axis. Compute the normal

stresses on planes normal to m1, m2, and m3.

(b) Compute two components of shear stress on the plane normal to m1 in the

directions m2 and m3.

(c) Is the vector n = {0, 1, 1}T a principal direction of stress? Explain. What is the

normal stress in the direction n?

(d) Draw an infinitesimal cube with faces normal to m1, m2 and m3 and display the

stresses on the positive faces of this cube.

(e) Express the state of stress at the point P with respect to the xyz coordinates

system that is aligned with the vectors m1, m2 and m3?

(f) What are the principal stress and principal directions of stress at the point P with

respect to the xyz coordinates system? Explain.

(g) Compute the maximum shear stress at the point P. Which plane(s) does this

maximum shear stress act on?

Solution:

(a)

m1

1

2

(1,1, 0)T

m2

1

2

(1,1, 0)T

m3 (0, 0,1)T

m1m1 m1 [ ] m1 15 MPa

m2m2 m 2 [ ] m 2 15 MPa

m 3m 3 m 3 [ ] m 3 50 MPa

(b)

1

T(m ) [] m1

1

2

{20 50 0}T

CHAP 1 Stress-Strain Analysis

33

m1m2 T(m ) m2 35 MPa

1

m1m3 T(m ) m 3 0 MPa

(c) Yes,

1

T(n)

(0,1,1)

50

1

1

[ ] n

50

50

1

50n

2

2

Since T(n) // n, n is a principal direction with principal stress = 50 MPa.

(d)

m3

-20

15

m2

35 35

m1

15

(e)

x y z

0.707 0.707 0 20 0 0

N N -0.707 0.707 0 0

50 0

0

0

1 0

0 50

0.707 -0.707 0

0.707 0.707 0

0

0

1

[ ]x y z

15 35 0

35 15 0 MPa

0 0 50

(f) Principal stresses = 50, 50, and 20 MPa

n3

1

2

(1, 1, 0)

n1 and n2 are any two perpendicular unit vectors that is on the plane perpendicular to n3.

34

Finite Element Analysis and Design

(g) The maximum shear stress occurs on a plane whose normal is at 45o from the

principal stress direction. Since 1 = 2, all directions that are 45o from x-axis (3 axis)

will have the maximum shear stress whose value is

max

1 3

2

35 MPa

The maximum shear stress planes are in the shape of a cone whose axis is parallel to xaxis and has an angle of 45o.

CHAP 1 Stress-Strain Analysis

35

11. A solid shaft of diameter d = 5 cm, as shown in the figure, is subjected to tensile

force P = 13,000 N and a torque T = 6,000 Ncm. At point A on the surface, what is

the state of stress (write in matrix form), the principal stresses, and the maximum

shear stress? Show the coordinate system you are using.

A

T

Solution:

Let us establish a coordinate system as shown in the figure. The axial force will cause

normal stress xx, while the torque will cause shear stress xy. Their magnitudes are

P

6.62 MPa

A

T r

2.44 MPa

J

Then, the stress matrix becomes

6.62 2.44 0

[ ]A 2.44

0

0 MPa

0

0

0

By solving the eigen value problem, the principal stress can be obtained as

1 7.43,

2 0,

3 0.81 MPa

Maximum shear stress is

max

1 2

2

4.11 MPa

36

Finite Element Analysis and Design

12. If the displacement field is given by

ux x 2 2y 2

uy y 2x (y z )

u z 2 2xy

(a) Write down 33 strain matrix.

(b) What is the normal strain component in the direction of (1,1,1) at point (1,3,1)?

Solution:

(a) 33 symmetric strain matrix can be calculated from its definition as

2x

y z

y

y z 2(x y ) 0

2

z

In addition, the unit normal vector in the direction of (1, 1, 1) is

nT

1

3

{1 1 1}

b) Thus, the normal component of strain is

1

2

n n (2x y z y y z 2x 2y y 2z ) y

3

3

Thus, the normal component of strain reduces as the y-coordinate of a point increases. At

point (1, 3, 1), y = 3

n n y 3 2 .

CHAP 1 Stress-Strain Analysis

37

13. Consider the following displacement field in a plane solid:

u(x, y) 0.04 0.01x 0.006y

v(x, y) 0.06 0.009x 0.012y

(a) Compute the strain components xx, yy, and xy. Is this a state of uniform strain?

(b) Determine the principal strains and their corresponding directions. Express the

principal strain directions in terms of angles the directions make with the x-axis.

(c) What is the normal strain at Point O in a direction 45o to the x-axis?

Solution:

(a) Strain components:

xy

xx

u

0.01

x

yy

v

0.012

y

v

u

0.009 0.006 0.015

x

y

Yes, this is a state of uniform strain, because the strains are independent of position x,y,z.

(b) Principal strains and principal directions.

xy

xx

xy

1

0.0075

2 xy

0.01 0.0075

xy

0.0075 0.012

yy

Find the eigen values (principal strains) and eigen vectors (principal direction) by solving

the eigen value problem:

0.01

0.0075

nx

0

0.0075

0.012

ny

0

The above equation yields two principal strains: 1 = 1 = 0.01231 and 2 = 2 =

0.01431. The principal direction corresponding to the first principal strain is

n(1) 0.9556 0.2948 ,

The angle the direction makes with the x-axis can be found from the relation

cos 0.9556, sin 0.2948 . Solving 163o

The principal direction corresponding to the second principal strain is

38

Finite Element Analysis and Design

n(2) 0.2948 0.9556 ,

and the angle is found to be 73o

(c)

Strain at point O

0.01 0.0075

,

0.0075

0.012

direction vector

2

1

Thus the normal strain in the direction of n becomes

45o

nn

T

1

0.01 0.0075

2

0.0085

0.0075 0.012 1

CHAP 1 Stress-Strain Analysis

39

14. The displacement field in a solid is given by

ux kx 2

uy 2kxy

u k (x y )z

where k is a constant.

(a) Write down the strain matrix.

(b) What is the normal strain in the direction of n = {1, 1, 1}T?

Solution:

(a) From the definition of strain

xx

ux

x

2kx ,

yy

uy

4kxy,

zz

y

uy

1 ux

ky 2

xy

2 y

x

u 1

1 uy

yz

z kz

2 z

y 2

u 1

1 u

xz x z kz

2 z

x 2

uz

z

k (x y )

Thus, the strain matrix is

2kx

[] ky 2

1

2 kz

4kxy

1

kz k (x y )

2

ky 2

1

kz

2

1

kz

2

(b) Unit normal vector

nT

1

3

{1 1 1}

Thus, the normal strain in the direction of n is

n [ ] n

1

3

2ky2 4kxy 3kx ky 2kz

40

Finite Element Analysis and Design

15. Draw a 22-inch square OABC on the engineering paper. The coordinates of O are

(0, 0) and B are (2, 2). Using the displacement field in Problem 13, determine the u

and v displacements of the corners of the square. Let the deformed square be denoted

as O'A'B'C'.

(a) Determine the change in lengths of OA and OC. Relate the changes to the strain

components.

(b) Determine the change in AOC . Relate the change to the shear strain.

(c) Determine the change in length in the diagonal OB. How is it related to the

strain(s)?

(d) Show that the relative change in the area of the square (change in area/original

area) is given by A/A = xx + yy = 1 + 2.

Hint: You can use the old-fashioned method of using set-squares (triangles) and

protractor or use Excel to do the calculations. Place the origin somewhere in the

bottom middle of the paper so that you have enough room to the left of the origin.

Solution:

y

A'(0.052, 2.084)

B'(2.032, 2.102)

C'(2.02, 0.078)

O'(0.04, 0.06)

O

x

C

(a) Let O O ', A A ', B B ',C C ' after deformation, suppose the coordinates

of each point are O(0, 0), A(0, 2), B(2, 2), C(2, 0). From the displacement field, we can

obtain the displacement of each point:

O : u(0, 0) 0.04, v(0, 0) 0.06 O '(0.04, 0.06)

A : u(0, 2) 0.052, v(0, 2) 0.084 A '(0.052, 2.084)

C : u(2, 0) 0.02, v(2, 0) 0.078 C '(2.02, 0.078)

OA O ' A ' OA

(0.052 0.04)2 (2.084 0.06)2 2 0.024 ;

CHAP 1 Stress-Strain Analysis

OC O ' C ' OC

(2.02 0.04)2 (0.078 0.06)2 2 0.0199 .

OA

0.024

OC

0.0199

0.012 yy ;

0.01 xx .

OA

2

OC

2

(b)

AOC

A ' O ' C '

2

0.052 0.04

0.078 0.06

sin1(

) sin1(

)

2.024

1.98

0.005929 0.00909

0.015

xy

(c)

B: u(2, 2) 0.032, v(2, 0) 0.102 C '(2.032, 2.102) ;

OB O ' B ' OB

(2.032 0.04)2 (2.102 0.06)2 2 2 0.0243

OB

0.0243

0.0086 45o

OB

2 2

(d)

Area

O ' A ' O ' C ' sin A ' O ' C ' 2 2

Orignal _ Area

22

2.024 1.98 sin 1.5558 4

0.00707

0.00177

4

4

Note that the change is area is close to the sum of two normal strains:

1 2 xx yy 0.012 0.01 0.002

41

42

Finite Element Analysis and Design

16. Draw a 22-inch square OPQR such that OP makes +73o to the x-axis. Repeat

questions (a) through (d) in Problem 15 for OPQR. Give physical interpretations to

your results.

Note: The principal strains and the principal strain directions are given by

1,2

xx

tan 2

yy

2

xy

xx yy 2 xy 2

xx yy

Solution:

y

P'(0.631,2.001)

P(0.585, 1.913)

Q'(2.520, 1.426)

Q(2.497, 1.328)

O'(0.04, 0.06)

o

73

O

R'(1.930, -0.515)

R(1.913, -0.585)

(a) Let O O ', P P ',Q Q ', R R ' after deformation. The coordinates of each

point are O(0, 0), P(0.585, 1.913), Q(2.497, 1.328), R(1.913, -0.585). From the

displacement field, we can obtain the displacement of each point:

O : u(0, 0) 0.04, v(0, 0) 0.06 O '(0.04, 0.06)

P : u(0.585,1.913) 0.0456, v(0.585,1.913) 0.0882 P '(0.6306, 2.0012)

R : u(1.913, 0.585) 0.0174, v(1.913, 0.585) 0.0702 R '(1.9304, 0.5148)

OP O ' P ' OP

(0.6303 0.04)2 (2.0012 0.06)2 2 0.0291

CHAP 1 Stress-Strain Analysis

OR O ' R ' OR

43

(1.9304 0.04)2 (0.5148 0.06)2 2 0.0241

OP

0.0291

OR

0.0241

0.0146 2 ;

0.0121 1

OP

2

OR

2

The change in length of OP and OR equal to the principal strains since 73 o is the

principal direction.

(b)

0.6303 0.04

0.5148 0.06

sin1(

) sin1(

)

2

2.0291

1.9759

0.2952 0.2952

2

2

P O R

POR 0 .

On principal direction, there is no shear deformation.

(c) The Point Q is moved to:

u(2.4973,1.3279) 0.023, v(2.4973,1.3279) 0.09841 Q '(2.520,1.4264)

OQ O ' Q ' OQ

(2.520 0.04)2 (1.4264 0.06)2 2 2 0.003

OQ

0.003

0.0011

OQ

2 2

28o xx cos2 (28) yy sin2 (28) xy sin(28)cos(28) 0.0011

Thus, the meaning of the length of diagonal change is the same as in (c) in Problem 15.

(d)

Area

O ' P ' O ' R ' sin P ' O ' R ' 2 2

Orignal _ Area

22

2.0291 1.9759 sin( ) 4

2

0.0023

4

1 2 0.0025

44

Finite Element Analysis and Design

17. For steel, the following material data are applicable: Youngs modulus E = 207 GPa

and shear modulus G = 80 GPa. For the strain matrix at a point shown below,

determine the symmetric 33 stress matrix.

0.003

0

0.006

[] 0

0.001 0.003

0.006 0.003 0.0015

Solution:

From Eq. (1.58) the elasticity matrix becomes

1

1

E

[C]

0

0

(1 )(1 2 ) 0

0

0

0

0

0

0

1

2

0

0

0

0

0

0

1

2

0

0

0

1

2

From the relation G E / 2(1 ) , we calculate (E / 2G ) 1 0.294 .

xx

0.003

0.879

yy

0.001 0.239

zz

[C]

0.0015

0.639

GPa

0.003

0.240

yz

0.006

0.480

xz

xy

0

0

In the matrix notation

0.879

0

0.480

0

0.239 0.240 GPa

0.480 0.240 0.639

CHAP 1 Stress-Strain Analysis

45

18. Strain at a point is such that xx = yy = 0, zz = 0.001, xy = 0.006, and xz = yz = 0.

Note: You need not solve the eigen value problem for this question.

(a) Show that n1 = i + j and n2 = i + j are principal directions of strain at this point.

(b) What is the third principal direction?

(c) Compute the three principal strains.

Solution:

(a) The strain matrix is

0 6 0

[] 6 0 0 103

0 0 1

In order to show a direction n is a principal direction, it is enough to show that [] n n .

After normalizing n1 and n2,

0 6 0 1

6

103

103

1

[] n

6

0

0

1

6

n

2

2

0

0

0 0 1

0 6 0 1

6

10

10

2

[] n 2

6

0

0

1

2

2

0

0

0 0 1

Thus, n1 and n2 are principal directions.

(b) From the orthogonal property of principal directions, the third principal direction can

be found using the cross product as

n 3 n1 n2 {0 0 1}T

Note that n3 in the above equation is normalized.

(c) Since the third principal direction is parallel to the z-axis, zz is the third principal

strain; i.e., 3 = zz = 0.001. From Part (a), the principal strain 1 and 2 can be obtained

because [] n n . Thus, the three principal strains are

1 0.006,

2 0.001,

Note that the three principal strains are reordered.

3 0.006

46

Finite Element Analysis and Design

19. Derive the stressstrain relationship in Eq. (1.60) from Eq. (1.55) and the plane stress

conditions.

Solution:

Three-dimensional stress-strain relation is given in Eq. (1.57). From the third equation of

Eq. (1.57),

E

(1 ) 0

yy

zz

(1 )(1 2 ) xx

zz

( yy )

1 xx

zz

Then, from the first equation of Eq. (1.57),

E

(1 )

xx

yy

zz

(1 )(1 2 )

2

E

(1 ) ( )

xx

yy

xx

yy

(1 )(1 2 )

1

xx yy

1 2

xx

In a similar way,

yy

xx

yy

1 2

Thus, if we combine these equations, we can obtain Eq. (1.60):

xx

yy

1 2

xy

0 0

xx

yy

(1

xy

0

0

CHAP 1 Stress-Strain Analysis

47

20. A thin plate of width b, thickness t, and length L is placed between two frictionless

rigid walls a distance b apart and is acted on by an axial force P. The material

properties are Youngs modulus E and Poissons ratio .

(a) Find the stress and strain components in the xyz coordinate system.

(b) Find the displacement field.

y

P

y

x

Solution:

(a) From the given force conditions, we can calculate the stress components, as

xx

P

bt

yy 0

zz 0

xy yz zx 0

(1)

We dont know 0 yet, but it is clear that there must be a compressive stress in the ydirection because of the effect of Poissons ratio. Since all shear stresses are zero, all

shear strain s are also zero:

xy yz zx 0

From the geometry, we can calculate the following strain components:

yy 0

xx

(2)

We dont know yet.

xx

0

Lets calculate unknown parameter 0 and using the stress-strain relation.

48

Finite Element Analysis and Design

1

(xx yy )

E

L

1

(yy xx ) 0

E

(xx yy )

E

xx

yy

zz

By substituting the relations in Eq. (1) in the above second equation, we obtain

1

P

0

0

E

bt

P

bt

And from the first relation, the unknown parameter can be calculated as

L (1 2 )P

PL

(1 2 )

E

bt

Ebt

Thus, the stress components are

xx

P

bt

yy

P

bt

And the normal strain in the z-direction is

zz

P(1 ) P (1 ) (1 )

E

bt

Ebt

L(1 2 ) L 1

(b) Displacement components can be calculated through integration as

ux x

uy 0

uz

z

1 L

CHAP 1 Stress-Strain Analysis

49

21. A solid with Youngs modulus E = 70 GPa and Poissons ratio = 0.3 is in a state of

plane strain parallel to the xy-plane. The in-plane strain components are measured

as follows: xx = 0.007, yy = 0.008, and xy = 0.02.

(a) Compute the principal strains and corresponding principal strain directions.

(b) Compute the stresses including zz, corresponding to the above strains.

(c) Determine the principal stresses and corresponding principal stress directions.

Are the principal stress and principal strain directions the same?

(d) Show that the principal stresses could have been obtained from the principal

strains using the stress-strain relations.

(e) Compute the strain energy density using the stress and strain components in xycoordinate system.

(f) Compute the strain energy density using the principal stresses and principal

strains.

Solution:

(a) The eigen value problem for the strain matrix is

0.007

0.01

0

nx

I {n}

0.01

0.008

n

0

y

The eigen values can be calculated by making the determinant of the coefficient matrix

zero, as

0.007

0.01

0

0.01

0.008

0.013, 0.012

Thus, the principal strains are: 1 0.012, 3 0.013 (notice: 2 0 in z-direction)

To find principal directions, substitute the principal strains into the characteristic

equation and solve for {n} with nx2 ny2 1 .

0.8944

for 1 0.012

n1 0.4472

-0.4472

for 3 0.013

n3 0.8944

(Notice: {0, 0, 1}T is the principal direction corresponding to 2 = 0)

(b) From the constitutive relation for a plane strain solid in Eq. (1.62),

xx

0.3365

0.4712

yy

GPa

0.5385

xy

50

Finite Element Analysis and Design

where {}T {xx

yy

xy } and

[C]

1

(1 )(1 2 )

0

0

0

0

1

2

zz component can be calculated from the condition the zero strain condition:

zz

zz

E

v

yy 0

E xx

zz 0.0404 GPa

Note that xz G xz 0 and yz G yz 0

(c) From Part (b),

0.3365 0.5385

GPa

0.5385 0.4712

0

0.0404

Solving the eigen-value problem, we obtain the following principal stresses:

1,2,3 0.6059, 0.0404, 0.7404 GPa

And the following principal directions

0.4472

0.8944

n1 0.4472 , n2 0 , n3 0.8944

0

Thus, the principal strain directions are the same as that of the principal stresses.

(d) If stress-strain relation for plane stress in Eq. (1.57) is applied to the principal strains,

1

0.6059

0.0404

2

GPa

2

0.7404

3

3

Note that all shear stresses are zero because it is in the principal directions. Note also that

three-dimensional constitutive relation is used rather than two-dimensional. However,

the same results will be expected if the plane strain relation is used.

(e)

1

y y z z xy xy xz xz yz yz

2 x x

8.45 106 J/m3

U0

CHAP 1 Stress-Strain Analysis

(f)

U0

1

22 33 8.45 106 J/m 3

2 1 1

51

52

Finite Element Analysis and Design

22. Assume that the solid in Problem 21 is under a state of plane stress. Repeat (b)

through (f).

Solution:

(b)

0.3538

xx

yy C 0.4538

GPa

xy

0.5385

1

[C]

1 2

0 0

E

where

1

(1 )

2

0

0

Note that for plane stress, zz xz yz 0 .

(c)

0.3538 0.5385 0

0.5385 0.4538 0

0

0

Solving the eigen-value problem, we obtain:

1,2,3 0.6231, 0, 0.7231 GPa

The principal stress directions are

0.8944

n1 0.4472 for 1 0.6231

0

n 0 for 2 0

0.4472

0.8944

for 3 0.7231

(d) Substitute principal stresses into equation (1.60) in the textbook to obtain principal

strains. Notice that zz 2 0.0004 0

CHAP 1 Stress-Strain Analysis

(e)

(f)

1

y y z z xy xy xz xz yz yz

2 x x

8.4 106 J/m 3

U0

U0

1

22 3 3 8.4 106 J/m 3

2 1 1

53

54

Finite Element Analysis and Design

23. A strain rosette consisting of three strain gages was used to measure the strains at a

point in a thin-walled plate. The measured strains in the three gages are: A = 0.001,

B = 0.0006, and C = 0.0007. Not that Gage C is at 45o with respect to the x-axis.

(a) Determine the complete state of strains and stresses (all six components) at that

point. Assume E = 70 GPa, and = 0.3.

(b) What are the principal strains and their directions?

(c) What are the principal stresses and their directions?

(d) Show that the principal strains and stresses satisfy the stress-strain relations.

C

A

x

Solution:

(a) From figure it is obvious xx = A = 0.001 and yy = B = 0.0006. Shear strain can be

found using the transformation relation in Eq. (1.50). The 2-D version of Eq. (1.50)

becomes

nn xx nx2 yy ny2 xy nx ny

where nx = cos(45o) and ny = sin(45o). Thus,

C nn (45 ) xx cos2 45 yy sin2 45 xy sin 45 cos 45 0.0007

By solving the above equation, we obtain xy = 0.003. Since the strain rosette only

measures plane stress state, zz is unknown. But, there is no shear strain in the zdirection, xz = yz = 0. In order to calculate the unknown stress zz , we use the

constitutive relation for plane stress. Since the plate is in a state of plane stress, zz = xz

= yz = 0. Other stresses can be obtained from stress-strain relations for plane stress

conditions as shown below:

x

x

63.1

E 1

MPa

23.1

1

xy G xy 26.9 MPa

For plane stress condition the through-the-thickness strain is obtained from Eq. (1.59), as

zz

xx yy 0.000171

E

CHAP 1 Stress-Strain Analysis

55

(b) For a state of plane stress, zz = 0.000171 is a principal stress and the z-axis (0,0,1) is

the corresponding principal strain direction. The other two principal strains can be found

from the eigen value problem in 2D strain state:

xy

0

nx

[ I]{n} xx

n 0

yy

xy

y

Two principal strains are calculated from the condition that the determinant of the

2

0 . The solution of the quadratic

coefficient matrix is zero: (xx )(yy ) xy

equation becomes 1 = 0.0011 and 2 = 0.0007. Thus, the three principal strains are 1 =

0.0011, 2 = 0.000171, and 3 = 0.0007. Two principal directions can be obtained from

the original eigen value problem. Adding z-axis, the three principal directions are

0.961

n 0.276

,

n 0

,

0.276

n 0.961

(c) Principal stresses

For plane stress condition, z = 0 is a principal stress and the z-axis (0,0,1) is the

corresponding principal direction. The other principal stresses and the directions can be

found by solving the following eigen value problem:

xy

nx

0

I {n} xx

yy

xy

ny

0

Two principal stresses are calculated from the condition that the determinant of the

2

0 . The solution of the quadratic

coefficient matrix is zero: (xx )(yy ) xy

equation becomes 1 = 70.8 and 2 = 30.8. Thus, the three principal stresses are 1 =

70.8 MPa, 2 = 0.0 MPa, and 3 = 30.8 MPa. Two principal directions can be obtained

from the original eigen value problem. Adding z-axis, the three principal directions are

0.961

n 0.276

,

n 0

,

0.276

n 0.961

For isotropic materials, principal stress directions and principal strain directions are the

same.

(d) Principal Stress-strain relations

From Eq. (1.55), the stress-strain relation can be written as

1

0.0011

0.0002

2

2

E

1

0.0007

3

3

56

Finite Element Analysis and Design

Also, all shear strains and stresses are zero because they are in the principal directions.

Thus, the stress-strain relation satisfies in the principal stresses and strains.

CHAP 1 Stress-Strain Analysis

57

24. A strain rosette consisting of three strain gages was used to measure the strains at a

point in a thin-walled plate. The measured strains in the three gages are: A = 0.016,

B = 0.004, and C = 0.016. Determine the complete state of strains and stresses (all

six components) at that point. Assume E = 100 GPa and = 0.3.

A

y

120

120o

B

x

Solution:

(a) The angle and direction cosines of each rosette are listed in the table below.

nx

ny

o

A

90

0

1

o

1 / 2

B

210

3/2

o

1 / 2

C

-30

3/2

Then, we can use the following transformation equation to related Cartesian components

to the strains in the rosettes

nn () x cos2 y sin2 xy sin cos

xx nx2 yy ny2 xy nx ny

The three rosette equations become

y A 16 103

B x

3

1

3

y xy

4 103

4

4

4

C x

3

1

3

y xy

16 103

4

4

4

The last two equations can be solved for the shear strain as

xy

3

12 103

2

xy

24

3

103 13.86 103

Then, from the second equation, we have

x

3

4 106 6 103 4 103

4

x 8 103

58

Finite Element Analysis and Design

Since it is the plane stress condition, z yz zx 0 .

relation for the plane stress problem, we have

From the stress-strain

3

9

x

E 1 x 100 10 1 0.3 8 10

1 0.09 0.3 1 16 103

y 1 2 1 y

1.407

100 106 12.8 1407

GPa

106

1 0.09 18.4 2022

2.022

xy G xy

E

100 109

xy

13.86 103 0.533 GPa .

2(1 )

2.6

yz

yz

G

0,

zx

zx

G

0.3

(x y )

(1.407 2.022) 109 0.01 .

9

E

100 10

CHAP 1 Stress-Strain Analysis

59

25. A strain rosette consisting of three strain gages was used to measure the strains at a

point in a thin-walled plate. The measured strains in the three gages are: A = 0.008,

B = 0.002, and C = 0.008. Determine the complete state of strains and stresses (all

six components) at that point. Assume E = 100 GPa and = 0.3.

o

B 120

y

A

120o

C

x

Solution:

(a) The angle and direction cosines of each rosette are listed in the table below.

nx

ny

o

A

0

1

0

o

1 / 2

B

120

3/2

o

1 / 2

C

240

3/2

Then, we can use the following transformation equation to relate the strains measured by

the strain gages to the strain components:

nn () x cos2 y sin2 xy sin cos

xx nx2 yy ny2 xy nx ny

The three rosette equations become

x A 8 103

B x

1

3

3

y xy ( ) 2 103

4

4

4

C x

1

3

3

y xy

8 103

4

4

4

The last two equations can be solved for the shear strain as

xy

3

6 103

2

xy

12

3

103 6.93 103

Then, from the second equation, we have

8

3

106 x xy

4 103

3

3

3

60

Finite Element Analysis and Design

Since it is the plane stress condition, z yz zx 0 .

relation for the plane stress problem, we have

From the stress-strain

3

9

x

E 1 x 100 10 1 0.3 8 10

1 0.09 0.3 1 16 103

y 1 2 1 y

1.011

100 106 9.2 9.2

GPa

1.099 108

1 0.09 6.4 6.4

0.703

xy G xy

yz

z

yz

G

E

0.267 GPa .

2(1 ) xy

0,

zx

zx

G

( y ) 5.142 103 .

E x

CHAP 1 Stress-Strain Analysis

61

26. The figure below illustrates a thin plate of thickness t. An approximate displacement

field, which accounts for displacements due to the weight of the plate, is given by

(2bx x 2 y 2 )

2E

uy (x , y ) y(b x )

E

ux (x , y )

(a) Determine the corresponding plane stress field.

(b) Qualitatively draw the deformed shape of the plate.

Solution:

(a) From the definition of strain

yy

xy

ux

(b x )

x

E

uy

(b x )

y

E

uy

1 u

0

x

2 y

x

xx

Also, from the stress-strain relation for the plane stress problem,

xx

yy

1 2

xy

0 0

(b x )

xx

yy

0

(1

xy

0

0

Thus, xx (b x ) is the only non-zero stress component.

(b) The deformed geometry is sketched below

62

Finite Element Analysis and Design

CHAP 1 Stress-Strain Analysis

27. The stress matrix at a particular point in a body is

2 1 3

[ ] 1 0 4 107 Pa

3 4 5

Determine the corresponding strain if E = 20 1010 Pa and = 0.3.

Solution:

xx

1

1

[ (yy zz )]

[2 0.3(0 5)] 107 1.75 104

11

E xx

2 10

yy

1

1

[yy (xx zz )]

[0 0.3(2 5)] 107 4.5 105

11

E

2 10

zz

1

1

[zz (xx yy )]

[5 0.3(2 0)] 107 2.8 104

11

E

2 10

xy

2(1 )

2(1 0.3)

xy

1 107 1.3 104

E

2 1011

yz

2(1 )

2(1 0.3)

yz

4 107 5.2 104

E

2 1011

xz

2(1 )

2(1 0.3)

xz

(3) 107 3.9 104

11

E

2 10

63

64

Finite Element Analysis and Design

28. For a plane stress problem, the strain components in the xy plane at a point P are

computed as

xx yy .125 102 , xy .25 102

(a) Compute the state of stress at this point if Youngs modulus E = 21011 Pa and

Poissons ratio = 0.3.

(b) What is the normal strain in the zdirection?

(c) Compute the normal strain in the direction of n = {1, 1, 1}T.

Solution:

(a) Compute the state of stress at this point if Youngs modulus E = 21011 Pa and

Poissons ratio = 0.3

xx

yy

xy

zz xz yz

357

0

xx

1

0

357

10 Pa

yy

0 (1 ) / 2

xy

385

0 (Plane Stress)

(b) What is the normal strain in the z-direction?

zz

( yy ) 0.1071 102

E xx

(c) Compute the normal strain in the direction of n = {1, 1, 1}T

n

{1, 1, 1}T

3

nn n [] n 0.2143 102

CHAP 1 Stress-Strain Analysis

65

29. The state of stress at a point is given by

80 20 40

[ ] 20 60 10 MPa

40 10 20

(a) Determine the strains using Youngs modulus of 100 GPa and Poissons ratio of

0.25.

(b) Compute the strain energy density using these stresses and strains.

(c) Calculate the principal stresses.

(d) Calculate the principal strains from the strains calculated in (a).

(e) Show that the principal stresses and principal strains satisfy the constitutive

relations.

(f) Calculate the strain energy density using the principal stresses and strains.

Solution:

(a) From Eq. (1.53),

xx

.25 .25

80

0.6

1

6

3

.25

1

.25

60

10

10

0.35

yy

11

10

.25

.25

1

20

0.15

zz

xy

xy

0.5 103

G

yz

yz

1.0 103

G

zx zx 0.25 103

G

(b) Strain energy density:

U

1

yy yy zz zz xy xy yz yz xz xz 59.25kPa

2 xx xx

(c) Principal stresses: 1 110,

(d)

Strain matrix:

[ ] 103

2 50,

3 0 MPa

0.6 0.25

0.5

0.25 0.35 0.125

0.5 0.125 0.15

Principal strains: 1 0.975 103 , 2 0.225 103 , 3 0.4 103

(e) From Eq. (1.55)

66

Finite Element Analysis and Design

.25 .25

110

1

0.975

1

6

3

.25

1

.25

50

10

10

0.225

2

11

10

.25

.25

1

0

0.4

Thus, the principal stresses and principal strains satisfy the constitutive relations.

(f) Strain energy density

U

1

22 33 59.25kPa

2 1 1

CHAP 1 Stress-Strain Analysis

67

30. Consider the state of stress in Problem 29 above. The yield strength of the material is

100 MPa. Determine the safety factors according to the following: (a) maximum

principal stress criterion, (b) Tresca Criterion, and (c) von Mises criterion.

Solution:

(a) Maximum principal stress criterion

SF

Y

1

0.91

(b) Tresca criterion

Y

2

50,

max

110 0

55,

2

SF

Y

max

0.91

(c) Von Mises criterion

12 22 32 12 23 13 95.39

VM

SF

Y

VM

1.048

68

Finite Element Analysis and Design

31. A thin-walled tube is subject to a torque T. The only non-zero stress component is

the shear stress xy, which is given by xy = 10,000 T (Pa), where T is the torque in

N.m. When the yield strength Y = 300 MPa and the safety factor N = 2, calculate the

maximum torque that can be applied using

(a) Maximum principal stress criterion (Rankine)

(b) Maximum shear stress criterion (Tresca)

(c) Distortion energy criterion (Von Mises)

Solution:

Since it is a pure shear stress state, the three principal stresses are

1 xy , 2 0, 3 xy

(a) Maximum stress criterion,

1 xy

T

xy

10, 000

Y

N

Y

10, 000N

15, 000 N m

(b) Maximum shear stress criterion

xy

T

2N

2

Y

20, 000N

10, 000T

7, 500 N m

(c) Von Mises criterion

VM

xy

2

3xy

Y

N

10, 000T

3N

T 8, 660 N m

CHAP 1 Stress-Strain Analysis

69

32. A thin-walled cylindrical pressure vessel with closed ends is subjected to an internal

pressure p = 100 psi and also a torque T around its axis of symmetry. Determine T

that will cause yielding according to von Mises yield criterion. The design requires a

safety factor of 2. The nominal diameter D of the pressure vessel = 20 inches, wall

thickness t = 0.1 inch, and yield strength of the material = 30 ksi. (1 ksi = 1000 psi).

Stresses in a thin walled cylinder are: longitudinal stress l, hoop stress h, and shear

stress due to torsion. They are given by

l

pD

pD

2T

, h

,

4t

2t

D 2t

Solution:

pD

5, 000 psi

4t

pD

h

10, 000 psi

2t

2T

D 2t

xx l

yy

xy

VM

2

2

2

xx

yy

xx yy 3xy

Y

N

xy 7.071 103 psi

1

D 2t 444 103 lb-in

2 xy

Y

2

15, 000

70

Finite Element Analysis and Design

33. A coldrolled steel shaft is used to transmit 60 kW at 500 rpm from a motor. What

should be the diameter of the shaft, if the shaft is 6 m long and is simply supported at

its ends? The shaft also experiences bending due to a distributed transverse load of

200 N/m. Ignore bending due to the weight of the shaft. Use a factor of safety 2.

The tensile yield limit is 280 MPa. Find the diameter using both maximum shear

stress theory and von Mises criterion for yielding.

Solution:

Note that in the below solution, failure will be governed by shear stresses due to torsion

and bending stresses from the distributed load. We will ignore the effects of transverse

shear stresses due to the distributed load, as it will be negligible compared to the bending

stresses and shear stresses due to torsion.

po = 200 N/m

R = poL/2

L/2

The maximum bending moment will occur at the center of the shaft, whose magnitude is

p L L p L L

p L2

M max o o o 900N-m

8

2 2 2 4

In addition, the applied torque can be calculated from the power, as

Power T

T 60000

60

1,146N-m

2(500)

Two stress components, xx and xy, can be calculated using the bending moment and

torque, as

x

M D2

Mr

32M

9167

Pa

4

3

I

D

D

D3

64

xy

T D2

Tr

5837

Pa

J

D 4

D3

32

(a) Max distortional energy theory: Since there are only two non-zero components of

stress, von Mises stress can be calculated by

CHAP 1 Stress-Strain Analysis

vm

2

x2 3xy

71

Substituting stress components in the above expression, we can solve for the unknown

diameter, D = 46.02 mm.

(b) Maximum shear stress criterion: In order to calculate the maximum shear stress, the

principal stresses are calculated first

1,2

x

2

2

x

2

2

xy

Then, the maximum shear stress becomes

max

max min

2

Y / 2

N

Y / 2

2

By substituting stress components in the above expression, we can solve for the unknown

diameter, D = 47.33 mm.

72

Finite Element Analysis and Design

34. For the stress matrix below, the two principal stresses are given as 1 = 2 and 3 = 3,

respectively. In addition, two principal directions corresponding to the two principal

stresses are also given below. The yield stress of the structure is given as Y = 4.5.

2

1

1 0 2

5

5

[ ] 0 1 0 , n1 0 and n 3 0

2 0 2

2

1

5

5

(a) Calculate the safety factor based on the maximum shear stress theory and

determine whether the structure is safe or not.

(b) Calculate the safety factor based on the distortion energy theory and determine

whether the structure is safe or not.

Solution: Continuation from Problem 9.

From Problem 9, 1 2, 2 1, 3 3 . Thus, the von Mises stress becomes

VM 22 12 (3)3 (2 1 1 3 2 3) 21 . Also, the maximum shear

stress becomes max (1 3 ) / 2 2.5 .

(1) N

Y

max

(2) NVM

Y

max

2.25

0.9 . Thus, the structure is not safe.

2.5

4.5

21

0.982 . Thus, the structure is not safe.

CHAP 1 Stress-Strain Analysis

73

35. The figure below shows a shaft of 1.5 in. diameter loaded by a bending moment Mz =

5,000 lbin, a torque T = 8,000 lbin, and an axial tensile force N = 6,000 lb. If the

material is ductile with the yielding stress Y = 40,000 psi, determine the safety factor

using: (a) the maximum shear stress theory and (b) the maximum distortion energy

theory.

y

N

Mz

Mz

Solution:

From the given loading conditions, the magnitude of shear will be the same for all outer

surfaces, whereas the bottom surface will have the maximum tensile stress due to bending

and tension. Thus, if the material fails, it will fail at the bottom surface first. Lets take an

infinitesimal rectangle at the bottom surface. Then, the non-zero stress component will be

xx and xz .

xz

z

xx

xz

xx

xz

xz

Each component of stress can be calculated from the mechanics of materials by

M r N

32 5000 4 6000

18, 486 psi

I

A

(1.5)3

(1.5)2

T r

16 8000

12, 072 psi

J

(1.5)3

xx

xz

Principal stresses

xx 0 xz

2

0

0 (2 xx xz

)0

xz

0

2

2

xx xx

4xz

24, 447, 2 0, 3 5, 961 psi

(a) The maximum shear stress theory

max

N

1 3

Y

max

15, 204 psi

20, 000

1.315

15, 204

74

Finite Element Analysis and Design

(b) Maximum distortion energy theory

244472 (5961)2 24447(5961) 27, 909 psi

40, 000

1.4332

27, 909

VM

NVM

CHAP 1 Stress-Strain Analysis

75

36. A 20-mm. diameter rod made of a ductile material with a yield strength of 350 MPa

is subject to a torque of T = 100 Nm and a bending moment of M = 150 Nm. An

axial tensile force P is then gradually applied. What is the value of the axial force

when yielding of the rod occurs? Solve the problem two ways using (a) the

maximum shear stress theory and (b) the maximum distortional energy theory.

y

Mz

Mz

Solution:

(a) The yielding occurs at the bottom surface in which both M and P produce tensile

stress. At this bottom surface, the stress components are

xz

32M

4P

191 106 3183P

d

d 2

16T

63.662 106

d 3

xx

And all other components are zero. Now, the maximum shear stress is expressed in term

of stress components:

max

1 3

2

1

2

2

xx

4xy

175

2

In the above equation, the following relations are used:

2

2

xx xx

4xz

, 3

2

2

xx xx

4xz

2

2

xx

3502 4xz

Then,

The above equation can be solved for axial force P = 41,413 N.

(b) The von Mises stress can be written in terms of stress components, as

VM

12 32 13

2

2

xx

3xz

350 106

xx 332 106 191 106 3183N

After solving for the axial force, we have P = 44,353 N. The distortion energy theory

allows a larger axial force.

76

Finite Element Analysis and Design

37. A circular shaft of radius r in the figure has a moment of inertia I and polar moment

of inertia J. The shaft is under torsion Tz in the positive z-axis and bending moment

Mx in the positive x-axis. The material is mild steel with yield strength of 2.8 MPa.

Use only the given coordinate system for your calculations.

(a) If Tz and Mx are gradually increased, which point (or points) will fail first among

four points (A, B, C, and D)? Identify all.

(b) Construct stress matrix []A at point A in xyz-coordinates in terms of given

parameters (i.e., Tz, Mx, I, J, and r).

(c) Calculate three principal stresses at point B in terms of given parameters.

(d) When the principal stresses at point C are 1 = 1, 2 = 0, and 3 = 2 MPa,

calculate safety factors (1) from maximum shear stress theory and (2) from

distortion energy theory.

z

x

A

D x

Tz

y

C

Mx

Solution:

(a) The bending moment will produce maximum stress at points A and C. Thus, A and

C will fail first.

(b) At point A, non-zero stress components are

xx

Mxr

I

xz

Tz r

J

Thus, the stress matrix becomes

M r / I

x

[ ]

0

T r /J

z

0 Tz r / J

0

0

0

0

(c) At point B, only non-zero stress component is

yz

Tz r

J

Thus, the three principal stresses are

1

Tz r

J

2 0,

(d) For maximum shear stress criterion,

Tz r

J

CHAP 1 Stress-Strain Analysis

max

1 3

2

Y

max

1.5,

Y

2

77

1.4

0.933

For von Mises criterion,

12 22 32 12 23 13

N Y 1.06

VM

VM

7 2.645

78

Finite Element Analysis and Design

38. A rectangular plastic specimen of size 10010010 mm3 is placed in a rectangular

metal cavity. The dimensions of the cavity are 1011019 mm3. The plastic is

compressed by a rigid punch until it is completely inside the cavity. Due to Poisson

effect, the plastic also expands in the x and y directions and fills the cavity. Calculate

all stress and strain components and the force exerted by the punch. Assume there is

no friction between all contacting surfaces. The metal cavity is rigid. Elastic

constants of the plastic are E = 10 GPa, = 0.3.

Rigid punch

Rigid punch

Plastic

Rigid die

Plastic

F

Rigid die

Solution:

The strains in the specimen are calculated as the ratio of change in length to original

length.

zz

9 10

10

0.1, xx yy

101 100

100

0.01

We have assumed that the plastic expands laterally and fill the cavity completely. If it

does not, then we will get positive values for xx and/or yy, which will indicate that our

assumption is wrong. Then we can assume xx and/or yy = 0, and redo the problem and

obtain corresponding strains xx and/or yy which will be less than that calculated above.

Since there is no friction between contacting surfaces, all shear stresses and hence all

shear strains will be identically equal to zero.

The normal stresses can be obtained from three-dimensional stress strain elations:

1 z

Substituting for the strains and elastic constants E and we obtain the stresses as

{xx

yy

xx } {385 385 1, 231} MPa

Since xx and yy are negative (compressive), our initial assumption about the strains is

correct. The punch force is obtained from z and the area of cross section:

F Az 0.1 0.1 1, 231 12.31 MN

CHAP 1 Stress-Strain Analysis

79

80

Finite Element Analysis and Design

39. Repeat Problem 38 with elastic constants of the plastic as E = 10 GPa and = 0.485.

Solution:

The strains in the plastic specimen are calculated as the ratio of change in length to

original length.

z

9 10

10

0.1, x y

101 100

100

0.01

We have assumed that the plastic expands laterally and fill the cavity completely. If it

does not, then we will get positive values for xx and/or yy, which will indicate that our

assumption is wrong. Then we can assume xx and/or yy = 0, and reiterate the problem

and obtain corresponding strains xx and/or yy which will be less than that calculated

above.

Since there is no friction between contacting surfaces, all shear stresses and hence all

shear strains will be identically equal to zero.

The normal stresses can be obtained from three-dimensional stress strain relations:

Substituting for the strains and elastic constants E and we obtain the stresses as

{xx

yy

xx } {8, 642 8, 642 9, 383} MPa

Since xx and yy are negative (compressive), our initial assumption about the strains is

correct. The punch force is obtained from zz and the area of cross section:

F Az 0.1 0.1 9, 383 93.83 MN

Note: Punch force for this problem is almost 8 times that for Problem 38. The increase is

due to Poissons ratio. As the material compressibility decreases, Poissons ratio

increases. For example, as 0.5 the material becomes incompressible, i.e., its

volume cannot be changed, and the stresses become unbounded. Note the term 1 2

in the denominator of the above constitutive relation.

CHAP 1 Stress-Strain Analysis

81

40. Repeat Problem 38 with the specimen of size 10010010 mm3 and the dimensions

of the cavity 1041049 mm3. Elastic constants of the plastic are E = 10 GPa, =

0.3.

Solution:

The strain in the z-direction remains the same as z (9 10) / 10 0.1 . As before,

if we assume that the specimen fills the cavity completely, the strains will be

x y

104 100

100

0.04,

The stresses are calculated using

1 1 2

We obtain {xx yy xx } {192 192 885} MPa .

The above stresses are not physically possible as the cavity walls cannot exert tensile

stresses on the specimen. We will repeat the calculations with x y 0 . This is

actually uniaxial state of stress, and the strains are obtained as x y z 0.03 .

The extension of the plate in the x and y-directions is given by

x x 104 0.03 3.12 mm . Note that the expansion of the specimen is less

than the 4 mm-clearance.

Das könnte Ihnen auch gefallen

- ST7201-Finite Element Analysis PDFDokument14 SeitenST7201-Finite Element Analysis PDFMadhan KumarNoch keine Bewertungen

- ME 2353 Finite Element FormulasDokument19 SeitenME 2353 Finite Element FormulasSHAIK NISHARNoch keine Bewertungen

- Matrices and System of Linear Equations PDFDokument20 SeitenMatrices and System of Linear Equations PDFMuhammad IzzuanNoch keine Bewertungen

- Shape Functions in Finite Element AnalysisDokument22 SeitenShape Functions in Finite Element AnalysissyampnaiduNoch keine Bewertungen

- From Structural Analysis To Finite Element MethodDokument25 SeitenFrom Structural Analysis To Finite Element MethodB S Praveen BspNoch keine Bewertungen

- Solution Manual For Introduction To Finite Element Analysis and Design - Nam H. Kim and Bhavani v. SankarDokument20 SeitenSolution Manual For Introduction To Finite Element Analysis and Design - Nam H. Kim and Bhavani v. SankarSaleh0% (2)

- 2018 Grade 10 Physics Notes PDFDokument136 Seiten2018 Grade 10 Physics Notes PDFSalifyanji100% (3)

- Stability of Structures FE-based Stability AnalysisDokument40 SeitenStability of Structures FE-based Stability AnalysisEsmar Cantu NetoNoch keine Bewertungen

- Statics ReviewDokument4 SeitenStatics Reviewsamir_ssh7151Noch keine Bewertungen

- FINITE BUCKLING ANALYSIS OF NON-UNIFORM COLUMNSDokument8 SeitenFINITE BUCKLING ANALYSIS OF NON-UNIFORM COLUMNSumeshapkNoch keine Bewertungen

- Numerical ExamplesDokument20 SeitenNumerical ExampleslitrakhanNoch keine Bewertungen

- Ansys Lab Manual BvcoekDokument26 SeitenAnsys Lab Manual Bvcoekavinash 879Noch keine Bewertungen

- Solution Manual Shigleys Mechanical Engineering Design 10th Edition by Budynas PDFDokument23 SeitenSolution Manual Shigleys Mechanical Engineering Design 10th Edition by Budynas PDFAbhinash KumarNoch keine Bewertungen

- G. I. Epifanov - Solid State Physics (1979, Mir Publisher)Dokument345 SeitenG. I. Epifanov - Solid State Physics (1979, Mir Publisher)puceiroaleNoch keine Bewertungen

- C05 - Stationary Potential EnergyDokument73 SeitenC05 - Stationary Potential Energyyttan1116Noch keine Bewertungen

- Finite Element AnalysisDokument34 SeitenFinite Element Analysisramamoorthy2587Noch keine Bewertungen

- Differential Geometry:: Delaunay Triangulations and The Laplace-Beltrami OperatorDokument56 SeitenDifferential Geometry:: Delaunay Triangulations and The Laplace-Beltrami OperatorTrần HươngNoch keine Bewertungen

- Bolotin VV-The Dynamic Stability of Elastic SystemsDokument455 SeitenBolotin VV-The Dynamic Stability of Elastic Systemshspanda100% (2)

- AE321 Homework SolutionsDokument13 SeitenAE321 Homework SolutionsArthur Ding100% (1)

- Homework 8Dokument3 SeitenHomework 8Arthur DingNoch keine Bewertungen

- Lecture Notes FEMDokument153 SeitenLecture Notes FEMVijendraAgarNoch keine Bewertungen

- Chapter 4 Multiple Degree of Freedom SystemsDokument89 SeitenChapter 4 Multiple Degree of Freedom SystemsTom LaNoch keine Bewertungen

- Chapter 9: Stress Transformation in Shafts and BeamsDokument27 SeitenChapter 9: Stress Transformation in Shafts and BeamsYahia Raad Al-AniNoch keine Bewertungen

- Assignment Booklet Me2353 Finite Element Analysis Dec 2013 May 2014Dokument85 SeitenAssignment Booklet Me2353 Finite Element Analysis Dec 2013 May 2014Ashok Kumar Rajendran100% (9)

- 05-Bar Element DuzeltilmisDokument56 Seiten05-Bar Element Duzeltilmismmk111Noch keine Bewertungen

- Minimum Potential EnergyDokument9 SeitenMinimum Potential EnergyBright MuzaNoch keine Bewertungen

- Chapter 8 - Types of Finite Elements - A4Dokument9 SeitenChapter 8 - Types of Finite Elements - A4GabrielPaintingsNoch keine Bewertungen

- Introduction to Variational Calculus and Variational Formulations in FEM (39Dokument49 SeitenIntroduction to Variational Calculus and Variational Formulations in FEM (39Ranjit Koshy AlexanderNoch keine Bewertungen

- Mechanics of MaterialsDokument282 SeitenMechanics of MaterialssydengineerNoch keine Bewertungen

- Chapter 5 Airy Stress FunctionDokument19 SeitenChapter 5 Airy Stress FunctionGilang Farhan Ramadhan MulyadiNoch keine Bewertungen

- Assignment 3 SolutionDokument9 SeitenAssignment 3 SolutionMurat BayrakNoch keine Bewertungen

- Finit Element Analysis MatlabDokument3 SeitenFinit Element Analysis MatlabAntehun MekonnenNoch keine Bewertungen

- Fea QBDokument11 SeitenFea QBPradeepNoch keine Bewertungen

- NPTEL Basics of FEM - I Week 4 SolutionsDokument18 SeitenNPTEL Basics of FEM - I Week 4 SolutionsVISMAY KG MechNoch keine Bewertungen

- Introduction To Finite Element Methods, 1/e: Book Information Sheet Book Information SheetDokument2 SeitenIntroduction To Finite Element Methods, 1/e: Book Information Sheet Book Information SheetVaibhavNoch keine Bewertungen

- Solution Manual For Introduction To Nonlinear Finite Element Analysis - Nam-Ho KimDokument10 SeitenSolution Manual For Introduction To Nonlinear Finite Element Analysis - Nam-Ho KimSalehNoch keine Bewertungen

- Matlab Code For Truss Problem, Generalised ProgramDokument2 SeitenMatlab Code For Truss Problem, Generalised ProgramShivdayal Patel80% (5)

- Chapter 6 Bending: Moments Forces Perpendicular To AxisDokument13 SeitenChapter 6 Bending: Moments Forces Perpendicular To AxisSumaya MahmoodNoch keine Bewertungen

- Point Collocation Method Used in Solving Differential Equations in Boundary Value ProblemsDokument12 SeitenPoint Collocation Method Used in Solving Differential Equations in Boundary Value ProblemsSuddhasheel Basabi GhoshNoch keine Bewertungen

- ME Structures Theory Elasticity PlasticityDokument3 SeitenME Structures Theory Elasticity PlasticityameykatdareNoch keine Bewertungen

- Minimum Potential Energy PrincipleDokument29 SeitenMinimum Potential Energy Principlemahesh84psgNoch keine Bewertungen

- Chapter 01Dokument38 SeitenChapter 01Bu sultanNoch keine Bewertungen

- Homework 4Dokument2 SeitenHomework 4Arthur DingNoch keine Bewertungen

- FEM Notes5Dokument65 SeitenFEM Notes5Debasis SahaNoch keine Bewertungen

- 11-Stability of ColumnsDokument41 Seiten11-Stability of Columnsali381Noch keine Bewertungen

- Finite Element Method (10ME64)Dokument72 SeitenFinite Element Method (10ME64)varun karthikeyanNoch keine Bewertungen

- PB 2 Rayleigh Ritz Method For General Plate Analysis 1993Dokument6 SeitenPB 2 Rayleigh Ritz Method For General Plate Analysis 1993ciscoNoch keine Bewertungen

- Theory of Elasticity: Solve The Following Problems. All Problems Are Having Equal Marks. Total Mark 100 PtsDokument7 SeitenTheory of Elasticity: Solve The Following Problems. All Problems Are Having Equal Marks. Total Mark 100 PtsAshebir Asrat100% (1)

- Matrix Derivation of Spring FormulaDokument7 SeitenMatrix Derivation of Spring FormulanoormqNoch keine Bewertungen

- Text Bookof Finite Element Analysis by P. Seshu PDFDokument342 SeitenText Bookof Finite Element Analysis by P. Seshu PDFChetan HcNoch keine Bewertungen

- Finite Element Analysis of Structures and Heat Transfer ProblemsDokument11 SeitenFinite Element Analysis of Structures and Heat Transfer Problemssimalaravi100% (2)

- Lecture 2 Theory of PlasticityDokument16 SeitenLecture 2 Theory of PlasticityprashanthattiNoch keine Bewertungen

- Finite Element MethodsDokument12 SeitenFinite Element Methodspraneeth4a100% (1)

- Response To Arbitrary, Step, and Pulse Excitations: Part A: Response To Arbitrarily Time-Varying ForcesDokument40 SeitenResponse To Arbitrary, Step, and Pulse Excitations: Part A: Response To Arbitrarily Time-Varying ForcesMakaraSoyNoch keine Bewertungen

- Finite Element Method Axially Loaded RodsDokument22 SeitenFinite Element Method Axially Loaded RodshalimsevimNoch keine Bewertungen

- Viscoplastic Model LS-DynaDokument14 SeitenViscoplastic Model LS-DynaJoe SatchNoch keine Bewertungen

- Homework 5Dokument2 SeitenHomework 5Arthur DingNoch keine Bewertungen

- Finite Element Analysis Test PaperDokument3 SeitenFinite Element Analysis Test Paperjb_mitmNoch keine Bewertungen

- 307 Tutorial2 2014 PDFDokument9 Seiten307 Tutorial2 2014 PDFNusret MeydanlikNoch keine Bewertungen

- StressDokument42 SeitenStressNauman SuriaNoch keine Bewertungen

- 1346-600 6.5 - Track Saw - 10 AmpDokument26 Seiten1346-600 6.5 - Track Saw - 10 AmpSiamakNoch keine Bewertungen

- Electric Vehicle Powertrain Architecture and ContrDokument13 SeitenElectric Vehicle Powertrain Architecture and Contrדרור טפירוNoch keine Bewertungen

- Hindi: Everwin Group of Schools - Class IxDokument2 SeitenHindi: Everwin Group of Schools - Class IxraehaanNoch keine Bewertungen

- Renewable Energy: Salih N. Akour, Mohammed Al-Heymari, Talha Ahmed, Kamel Ali KhalilDokument9 SeitenRenewable Energy: Salih N. Akour, Mohammed Al-Heymari, Talha Ahmed, Kamel Ali KhalilJuan ApzNoch keine Bewertungen

- Differential Geometry Theorem and ApplicationsDokument92 SeitenDifferential Geometry Theorem and ApplicationsJuan David MesaNoch keine Bewertungen

- Bomba 750 GPM 110 PSIDokument1 SeiteBomba 750 GPM 110 PSIEDWIN HUMBERTO QUICENO CANONoch keine Bewertungen

- Bode Plots Lecture Notes Study MaterialDokument9 SeitenBode Plots Lecture Notes Study MaterialShivam GaunsNoch keine Bewertungen

- Technical Specifi Cations: SympatecDokument3 SeitenTechnical Specifi Cations: SympatecMiguel RomanNoch keine Bewertungen

- Biomass Gasification Solver Based On OpeDokument29 SeitenBiomass Gasification Solver Based On OpeIsraelNoch keine Bewertungen

- Space Power Satellite-Japanese ScientistsDokument10 SeitenSpace Power Satellite-Japanese ScientistsUmair MansoorNoch keine Bewertungen

- Welding StudsDokument80 SeitenWelding StudscongtubatdaNoch keine Bewertungen

- Differential Equation Part 2Dokument25 SeitenDifferential Equation Part 2ABHRANEEL KARMAKARNoch keine Bewertungen

- XENOY™ Resin 1760E - AmericasDokument4 SeitenXENOY™ Resin 1760E - AmericasWellington C. de AraujoNoch keine Bewertungen

- Dissertation Maria Gaschler 2017Dokument182 SeitenDissertation Maria Gaschler 2017martadinata89Noch keine Bewertungen

- Year 8. End of Semester Exam Final VersionDokument20 SeitenYear 8. End of Semester Exam Final VersionAlejandro EspiNoch keine Bewertungen

- Coordination of Virtual Inertia Control and Frequency Damping in PV Systems For Optimal Frequency SupportDokument12 SeitenCoordination of Virtual Inertia Control and Frequency Damping in PV Systems For Optimal Frequency SupportLucas Adriano Maciel Dos SantosNoch keine Bewertungen

- MRAFF ProcessDokument9 SeitenMRAFF ProcessAnupam AlokNoch keine Bewertungen

- Fiber Laser Recent-Improvements and Applications PhotonicsDokument21 SeitenFiber Laser Recent-Improvements and Applications PhotonicsFausto EstradaNoch keine Bewertungen

- Burke - 2021 - JEnergyStorage-Past Present and Future of Electrochemical Capacitors TechnologiesDokument24 SeitenBurke - 2021 - JEnergyStorage-Past Present and Future of Electrochemical Capacitors TechnologiesvituruchNoch keine Bewertungen

- WinnerDokument26 SeitenWinnerNguyễn Tấn PhátNoch keine Bewertungen

- Introduction To DataFRACDokument29 SeitenIntroduction To DataFRACTarak AbuziadNoch keine Bewertungen

- Question: Figure Shows The Spring-Mass Damper System of Two DegreeDokument3 SeitenQuestion: Figure Shows The Spring-Mass Damper System of Two DegreeMoney GamesNoch keine Bewertungen

- YEAR PLAN - 10 (2023-2024) Mathematics WMDokument4 SeitenYEAR PLAN - 10 (2023-2024) Mathematics WMMurali KrishnaNoch keine Bewertungen

- Acta Materialia: Full Length ArticleDokument16 SeitenActa Materialia: Full Length ArticleDeepak SharmaNoch keine Bewertungen

- 4PH0 2PR Rms 20160824Dokument14 Seiten4PH0 2PR Rms 20160824Nay Chi HtetNoch keine Bewertungen

- Physics For Scientists and Engineers, 6e Chapter 11 - Angular MomentumDokument15 SeitenPhysics For Scientists and Engineers, 6e Chapter 11 - Angular MomentumHoàng HàNoch keine Bewertungen

- Force and Motion Engineering InternshipDokument67 SeitenForce and Motion Engineering InternshiptmutawiNoch keine Bewertungen

- PINOYBIX SATELLITE COMMUNICATION QuestionDokument47 SeitenPINOYBIX SATELLITE COMMUNICATION QuestionCamille VeaNoch keine Bewertungen