Beruflich Dokumente

Kultur Dokumente

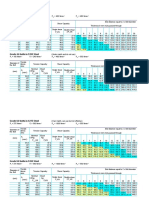

High Power BB Trunking 800-4000a Spec en

Hochgeladen von

Chea VirakOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

High Power BB Trunking 800-4000a Spec en

Hochgeladen von

Chea VirakCopyright:

Verfügbare Formate

SpecificationforTender

259340088.doc

GeneralSpecificationforHighPower

BusbarTrunkingSystemfrom800A

to4000A

Lastupdate:20080611

SpecificationforTender

259340088.doc

Tableofcontents:

1.General......................

p.3

2.Conformitytostandard.

p.3

3.Environment.....................

p.3

4.Conductors....................

p.3

5.Shortcircuitcapacity...............

p.4

6.Joints.................................

p.4

7.Expansionjoints...........................

p.4

8.Enclosure...........

p.4

9.Tapoffoutlets..................................

p.4

10.Tapoffunits.......

p.5

Lastupdate:20080611

SpecificationforTender

259340088.doc

1.General

Thebusbartrunkingsystem,bothfeederandplugin,shallbeoflowimpedanceandsandwiched

constructionmeaningnoairgapshallexistbetweenbusbarsexpectatpluginopening.Itshallbetotally

enclosedprepaintedgalvanizedsteelandbeofthenonlouveredtypemaintaininganoveralldegreesof

ingressprotection.Alltheinsulationmaterialsshallbehalogenfree.

Thebusbartrunkingsystemshallbesuitablefora3phases4wiressystemwithfullsizeneutraland

continuousinternalcopperearthbarofhalfsizeifrequested.

Allbusbartrunkingsystemincludingallfittings(elbows,zeds,endfeedunits,tapoffunits,etc.)shallbe

IP55inaccordancetoIEC60529andsprinklerproofwithoutanyextraaccessory.

Allfittingsandtapoffunitsshallbefromthesamemanufacturerasthebusbartrunkingsystem.

Thebusbartrunkingsystemshallbecapableofbeingmountedinanyposition.Pluginandfeedersections

shallbeinterchangeablewithouttheuseofspecialadapterjointcovers.Thecompleteinstallationshallbe

coordinatedthroughoutandwherepossible,shallconsistofstandard4msectionswithspecialsectionsand

fittingsprovidedtosuittheinstallation.Fittingsshallbethemostcompactandlightweightaspossiblein

ordertomakethedesignandtheinstallationeasier.

Thebusbartrunkingcompactdesignshallallowstandardtransportstraightlengthsorelbowstobeinstalled

throughafloorslaborfirebarrierwall.

Horizontalrunsofbusbartrunkingsystemshallbesupportedbyhangersatevery3meters.Verticalrunsof

busbartrunkingsystemshallbesupportedbyhangersnotmorethan4mapart.

Busbartrunkingsystemshallbeterminatedbyendclosure.

Thebusbartrunkingsystemshallhavethefollowingcharacteristics:

RatedInsulationVoltage(A/C):1000Volts

RatedOperatingVoltage(A/C):1000Volts

2.ConformitytoStandard

Thebusbartrunkingsystemshallbeconstructedinaccordancewiththeapplicablerequirementsofthelatest

IEC604391&2

3.Environment

Thebusbartrunkingsystemshallbesuitableforcontinuousoperationwithoutderatingatanaverage

ambienttemperatureof35oCfor24h(40Cmaximumpeak).

4.Conductors

Conductorsshallbeofharddrawn99%purityaluminium.

Lastupdate:20080611

SpecificationforTender

259340088.doc

TheinsulationusedonthebusbarshallbeclassBpolyestermaterialratedat130Candhalogenfree.

Bothendsofaluminiumconductorsshallbefittedwithbimetalcopper/aluminiumlaminateriders,

electricallywelded.

Ateachtapoffpositionsilverplatedbimetalcopper/aluminiumlaminateridersshallbeelectricallywelded

towarrantythemostreliablecontactbetweenbusbarandtapoffunits.

Fullsizeneutralofthesamecrosssectionalareaasthephaseconductorshallbeprovidedforallratingsof

thebusbartrunkingsystem.

5.ShortCircuitCapacity

Thewholebusbartrunkingsystemshallbecapableofwithstandingtheshortcircuitcapacityoftheelectrical

installationwithoutdamagingtheelectrical,mechanicalandthermalstressunderfaultconditionataservice

voltageof415V50Hz.CoordinationofthedistributionshouldbeguaranteedsuchthattheCircuitbreaker/

trunkingcombinationwilllimitthepeakcurrenttoavaluelessthantheratedpeakcurrentofthebusbar

trunking.

Typetestcertificatesshallbeappliedtoatleastonecompleteapparatusofeachrating,typeanddesign.

6.Joints

Theelectricaljointsshallbeofonetofourbolttypedesignedforevendistributionofcontactpressure.

Bellevillewashersshallbeusedtomaintainproperpressureoveralargecontactsurface.

Boltsshallincludeanexternalbreakableheadwhichbreakswhenthecorrecttorqueisreachandrequire

onlyastandardhandlewrenchtocarryoutsuchwork.

Boltsshallbeaccessiblewithoutremovingcovers.

Thejointsshallbesodesignedastoallowremovalofanylengthwithoutdisturbingadjacentlengths.

7.ExpansionJoint

Busbarexpansionunitsshallbeuseincaseswhenitcrossesabuildingexpansionjointorasrecommended

bythevendortoreducethestressonthesystembydifferentialexpansionbetweenthebusbarsandthe

casing;particularlyforlongrunofthebusbar.

Itshallbeconsistofaflexiblejointinthemiddleontheconductorsandaslidingcasingin2sectionswhich

canabsorbtherelativemovementsofeachsectionofthelength.

8.Enclosure

Thebusbartrunkinghousingshallbenonventilatedandatleastof1.5mmthickforprotectionagainstdust

accumulationandmechanicaldamage.Theenclosureshallbeofhotdipgalvanizedandprepaintedsheet

steel.Busbartrunkingsystemwithoutpaintprotectionshallnotbeacceptable.Inordertolimitmagnetic

fieldaroundthebuswaysystem,aluminiumenclosuresarenotrecommended.

PaintFinish:RAL9001

9.Tapoffoutlets

Lastupdate:20080611

SpecificationforTender

259340088.doc

EachtapoffoutletsshallbeatleastIP55,withnoadditionalaccessory.

Tapoffoutletsshuttershallbeabletoopenandcloseautomaticallywhenpluginunitsarepluggedinor

removed.

10.Tapoffunits

Tapoffunitsandcircuitbreakershallbefromthesamemanufacturerasthebusbartrunkingsystemand

shallbe100%compatiblewithmediumpowerbuswayofthesamemanufacturer.Certificatesshallprove

thatthewholesystem(busbartrunking,tapoffunitsandapparatus)hasbeensuccessfullytested.Allcircuit

breakersusedshallbeabletooperatenormallywhenmountedupsidedownoratanyangles.

Tapoffunitsshallbeofdustanddampproofversion,degreeofprotectionIP55andsprinklerproof.

Tapoffunitsshallbeprovidedwithoffloadsisolatorsuitableforfusesorcircuitbreakersaccordingto

ratingsasindicatedinthedrawings.

Theplugintapoffunitsshallbeconnectedtothebusbartrunkingwhilstlive(offload)viasilverplated

copperspringjawconnections.

Theearthcontactofthetapoffunitshallalwaysbemadebeforethatoftheliveconductorsandthelastto

breakduringremoval.

ThetapoffunitandthebusbartrunkingsystemshallbeinterlockedtoensurethatthedeviceisintheOFF

positionpriortoinstallationorremovaloftheunit.

Thetapoffunitshallhaveaninterlockwhichpreventsthecoverfrombeingopenedwhilethedeviceisin

theONpositionandtopreventaccidentalclosingofthedevicewhenthecoverisopened.

TheMCCBusedinthetapoffunitmustcomplytoIEC9472.AllMCCBsshallhavearatedservice

breakingcapacity(Ics)ofRMSvalueat415VACequalorhigherthantheprospectivefaultlevelof

installation.Itshallhavecurrentlimitingcapabilitiestoprotectthebusbartrunkingsystemandcoordination

tableshallbefurnishedbymanufacturer.

Lastupdate:20080611

Das könnte Ihnen auch gefallen

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Site Work Part 3Dokument13 SeitenSite Work Part 3Chea VirakNoch keine Bewertungen

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Site Work Part 3Dokument13 SeitenSite Work Part 3Chea VirakNoch keine Bewertungen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Site Work Part 24Dokument13 SeitenSite Work Part 24Chea VirakNoch keine Bewertungen

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Site Work Part 3Dokument13 SeitenSite Work Part 3Chea VirakNoch keine Bewertungen

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- Site Work Part 24Dokument13 SeitenSite Work Part 24Chea VirakNoch keine Bewertungen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Site Work Part 3Dokument13 SeitenSite Work Part 3Chea VirakNoch keine Bewertungen

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Site Work Part 3Dokument13 SeitenSite Work Part 3Chea VirakNoch keine Bewertungen

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Site Work Part 24Dokument13 SeitenSite Work Part 24Chea VirakNoch keine Bewertungen

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Site Work Part 24Dokument13 SeitenSite Work Part 24Chea VirakNoch keine Bewertungen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Site Work Part 24Dokument13 SeitenSite Work Part 24Chea VirakNoch keine Bewertungen

- Site Work Part 24Dokument13 SeitenSite Work Part 24Chea VirakNoch keine Bewertungen

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Site Work Part 24Dokument13 SeitenSite Work Part 24Chea VirakNoch keine Bewertungen

- Site Work Part 24Dokument13 SeitenSite Work Part 24Chea VirakNoch keine Bewertungen

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- Site Work Part 19Dokument14 SeitenSite Work Part 19Chea VirakNoch keine Bewertungen

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- Site Work Part 19Dokument14 SeitenSite Work Part 19Chea VirakNoch keine Bewertungen

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Site Work Part 19Dokument14 SeitenSite Work Part 19Chea VirakNoch keine Bewertungen

- Site Work Part 19Dokument14 SeitenSite Work Part 19Chea VirakNoch keine Bewertungen

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Site Work Part 19Dokument14 SeitenSite Work Part 19Chea VirakNoch keine Bewertungen

- Site Work Part 3Dokument13 SeitenSite Work Part 3Chea VirakNoch keine Bewertungen

- Site Work Part 24Dokument13 SeitenSite Work Part 24Chea VirakNoch keine Bewertungen

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Site Work Part 19Dokument14 SeitenSite Work Part 19Chea VirakNoch keine Bewertungen

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Site Work Part 18Dokument14 SeitenSite Work Part 18Chea VirakNoch keine Bewertungen

- Site Work Part 19Dokument14 SeitenSite Work Part 19Chea VirakNoch keine Bewertungen

- Site Work Part 17Dokument14 SeitenSite Work Part 17Chea VirakNoch keine Bewertungen

- Site Work Part 3Dokument13 SeitenSite Work Part 3Chea VirakNoch keine Bewertungen

- Preliminary Assessment/Site Inspection: o o o o oDokument1 SeitePreliminary Assessment/Site Inspection: o o o o oChea VirakNoch keine Bewertungen

- Site Work Part 3Dokument13 SeitenSite Work Part 3Chea VirakNoch keine Bewertungen

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Site Work Part 3Dokument13 SeitenSite Work Part 3Chea VirakNoch keine Bewertungen

- Site Work Part 3Dokument13 SeitenSite Work Part 3Chea VirakNoch keine Bewertungen

- Site Work Part 3Dokument13 SeitenSite Work Part 3Chea VirakNoch keine Bewertungen

- New COADokument15 SeitenNew COAAhadNurParagNoch keine Bewertungen

- KBK Installations: KBK II Extending CranesDokument2 SeitenKBK Installations: KBK II Extending CranesMAGST100% (1)

- Universiti Kuala Lumpur Malaysian Spanish Institute: Name: Mohamad Adib Fahmi Bin MahadzirDokument9 SeitenUniversiti Kuala Lumpur Malaysian Spanish Institute: Name: Mohamad Adib Fahmi Bin MahadzirAizzat ZackNoch keine Bewertungen

- MOS Main Truss Bridge Rev 01Dokument35 SeitenMOS Main Truss Bridge Rev 01Ami ShafiNoch keine Bewertungen

- Bronzeystrainer - Kvs 200 TDokument1 SeiteBronzeystrainer - Kvs 200 TTiến Lý NhậtNoch keine Bewertungen

- Metode Kerja Umum PDA Test - 2021Dokument23 SeitenMetode Kerja Umum PDA Test - 2021WannNoch keine Bewertungen

- Chapter 11Dokument12 SeitenChapter 11Erika Rose LaronNoch keine Bewertungen

- Injection Mould Hot RunnerDokument17 SeitenInjection Mould Hot RunnerKiran KumarNoch keine Bewertungen

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- C PJPT P020 S BLKC LMR SP 001 (A) Layout1Dokument1 SeiteC PJPT P020 S BLKC LMR SP 001 (A) Layout1Alexander SNoch keine Bewertungen

- Rheomac® 707Dokument4 SeitenRheomac® 707M HAFEEZ RAJANoch keine Bewertungen

- Piling BQDokument4 SeitenPiling BQLeeZhengxian100% (1)

- The History of Investment Foundry ProcessDokument11 SeitenThe History of Investment Foundry ProcessVrinda NilotpalNoch keine Bewertungen

- 2011 UK Waste WoodDokument31 Seiten2011 UK Waste WoodStuart JonesNoch keine Bewertungen

- Required Assets & SR - No.Dokument20 SeitenRequired Assets & SR - No.amitboeNoch keine Bewertungen

- Grade 4.6 Bolts in S275 Steel: S - 2 T - 2 BB - 2 Bs - 2Dokument3 SeitenGrade 4.6 Bolts in S275 Steel: S - 2 T - 2 BB - 2 Bs - 2vthamarai999543Noch keine Bewertungen

- Technical Topics: Allowable Depth-to-Width Ratios For Glulam BeamsDokument2 SeitenTechnical Topics: Allowable Depth-to-Width Ratios For Glulam BeamsciviliiiNoch keine Bewertungen

- Furniture Materials and CharacteristicsDokument2 SeitenFurniture Materials and CharacteristicsKathleen Anne CabreraNoch keine Bewertungen

- Tank-A Tank-B Tank-C: Bus BayDokument4 SeitenTank-A Tank-B Tank-C: Bus BayMohit AgarwalNoch keine Bewertungen

- Design Calculation of Spillway GateDokument11 SeitenDesign Calculation of Spillway GateAnonymous sfkedkymNoch keine Bewertungen

- 11L Psi NG Engine PartsDokument75 Seiten11L Psi NG Engine PartsPortable Power RayNoch keine Bewertungen

- Washing Machine Manual Kenmore HE5tDokument76 SeitenWashing Machine Manual Kenmore HE5tmachnerdNoch keine Bewertungen

- Material Consumption Norms For Various Civil Works - Civil4MDokument1 SeiteMaterial Consumption Norms For Various Civil Works - Civil4MAnubhav NautiyalNoch keine Bewertungen

- Catalogo - Sispro S.A.Dokument21 SeitenCatalogo - Sispro S.A.JUAN CNoch keine Bewertungen

- Busway Installation & MaintenanceDokument18 SeitenBusway Installation & Maintenanceminhtutran1983Noch keine Bewertungen

- Muhammad Atif KhanDokument6 SeitenMuhammad Atif KhanKQ House of DesignNoch keine Bewertungen

- Case Study 2Dokument24 SeitenCase Study 2VeereshNoch keine Bewertungen

- Quick SeriesDokument46 SeitenQuick SeriesIrfan PoeNoch keine Bewertungen

- Annexure - B Safety SOP ChecklistDokument4 SeitenAnnexure - B Safety SOP ChecklistANUJ SHAHNoch keine Bewertungen

- FM9 Rev 1 ManualDokument30 SeitenFM9 Rev 1 ManualTomaszNoch keine Bewertungen

- 2006 Navistar DT466 Engine Torque ValuesDokument5 Seiten2006 Navistar DT466 Engine Torque ValuesMeadows TruckNoch keine Bewertungen

- How to Estimate with RSMeans Data: Basic Skills for Building ConstructionVon EverandHow to Estimate with RSMeans Data: Basic Skills for Building ConstructionBewertung: 4.5 von 5 Sternen4.5/5 (2)

- The Complete Guide to Building Your Own Home and Saving Thousands on Your New HouseVon EverandThe Complete Guide to Building Your Own Home and Saving Thousands on Your New HouseBewertung: 5 von 5 Sternen5/5 (3)

- Pressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedVon EverandPressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedBewertung: 5 von 5 Sternen5/5 (1)

- Building Construction Technology: A Useful Guide - Part 1Von EverandBuilding Construction Technology: A Useful Guide - Part 1Bewertung: 4 von 5 Sternen4/5 (3)

- Transformed: Moving to the Product Operating ModelVon EverandTransformed: Moving to the Product Operating ModelBewertung: 4 von 5 Sternen4/5 (1)

- A Place of My Own: The Architecture of DaydreamsVon EverandA Place of My Own: The Architecture of DaydreamsBewertung: 4 von 5 Sternen4/5 (242)

- CATIA V5-6R2015 Basics - Part I : Getting Started and Sketcher WorkbenchVon EverandCATIA V5-6R2015 Basics - Part I : Getting Started and Sketcher WorkbenchBewertung: 4 von 5 Sternen4/5 (10)