Beruflich Dokumente

Kultur Dokumente

MS For Installation - Hypochlorination 23.10.07 Hamdy

Hochgeladen von

unnicyriacOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

MS For Installation - Hypochlorination 23.10.07 Hamdy

Hochgeladen von

unnicyriacCopyright:

Verfügbare Formate

N2664-W-M-MS-07-A/N-2480

METHOD STATEMENT

Rev.: 0

INSTALLATION OF HYPOCHLORITE DOSING

SYSTEM

Date: 19.09.07

Page 1 of 7

METHOD STATEMENT

INSTALLATION OF HYPOCHLORITE DOSING

SYSTEM

N2664-W-M-MS-07-A/N 2480

19.09.07

00

First Issue For Approval

UNNI CYRIAC

MECH. ENG.

HAMDY

M&E COORD.

JOHN MEKDISSI

PROJECT

MANAGER

Date

Revision

Description of Revision

Prepared by

Checked by

Approved by

N2664-W-M-MS-07-A/N-2480

METHOD STATEMENT

Rev.: 0

INSTALLATION OF HYPOCHLORITE DOSING

SYSTEM

Date: 19.09.07

Page 2 of 7

REVISION RECORDING

Date

Revision

Description of Revision

Prepared by

Checked by

Approved by

19.09.07

00

First Issue For Approval

UNNI CYRIAC

MECH. ENG.

HAMDY

M&E COORD.

JOHN MEKDISSI

PROJECT

MANAGER

N2664-W-M-MS-07-A/N-2480

METHOD STATEMENT

INSTALLATION OF HYPOCHLORITE DOSING

SYSTEM

Rev.: 0

Date: 19.09.07

Page 3 of 7

TABLE OF CONTENTS

TABLE OF CONTENTS...................................................................................................................................

1.

PURPOSE.................................................................................................................................................

2.

SCOPE......................................................................................................................................................

3.

REFERENCE............................................................................................................................................

4.

RESPONSIBILITY....................................................................................................................................

5.

ADMMI INSTALLATION ENGINEERS.....................................................................................................

6.

PROCEDURE...........................................................................................................................................

7.

TOOLS......................................................................................................................................................

8.

SAFETY....................................................................................................................................................

9.

ATTACHMENT..........................................................................................................................................

N2664-W-M-MS-07-A/N-2480

METHOD STATEMENT

INSTALLATION OF HYPOCHLORITE DOSING

SYSTEM

1.

Rev.: 0

Date: 19.09.07

Page 4 of 7

PURPOSE

This describes the procedure for the Installation of Hypochlorite dosing

equipment at Lot F.

2.

SCOPE

This method statement covers the installation of the following main plant items :

2x 100% Hypo chlorination dosing pumps and electrical and mechanical

accessories

3.

4.

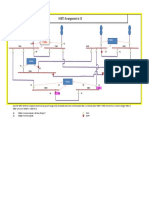

1x Instrument Control Panel (ICP)

RTU

REFERENCE

ADWEA Standards

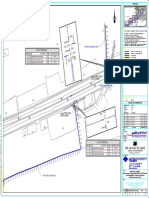

P&I Drawing, Ref: N2664-W-M-D-06-A/N 2663 R4

Layout of Sodium Hypochlorite Dosing Plant, Ref: N2664-W-M-D-06-A/N 2664 R1

Method Statement GRE Pipe work Ref: N2664-W-M-MS-07-A/N 2471 R1

Method Statement for Tapping the existing pipeline to connect the suction line of

the new dosing system for lot-f Ref: N2664-W-M-MS-07-A/N-2473 R0

Method Statement for Commissioning of Hypochlorite Dosing System Ref: N2664W-M-MS-07-A/N 2472 R0

Method Statement for enhancement of VFD KW rating for Lot F Ref: N2664-W-MMS-07-A/N-2470 R1

RESPONSIBILITY

The M/s. ADMMI shall be responsible for supervising, preparing and installation of

electromechanical equipment in the hypo chlorination room.

4.2

The QC/Mechanical/Electrical Engineer shall be assisting M/s. ADMMI for the

installation, alignment and testing of the equipment.

4.3

The Site Engineer shall be responsible for making all necessary preparation for the

installation including cleaning and performing the test in accordance with this

instruction.

4.4

The QC Inspector shall be responsible for the witnessing the test, inspection with

Client/Consultant representative and recording the results.

4.5

All the installation shall be carried out during working hours and in the presence of

ADWEA/Engineer.

N2664-W-M-MS-07-A/N-2480

METHOD STATEMENT

INSTALLATION OF HYPOCHLORITE DOSING

SYSTEM

5.

Rev.: 0

Date: 19.09.07

Page 5 of 7

ADMMI INSTALLATION ENGINEERS

The CV of the ADMMI Engineers will be forwarded to Client/Consultant prior to the time

of work.

6.

PROCEDURE

The stainless steel pump skid will be moved to the hypo chlorination room with

forklift/ hydraulic trolley or any other suitable lifting equipment.

The skid will be placed on the prepared foundation and checked for the position and

orientation as per the drawings.

The skid is properly aligned and levelled and inspected with Client/Consultant

before grouting.

Once the position and orientation is checked, then skid is grouted to the foundation.

The pumps and pump accessories will be moved and installed on the skid with

supplied bolts and nuts and tightening them to specified torques (Torques values

are attached).

Electrical cabling shall be done B/w skid and ICP, b/w skid and modified MCC

thorough the existing cable tray as per the contract.

The pumps are pre-aligned and inspected at the factory before despatch, so there is

no need of any alignment to be carried out on site. But, if Client/Consultant is

required to check the alignment, M/s. ADMMI Engineers can show this at site.

The ICP and the RTUs will be moved to hypochlorination room to the specified

location as per the drawings and the marked locations.

The orientation of ICP and RTUs will be checked and inspected by the

Client/Consultant prior to carry out further commissioning procedure.

After the installation of pump and its accessories, the GRE pipeline is connected to

the suction & discharge of the pump as per GRE Pipe work method statement.

The GRE Pipeline will be connected to the existing tanks as per the Method

Statement of Tapping the existing pipeline to connect the suction line of the new

dosing system for lot-F

The testing and commissioning will be carried out as per the Method Statement for

Commissioning of Hypochlorite Dosing System.

Ensure that the appropriate commissioning method statements have been

approved.

N2664-W-M-MS-07-A/N-2480

METHOD STATEMENT

Rev.: 0

INSTALLATION OF HYPOCHLORITE DOSING

SYSTEM

7.

8.

Date: 19.09.07

Page 6 of 7

TOOLS

The crane/forklift shall be used for unloading and erection purposes. A formal

request shall be submitted to ADWEA/Engineer prior to activity being carried out

for Approval.

The tools & equipments required are as mentioned below

Open ended spanners(wrenches) to suit screws/nuts

Socket spanners(wrenches)

Allen keys, up to 10 mm(A/F)

Range of screw drivers, soft mallet

Dial test indicator.

C spanner (wrench) for removing shaft nut.

Do not carry anything in your hands when climbing up and down the ladder. Items

that are too large for your pockets or belt should always be fitted or lowered from

the overhead crane by rope

Do not operate a sling / crane if limit switches are out of order, or if the cables

show they are defected

Do not attempt to lift a load beyond the rated load capacity of a crane or sling

hoist.

Never lift a load from the side. Center the overhead crane / sling directly over your

load before attempting to hoist it, to avoid the load swinging

Ensure all loose materials, parts, blocking and packing have been removed from

the load before lifting

Follow signals only from one slinger in charge of the lift, except a stop signal

Make sure everyone is away from the load before hoisting it. Sound a bell, siren or

other warning device and start to hoist the load slowly.

All employees working near exposed energized conductors or circuit parts are

required to use insulated tools or handling equipments.

To be use rubber Insulating gloves, hoods, sleeves, matting and blankets and

Hard Hat (insulated non conductive)

To be use Lineman Sleeves and aprons.

SAFETY

HAZARDOUS

ACTIVITY

1.Electical

shock

RISK

Death

CONTROL

Competent persons only.

All energising and isolation of

equipment to be carried out by

ASAP.

N2664-W-M-MS-07-A/N-2480

METHOD STATEMENT

Rev.: 0

INSTALLATION OF HYPOCHLORITE DOSING

SYSTEM

Date: 19.09.07

Page 7 of 7

2. Injury from Injury to body from ruptured Cordon off area

pipelines

PVC, carbon and Galvanised warning signs.

rupturing,

steel pipe work.

Wear safety goggles

during

pressure

testing.

3.

Lifting Injuries

Equipments

during

installation

and

post

Proper PPE, lifting slings, hooks,

belts etc.

LIST ANY OTHER SAFETY CONSIDERATIONS BELOW

(Including methods to be adopted to reduce risks)

1. Working area will be cordoned off during working hours.

2. Entry to working area controlled by AL JABER, access will be restricted to only

those involved in the procedure.

3. Only competent and trained personnel to be involved in this procedure.

4. Work areas to be kept clean and tidy.

9.

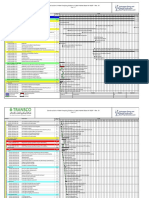

ATTACHMENT

P&ID : N2664-W-M-D-06-A/N 2663 R4

Torque Values

Hypochlorite Dosing System Check List

Layout of Sodium Hypochlorite Dosing Plant : N2664-W-M-D-06-A/N

2664 R1

xxxxxxxxxxxxxxxxxxx

Das könnte Ihnen auch gefallen

- Rotating Equipment Installation ProcedureDokument2 SeitenRotating Equipment Installation ProcedureathithancapeNoch keine Bewertungen

- Eis-Cms-Pk - 023-Replacement of Girth Gear Assembly For 03-Vr-2701abDokument5 SeitenEis-Cms-Pk - 023-Replacement of Girth Gear Assembly For 03-Vr-2701abhastmishNoch keine Bewertungen

- Epic For Upgrade of Port Control Tower and Systems at RlicDokument8 SeitenEpic For Upgrade of Port Control Tower and Systems at RlicsreeNoch keine Bewertungen

- Ms Ahu, Fcuand FansDokument36 SeitenMs Ahu, Fcuand FansUmair Liaqat100% (1)

- MS & RA CombinedDokument49 SeitenMS & RA Combinedanishdev6100% (1)

- Turbomachinery Package Installation Guidline 1000 Rev - BDokument85 SeitenTurbomachinery Package Installation Guidline 1000 Rev - Beugenio_meza_9100% (3)

- Catalyst Loading by Sock Method Single Bed Reactor Normal AtmosphereDokument5 SeitenCatalyst Loading by Sock Method Single Bed Reactor Normal Atmospherevishal bailurNoch keine Bewertungen

- Circuit Breaker TestingDokument6 SeitenCircuit Breaker TestingPandrayar MaruthuNoch keine Bewertungen

- Ms For Demin Water Tank Modification Rev 1 Feb. 28 2011lastDokument9 SeitenMs For Demin Water Tank Modification Rev 1 Feb. 28 2011lastsharif339100% (1)

- GRP ProcedureDokument42 SeitenGRP Proceduremansih45775% (4)

- BTC004-B010-CM-PRO-00031 C01 - Pipeline Cleaning and GaugingDokument29 SeitenBTC004-B010-CM-PRO-00031 C01 - Pipeline Cleaning and GaugingAbdulkadir Berk Malkoç100% (2)

- Thai 4a Gen P02a 15-01-0011 - Rev.1 Cameron b4d Instructions ManualDokument18 SeitenThai 4a Gen P02a 15-01-0011 - Rev.1 Cameron b4d Instructions Manualkid6232863Noch keine Bewertungen

- Erection of LV Switchgears (PCC, MCC, Aux PDB'S)Dokument6 SeitenErection of LV Switchgears (PCC, MCC, Aux PDB'S)Sutanu BiswasNoch keine Bewertungen

- Section 5 Construction PhilosophyDokument11 SeitenSection 5 Construction Philosophyjeya vasanthNoch keine Bewertungen

- Use and Refuelling of Portable GeneratorDokument4 SeitenUse and Refuelling of Portable GeneratorJonasNoch keine Bewertungen

- Uic-qp-Ins-011 PSV Rev11Dokument12 SeitenUic-qp-Ins-011 PSV Rev11Iksan Adityo MulyoNoch keine Bewertungen

- PP13 00 y QNQ Gam 043 0 PDFDokument22 SeitenPP13 00 y QNQ Gam 043 0 PDFRıdvan UyarNoch keine Bewertungen

- 50037-QA-PLN-002 Rev.0Dokument13 Seiten50037-QA-PLN-002 Rev.0seehari100% (3)

- Spec Clauses NotesDokument4 SeitenSpec Clauses NoteszohaNoch keine Bewertungen

- 23-019 Installation Procedures Mechanical WtemplateDokument7 Seiten23-019 Installation Procedures Mechanical WtemplateAli Khalid QureshiNoch keine Bewertungen

- Erection Method Statement Royal Comision (Hollow Core)Dokument17 SeitenErection Method Statement Royal Comision (Hollow Core)marcke0% (1)

- ITP For Fire Fighting SystemDokument7 SeitenITP For Fire Fighting Systemjiturit33% (3)

- Mackintosh Probe TestDokument9 SeitenMackintosh Probe Testmyke_0101100% (2)

- Loading of ReactorsDokument3 SeitenLoading of ReactorsVishal BailurNoch keine Bewertungen

- PDOC-476-CTRU-06 Rotating Equipment Installation ProcedureDokument7 SeitenPDOC-476-CTRU-06 Rotating Equipment Installation Procedure1339979Noch keine Bewertungen

- ABB Construction MS 020 Pump InstallationDokument5 SeitenABB Construction MS 020 Pump InstallationMike MatshonaNoch keine Bewertungen

- 64-Crane Operator Program NcmscurrentDokument5 Seiten64-Crane Operator Program NcmscurrentJojo Betanio AkajoknoNoch keine Bewertungen

- Method Statement Piping Works DABBIYADokument11 SeitenMethod Statement Piping Works DABBIYAsivaparthiban100% (3)

- Method of Statement For MV&LV SwitchgearsDokument12 SeitenMethod of Statement For MV&LV SwitchgearsUtku Can Kılıç100% (1)

- V-31P0-0001-A-0011 - 2 - 001 - Hydrostatic Test Procedure For Pipeline PDFDokument32 SeitenV-31P0-0001-A-0011 - 2 - 001 - Hydrostatic Test Procedure For Pipeline PDFpertmaster100% (1)

- Method Statement Acc Installation Works GZT 190121Dokument19 SeitenMethod Statement Acc Installation Works GZT 190121eccxp555Noch keine Bewertungen

- Catalyst Loading by Dense Method (SingleBed) in Inert AtmosphereDokument5 SeitenCatalyst Loading by Dense Method (SingleBed) in Inert Atmospherevishal bailurNoch keine Bewertungen

- MS-M-063 Rev. 1 - Air Fin Cooler InstallationDokument6 SeitenMS-M-063 Rev. 1 - Air Fin Cooler InstallationwalitedisonNoch keine Bewertungen

- Chiller Unit Method Statement PDFDokument5 SeitenChiller Unit Method Statement PDFmostafaabdelrazik100% (1)

- SATIP-X-400-01 Rev 5Dokument3 SeitenSATIP-X-400-01 Rev 5aamirapiNoch keine Bewertungen

- Directional Drill SafetyDokument7 SeitenDirectional Drill SafetyMartahan ManurungNoch keine Bewertungen

- MS For Putting Plugs at Ps 50Dokument8 SeitenMS For Putting Plugs at Ps 50deepakjoyinNoch keine Bewertungen

- Crane Hoist Safety ProgramDokument11 SeitenCrane Hoist Safety ProgramAssawin AnonuNoch keine Bewertungen

- Method Statement For Installation of Diesel Generator Set - Safe Work Method of StatementDokument5 SeitenMethod Statement For Installation of Diesel Generator Set - Safe Work Method of StatementMohamed AliNoch keine Bewertungen

- Fire Protetion Alarm Check ValveDokument7 SeitenFire Protetion Alarm Check ValveAbdul HakkimNoch keine Bewertungen

- Hip Plan - Hvac WorkDokument30 SeitenHip Plan - Hvac WorksrisetNoch keine Bewertungen

- Ump Fan-Air Om Manual - Rev Dec 2014Dokument12 SeitenUmp Fan-Air Om Manual - Rev Dec 2014api-252481722Noch keine Bewertungen

- MOS For Metallic Conduit InstallationDokument23 SeitenMOS For Metallic Conduit InstallationAhmed MhnaNoch keine Bewertungen

- Electrical Feeder System Method StatementDokument7 SeitenElectrical Feeder System Method StatementAngelo Castro100% (1)

- Load Test ProcedureDokument70 SeitenLoad Test ProcedureMohammed Rizwan Ahmed75% (4)

- QCP 040 QCP CrmsDokument7 SeitenQCP 040 QCP Crmsarockiyathass100% (1)

- Chains Slings and Rigging ProgramDokument34 SeitenChains Slings and Rigging ProgramRuperto Caruanambo MalcaNoch keine Bewertungen

- PP13 00 y QNQ Gam 044 0 PDFDokument20 SeitenPP13 00 y QNQ Gam 044 0 PDFRıdvan UyarNoch keine Bewertungen

- Sop For Set Up & Operation of Concrete PumpDokument3 SeitenSop For Set Up & Operation of Concrete Pumplelu ojhaNoch keine Bewertungen

- Bhr240n Iom Rev 0Dokument60 SeitenBhr240n Iom Rev 0Saipavan ChanduNoch keine Bewertungen

- Method Statement GIS HV TestDokument28 SeitenMethod Statement GIS HV Testnayagammailbox75% (4)

- MOS Panel InstallationDokument10 SeitenMOS Panel InstallationEm NiaxNoch keine Bewertungen

- MST Installation of UPVC PIPESDokument10 SeitenMST Installation of UPVC PIPESShahzaib ShahidNoch keine Bewertungen

- Method Statemnet For 11kV Cable SATDokument47 SeitenMethod Statemnet For 11kV Cable SATZaheer Ahamed92% (12)

- Installation Procedure For Pressure VesselDokument8 SeitenInstallation Procedure For Pressure VesselSamuel Babu100% (1)

- Hydraulics and Pneumatics: A Technician's and Engineer's GuideVon EverandHydraulics and Pneumatics: A Technician's and Engineer's GuideBewertung: 4 von 5 Sternen4/5 (8)

- GM Automatic Overdrive Transmission Builder's and Swapper's GuideVon EverandGM Automatic Overdrive Transmission Builder's and Swapper's GuideBewertung: 4.5 von 5 Sternen4.5/5 (8)

- SAFETY IN PETROLEUM FACILITIES TURNAROUND MAINTENANCEVon EverandSAFETY IN PETROLEUM FACILITIES TURNAROUND MAINTENANCENoch keine Bewertungen

- Safety Analysis and Licensing Documentation for Nuclear Fuel Cycle FacilitiesVon EverandSafety Analysis and Licensing Documentation for Nuclear Fuel Cycle FacilitiesNoch keine Bewertungen

- 50 Me HR RO Project - Vc0-ReportDokument7 Seiten50 Me HR RO Project - Vc0-ReportunnicyriacNoch keine Bewertungen

- N17759-PLR-SANA-D029 Rev-02Dokument1 SeiteN17759-PLR-SANA-D029 Rev-02unnicyriacNoch keine Bewertungen

- Zoo Pumping Station Plan & Profile Drawings Flow PathDokument1 SeiteZoo Pumping Station Plan & Profile Drawings Flow PathunnicyriacNoch keine Bewertungen

- HHDokument2 SeitenHHunnicyriacNoch keine Bewertungen

- N15907-PIL-HYD-NCR-I016 Fire Alarm Installation Non Conformity TAP X (For Approval)Dokument11 SeitenN15907-PIL-HYD-NCR-I016 Fire Alarm Installation Non Conformity TAP X (For Approval)unnicyriacNoch keine Bewertungen

- 6.1 Chamber R1Dokument2 Seiten6.1 Chamber R1unnicyriacNoch keine Bewertungen

- Status Routing ExcelDokument1 SeiteStatus Routing ExcelunnicyriacNoch keine Bewertungen

- N 17761MainIndexDokument22 SeitenN 17761MainIndexunnicyriacNoch keine Bewertungen

- N17759-L-0146 (IB-127) Material Submittal-Pilot Operated Control Valve R..Dokument4 SeitenN17759-L-0146 (IB-127) Material Submittal-Pilot Operated Control Valve R..unnicyriacNoch keine Bewertungen

- 01 FAT Certificate & CommentsDokument5 Seiten01 FAT Certificate & CommentsunnicyriacNoch keine Bewertungen

- New Pumping Station at Jabel Haffet Base EPC Contract No:-N-16297Dokument60 SeitenNew Pumping Station at Jabel Haffet Base EPC Contract No:-N-16297unnicyriacNoch keine Bewertungen

- Method Statement For Trial Pit For Exposing Transco PipelineDokument5 SeitenMethod Statement For Trial Pit For Exposing Transco Pipelineunnicyriac100% (1)

- Al Ahail PFDDokument3 SeitenAl Ahail PFDunnicyriacNoch keine Bewertungen

- Mechanical GA Drawings - Rev.1Dokument14 SeitenMechanical GA Drawings - Rev.1unnicyriacNoch keine Bewertungen

- L-0288 - CS Pipe Wall Thickness Calculation - Rev.1Dokument16 SeitenL-0288 - CS Pipe Wall Thickness Calculation - Rev.1unnicyriacNoch keine Bewertungen

- 03 Fat Notification ApprovalDokument3 Seiten03 Fat Notification ApprovalunnicyriacNoch keine Bewertungen

- Drawing For Jabel Haffet Base Pumping Station Proposed DN300 C.S Suction Pipline Plan and Profile - Rev.1Dokument4 SeitenDrawing For Jabel Haffet Base Pumping Station Proposed DN300 C.S Suction Pipline Plan and Profile - Rev.1unnicyriacNoch keine Bewertungen

- CLA-VAL Sizing: Date: 2021-02-04 To: From: Ref: Remah DN800Dokument6 SeitenCLA-VAL Sizing: Date: 2021-02-04 To: From: Ref: Remah DN800unnicyriacNoch keine Bewertungen

- Hydraulic Control Valves - General: Hydrobloc System - Series KDokument36 SeitenHydraulic Control Valves - General: Hydrobloc System - Series KunnicyriacNoch keine Bewertungen

- 3) Project ScheduleDokument7 Seiten3) Project ScheduleunnicyriacNoch keine Bewertungen

- Vendor Documentation: Fujairah Water and Power Project (Pipelines) Project No.: 06730RDokument10 SeitenVendor Documentation: Fujairah Water and Power Project (Pipelines) Project No.: 06730RunnicyriacNoch keine Bewertungen

- 12 Fire Protection SystemDokument8 Seiten12 Fire Protection SystemunnicyriacNoch keine Bewertungen

- 02 - SIM DN150 PN160 Valve 2 PDFDokument4 Seiten02 - SIM DN150 PN160 Valve 2 PDFunnicyriacNoch keine Bewertungen

- 01 - SIM DN150 PN16 Valve 1 PDFDokument4 Seiten01 - SIM DN150 PN16 Valve 1 PDFunnicyriacNoch keine Bewertungen

- Pages From w-c-ss-014Dokument1 SeitePages From w-c-ss-014unnicyriacNoch keine Bewertungen

- List of Material: 5.00m PIPE LINE Shut DownDokument1 SeiteList of Material: 5.00m PIPE LINE Shut DownunnicyriacNoch keine Bewertungen

- 60222102-ACM-XX-XX-LT-PM-000295-AAN - Shop Drawings For General Layout Plan and Section For TRANSCO & AADC Interface Works (Rev.1)Dokument3 Seiten60222102-ACM-XX-XX-LT-PM-000295-AAN - Shop Drawings For General Layout Plan and Section For TRANSCO & AADC Interface Works (Rev.1)unnicyriacNoch keine Bewertungen

- Facsimile Transmittal Sheet: Irrigation Stations - Al Ain, Abu Dhabi and Al Dhafrah Regions in Accordance With TheDokument1 SeiteFacsimile Transmittal Sheet: Irrigation Stations - Al Ain, Abu Dhabi and Al Dhafrah Regions in Accordance With TheunnicyriacNoch keine Bewertungen

- API 614/ISO 10438-2 DATASHEET Scope and Attachments Si Units (Kpa)Dokument7 SeitenAPI 614/ISO 10438-2 DATASHEET Scope and Attachments Si Units (Kpa)Ricardo NapitupuluNoch keine Bewertungen

- Air Circuit Breakers For The 21st Century: Catalogue No.'00-P55EDokument4 SeitenAir Circuit Breakers For The 21st Century: Catalogue No.'00-P55EAsif ShahNoch keine Bewertungen

- Mic Electronics Research ReportDokument17 SeitenMic Electronics Research ReportSudipta BoseNoch keine Bewertungen

- Company Profile - Grrsb-SmallDokument2 SeitenCompany Profile - Grrsb-Smallmsis81Noch keine Bewertungen

- SPCSP CatalogDokument24 SeitenSPCSP Catalogleojay24Noch keine Bewertungen

- CATERPILAR3516 1550-2200 BHPDokument6 SeitenCATERPILAR3516 1550-2200 BHPNadia AnandaNoch keine Bewertungen

- Slope Efficiency: Threshold Above Current Input in Increase Power Output Optical in IncreaseDokument34 SeitenSlope Efficiency: Threshold Above Current Input in Increase Power Output Optical in IncreaseRIzwanaNoch keine Bewertungen

- 1.diesel Engine AssemblyDokument22 Seiten1.diesel Engine Assemblypepenapao1217Noch keine Bewertungen

- Ipfest 2022 - Registration BookletDokument70 SeitenIpfest 2022 - Registration BookletMarojahan Benedict Efrata, S.TNoch keine Bewertungen

- Actuador VAURIEN (ON-OFF)Dokument1 SeiteActuador VAURIEN (ON-OFF)Rafael SalazarNoch keine Bewertungen

- Al Kindi Research Complex / Saad 16 Sa'ad General Establishment Mosul 36 ??'N 43 ??'EDokument4 SeitenAl Kindi Research Complex / Saad 16 Sa'ad General Establishment Mosul 36 ??'N 43 ??'EMoltaz AwdNoch keine Bewertungen

- Aula Balancim DifusaoDokument29 SeitenAula Balancim DifusaoGabrielAntoniazziNoch keine Bewertungen

- RAC Lecture 10 PDFDokument18 SeitenRAC Lecture 10 PDFSalman KhanNoch keine Bewertungen

- Learning Module No. 4 - Aircraft Air Conditioning and Pressurization SystemDokument36 SeitenLearning Module No. 4 - Aircraft Air Conditioning and Pressurization SystemDavidSamsonNoch keine Bewertungen

- A Novel High-Gain DC-DC Converter Applied in Fuel Cell VehiclesDokument13 SeitenA Novel High-Gain DC-DC Converter Applied in Fuel Cell Vehiclesrock starNoch keine Bewertungen

- Maintenance Issues of Photovoltaic System: Presented byDokument10 SeitenMaintenance Issues of Photovoltaic System: Presented byjunaid bashirNoch keine Bewertungen

- 16operation StartingadieselengineDokument76 Seiten16operation StartingadieselengineVijay HanchinalNoch keine Bewertungen

- 434 02Dokument28 Seiten434 02Luiz Filipe Silva100% (1)

- Approximation Methods: Physics 130B, UCSD Fall 2009Dokument90 SeitenApproximation Methods: Physics 130B, UCSD Fall 2009Luz PeñaNoch keine Bewertungen

- HSBTS Diagram PDFDokument1 SeiteHSBTS Diagram PDFMayurNoch keine Bewertungen

- 7W Amplifier Circuit TDA2003Dokument7 Seiten7W Amplifier Circuit TDA2003Mar EscNoch keine Bewertungen

- ICE 160 230 0296 HammerDokument119 SeitenICE 160 230 0296 HammerRıfat BingülNoch keine Bewertungen

- VCB ToshibaDokument16 SeitenVCB Toshibaaris soepandiNoch keine Bewertungen

- Service Station Manual Vespa LX 125 - 150 4t Euro 3Dokument241 SeitenService Station Manual Vespa LX 125 - 150 4t Euro 3Adèle Standard100% (1)

- Act 4070Dokument10 SeitenAct 4070Diego PachecoNoch keine Bewertungen

- Annexure-3 Calculation of Safe Bearing Pressure Based On N Value Settlement CriteriaDokument4 SeitenAnnexure-3 Calculation of Safe Bearing Pressure Based On N Value Settlement CriteriaAnkitaNoch keine Bewertungen

- Test Format Light & WaveDokument7 SeitenTest Format Light & WaveDewan Olin ChotepadaeNoch keine Bewertungen

- Decarbonization MagazineDokument86 SeitenDecarbonization MagazineSynergy IndustriesNoch keine Bewertungen

- Pump Head CalculationDokument10 SeitenPump Head CalculationHussien Al-gaafary100% (4)

- PWM Control IC: BM1P107FJDokument30 SeitenPWM Control IC: BM1P107FJArokiaraj RajNoch keine Bewertungen