Beruflich Dokumente

Kultur Dokumente

MGP Chapter3 Wastewater Treatment Overview Jan 2005

Hochgeladen von

sauroOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

MGP Chapter3 Wastewater Treatment Overview Jan 2005

Hochgeladen von

sauroCopyright:

Verfügbare Formate

NATIONAL MANUAL OF GOOD PRACTICE FOR BIOSOLIDS

Chapter 3 - Wastewater Treatment Overview

The treatment of wastewater, the processing of solids generated and use or disposal of biosolids

must be considered as a system designed to produce two products: clean water that can be reused

or released into the environment, and biosolids. Wastewater treatment facility processes have a

significant impact on biosolids characteristics. Careful consideration must be given when

evaluating changes to either the liquid or solids handling system as one impacts the other. If

changes are done correctly, the processes will complement each other.

This manual addresses wastewater treatment as one location on the biosolid value chain. The

four primary processes (sections) within this location (chapter) are pretreatment and pollution

prevention, liquid stream as it relates to solids management; solids generation; and septage

handling.

This chapter is not intended to fully explain each of the process associated with wastewater

treatment, but rather to highlight the relationship between influent characteristics, wastewater

treatment and biosolids management. The processes associated with wastewater treatment that

relate to biosolids management include:

Pretreatment and pollution prevention programs

Liquid stream impact on solids management

Primary solids generation

Secondary solids generation

Tertiary solids generation

Solids processing side stream characteristics

Septage handling

3.1 Pretreatment and Pollution Prevention Programs

Influent characteristics are crucial to wastewater treatment and solids management. Waste

diversion and pretreatment programs are designed to remove pollutants at their source, protecting

the public investment in a wastewater treatment facility. Pretreatment also reduces the potential

for process upsets and enhances biosolids characteristics.

Pretreatment programs were established by the USEPA in 1978 (requirements were set forth in

40CFR Part 403), requiring industrial users to limit the discharge of certain pollutants. The

regulation addresses metals within wastewater along with organic chemicals. Pollution

prevention programs are designed to reduce or eliminate the discharge of certain contaminants.

In addition to protecting the wastewater

treatment facilities, pollution prevention

often results in savings to the industry

implementing the programs.

The implementation of pretreatment and

pollution prevention programs have had a

significant positive impact on the

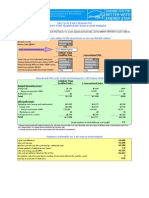

characteristics of biosolids generated. Table 3.1 compares the results of two surveys conducted

Chapter 3

Page 1

NATIONAL MANUAL OF GOOD PRACTICE FOR BIOSOLIDS

to assess the characteristics of biosolids. The 40-city study was conducted in 1979 and 1980. The

study summarizes the results of sampling and analysis performed on solids generated at 40

publicly owned wastewater treatment facilities. In 1989, during the development of the 40CFR

Part 503 Rule regulations, the USEPA sponsored a second survey of biosolids. The second

survey, the National Sewage Sludge Survey, summarizes the results of testing conducted at over

200 wastewater treatment facilities. (USEPA 1990).

Table 3.1 Pretreatment Impacts National Trends

Element

40-City Study (1980) mg/kg National Sewage Sludge Study

dry weight

(1989) mg/kg dry weight

Arsenic

9.9

6.7

Cadmium

69

6.9

Chromium

429

119

Copper

602

741

Lead

369

134.4

Mercury

2.8

5.2

Molybdenum

17.7

9.2

Nickel

135.1

42.7

Selenium

7.3

5.2

Zinc

1,594

1,202

While dated, the results of the two surveys illustrate the trends occurring within biosolids

characteristics. A review of the table indicates that in almost every case, the characteristics found

in the National Sewage Sludge Survey are significantly less than those in the 40-city study. In

two cases, copper and mercury, the results from the National Sewage Sludge Survey are greater

than those from the 40-city study. The copper concentrations are most likely the result of

increased use of copper plumbing in new homes. There is not a clear explanation for the increase

in the mercury concentration. It may be the result of changes in analytical techniques and an

increase in the number of samples collected in the NSSS. The USEPA is in the process of

implementing a Biosolids Data Management System (BDMS) that collects biosolids quality data

reported by wastewater treatment facilities. The database can be accessed through

www.epa.gov/region08/water/wastewater/biohome/biohome.html.

In addition to industrial contributions, the waste stream from individual residences can impact

wastewater treatment and biosolids characteristics. Educating the public about the impacts of

household hazardous waste on the treatment facility, along with making household hazardous

waste recycling and disposal convenient, can result in a marked improvement in biosolids

characteristics.

Chapter 3

Page 2

NATIONAL MANUAL OF GOOD PRACTICE FOR BIOSOLIDS

3.2 Liquid Stream Impact on Solids Management

The liquid stream processes in a wastewater treatment

facility can impact both solids characteristics and the types

of solids handling processes that are appropriate. While it

is unlikely that an organization will change its entire

wastewater treatment process to improve solids handling,

both the liquid and solid stream processes need to be

considered when contemplating a change.

The type of liquid stream treatment process employed impacts the amount, dry weight, and

volume of solids generated. To illustrate, consider use of a primary clarifier as part of a

conventional activated sludge process and the absence of a primary clarifier in an extended air

process. A primary clarifier removes solids from wastewater by gravity settling. Primary solids

are a benefit to certain solids management processes including anaerobic digestion and

mechanical dewatering. They are not a benefit to other processes such as dissolved air flotation

thickening and aerobic digestion.

In addition, the impact a solids handling process can have on the liquid stream should be

considered. For example, mechanical dewatering with a belt filter press generates significantly

more sidestream volume than centrifuge dewatering. The impact of these sidestreams on the

liquid stream process should be considered when evaluating these alternatives.

3.3 Solids Generation

Understanding solids generation within the facility helps optimize the operation of subsequent

solids handling processes. The most effective method to establish the treatment efficiency of

primary, secondary, and tertiary processes is to measure wastewater characteristics entering and

leaving each process. For solids production, the total suspended solids and the biochemical

oxygen demand are typically monitored. If historical data is not available, limited analysis and

some rules of thumb can be used to establish an estimate of solids generation.

3.3.1 Primary Solids Generation

Primary clarifiers, the principle means of wastewater treatment in the U.S. prior to the

passage of the Clean Water Act, remove suspended solids within the wastewater by the

use of gravity. They also reduce the organic load, measured as biochemical oxygen

demand (BOD), which enters the secondary treatment process.

Efficiently designed and operated primary

clarifiers can remove 50 to 70 percent of

the suspended solids that enter the process.

During the removal of theses suspended

solids, 25 to 40 percent of the 5-day BOD

is also removed. (Metcalf & Eddy, 1991).

The most effective way to determine the

performance of a primary clarifier is to monitor the influent and effluent total suspended

Chapter 3

Page 3

NATIONAL MANUAL OF GOOD PRACTICE FOR BIOSOLIDS

solids and BOD. This will allow the organization to closely estimate the removal

efficiency of their process.

Recording the surface overflow and weir overflow rate in addition to the removal rates

will allow the organization to predict the performance at various hydraulic loading rates.

3.3.2 Secondary Solids Generation

The secondary process includes a fixed film or suspended growth biological treatment

along with secondary clarification. Parameters that will impact secondary solids

generation include:

Presence or absence of primary clarification

Type of secondary treatment process employed

Secondary clarifier loading rates

Similar to primary solids generation, it is necessary to establish the characteristics of the

influent and effluent to understand the solids and organic removal through the process.

To establish performance, an organization needs to determine the solids generated per

unit of organics removed. This is typically referred to as the pounds of solids generated

per pound of BOD removed (lb/lb BODr). This generation rate is best determined over

time with actual operating data. If data is not available, a generation rate of 0.75 to 0.85

lb/lb BODr can be used for facilities that do not nitrify. Nitrification increases the solids

generation rate. If the facility does nitrify, the solids generation will approach 1.0 lb/lb

BODr. In addition to the biological solids generated through secondary treatment, the

suspended solids entering and leaving the secondary treatment process should be

monitored. The suspended solids removed in the secondary treatment process should be

added to the biological solids to determine the total secondary solids. [(3) WEF Design of

Municipal Wastewater Treatment Plants WEF MOP, 8]

3.3.3 Tertiary Treatment and Solids Generation

Advanced secondary and tertiary treatment impacts the solids generated during

wastewater treatment, but the manner in which the performance is monitored and the

solids generation is estimated will not change. Nitrification will increase the biosolids

generated in the secondary treatment process. Chemical addition for phosphorus removal

will enhance settling and increase the generation of primary and/or secondary solids.

Biological nutrient removal also impacts the volume and characteristics of the solids

generated.

3.3.4 Impact of Sidestreams on Solids Generation

Sidestream generated from solids handling unit process have an impact on the liquid

stream of a wastewater treatment facility and subsequently the solids generation. It is

important to estimate the characteristics of any sidestreams that will be generated from a

new unit process. The sidestreams can be modeled to determine their impact on the

Chapter 3

Page 4

NATIONAL MANUAL OF GOOD PRACTICE FOR BIOSOLIDS

hydraulic and organic capacity of a wastewater treatment facility.

The characteristics of the sidestreams should be considered when determining where they

will enter the stream. Because a number of solids handling process have extremely high

solids capture rates, it may not be necessary to introduce the sidestream upstream of a

primary clarifier, thereby maintaining as much reserve hydraulic capacity in the primary

treatment process as possible.

3.3.5 Solids Generation for Lagoon Systems

A number of small wastewater treatment facilities employ lagoon treatment technology.

These systems include either a facultative or aerated lagoon. In the majority of these

systems, wastewater that has undergone preliminary treatment is discharged directly into

a lagoon. Lagoon systems typically include baffles or a series of lagoons to minimize the

opportunity for short-circuiting. All solids (suspended and biological) generated within

the lagoon treatment system remain within the lagoon and are periodically removed. The

method to estimate the solids generation within the lagoon system is similar to that of an

extended aeration activated sludge process, starting with monitoring the suspended solids

and BOD entering and leaving the lagoon system. Due to the endogenous respiration that

occurs within the solids settled in the lagoon, the solids generation rate per pound of

BOD removed is significantly lower than that experienced in an extended air activated

sludge system. It should be anticipated that 40 percent of the volatile solids estimated

within the lagoon solids will be destroyed through endogenous respiration, resulting in a

solids generation rate of approximately 0.5 lb/lb BODr.

3.4 Septage Handling at a Wastewater Treatment Facility

Cotreatment of septage with wastewater at a municipal treatment facility is a viable option for

septage management. Septage, however, has several significant effects on the conventional

wastewater treatment process. It exerts a load on both the liquid and solids stream treatment

systems, with resulting increases in solids production and operating costs. It can also have an

effect on facility performance and, ultimately, on the quality of effluent and biosolids produced.

The latter effect depends on a number of factors, including the proportion of septage loading

being treated compared to total facility loading, and the manner in which septage is introduced

into the treatment facility.

3.4.1 Characteristics of Septage

The characteristics of septage are similar to wastewater,

though significantly higher in strength. In addition to the

organic loading, septic tanks concentrate rags, plastics, and

other nondegradable materials, which can cause operational

and aesthetic problems at the wastewater treatment facility

and in the resulting biosolids. Odors may be the most

significant factor to consider when dealing with septage.

Septage strength varies, but can be characterized based on an average composition.

Septage can be managed as high strength wastewater or as a dilute solid. Data collected at

the King County, Washington East Division Reclamation Plant since the mid-1970s

Chapter 3

Page 5

NATIONAL MANUAL OF GOOD PRACTICE FOR BIOSOLIDS

indicate total solids concentrations averaging approximately 23,000 mg/L, with

suspended solids averaging 22,000 mg/L. The concentration of oil and grease average

approximately 1,400 mg/L. Total BOD values have averaged approximately 7,400 mg/L,

whereas soluble BOD values have averaged approximately 800 mg/L. The solids

concentration is approximately 100 times greater, and BOD approximately 30 times

greater, than for domestic wastewater being received at this facility. [(2)WEF MOP 24,

1997)].

3.4.2 Incorporation with the Liquid Stream

A number of factors must be considered when deciding to add septage to the liquid

stream process. These include where in the process the septage will be introduced; how it

will be introduced; and its impact on both the liquid and solids stream unit operations.

The solids and organic loading to the WWTF from the septage must be considered in

each unit process, including the size of the facility, the unit process sequence, and the

manner in which the septage is fed into the facility.

Primary Treatment

Because septage has a much higher solids content than typical domestic wastewater, the

effects of septage discharges on liquid stream processes such as primary treatment are

more significant from a solids loading viewpoint than from a hydraulic viewpoint.

Because the solids contained in the septage have already been removed by settling in the

septage system, they should be effectively removed during the primary treatment process.

These additional solids subsequently would be discharged to the solids stream process for

additional treatment and management. Because the loading is predominantly solids, it is

important to ensure that the solids collection and pumping capacity for the primary solids

are adequate to handle the increased loading that septage represents. Peak loading

conditions will be of the greatest concern.

Secondary Treatment

While most of the BOD in the septage is associated with the solids, there is some BOD

that will be discharged to the secondary process. This will result in higher aeration

requirements and an increase in secondary solids production. The actual effect will be

dependent on the specific facility because factors such as type of aeration diffuser, mean

cell residence time (MCRT) at which the system is operated, and ambient temperature

can affect both air demand and solids production.

Odors associated with septage must be addressed to reduce the potential for odor

complaints at the facility. Even if odors have been addressed at the receiving station, it is

possible to have additional odors released during liquid stream processing.

3.4.3 Septage Treatment and the Solids Process Stream

It may be possible to discharge the septage directly to the solids process stream to reduce

effects on the liquid stream processing facilities. For this approach to be successful, it is

important that a mechanism be present, either as a part of the septage receiving station or

as a part of the solids processing system, to remove grit and screenings. Failure to

provide this treatment will result in grit and materials such as rags and plastics in the final

Chapter 3

Page 6

NATIONAL MANUAL OF GOOD PRACTICE FOR BIOSOLIDS

biosolids product and can have such adverse effects on the solids processing units as

ragging and accumulation of grit, which require periodic draining and cleaning of process

units. Some agencies have reported success with the use of a rotary screen device;

however, the screened materials represent an additional sidestream that requires disposal.

Solids Processing

Consideration also must be given to the effects of the septage on the solids processing

units when determining the point in the process at which the solids will be introduced. As

an example, unless the septage is prethickened, it may not be desirable to feed it directly

into a digestion process because of the dilution and resulting reduction in solids retention

time. Similarly, the direct introduction of the septage solids to the dewatering processing

system could have adverse effects on the resultant biosolids quality and may create

compliance issues with regard to vector -- attraction reduction and pathogen reduction

requirements.

Solids Stream Effects

The solids stream effects of septage are primarily related to the solids loading on the

processing units and the resultant increase in biosolids production. It is probable that the

loading will be comparable to that assumed for the solids stream loading under the

previous liquid stream treatment scheme.

Liquid Stream Effects

Although the septage stream would be discharged to the solids processing area under this

treatment scheme, the liquid fraction would still need to be treated in the liquid stream

processing unit as a portion of the solids recycle stream.

Chapter 3

Page 7

NATIONAL MANUAL OF GOOD PRACTICE FOR BIOSOLIDS

References

Metcalf and Eddy, Inc., (1991), Wastewater Engineering, Treatment, Disposal and Reuse, Third

Edition McGraw-Hill, Inc., New York, N.Y

.

United States Environmental Protection Agency, (November, 1990), USEPA 40 Code of Federal

Regulations Part 503 National Sewage Sludge Survey; Availability of Information and Data, and

Anticipated Impacts on Proposed Regulations; Proposed Rule

Water Environment Federation, (1992), Design of Municipal Wastewater Treatment Plants,

Manual of Practice No.8, Alexandria, Va.; Am. Soc. Civ. Eng., Manual and Report on

Engineering Practice No.76, New York, N.Y.

Water Environment Federation, (1997), Septage Handling, Manual of Practice No.24

Chapter 3

Page 8

Das könnte Ihnen auch gefallen

- Hydraulic Calculations Manual (Rev 3) PDFDokument6 SeitenHydraulic Calculations Manual (Rev 3) PDFsauroNoch keine Bewertungen

- Escalators - How To Plan, Design and Update 1Dokument5 SeitenEscalators - How To Plan, Design and Update 1sauroNoch keine Bewertungen

- Non-Stationary Thermal Model of Indoor Transformer StationsDokument9 SeitenNon-Stationary Thermal Model of Indoor Transformer StationssauroNoch keine Bewertungen

- Typical Uses for Positive Displacement PumpsDokument3 SeitenTypical Uses for Positive Displacement PumpsQasim SarwarNoch keine Bewertungen

- CALC Pressure Loss SUL-13-214Dokument1 SeiteCALC Pressure Loss SUL-13-214sauroNoch keine Bewertungen

- Eaching High-Rise Plumbing DesignDokument19 SeitenEaching High-Rise Plumbing Designm_salah20202000Noch keine Bewertungen

- CALC Plant Volume SUL-13-212Dokument1 SeiteCALC Plant Volume SUL-13-212sauroNoch keine Bewertungen

- Compressed Air Installation GuideDokument24 SeitenCompressed Air Installation Guidesauro100% (1)

- Hose Usage ChartDokument1 SeiteHose Usage ChartsauroNoch keine Bewertungen

- Improve Your Vehicle Workshop with Nederman SolutionsDokument8 SeitenImprove Your Vehicle Workshop with Nederman SolutionssauroNoch keine Bewertungen

- BSPT Thread Sizes & TypesDokument3 SeitenBSPT Thread Sizes & TypesuttampokharkarNoch keine Bewertungen

- Plan Your Plumbing Grey and Black Water LayoutDokument1 SeitePlan Your Plumbing Grey and Black Water LayoutsauroNoch keine Bewertungen

- M13L17 Digester DesignDokument12 SeitenM13L17 Digester DesignPragathees WaranNoch keine Bewertungen

- Ashp Sav CalcDokument5 SeitenAshp Sav CalcsauroNoch keine Bewertungen

- Methods and Devices For The Prevention of Backflow and Back-SiphonageDokument9 SeitenMethods and Devices For The Prevention of Backflow and Back-SiphonagesauroNoch keine Bewertungen

- LC 125 LabGuidelinesStandardsDokument36 SeitenLC 125 LabGuidelinesStandardssauroNoch keine Bewertungen

- Ac 3134Dokument40 SeitenAc 3134sauroNoch keine Bewertungen

- Design of SBR Activated Sludge ProcessDokument2 SeitenDesign of SBR Activated Sludge ProcesssauroNoch keine Bewertungen

- An Intro To Sludge Hand Treat DisposalDokument44 SeitenAn Intro To Sludge Hand Treat DisposalEusoofNoch keine Bewertungen

- Environmental Risk-Based Approaches For Managing Municipal Wastewater Effluent (MWWE)Dokument230 SeitenEnvironmental Risk-Based Approaches For Managing Municipal Wastewater Effluent (MWWE)sauroNoch keine Bewertungen

- Loading S Calculations by Dr. Ghaida Abu Rumman enDokument36 SeitenLoading S Calculations by Dr. Ghaida Abu Rumman ensauroNoch keine Bewertungen

- Correlating Biochemical and Chemical Oxygen Demand of EffluentsDokument11 SeitenCorrelating Biochemical and Chemical Oxygen Demand of EffluentssauroNoch keine Bewertungen

- Design of Primary Sewage Treatment PlantDokument80 SeitenDesign of Primary Sewage Treatment Plant000123456789Noch keine Bewertungen

- Eqpm Ventilation and Airconditioning PDFDokument79 SeitenEqpm Ventilation and Airconditioning PDFRodrigo Alonso Rosales OrtegaNoch keine Bewertungen

- Low-Cost Innovative Solutions For Treating Public Market Wastewater in The PhilippinesDokument6 SeitenLow-Cost Innovative Solutions For Treating Public Market Wastewater in The PhilippinessauroNoch keine Bewertungen

- Energy Impacts of Chiller Water Piping ArrangementDokument8 SeitenEnergy Impacts of Chiller Water Piping ArrangementSharon LambertNoch keine Bewertungen

- Dairy Wastewater CharacteristicsDokument189 SeitenDairy Wastewater Characteristicsjoozmax6Noch keine Bewertungen

- 03 Sewage Treatment Utilizing SoilDokument41 Seiten03 Sewage Treatment Utilizing SoilsauroNoch keine Bewertungen

- 06 Plumbing and CollectionDokument28 Seiten06 Plumbing and CollectionsauroNoch keine Bewertungen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5784)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- High Purity Oxygen Production using VPSA (≤40 charsDokument2 SeitenHigh Purity Oxygen Production using VPSA (≤40 charsankur2061Noch keine Bewertungen

- Engenvi NotesDokument12 SeitenEngenvi NotesMariaNoch keine Bewertungen

- Everything About Ecotourism (39Dokument3 SeitenEverything About Ecotourism (39TIRTHA DEB NATHNoch keine Bewertungen

- Designing of Biomass Based Power Plant For BuildingDokument6 SeitenDesigning of Biomass Based Power Plant For Buildingnanik smkn5Noch keine Bewertungen

- Possibilities of Solar EnergyDokument18 SeitenPossibilities of Solar Energyarslan0% (1)

- Threats To Water ScarcityDokument2 SeitenThreats To Water ScarcityJ Stephen SheedyNoch keine Bewertungen

- Water TreatementDokument7 SeitenWater TreatementAnuj KumarNoch keine Bewertungen

- Laporan Soil Investigation PT Eti Palu Mining Power Plant 20MWDokument20 SeitenLaporan Soil Investigation PT Eti Palu Mining Power Plant 20MWAgus WahyudiNoch keine Bewertungen

- Xe-Pian Xe-Namnoy Project OverviewDokument61 SeitenXe-Pian Xe-Namnoy Project OverviewLovewater RainingNoch keine Bewertungen

- Renewable EnergyDokument38 SeitenRenewable EnergyAnirban DebNoch keine Bewertungen

- MBR CalculationsDokument13 SeitenMBR Calculationsisquare77Noch keine Bewertungen

- Lecture 5-Sedimentation and Flocculation (Part 2)Dokument21 SeitenLecture 5-Sedimentation and Flocculation (Part 2)Harold Taylor100% (1)

- Sustainable Architecture of Tadao AndoDokument36 SeitenSustainable Architecture of Tadao AndoSampada MgrNoch keine Bewertungen

- Discover NC River Basins BookletDokument16 SeitenDiscover NC River Basins Bookletapi-290100812Noch keine Bewertungen

- Sustainable Energy Technology: MSC ProgrammeDokument2 SeitenSustainable Energy Technology: MSC ProgrammeFirman NugrahaNoch keine Bewertungen

- Urban Lakes: Ecosystems at Risk, Worthy of The Best Care: January 2008Dokument6 SeitenUrban Lakes: Ecosystems at Risk, Worthy of The Best Care: January 2008Bill BernoulliNoch keine Bewertungen

- AL-2 Flowdiagram SeparationDokument1 SeiteAL-2 Flowdiagram SeparationCitramanda ServicesNoch keine Bewertungen

- Part A, Part B Questions Unit I EE IIDokument21 SeitenPart A, Part B Questions Unit I EE IIsubhaNoch keine Bewertungen

- Fuel Production Cost Estimates and Assumptions.: This Is Part of Zero-Emission Vessels: Transition PathwaysDokument44 SeitenFuel Production Cost Estimates and Assumptions.: This Is Part of Zero-Emission Vessels: Transition PathwaysPanchadcharam PushparubanNoch keine Bewertungen

- The Kaldnes Moving Bed Process For Wastewater Treatment at Pulp and Paper MillsDokument3 SeitenThe Kaldnes Moving Bed Process For Wastewater Treatment at Pulp and Paper Millsvinhphat90Noch keine Bewertungen

- Caterpillar Air Filter Pehj0092-01Dokument2 SeitenCaterpillar Air Filter Pehj0092-01Parinpa Ketar0% (1)

- Malaysia's Water Resources ChallengesDokument2 SeitenMalaysia's Water Resources Challengesakram05Noch keine Bewertungen

- BR 2007-322 - EUF (Wastewater Charge System)Dokument8 SeitenBR 2007-322 - EUF (Wastewater Charge System)Pacific SpectrumNoch keine Bewertungen

- BDP Presentation AwardDokument10 SeitenBDP Presentation Awardcwc208Noch keine Bewertungen

- Access To Safe Water Is An Absolute Necessity For Everyone Around The WorldDokument4 SeitenAccess To Safe Water Is An Absolute Necessity For Everyone Around The WorldSuvashreePradhanNoch keine Bewertungen

- Study Session 7 Pollution: Types, Sources and CharacteristicsDokument9 SeitenStudy Session 7 Pollution: Types, Sources and CharacteristicsThế Anh ĐoànNoch keine Bewertungen

- Gopu Venugopala Reddy Team Labs and Consultants India PDFDokument22 SeitenGopu Venugopala Reddy Team Labs and Consultants India PDFHardik VavdiyaNoch keine Bewertungen

- Plumbing Design Service ProposalDokument2 SeitenPlumbing Design Service ProposalChristan Daniel RestorNoch keine Bewertungen

- Water PollutionDokument27 SeitenWater Pollutionsatybodh6752Noch keine Bewertungen

- Green Roof Pocket GuideDokument11 SeitenGreen Roof Pocket Guidestranger00Noch keine Bewertungen