Beruflich Dokumente

Kultur Dokumente

Kollmorgen PMA Series Catalog

Hochgeladen von

ElectromateCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Kollmorgen PMA Series Catalog

Hochgeladen von

ElectromateCopyright:

Verfügbare Formate

Sold & Serviced By:

ELECTROMATE

Toll Free Phone (877) SERVO98

Toll Free Fax (877) SERV099

www.electromate.com

sales@electromate.com

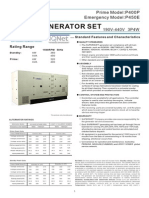

PMA SERIES

BRUSHLESS

SERVOMOTORS

Unmatched Ruggedness & Cost Effectiveness in a

Comprehensive Family of Brushless Servomotors

Pacific Scientifics new wide voltage range

(from 240 to 480V ac) PMA Series is industrys

most rugged, comprehensive line of reliable,

customizable and cost-effective brushless

servomotors.

Rugged construction earns IP67 rating (on

selected models) and enhances your equipment

reliability. CE compliance and medium-voltage

capability open the door to a world-wide range

of applications. Making the PMA Series the

ultimate cost-effective choice for your motion

control needs.

This line extends Pacific Scientifics commitment

to offering you the highest performance products,

backed by unmatched customer support and

quality, with an ability to offer custom products

to fit your unique applications.

Sold & Serviced By:

ELECTROMATE

Toll Free Phone (877) SERVO98

Toll Free Fax (877) SERV099

www.electromate.com

sales@electromate.com

DRIVE & MOTOR PERFORMANCE DATA

EXAMPLE CHART

Torque

In the table below, performance data for

combinations of PMA Series motors and

SCE900 or SC900 drives are shown. In addition

to continuous stall current (ICS), inertia (J) and

line-line inductance (L), each system has ratings

provided that enable you to construct a reference

chart for in comparing and sizing systems. The

ratings required to construct the chart are:

To construct a chart, plot the points as in the

example shown. Note that the chart provides

continuous and intermittent duty zones.

Peak Stall Torque (TPS)

Operation in the intermittent duty zone must be

limited to a duty cycle which will produce an

RMS system torque falling within the continuous

duty area. The RMS torque value is defined by

the magnitude of the intermittent torque and

the percentage of time spent at that torque.

Peak Rated Torque (TPR)

Continuous Stall Torque (TCS)

Continuous Rated Torque (TCR)

Rate Speed (WR)

Motor Speed Unloaded (WNL)

TPS

TPR

TCS

Systems can be operated continually at

torque/speed combinations anywhere in the

continuous duty area, assuming the ambient

temperature is less than 40C.

TCR

WR

WNL

Speed

Test conditions

Motor operated at rated winding

temperature of t = 100C above

ambient, at 25C ambient.

Intermittent duty zone

Continuous duty zone

Peak rated

torque

TPR

lb-in./Nm

Cont. stall

torque

TCS

lb-in./Nm

Cont. rated

torque

TCR

lb-in./Nm

Rated

speed

WR

rpm

No-load

speed

WNL

rpm

Motor

Weight

lb-in./kg.

Current

at peak

torque

IPK

A

Inertia x103

J

lb-in-S2/

kgm2

Servo Drive Model

Servo Motor Model

Peak stall

torque

TPS

lb-in./Nm

240V ac

SC902-AN-001-01

SCE902-AN-001-01

SC902-AN-001-01

SCE902-AN-001-01

SC903-AN-001-01

SC903-AN-001-01

SC902-AN-001-01

SCE902-AN-001-01

SC903-AN-001-01

SC903-AN-001-01

SC903-AN-001-01

SC904-AN-001-01

SC904-AN-001-01

SC904-AN-001-01

SC904-AN-001-01

SC904-AN-001-01

SC904-AN-001-01

SC904-AN-001-01

SC905-AN-001-01

SC905-AN-001-01

SC905-AN-001-01

SC905-AN-001-01

SC905-AN-001-01

SC905-AN-001-01

PMA21B-00100-00

PMA21B-00100-00

PMA22B-00100-00

PMA22B-00100-00

PMA23D-00100-00

PMA24D-00100-00

PMA42M-00100-00

PMA42M-00100-00

PMA42P-00100-00

PMA43P-00100-00

PMA44P-00100-00

PMA43R-00100-00

PMA44R-00100-00

PMA45R-00100-00

PMA53R-00100-00

PMA54R-00100-00

PMA55R-00100-00

PMA57R-00100-00

PMA55S-00100-00

PMA57S-00100-00

PMA65S-00100-00

PMA66S-00100-00

PMA67S-00100-00

PMA69S-00100-00

16.8/1.9

16.8/1.9

23.2/2.6

23.2/2.6

37.2/4.2

46.9/5.3

69.9/7.9

69.9/7.9

80.5/9.1

123.9/14.0

143.4/16.2

113.3/12.8

152.2/17.2

193.8/21.9

179.7/20.3

221.3/25.0

278.8/31.5

405.4/45.8

278.8/31.5

393.9/44.5

499.2/56.0

601.8/68.0

703.6/80.0

911.6/103.0

16.8/1.9

16.8/1.9

23.2/2.6

23.2/2.6

37.2/4.2

46.9/5.3

69.9/7.9

69.9/7.9

80.5/9.1

123.9/14.0

143.4/16.2

113.3/12.8

152.2/17.2

193.8/21.9

179.7/20.3

221.3/25.0

278.8/31.5

405.4/45.8

278.8/31.5

393.9/44.5

499.2/56.0

601.8/68.0

703.6/80.0

911.6/103.0

5.6/0.63

5.6/0.63

11.5/1.3

11.5/1.3

17.7/2.0

23.0/2.6

36.3/4.1

36.3/4.1

36.3/4.1

54.0/6.1

72.6/8.2

54.0/6.1

72.6/8.2

90.3/10.2

92.9/10.5

119.5/13.5

150.5/17.0

194.7/22.0

150.5/17.0

194.7/22.0

265.5/30.0

318.6/36.0

371.7/42.0

477.9/54.0

4.4/0.50

4.4/0.50

8.9/1.0

8.9/1.0

11.5/1.3

16.1/1.8

34.5/3.9

34.5/3.9

31.9/3.6

49.6/5.6

66.4/7.5

39.8/4.5

59.3/6.7

78.8/8.9

77.9/8.8

102.7/11.6

134.5/15.2

181.4/20.5

115.9/13.1

162.9/18.4

216.8/24.5

274.4/31.0

327.5/37.0

429.3/48.5

6,050

6,050

5,750

5,750

7,400

5,850

1,600

1,600

2,950

1,850

1,750

4,700

3,450

2,700

2,350

2,100

1,650

1,150

3,450

2,450

1,750

1,450

1,250

950

9,250

9,250

7,100

7,100

8,750

6,950

2,350

2,350

4,000

2,600

2,250

5,650

4,200

3,300

3,200

2,700

2,150

1,550

4,300

3,050

2,400

2,000

1,700

1,300

3.3/1.5

3.3/1.5

4.6/2.1

4.6/2.1

5.9/2.7

7.3/3.3

13.2/6

13.2/6

13.2/6

15.4/7

17.6/8

15.4/7

17.6/8

19.8/9

23.1/10.5

26.4/12

29.7/13.5

36.3/16.5

29.7/13.5

36.3/16.5

68.3/31

79.3/36

92.5/42

119/54

5.4

5.4

5.4

5.4

10.6

10.6

5.4

5.4

10.6

10.6

10.6

21.2

21.2

21.2

21.2

21.2

21.2

22.5

42.4

42.4

42.4

42.4

42.4

42.4

0.23/0.026

0.23/0.026

0.38/0.044

0.38/0.044

0.55/0.062

0.71/0.08

3.1/0.35

3.1/0.35

3.1/0.35

4.5/0.51

5.9/0.67

4.5/0.51

5.9/0.67

7.3/0.83

16.9/1.91

21.9/2.48

27.0/3.05

37.2/4.20

27.0/3.05

37.2/4.20

69.9/7.90

83.1/9.40

98.4/10.90

123.0/13.90

480V ac

SCE903AN-001-01

SCE903AN-001-01

SCE903AN-001-01

SCE903AN-001-01

SCE904AN-001-01

SCE904AN-001-01

SCE904AN-001-01

SCE904AN-001-01

SCE904AN-001-01

SCE904AN-001-01

SCE905AN-001-01

SCE905AN-001-01

SCE905AN-001-01

SCE905AN-001-01

SCE905AN-001-01

SCE905AN-001-01

SCE906AN-001-01

SCE906AN-001-01

SCE906AN-001-01

SCE906AN-001-01

PMA42M-00100-00

PMA43N-00100-00

PMA44N-00100-00

PMA45N-00100-00

PMA43P-00100-00

PMA44P-00100-00

PMA45Q-00100-00

PMA53Q-00100-00

PMA54Q-00100-00

PMA55Q-00100-00

PMA53R-00100-00

PMA54R-00100-00

PMA55R-00100-00

PMA57R-00100-00

PMA65R-00100-00

PMA66R-00100-00

PMA65S-00100-00

PMA66S-00100-00

PMA67S-00100-00

PMA69S-00100-00

69.9/7.9

110.6/12.5

149.6/16.9

187.6/21.2

123.9/14.0

143.4/16.2

190.3/21.5

180.6/20.4

226.6/25.6

286.8/32.4

179.7/20.3

221.3/25.0

278.8/31.5

405.4/45.8

486.8/55.0

587.7/66.0

409.3/46.2

493.5/55.8

577.0/65.2

747.5/84.5

69.9/7.9

110.6/12.5

149.6/16.9

187.6/21.2

123.9/14.0

143.4/16.2

190.3/21.5

180.6/20.4

226.6/25.6

286.8/32.4

179.7/20.3

221.3/25.0

278.8/31.5

405.4/45.8

486.8/55.0

587.7/66.0

409.3/46.2

493.5/55.8

577.0/65.2

747.5/84.5

36.3/4.1

54.0/6.1

72.6/8.2

90.3/10.2

54.0/6.1

72.6/8.2

90.3/10.2

92.9/10.5

119.5/13.5

150.5/17.0

92.9/10.5

119.5/13.5

150.5/17.0

194.7/22.0

265.5/30.0

318.6/36.0

265.5/30.0

318.6/36.0

371.7/42.0

477.9/54.0

30.1/3.4

45.1/5.1

63.7/7.2

82.3/9.3

42.5/4.8

57.5/6.5

64.6/7.3

69.0/7.8

97.4/11.0

128.3/14.5

59.3/6.7

85.0/9.6

116.8/13.2

164.6/18.6

212.4/24.0

269.9/30.5

159.3/18.0

185.9/21.0

283.2/32.0

380.6/43.0

3,700

3,350

2,300

1,900

4,150

3,750

4,000

3,350

2,800

2,200

4,900

4,400

3,450

2,400

1,900

1,600

3,650

3,000

2,550

1,950

4,650

4,150

3,050

2,450

5,150

4,500

4,750

4,450

3,650

2,900

6,400

5,450

4,300

3,050

2,600

2,150

4,800

3,950

3,400

2,650

13.2/6

15.4/7

17.6/8

19.8/9

15.4/7

17.6/8

19.8/9

23.1/10.5

26.4/12

29.7/13.5

23.1/10.5

26.4/12

29.7/13.5

36.3/16.5

68.3/31

79.3/36

68.3/31

79.3/36

92.5/42

119/54

5.4

7.5

7.5

7.5

10.6

10.6

15.0

15.0

15.0

15.0

21.2

21.2

21.2

22.5

22.5

22.5

33.7

33.7

33.7

33.7

3.1/0.35

4.5/0.51

5.9/0.67

7.3/0.83

4.5/0.51

5.9/0.67

7.3/0.83

16.9/1.91

21.9/2.48

27.0/3.05

16.9/1.91

21.9/2.48

27.0/3.05

37.2/4.20

69.9/7.90

83.1/9.40

69.9/7.90

83.1/9.40

96.4/10.9

123.3/13.90

Sold & Serviced By:

ELECTROMATE

Toll Free Phone (877) SERVO98

Toll Free Fax (877) SERV099

www.electromate.com

sales@electromate.com

NUMBERING SYSTEM GLOBAL MOTOR RANGE

To construct a motor model number code, select the combination of features required and put all of the

coded information in the proper sequence. Please account for an entry in each field. The model number

shown is an example of a properly specified motor.

Pacific Scientific

Customization Code, Factory Assigned

Brake

Brushless Servomotor

00 = Indicates Standard Motor

0 = No Brake

01 = Indicates Oil Seal

1 = 24V Brake

Product Series

Frame Size

Connector

2 = 70mm motor body square

Right Angle Type Standard

6 Pole Power = 6PP etc.

12 Pole Sensor, O deg. Code

4 = 115mm motor body square

5 = 142 mm motor body square

1 = 6PP, 12PSO*

6 = 190mm motor body square

*Mating plugs available seperately.

Contact Pacific Scientific for details.

Stack Length

1-9 = Stack length in multiples

Sensor

00 = Std. Alignment Resolver

Winding

12 = Digital Encoder with commutation, 1024 ppr

Winding Designator:

Nominal Stall

14 = Digital Encoder with commutation, 2048 ppr

240V ac

240-480V ac

Current, ARMS

20 = SinCos Encoder (Stegmann SNS50/60)

1.3

2.7

3.8

(max.)

5.4

7.4

11.0

22.0

30 = Resolver, Std. Alignment + Encoder Mount

Shaft

0=

Smooth Shaft, DIN42955 N

1=

Closed Keyway, Key Fitted, DIN42995 N

3=

Smooth Shaft, DIN42955 R

4=

Closed Keyway, Key Fitted, DIN42995 R

In designing the PMA series, Pacific Scientific engineers analyzed real-world motion control

applications and tailored the windings for maximum efficiency using matched SCE900 and SC900

drives. The combination of Pacific Scientific motors and drives results in higher performance and

efficiency, delivering more usable torque in your application.

BRAKE DATA

Motor

Family

Static Torque

@ 120C

lb.-in.

PMA2

PMA4

PMA5

PMA6

Weight

Inertia

Nm.

lb.

Kg

lb.-in/sec2

Kg/cm2

+/-30%

10.6

1.2

88.5

10

159.3

18

354.0

40

0.4

1.3

3.3

4.8

0.2

0.6

1.5

2.2

0.00011

0.00097

0.00319

0.00841

0.12

1.1

3.6

9.5

Sold & Serviced By:

ELECTROMATE

Toll Free Phone (877) SERVO98

Toll Free Fax (877) SERV099

www.electromate.com

sales@electromate.com

6

.24

POWER

CONNECTOR

1 9 8

2 10 12 7

85

Motor

L Max

PMA21

145/5.7

FEEDBACK

CONNECTOR

6

11 5

4

3,5

.14

23

.90

11 + 6

.43 + .24

PMA22

170/6.7

PMA23

195/7.7

PMA24

220/8.7

Metric dimensions in mm on top

GND

81

.31 .04

3.34

60 - 6

2.36 - .24

43

1.69

CENTRE HOLE

DR M4 DIN 332

2,5 0.3

.1 .01

16,0

15.8

.63

.62

12,5

.49

45

KEY A 4x4x16 DIN 6885

5,8 ( x4 )

45 ( x4 )

1.77 ( x4 )

SQ.70

SQ.2.75

23 0.5

CUSTOMER KEY OPTION

.23 ( x4 )

( L ) MAX.

.90 .02

19 +6

4.32 -.24

110 -6

.75 +.24

18

.71

POWER

CONNECTOR

GND

1.63

41,5

3,5 0.3

.14 .01

91

.35 .04

1 9 8

2 10 12 7

130

5.11

6

11 5

4

Motor

L Max

PMA42

185/7.3

PMA43

210/8.3

PMA44

235/9.2

PMA45

260/10.2

Metric dimensions in mm on top

FEEDBACK

CONNECTOR

5

.20

40

1.57

32.0

31,7

1.26

1.25

21,5

.85

CENTRE HOLE

DR M6 DIN 332

45

KEY A 6x6x32 DIN 6885

CUSTOMER KEY OPTION

9 ( x4 )

75 ( x4 )

2.95 ( x4 )

SQ.115

SQ.4.52

40 0.5

( L ) MAX.

.35 ( x4 )

10 MAX.

.39 MAX.

1.57 .02

32.0

18

.71

24 +6

5.11 -.24

130 -6

.94 +.24

POWER

CONNECTOR

Motor

L Max

PMA53

205/8.1

PMA54

230/9.0

PMA55

255/10.0

PMA57

305/12.0

1.63

GND

41,5

3,5 0.1

.14 0.1

12 1

.47 .04

165

6.49

1 9 8

2 10 12 7

3

6

11 5

4

FEEDBACK

CONNECTOR

Metric dimensions in mm on top

5

.20

50

1.97

CENTRE HOLE

DR M8 DIN 332

40,00

39,70

1.57

1.56

27

1.06

45

KEY A 8x7x40 DIN 6885

94 ( x4 )

CUSTOMER KEY OPTION

11 ( x4 )

3.70 ( x4 )

50 0.5

SQ.142

SQ.5.58

1.97 .02

.43 ( x4 )

( L ) MAX.

10 MAX.

.39 MAX.

5

40,00

39,70

4 0,3

.16 .01

17

.67

15 1

.59 .04

1.26 +.24

32 +6

180 -6

1

2

POWER

CONNECTOR

Motor

L Max

PMA65

205/8.1

PMA66

230/9.0

PMA67

255/10.0

41,5

1.63

41,5

1.63

GND

1 9 8

2 10 12 7

215

7.08 -.24

27

8.45

6

11 5

4

FEEDBACK

CONNECTOR

Metric dimensions in mm on top

4

.16

58

2.28

CENTRE HOLE

DR M12 DIN 332

50,00

49,70

1.97

1.96

35

1.38

45

14 ( x4 )

125 (x4)

4.91 (x4)

SQ.190

SQ.7.47

.55 ( x4 )

58 } 0,5

( L ) MAX.

6 MAX.

2.28 .02

Feedback Connector

Connector

Standard

Pin

Resolver

1

S1 Cos+

2

S3 Cos3

S4 Sin4

S2 Sin+

5

R1 Excit

6

R2 Excit Rtn

7

PTC

8

PTC rtn

9

not used

10

not used

11

not used

12

not used

.24 MAX.

Power Connector

Connector

Pin

Motor

1

Phase U

2

Phase W

gnd

Earth Case

4

Optional Brake5

Phase V

E

Optional Brake+

KEY A 10x8x50 DIN 6885

CUSTOMER KEY OPTION

PMA69

305/12.0

Sold & Serviced By:

ELECTROMATE

Toll Free Phone (877) SERVO98

Toll Free Fax (877) SERV099

www.electromate.com

sales@electromate.com

ition!

d

d

A

New

The Comprehensive Line of Rugged, Cost-Effective Servomotors is Now Larger (and Smaller)

THE NEW PMA1

SERIES BRUSHLESS

SERVO MOTORS

This motor family extends Pacific Scientific's commitment to

offering you the highest performance, backed by unmatched

quality and customer support, tailored to your applications.

Pacific Scientific's PMA Series is industry's most rugged,

comprehensive line of cost-effective brushless servomotors

available. Now, with the addition of the new PMA1 series

motors, the family gets bigger - and smaller.

These compact motors feature a 55 mm square frame, in three

stack lengths. A continuous rated torque range from 0.21 to

0.6 Nm, optional sealing to IP67, CE compliance and the

capability of integral parking brake give these motors the

flexibility to meet your application.

Part Number Configurator - PMA1 Series

To construct a motor model number code, select the

combination of features required and put all of the coded

information in the proper sequence. Please account for

an entry in each field. The model number shown is an

example of a properly specified motor.

Brake

0 = No brake

1 = 24V brake

Pacific Scientific

Brushless Servomotor

Product Series

Connector

1 = 6PP, 12PSO

Sensor

00 = Std. alignment resolver

P M A 1 2 A - 0 0 1 00 - 00

Frame Size

1 = 55mm motor body square

Stack Length

1 - 3 = Stack length in multiples

Winding

Winding Designator: Nominal Stall

240V ac (max.)

Current, ARMS

A

1.3

B

2.7

In designing the PMA1 Series,

Pacific Scientific engineers

analyzed real-world motion

control applications and tailored

the windings for maximum

efficiency using matched

PC832, SC902 and SCE902

drives. The combination of

Pacific Scientific motors and

drives results in higher

performance and efficiency,

delivering more usable torque

in your application.

Customization Code, Factory Assigned

00 = Indicates standard motor

01 = Indicates oil seal

Shaft

0 = Smooth shaft, DIN42955 N

3 = Smooth shaft, DIN42955 R

Sold & Serviced By:

ELECTROMATE

Toll Free Phone (877) SERVO98

Toll Free Fax (877) SERV099

www.electromate.com

sales@electromate.com

Dimensions

45.5

2.5 0.3

[ .10 .01 ]

[ 1.79 ]

POWER

CONNECTOIR

FEEDBACK

CONNECTOR

81

[ .31 .04 ]

63

[ 2.48 ]

9 k6

59

20 0.5

(L)

[ .787 0.02 ]

Model

L

PMA13

PMA12

[ 2 .323 ]

[ .787 ]

CENTRE HOLE

DR M3 DIN 332

[ .3547 ]

[ .3544 ]

40 j6

[ 1.5752 ]

[ 1.5746 ]

20

45fl

4.8 ( x4 )

[ .19 ]

Brake adds 25 mm

PMA11

SQ.55

[ SQ 2.17 ]

175 (6.89) 150 (5.91) 125 (4.92)

Drive & Motor Performance Data

In the table below, we show the performance data for the recommended combinations of

PMA1 motors and PC832, SC902 or SCE902 drives. In addition to continuous stall current

(ICS), inertia (J) and line-line inductance (L), each system has ratings provided that enable

you to construct a reference chart to compare and size systems. The ratings required to

construct the chart are:

Servo

Motor

Model

Servo Drive

Model

PMA11A PC8x2,SC,SCE9x2

PMA12A PC8x2,SC,SCE9x2

PMA13B PC8x2,SC,SCE9x2

Torque

Test Conditions

Peak Stall Torque (TPS)

Peak Rated Torque (TPR)

Continuous Stall Torque (TCS)

Continuous Rated Torque (TCR)

Rated Speed (WR)

Unloaded Motor Speed (WNL)

TPS

Motor operated at rated winding

temperature of Dt = 100C above

ambient, at 25C ambient.

Cont. stall

torque

TCS

Nm/lb-in.

1.4/12.4

1.7/15.0

1.8/15.5

0.26/2.3

0.6/5.3

0.9/8.0

1.4/12.4

1.7/15.0

1.8/15.5

Cont. rated No-load

torque

speed

TCR

WNL

Nm/lb-in.

rpm

0.21/1.9

0.48/4.2

0.6/5.3

7,000

8,500

9,000

Rated

speed

WR

rpm

12,900

10,800

10,600

Systems can be operated continually at torque/speed combinations anywhere in the

continuous duty area, assuming the ambient temperature is less than 40C.

Operation in the intermittent duty zone must be limited to a duty cycle, which will

produce an RMS system torque falling within the continuous duty area. The RMS

torque value is defined by the magnitude of the intermittent torque and the

percentage of time spent at that torque.

Brake Data

Nm

PMA1

lb-in.

30%

1.2

10.6

TCS

TCR

Continuous duty zone

Peak

Peak rated

stall

torque

torque

TPR

TPS

Nm/lb-in.

Nm/lb-in.

Static Torque @ 120C

TPR

Intermittent duty zone

To construct a chart, plot the points as shown in the example. Note that the chart

provides continuous and intermittent duty zones.

Motor Family

Example Chart

Weight

kg

0.2

Inertia

lb.

0.4

kg/cm2

lb-in-sec2

0.12

0.00011

WR

Continuous Current at

stall current

peak

ICS

torque

IPS

A

A

0.96

1.88

2.73

5.4

9.4

13.8

WNL Speed

Inertia

x 10-3

J

kgm2/

lb-in-S2

Inductance

line-line

L

mH

0.012/0.102

0.019/0.164

0.026/0.226

7.1

4.3

2.7

Das könnte Ihnen auch gefallen

- Analog Circuit Design: A Tutorial Guide to Applications and SolutionsVon EverandAnalog Circuit Design: A Tutorial Guide to Applications and SolutionsBewertung: 3.5 von 5 Sternen3.5/5 (6)

- Technical Service Information: Jatco Jr710EDokument5 SeitenTechnical Service Information: Jatco Jr710EUrszula Walczewska100% (2)

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2Von EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2Noch keine Bewertungen

- 110 Waveform Generator Projects for the Home ConstructorVon Everand110 Waveform Generator Projects for the Home ConstructorBewertung: 4 von 5 Sternen4/5 (1)

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Von EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Bewertung: 2.5 von 5 Sternen2.5/5 (3)

- Great Wall Florid 2011Dokument218 SeitenGreat Wall Florid 2011CharlyASecasNoch keine Bewertungen

- Load Cell AmplifierDokument2 SeitenLoad Cell AmplifiercanopusinstrumentsNoch keine Bewertungen

- Columbia Maintenance Manual Models: CL112 CL120Dokument137 SeitenColumbia Maintenance Manual Models: CL112 CL120atsa03Noch keine Bewertungen

- Terco Electrical Machines Lab Eng Low Ny 2Dokument52 SeitenTerco Electrical Machines Lab Eng Low Ny 2bariaw167% (3)

- How to dismantle and inspect a recirculating ball steering gear boxDokument4 SeitenHow to dismantle and inspect a recirculating ball steering gear boxsaffrin100% (1)

- HD465-7 PresentationDokument28 SeitenHD465-7 PresentationYopi100% (1)

- Technical Data ManualDokument213 SeitenTechnical Data ManualKanth KanthanNoch keine Bewertungen

- LT Motors AC Generators DC Motors Drives CatalogDokument76 SeitenLT Motors AC Generators DC Motors Drives CatalogSaravanan Mani100% (1)

- Introduction To Electronics, Familiarization With Basic Electronic Components and Measuring Instruments.Dokument66 SeitenIntroduction To Electronics, Familiarization With Basic Electronic Components and Measuring Instruments.Dogra100% (1)

- DC MotorsDokument216 SeitenDC Motorsdin_thorpe3248Noch keine Bewertungen

- Perkins Diesel Generator P400pub 360kwDokument4 SeitenPerkins Diesel Generator P400pub 360kwTariq KoyrattyNoch keine Bewertungen

- MEWP Pre-Use Inspection Checklist NewDokument1 SeiteMEWP Pre-Use Inspection Checklist NewPrimelift Safety Resources LimitedNoch keine Bewertungen

- 06 - 0010 LED Anti-Collision Lighting System A320Dokument12 Seiten06 - 0010 LED Anti-Collision Lighting System A320premica100% (1)

- A1000Dokument8 SeitenA1000monikaNoch keine Bewertungen

- 3G3JXDokument8 Seiten3G3JXrwciriloNoch keine Bewertungen

- AC Invertor1000dsDokument20 SeitenAC Invertor1000dsRonak PatelNoch keine Bewertungen

- Ametek MCG Stepper CatalogDokument34 SeitenAmetek MCG Stepper CatalogElectromateNoch keine Bewertungen

- NPM Stepper CatalogDokument40 SeitenNPM Stepper CatalogElectromateNoch keine Bewertungen

- NPM Stepper CatDokument40 SeitenNPM Stepper CatMarius BudauNoch keine Bewertungen

- RoehrigDokument40 SeitenRoehrigGuille GarofaloNoch keine Bewertungen

- Kollmorgen N&K Series Nema 42 SpecsheetDokument4 SeitenKollmorgen N&K Series Nema 42 SpecsheetElectromateNoch keine Bewertungen

- Kollmorgen Nema 34 N3 K3 Stepper Systems TB SpecsheetDokument4 SeitenKollmorgen Nema 34 N3 K3 Stepper Systems TB SpecsheetElectromateNoch keine Bewertungen

- AC Inverter Drive: A1000 SeriesDokument8 SeitenAC Inverter Drive: A1000 Seriesabhi_0302Noch keine Bewertungen

- 2655-U1100 50 1100kw Kta50 g3Dokument7 Seiten2655-U1100 50 1100kw Kta50 g3ShaliniNoch keine Bewertungen

- Torque Systems Bmr4400 SpecsheetDokument4 SeitenTorque Systems Bmr4400 SpecsheetElectromateNoch keine Bewertungen

- MPCBDokument21 SeitenMPCBDheeraj YadavNoch keine Bewertungen

- PDDR Direct Drive Rotary MotorDokument14 SeitenPDDR Direct Drive Rotary MotorjuliangoalNoch keine Bewertungen

- Servo-Motor Selection-Guide en-US 2006 PDFDokument48 SeitenServo-Motor Selection-Guide en-US 2006 PDFIsaac Gutierrez PayanNoch keine Bewertungen

- Actuator CatalogDokument71 SeitenActuator CatalogaquinorickyNoch keine Bewertungen

- P400PB (2206C E13tag3) PDFDokument4 SeitenP400PB (2206C E13tag3) PDFFirstiawanNoch keine Bewertungen

- SM Series Stepper MotorsDokument7 SeitenSM Series Stepper MotorsPham LongNoch keine Bewertungen

- Panther Drilling Systems, LLC Overview - MWD - Motor SheetsDokument4 SeitenPanther Drilling Systems, LLC Overview - MWD - Motor SheetsdehamardNoch keine Bewertungen

- Kollmorgen - Nema 23 T - SpecsheetDokument4 SeitenKollmorgen - Nema 23 T - SpecsheetElectromateNoch keine Bewertungen

- Dyadic Mechatronics Cylinder CatalogDokument16 SeitenDyadic Mechatronics Cylinder CatalogElectromateNoch keine Bewertungen

- 4 Ad633Dokument6 Seiten4 Ad633Alcemir CampeloNoch keine Bewertungen

- Torque Systems Bnr3000 SpecsheetDokument4 SeitenTorque Systems Bnr3000 SpecsheetElectromateNoch keine Bewertungen

- Presentasi AwalDokument77 SeitenPresentasi AwalFadil AdamNoch keine Bewertungen

- R1000 CatalogueDokument24 SeitenR1000 CataloguemssurajNoch keine Bewertungen

- 10 A 8 DDDokument7 Seiten10 A 8 DDElectromateNoch keine Bewertungen

- BrushlessDokument141 SeitenBrushlessalysonmicheaalaNoch keine Bewertungen

- Catalogo Generador Olimpian 150-200 KWDokument5 SeitenCatalogo Generador Olimpian 150-200 KWlujes99Noch keine Bewertungen

- Emd PM MotorsDokument8 SeitenEmd PM Motorsxyz0080% (1)

- Ats46 BrochureDokument2 SeitenAts46 BrochureRafael CoronaNoch keine Bewertungen

- LV Generator Catalogue - Standard Marine EN LR 201205 PDFDokument30 SeitenLV Generator Catalogue - Standard Marine EN LR 201205 PDFPutra Kusuma HarditoNoch keine Bewertungen

- LSIS Meta Solution Contactors and Overload Relays GuideDokument120 SeitenLSIS Meta Solution Contactors and Overload Relays GuideLindsey Bentley100% (1)

- ALTIVAR 18 AC Drives: File 8805Dokument28 SeitenALTIVAR 18 AC Drives: File 8805charlyzeusNoch keine Bewertungen

- Dyadic Systems 2011 CatalogDokument16 SeitenDyadic Systems 2011 CatalogElectromateNoch keine Bewertungen

- Sprint Single Phase DC DrivesDokument16 SeitenSprint Single Phase DC DrivesNelson P. ColoNoch keine Bewertungen

- R Series.255131941Dokument4 SeitenR Series.255131941Rajabhau VaidyaNoch keine Bewertungen

- L&T's New 1000 Series AC DrivesDokument20 SeitenL&T's New 1000 Series AC Drivesjunfa0% (1)

- Trane Commercial SystemsDokument20 SeitenTrane Commercial SystemsSantosh Baladhye100% (2)

- Inverter Duty Vector Performance AC Motors Product GuideDokument14 SeitenInverter Duty Vector Performance AC Motors Product GuidebamankarmaheshNoch keine Bewertungen

- Cartepillar C32 Diesel Oilfield Generator SetDokument4 SeitenCartepillar C32 Diesel Oilfield Generator SetJesus Enrique Figueroa GilNoch keine Bewertungen

- Kollmorgen Gearmotor Series Servodisc Cat CatalogDokument14 SeitenKollmorgen Gearmotor Series Servodisc Cat CatalogElectromateNoch keine Bewertungen

- MARELLI Catalogo e Scheda TecnicaDokument20 SeitenMARELLI Catalogo e Scheda TecnicaFabio Emanuele Branda0% (1)

- Tolomatic ACS Drive Controller BrochureDokument12 SeitenTolomatic ACS Drive Controller BrochureElectromateNoch keine Bewertungen

- Galil Achieves Prestigious UL-CSA Certification For Its Motion Controller SeriesDokument1 SeiteGalil Achieves Prestigious UL-CSA Certification For Its Motion Controller SeriesElectromateNoch keine Bewertungen

- Electromate Announces Pre-Order Availability of Universal Robots New UR30 Cobot Press ReleaseDokument1 SeiteElectromate Announces Pre-Order Availability of Universal Robots New UR30 Cobot Press ReleaseElectromateNoch keine Bewertungen

- Exor X5 Wireless Press ReleaseDokument1 SeiteExor X5 Wireless Press ReleaseElectromateNoch keine Bewertungen

- Introducing The New VLM-60 Absolute Multi-Turn Encoder From Netzer PrecisionDokument1 SeiteIntroducing The New VLM-60 Absolute Multi-Turn Encoder From Netzer PrecisionElectromateNoch keine Bewertungen

- Electromate Recertified As A Great Place To Work' Press ReleaseDokument1 SeiteElectromate Recertified As A Great Place To Work' Press ReleaseElectromateNoch keine Bewertungen

- New LDL Programmable Linear Actuator From SMAC Moving Coil ActuatorsDokument1 SeiteNew LDL Programmable Linear Actuator From SMAC Moving Coil ActuatorsElectromateNoch keine Bewertungen

- Kollmorgen Debuts EKM Series Servo MotorsDokument1 SeiteKollmorgen Debuts EKM Series Servo MotorsElectromateNoch keine Bewertungen

- New High-Performance Hollow Shaft Gear Unit From Harmonic Drive: The HPF SeriesDokument2 SeitenNew High-Performance Hollow Shaft Gear Unit From Harmonic Drive: The HPF SeriesElectromateNoch keine Bewertungen

- Mecademic Robotics Releases New Firmware For Its Meca500 RobotDokument2 SeitenMecademic Robotics Releases New Firmware For Its Meca500 RobotElectromateNoch keine Bewertungen

- Electromate Partners With Spin Robotics To Offer Cobot Screwdriving Solutions in CanadaDokument1 SeiteElectromate Partners With Spin Robotics To Offer Cobot Screwdriving Solutions in CanadaElectromateNoch keine Bewertungen

- AMC Release New Micro-Sized FlexPro Servo Drive Model FM060-60C-CMDokument2 SeitenAMC Release New Micro-Sized FlexPro Servo Drive Model FM060-60C-CMElectromateNoch keine Bewertungen

- Electromate Elated With Win at The 2022 Business Achievement AwardsDokument2 SeitenElectromate Elated With Win at The 2022 Business Achievement AwardsElectromateNoch keine Bewertungen

- Electromate® Made It Onto The 2021 List of Best Workplaces™ in Professional ServicesDokument2 SeitenElectromate® Made It Onto The 2021 List of Best Workplaces™ in Professional ServicesElectromateNoch keine Bewertungen

- Electromate Extends Its Product Portfolio To Include Robots From MecademicDokument1 SeiteElectromate Extends Its Product Portfolio To Include Robots From MecademicElectromateNoch keine Bewertungen

- ADVANCED Motion Controls Releases 60A Continuous Micro-Sized FlexPro Servo DrivesDokument2 SeitenADVANCED Motion Controls Releases 60A Continuous Micro-Sized FlexPro Servo DrivesElectromateNoch keine Bewertungen

- Meet The World's Most Precise Six-Axis RobotDokument1 SeiteMeet The World's Most Precise Six-Axis RobotElectromateNoch keine Bewertungen

- Netzer Introduce VLP-60 Two-Plate Ring Absolute Encoder For Harsh EnvironmentsDokument1 SeiteNetzer Introduce VLP-60 Two-Plate Ring Absolute Encoder For Harsh EnvironmentsElectromateNoch keine Bewertungen

- Electromate Recertified For The 2021 Canada's Most Admired Corporate Cultures AwardDokument2 SeitenElectromate Recertified For The 2021 Canada's Most Admired Corporate Cultures AwardElectromateNoch keine Bewertungen

- POSITAL Kit Encoders Certified For Compliance With BiSS Interface StandardsDokument1 SeitePOSITAL Kit Encoders Certified For Compliance With BiSS Interface StandardsElectromateNoch keine Bewertungen

- New Robotic Cycloidal Gearbox From GAM - New Product Press ReleaseDokument1 SeiteNew Robotic Cycloidal Gearbox From GAM - New Product Press ReleaseElectromateNoch keine Bewertungen

- Electromate Made It To The 2021 List of Best Workplaces™ in Ontario Press ReleaseDokument2 SeitenElectromate Made It To The 2021 List of Best Workplaces™ in Ontario Press ReleaseElectromateNoch keine Bewertungen

- Electromate Extends Its Product Portfolio To Include Collaborative Robots Manufactured by Universal RobotsDokument2 SeitenElectromate Extends Its Product Portfolio To Include Collaborative Robots Manufactured by Universal RobotsElectromateNoch keine Bewertungen

- New LDL25 Series Linear Actuator From SMAC Moving Coil ActuatorsDokument1 SeiteNew LDL25 Series Linear Actuator From SMAC Moving Coil ActuatorsElectromateNoch keine Bewertungen

- New Integrated Spindle Drives Available From JVLDokument1 SeiteNew Integrated Spindle Drives Available From JVLElectromateNoch keine Bewertungen

- New 100 Amps Peak FlexPro Servo Drives Available From AMCDokument1 SeiteNew 100 Amps Peak FlexPro Servo Drives Available From AMCElectromateNoch keine Bewertungen

- Excellence Canada Announces Electromate Is A Recipient of The 2021 Canadian Business Excellence Awards For Private BusinessesDokument2 SeitenExcellence Canada Announces Electromate Is A Recipient of The 2021 Canadian Business Excellence Awards For Private BusinessesElectromateNoch keine Bewertungen

- Electromate Recognized With 2021 AHTD Foundation AwardDokument1 SeiteElectromate Recognized With 2021 AHTD Foundation AwardElectromateNoch keine Bewertungen

- ADVANCED Motion Controls Releases The FM060-25-CMDokument1 SeiteADVANCED Motion Controls Releases The FM060-25-CMElectromateNoch keine Bewertungen

- Maxon's New IDX Integrated Motor - Power at The Press of A ButtonDokument1 SeiteMaxon's New IDX Integrated Motor - Power at The Press of A ButtonElectromateNoch keine Bewertungen

- Electromate Inc. Recognized As Canadas Most Admired Corporate Cultures For 2020Dokument2 SeitenElectromate Inc. Recognized As Canadas Most Admired Corporate Cultures For 2020ElectromateNoch keine Bewertungen

- OISD 225 ROs Oct2010Dokument17 SeitenOISD 225 ROs Oct2010taranakgecNoch keine Bewertungen

- Sunday MaintDokument33 SeitenSunday MaintRonnel Delos ReyesNoch keine Bewertungen

- Outdoor 25kV Vacuum Circuit Breaker SpecificationDokument41 SeitenOutdoor 25kV Vacuum Circuit Breaker SpecificationpradeeepgargNoch keine Bewertungen

- Simosec Ha41 21 2003 enDokument44 SeitenSimosec Ha41 21 2003 enJosue Espinoza YachachinNoch keine Bewertungen

- Azur 640H User Manual - EnglishDokument20 SeitenAzur 640H User Manual - EnglishniceguymatNoch keine Bewertungen

- Western Digital JumperDokument3 SeitenWestern Digital JumperNeyder Jose ColoradoNoch keine Bewertungen

- Elgin 2018 ProStock CatalogDokument92 SeitenElgin 2018 ProStock CatalogYESENIA TOLOZANoch keine Bewertungen

- bq27z561 Impedance Track™ Battery Gas Gauge Solution For 1-Series Cell Li-Ion Battery PacksDokument27 Seitenbq27z561 Impedance Track™ Battery Gas Gauge Solution For 1-Series Cell Li-Ion Battery PacksRakeshNoch keine Bewertungen

- EXTRAC TEC HPC 15 Specifications PDFDokument4 SeitenEXTRAC TEC HPC 15 Specifications PDFAlejandro VillanuevaNoch keine Bewertungen

- Parking Brake System: SectionDokument10 SeitenParking Brake System: SectionPiyapong SaerimNoch keine Bewertungen

- ATV61 FaultsDokument6 SeitenATV61 FaultsKiki Prayogo (Kimbeg)Noch keine Bewertungen

- 6679gs Mosfet Canal PDokument6 Seiten6679gs Mosfet Canal PMarta_d_eNoch keine Bewertungen

- Montageanleitung Cycle R: Art.-Nr. 07986-996Dokument14 SeitenMontageanleitung Cycle R: Art.-Nr. 07986-996Beth KananiaNoch keine Bewertungen

- RT310i FULL MANUAL UK V005-Revied-1 PDFDokument23 SeitenRT310i FULL MANUAL UK V005-Revied-1 PDFsekula_zrNoch keine Bewertungen

- Philips 32pfl2508 f8Dokument118 SeitenPhilips 32pfl2508 f8Victor Hugo PiedrahitaNoch keine Bewertungen

- GMT Global Mixed Mode Tech G2898KD1U - C356810Dokument8 SeitenGMT Global Mixed Mode Tech G2898KD1U - C356810ziya tutuNoch keine Bewertungen

- #Milling Presentation 2011Dokument47 Seiten#Milling Presentation 2011HABTAMU FEKADUNoch keine Bewertungen

- MITSUBISHI - CR750CR751 Controller Instruction Manual Troubleshooting PDFDokument60 SeitenMITSUBISHI - CR750CR751 Controller Instruction Manual Troubleshooting PDFayxworks eurobotsNoch keine Bewertungen

- Cabin Stores: (Bathroom Equipment - Bathroom Accessories)Dokument2 SeitenCabin Stores: (Bathroom Equipment - Bathroom Accessories)AlexanderNoch keine Bewertungen

- Pilot CartridgeDokument2 SeitenPilot CartridgeJosé Alberto RodríguezNoch keine Bewertungen

- Tle10 Ict Technicaldrafting q4 Mod2 Draftingmechanicallayoutanddetailsusingcad (2) v4Dokument22 SeitenTle10 Ict Technicaldrafting q4 Mod2 Draftingmechanicallayoutanddetailsusingcad (2) v4Mark Anthony RobleNoch keine Bewertungen

- HOTSTART IMC 800 Standard Product Catalog PDFDokument52 SeitenHOTSTART IMC 800 Standard Product Catalog PDFalexel_unamNoch keine Bewertungen