Beruflich Dokumente

Kultur Dokumente

Chemical Engineering Units and Calculations

Hochgeladen von

nhalieza1067Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Chemical Engineering Units and Calculations

Hochgeladen von

nhalieza1067Copyright:

Verfügbare Formate

2/12/15

OBJECTIVES

Understand & convert units

Understand processes & process variables

Formulate material balance equation

Calculate material balances

Use ideal gas law

Use the compressibility charts

2/12/15

SOME APPLICATIONS OF

MATERIAL (& ENERGY)

BALANCES

Process & Equipment Design

Process Monitoring

Process Troubleshooting

Process Improvement & Development

2/12/15

Units & Dimensions

110 mg of sodium

5 litre of gasoline

6 metre

Value

Unit

Dimension

110

mg

mass

litre

volume

metre

length

Conversion of Units

To convert

terms

of one unit

to

2

Convert

23 Ibamquantity

.ft/min2 toinits

equivalent

in kg.cm/s

an equivalent in new units

1. Convert one unit to an equivalent new unit

Multiply by a conversion factor (a ratio of

2.

Multiply quantities)

by a conversion factor

equivalent

4. Units & values

raised

3.2808

ft to same power

1m

3. Old units cancel

out

1 min

23 Old

Ibm .ft

0.454

kg out

units

cancel

min2

1 Ibm

60 s

30.48 cm

1 ft

0.088 kg.cm

s2

2/12/15

Systems of Units

SI (Systeme Internationale d Unites)

cgs

Engineering (American, English, fps)

Systems Base units

SI

cgs

Eng.

Multiples

kg,m,s,K,A powers of 10 - k,c,m

g,cm

same as SI

Derived

N,Pa,J,W

dyne, erg

Ibm,ft,s,R yds,inches,miles,tons Ibf,gal,psi,BTU

Mass, Force and Weight

Newton s 2nd law of Motion

Force = mass x acceleration

Weight

Units of force:

kg.m/s2 = Newton(N)

g.cm/s2 = 1 dyne

The force exerted on the

2 by

Ibobject

m.ft/s = 1 Ibf

gravitational attraction,g

mg

gc

2

2

lb .ft/s2

gc = a constant = 1 kg.m/s = 1 g.cm/s = 32.174 mlb

N

dyne

f

W=

g = acceleration of gravity

= 9.8066 m/s2 = 980.66 cm/s2 = 32.174 ft/s2

2/12/15

Process

Any operation or series of operations that

causes a physical or chemical change in a

substance or mixture of substances

CO2

Glycol

product

C2H4

Diglycol

O2 & N2

2/12/15

Process Unit

An apparatus in which one of the operation

that constitute a process is carried out. Each

process unit has a set of input and output

process stream

Input or

feed

Output or

product

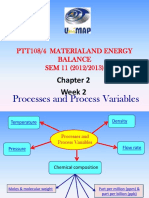

Process Variables

Properties and conditions of the materials

that enter and leave each process unit

Examples:

Mass, volume and density

Flow rate

Chemical composition

Concentration

Pressure

Temperature

2/12/15

Flow Rate

rate at which material is transported

through a process line

Mass flow rate = mass (kg)

time (s)

Volumetric flow rate = volume (m3)

time (s)

Mass and Volume

Density, = mass, m (kg)

volume, V (m3)

Specific volume = volume, V (m3)

mass, m (kg)

Specific

=

density of a substance

gravity, SG

density of a reference substance

= / ref

2/12/15

Moles & Molecular Weight

Molecular weight, M

sum of all the atomic weights of its atoms

Mol

MO2 = 2(16) = 32

amount of a species whose mass (g) equivalent

to its molecular weight

Example

1 mol O2 = 32 g

For NH3, 1 mol

NHO32 contains

1 kmol

= 32 kg 17g (M=17)

Therefore,

34 kg NH3 = 34 kg NH3 1 kmol NH3

17 kg NH3

= 2 kmol NH3

Composition

Composition fractions :

Mass fraction, xA = mass of A (kg A)

total mass (kg total)

Mole fraction, yA = moles of A (moles A)

total moles (moles total)

x

= y

all

components

=1

all

components

2/12/15

Conversion of Mass Fractions to

Mole Fractions (or vice versa)

1

Assume a basis of calculation

Calculate the mass of each

component in the basis quantity

Convert these masses to moles

Take the ratio of the moles of each

component to the total number of

moles

Conversion from % mass to %

mole

A mixture of gases has the following composition

by mass :

O2

CO

CO2

N2

16%

4.0%

17%

63%

What is the molar composition ?

2/12/15

Solution:

Basis : 100 g of the mixture

For O2, amount of moles, nO2 =

100 g total 0.16 g O2 1 mol O2

g total

32 g O2

= 0.5 mol O2

nO2 = 0.5 mol

O2

CO

nCO =

(100)(0.04)

= 0.143 mol

28

CO2

nCO2 =

(100)(0.17)

= 0.386 mol

44

N2

nN2 =

(100)(0.63)

= 2.250 mol

28

Total moles = 3.279 mol

Step

Step 421 & 3

Molar fraction

Assume

Amount

of

a moles

basis of

calculation

each

components

component in

100g of the mixture

mol O2

=

mol total

mol CO

=

yCO =

mol total

mol CO2

=

yCO2 =

mol total

mol N2

=

yN2 =

mol total

yO2 =

0.5

= 0.15

3.279

0.143

= 0.044

3.279

0.386

= 0.12

3.279

2.25

= 0.69

3.279

Check : yi = 1.00

Average molecular weight of a

mixture

Mole fractions,

M = y 1M 1 + y 2M 2 +

Mass fractions,

1 / M = (x1 / M1) + (x2 / M2) +

10

2/12/15

Average Molecular Weight of Air

Calculate the average molecular weight of

air from its approximate

1. molar composition of 79% N2, and 21% O2

2. mass composition of 76.7% N2, and 23.3%

O2

Solution:

Given :

Mole fraction:

yN2 = 0.79, yO2 = 0.21

Mass fraction: xN2 = 0.767, xO2 = 0.233

1. M = yN2MN2 + yO2MO2

=

0.79 kmol N2 28 kg N2 0.21 kmol O2 32 kg O2

kmol

kmol N2 +

kmol

kmol O2

= 29 kg / kmol

2. 1 / M = (x1 / M1) + (x2 / M2)

=

0.767 g N2 mol N2

0.233 g O2 mol O2

+

g

28 g N2

g

32 g O2

= 0.035 mol / g

11

2/12/15

Concentration

Concentrations are based on volume

Mass concentration = mass kg

volume m3

Molar concentration = moles kmol

volume m3

Molarity - concentration calculated in terms of mol/liter

Can be used to convert mass or mass flow

rates (moles or molar flow rates) to total

volume or volumetric flow rates

Pressure

Atmospheric

Pressure =pressure,

force,

Patm.F

N

the hydrostatic

areapressure

the forceon

acts,

theAsurface

m2

of the earth at sea level = 1 atm =

Po (N/m

14.696

psi2) = 760mm Hg = 101.325 kPa

A (m2)

Gauge pressure, Pgauge

Fluidtodensity

pressure relative

atmospheric pressure

h (m)

P (N/m2)

(kg/m3)

Absolute pressure, Pabs.

relative to a perfect P

vacuum

= Po + which

(g / gisc)given

h

a pressure of zero

P(mm Hg) = Po(mm Hg) + h (mm Hg)

Pabs. = Pgauge + Patm.

12

2/12/15

Temperature

Absolute

The degree

temperature

of hotnessscales

or coldness

is scalesofthat

a

substance

began

at absolute

measured

zero

on some definite scale

Conversion between temperature

units

Fahrenheit

Kelvin

(K)

(oF)

0K

= -273.15oCo

0oC = 273.15 K

Most

common

T(K)

=

T(

C)

+

273.15

temperature

scales o

o

oF = 459.67oR

o

o

0 RT(

= -459.67

F F) +0459.67

Rankine

Celsius ((ooC)

R)

R) = T(

T(oR) = 1.8 T(K)

T(oF) = 1.8 T(oC) + 32

Process Classification

Process Classification

Batch Process

Continuous Process Semibatch Process

13

2/12/15

Batch Process

Feed is charged into the system at the begining of

the process and product is removed all at once at

sometime later

Continuous Process

Input and outputs flow continuously throughout

the duration of the process

Semibatch Process

Any process that is neither batch nor continuous

14

2/12/15

Material Balances

Law of Conservation of Mass :

Mass can neither be created nor destroyed

(except in nuclear reactions)

General balance equation:

Input + Generation Output Consumption = Accumulation

enter thru

system

boundaries

Produced

within

system

leaves thru

system

boundaries

consumed

within

system

Buildup

within

system

Balance on Non-reactive System

Continous Steady-State Processes:

Material balance is simply

Input = Output

15

2/12/15

Balance on Reactive System

Balance on a reactive substance does not have

the simple form input = output, but must

include a generation or consumption term.

Input + Generation = Output + Consumption

Calculation Procedure for

Material Balance Calculations

1. Draw flowchart with known values

400 mol/h

2. Label

allO2unknowns

0.21 mol

/mol

3.

4.

5.

0.79 mol N2/mol

Q mol/h

400

mol/h

T = 320oC,aP basis

= 1.4 atm

Choose

x0.21

mol

mol

O2O

/mol

2/mol

10.79

- x molgiven

N22/mol

flow

rate eg.

mol/hwith

feeda

Or Use

assume

an

amount

of 400

a stream

oC, P =

T = 320the

1.4 atm

Write

material

known composition

e.g. Qbalances

= 100 mol/h feed

400 mol/h

Q 0.21

mol/hmol O /mol

2

0.21problems

mol O2/mol

Solve

for unknowns

0.79 mol N

2/mol

0.79

mol

N

/mol

o

2

T = 320

C, P = 1.4

atm

Check

material balance

T = answer

320oC, Pusing

= 1.4redundant

atm

16

2/12/15

Continous Distillation Process

1000 kg/hr of mixture benzene (B) and toluene (T)

that contains 50% benzene by mass are separated

by distillation into two fractions. The mass flow

rate of benzene in the top stream is 450 kg B/hr and

the toluene in the bottom stream is 475 kg T/hr.

The operation is at steady state. Calculate the

unknown component flow rate in the output

streams.

17

2/12/15

Solution :

Step 31

L a b e l chart

Flow

u n k n with

own

known values

variables

450 kg B/h

1000 kg/hr of mixture

contains 50% benzene

q1 kg T/h

1000 kg/h

0.5 kg B/kg

0.5 kg T/kg

475 kg T/h

q2 kg B/h

Step 542

Basis of

Material

Solve

unknowns

Calculation

Balance

Basis: 1000 kg/h feed

Input = Output

450 kg B/h

q1 kg T/h

Benzene balance:

0.5(1000) kg B/h = 450 kg B/h + q2

q2 = 50kg B/h

1000 kg/h

0.500 kg B/kg

0.500 kg T/kg

Toluene balance:

475 kg T/h

q2 kg B/h

0.5(1000) kg T/h = 475 kg T/h + q1

q1 = 25kg T/h

Checking: Total Mass Balance:

1000kg/h = (450 +q1 + q2+475) kg/h

1000kg/h = 1000 kg/h

18

2/12/15

Multiple-unit Processes

Material

Most

processes

balances

consists

(boundaries)

of a number

can be written

of interconnected

around

any

unit subsystem

processes. of the plant. Material balances can also be

written for mixing points or splitters.

Feed 2

C

D

Feed 1

Product 3

Unit 2

Unit 1

B

E

Product 1 Product 2 Feed 3

A Entire process

C Process unit 1

B mixing point

D Splitter point

E Process unit 2

A labeled flowchart of a continous steady-state two-unit

distillation process is shown below. Each stream contains two

Components, A and B, in different proportions. Three streams

whose flow rates and/or compositions are not known are labeled

1,2, and 3. Calculate the unknown flow rates and compositions

of streams 1, 2, and 3.

40 kg/h

0.900 kg A/kg

0.100 kg B/kg

100 kg/h

0.5 kg A/kg

0.5 kg B/kg

Unit 1

30 kg/h

0.600 kg A/kg

0.400 kg B/kg

30 kg/h

Unit 2

0.300 kg A/kg

0.700 kg B/kg

19

2/12/15

Solution:

40 kg/h

0.900 kg A/kg

0.100 kg B/kg

100 kg/h

0.5 kg A/kg

0.5 kg B/kg

Unit 1

1 Q1(kg/h)

x1(kg A/kg)

1x1(kg B/kg)

30 kg/h

30 kg/h

0.600 kg A/kg

0.400 kg B/kg

2 Q2(kg/h)

x2(kg A/kg)

1x2(kg B/kg)

Unit 2

3 Q3(kg/h)

x3(kg A/kg)

1x3(kg B/kg)

0.300 kg A/kg

0.700 kg B/kg

Basis : Given flow rates

Steady-state without reaction :

40 kg/h

0.900 kg A/kg

0.100 kg B/kg

100 kg/h

0.5 kg A/kg

0.5 kg B/kg

Unit 1

30 kg/h

0.600 kg A/kg

0.400 kg B/kg

Q1(kg/h)

Q2(kg/h)

x1(kg A/kg)

1x1(kg B/kg)

x2(kg A/kg)

1x2(kg B/kg)

30 kg/h

Entire process

Input = Output

Unit 2

Q3(kg/h)

x3(kg A/kg)

1x3(kg B/kg)

0.300 kg A/kg

0.700 kg B/kg

Overall Mass Balance :

(100 + 30) = (40 + 30) + Q3

Q3 = 60 kg/h

Overall Balance on A :

0.5(100) + 0.3(30) = 0.9(40) + 0.6(30) + x3(60)

x3 = 0.0833 kg A/kg

20

2/12/15

30 kg/h

0.600 kg A/kg

0.400 kg B/kg

40 kg/h

0.900 kg A/kg

0.100 kg B/kg

100 kg/h

Unit 1

0.5 kg A/kg

0.5 kg B/kg

Q1(kg/h)

Q2(kg/h)

x1(kg A/kg)

1x1(kg B/kg)

x2(kg A/kg)

1x2(kg B/kg)

30 kg/h

60 kg/h

Unit 2

0.0833 kg A/kg

0.9167 kg B/kg

0.300 kg A/kg

0.700 kg B/kg

Total Mass Balance :

Unit 1

100 kg/h = 40 kg/h + Q1

Q1 = 60 kg/h

Mass Balance on A :

0.5(100) = 0.9(40) + x1(60)

x1 = 0.233 kg A/kg

40 kg/h

0.900 kg A/kg

0.100 kg B/kg

100 kg/h

0.5 kg A/kg

0.5 kg B/kg

Q2 (kg/h)

60 kg/h

Unit 1

0.233 kg A/kg

0.767 kg B/kg

30 kg/h

Stream Mixing Point

30 kg/h

0.600 kg A/kg

0.400 kg B/kg

x2 (kg A/kg)

1x2(kg B/kg)

60 kg/h

Unit 2

0.0833 kg A/kg

1x3(kg B/kg)

0.300 kg A/kg

0.700 kg B/kg

Total Mass Balance :

60 + 30 = Q2

Q2 = 90 kg/h

Mass Balance on A :

0.233(60) + 0.3(30) = x2(90)

x2 = 0.255 kg A/kg

21

2/12/15

Recycle & Purge

Purge

Recycleisis a stream

stream that

bledreturns

off tomaterial

removefrom

an

accumulation

downstream ofof ainerts

process

or unwanted

unit backmaterial

to the

that

process

might

unit otherwise

(or to a unitbuild

upstream

up inofthe

the unit).

recycle

stream

Recycle R

Feed

Mixer

Process

Divider

Separator

Purge

Product

Bypass

A stream that skips one or more stages of the

process and goes directly to another

downstream stage. Here a fraction of the feed to

a process unit is diverted around the unit and

combined with the output stream from the unit.

Feed

Product

Process Unit

Bypass stream

22

2/12/15

Recycle in Distillation Column

A distillation column separates 10,000 kg/hr of a 50%

benzene (B) 50% toulene (T) mixture. The product D

recovered from the condenser at the top of the column

contains 95% benzene, and the bottom W from the

column contains 96% toulene. The vapour stream V

entering the condenser from the top of the column is

8000 kg/hr. A portion of the product from the

condenser is returned to the column as reflux, and the

rest is withdrawn for use elsewhere. Assume that the

compositions of the streams at the top of the column

(V), the product withdrawn (D) and the reflux (R) are

identical because the V stream is condensed completely.

Find the ratio of the amount refluxed R to the product

withdrawn (D).

Solution:

Basis : 10,000 kg/h of feed

D

0.95 kg B/kg

0.05 kg T/kg

V = 8000 kg/h

0.95 kg B/kg

0.05 kg T/kg

R

F = 10000 kg/h

0.5 kg B/kg

0.5 kg T/kg

0.95 kg B/kg

0.05 kg T/kg

W

0.04 kg B/kg

0.96 kg T/kg

23

2/12/15

Basis : 10,000 kg/h of feed

D

0.95 kg B/kg

0.05 kg T/kg

V = 8000 kg/h

0.95 kg B/kg

0.05 kg T/kg

F = 10000 kg/h

0.95 kg B/kg

0.05 kg T/kg

0.5 kg B/kg

0.5 kg T/kg

Entire process

W

0.04 kg B/kg

0.96 kg T/kg

Overall Mass Balance:

10000 kg/h = (D + W) kg/h

Overall Mass Balance on B:

0.5(10000) kg/h = 0.95D + 0.04W

Solving simultaneously,

D = 5050 kg/h

W = 4950 kg/h

D = 5050 kg/h

0.95 kg B/kg

0.05 kg T/kg

V = 8000 kg/h

0.95 kg B/kg

0.05 kg T/kg

F = 10000 kg/h

0.5 kg B/kg

0.5 kg T/kg

Condenser

R

0.95 kg B/kg

0.05 kg T/kg

W = 4950 kg/h

0.04 kg B/kg

0.96 kg T/kg

Total Material Balance:

8000 kg/h = (R + 5050) kg/h

R = 2950 kg/h

Hence, R/D = 2950/5050 = 0.58

24

2/12/15

Stoichiometry

Stoichiometry is the theory of the proportions in

which chemical species combine with one another

Stoichiometry Equation:

2 SO2 + 1 O2 2 SO3

Stoichiometric coefficients

Stoichiometric Ratio

2 mol SO3 produced

2 mole SO3 produced

1600 kg SO3 produced

1 kmol O2 or

reacted

1 kmol SO3

1 mol O2 reacted 80 kg SO32 mole

SO2SO

reacted

h

2 kmol

3 produced

= ?10 kmol O2

h

25

2/12/15

Limiting Reactant

Reactant that would disappear first if a

reaction proceeded to completion

Reactant that has the lowest ratio of nio/i

nio = moles of reactant i in feed

i = stoichiometric coefficient for reactant i

Excess reactants

reactants present in excess of the

limiting reactant

% excess = 100% non-sns

no = moles feed

ns = moles corresponding to stoichiometric

proportion

Fractional Conversion

Fractional conversion,f = moles reacted

moles fed

f = i / nio

= extent of reaction

Overall conversion

reactant input to process - reactant output from process

reactant input to process

Single-pass conversion

reactant input to reactor - reactant output from reactor

reactant input to reactor

26

2/12/15

Balance Equation

Single reaction:

ni = nio i

Where

ni = mole of reactant i

nio = mole of reactant i in feed

i = stoichiometric coefficient for reactant I

= extent of reaction

+ when reactant i is being produced

when reactant i is being consumed

Single reaction

Acrylonitrile is produced by the reaction of propylene,

ammonia and oxygen

C3H6 + NH3 + 3/2 O2 C3H3N + 3H2O

propylene

ammonia

oxygen

acrylonitrile

water

The feed contains 10 mole % propylene, 12%

ammonia, and 78% air. A fractional conversion of 30%

of the limiting reactant is achieved. Determine which

reactant is limiting, the percentage by which each of

the other reactants is in excess, and the molar flow

rates of all product gas constituents.

27

2/12/15

Solution:

C3H6 + NH3 + 3/2 O2 C3H3N + 3H2O

n1 mol C3H6

n2 mol NH3

Q mol = 100 mol

0.10 mol C3H6 / mol

Process

n3 mol O2

n4 mol N2

0.12 mol NH3 / mol

n5 mol C3H3N

0.78 mol air

0.21 mol O2/mol

0.79 mol N2/mol

n6 mol H2O

Basis: 100 mol Feed

C3H6 + NH3 + 3/2 O2 C3H3N + 3H2O

100 mol

0.10 mol C3H6 / mol

0.12 mol NH3 / mol

0.78 mol air

0.21 mol O2/mol

0.79 mol N2/mol

n1 mol C3H6

n2 mol NH3

n3 mol O2

n4 mol N2

n5 mol C3H3N

n6 mol H2O

Feed to the reactor contains

(C3H6)o = 10.0 mol

(NH3)o = 12.0 mol

(O2)o = 78.0 mol air 0.21 mol O2 = 16.4 mol

mol air

(N2)o = 16.4 mol O2 0.79 mol N2 = 61.7 mol

0.21 mol O2

28

2/12/15

C3H6 + NH3 + 3/2 O2 C3H3N + 3H2O

n1 mol C3H6

n2 mol NH3

n3 mol O2

n4 mol N2

n5 mol C3H3N

n6 mol H2O

100 mol

10 mol C3H6

12 mol NH3

16.4 mol O2

61.7 mol N2

A) Limiting reactant has the lowest nio/i

nio = initial feed for component i

i = stoichiometric coefficient for component i

(C3H6)o / C3H6 = 10.0/1 = 10.0

Lowest ratio

(NH3)o / C3H6 = 12.0/1 = 12.0

(O2)o / C3H6 = 16.4/1.5 = 10.9

Propylene (C3H6) is the limiting reactant

C3H6 + NH3 + 3/2 O2 C3H3N + 3H2O

n1 mol C3H6

n2 mol NH3

n3 mol O2

n4 mol N2

n5 mol C3H3N

n6 mol H2O

100 mol

10 mol C3H6 (L)

12 mol NH3

16.4 mol O2

61.7 mol N2

% by which NH3 & O2 are in excess:

% excess = 100% non-sns

no =moles feed

ns = moles corresponding to stoichiometric proportion

Stoichiometric

C3H6 + NH3 + 3/2 O2 C3H3N + 3H2O

10

10

1.5(10)

10

3(10)

12 - 10

= 20%

(% excess)NH3 = 100%

10

(% excess)O2 = 100% 16.4 - 15 = 9.3%

15

proportion

based

on propylene

29

2/12/15

C3H6 + NH3 + 3/2 O2 C3H3N + 3H2O

100 mol

10 mol C3H6 (L)

12 mol NH3

16.4 mol O2

61.7 mol N2

n1 mol C3H6

n2 mol NH3

n3 mol O2

n4 mol N2

n5 mol C3H3N

n6 mol H2O

Product gas constituents:

moles C3H6 reacted

Given f C3H6 = 0.3 = moles C3H6 fed

Moles C3H6 reacted = 0.3(moles C3H6 fed)

= 0.3 (10) = 3 mol = C3H6 = 1( )

=3

Components C3H6 NH3

O2

N2

C3H3N H2O

Input (mol)

10

12

16.4

61.7

i mol

-1(3) -1(3) -1.5(3) 0(3)

+(3)

+3(3)

Output (mol) n1 = 7 n2 = 9 n3 =11.9 n4 =61.7 n5 = 3 n6 = 9

Multiple reaction:

ni = nio i

Need to consider each reaction in the process separately

Yield

moles of desired product formed

moles that would have been formed if without side

reaction & reaction proceed to completion

Selectivity

moles of desired product formed

moles of undesired product formed

30

2/12/15

Multiple reactions

C2H6 C2H4 + H2

C2H6 + H2 2CH4

reaction (1)

reaction (2)

The feed contains 85.0 mole% ethane (C2H6) and the balance inerts

(I). The fractional conversion of ethane is 0.501, and the fractional

yield of ethylene is 0.471.

Required: the molar composition of the product gas &

selectivity of C2H4 to CH4.

fC2H6 = 0.501

Fractional yield of C2H4 =0.471

F

0.85 mol C2H6/mol

0.15 mol I/mol

Process

n1 mol C3H6

n2 mol C2H4

n3 mol H2

n4 mol CH4

n5 mol I

Solution:

fC2H6 = 0.501

Fractional yield of C2H4 =0.471

F =100 mol

0.85 mol C2H6/mol

0.15 mol I/mol

C2H6 C2H4 + H2

C2H6 + H2 2CH4

n1 mol C3H6

n2 mol C2H4

Process

n3 mol H2

n4 mol CH4

n5 mol I

reaction 1

reaction 2

Basis : 100 mol feed

Given : fC2H6 = 0.501 = moles of C2H6 reacted

moles

0.85(100)

of C2H6 fed

Therefore, moles of C2H6 reacted = 0.501(85 mol)

= 42.585 mol

1 + 2 = 42.585 mol

(1)

31

2/12/15

C2H6 C2H4 + H2

C2H6 + H2 2CH4

reaction 1

reaction 2

F= 100 mol

0.85 mol C2H6/mol

0.15 mol I/mol

Process

1 + 2 = 42.585 mol

(1)

n1 mol C3H6

n2 mol C2H4

n3 mol H2

n4 mol CH4

n5 mol I

moles of C2H4 formed

Fractional yield =

moles

C

H

of C2H4

2 4 that would have been

formed if reaction 1 reacted completed

0.471 = moles of C2H4 formed

85 mol C2H4

Therefore, moles of C2H4 formed = 0.471(85 mol)

= 40 mol

1 = 40 mol

(2)

C2H6 C2H4 + H2

C2H6 + H2 2CH4

F= 100 mol

0.85 mol C2H6/mol

0.15 mol I/mol

1 + 2 = 42.585 mol

1 = 40 mol

From equation (1),

reaction 1

reaction 2

n1 mol C3H6

n2 mol C2H4

n3 mol H2

n4 mol CH4

n5 mol I

Process

(1)

(2)

40 + 2 = 42.585 mol

2 = 2.585 mol

Table of component amounts for all input and output streams

Components

C2H6

C2H4

Input (mol)

85

Generated/Consumed (+i 1 mol) -1(40)

Generated/Consumed (+i 2 mol) -1(2.585)

Output (mol)

H2

-

+1(40) +1(40)

-

CH4

-

I

15

0(40)

-1(2.585) +2(2.585) 0(2.585)

n1= 42.4 n2= 40 n3 =37.4 n4 = 5.2 n5 = 15

32

2/12/15

F = 100 mol

0.85 mol C2H6

0.15 mol I

Total moles = 42.4 + 40 + 37.4

+ 5.2 + 15 = 140 mol

42.4 mol C3H6

40 mol C2H4

37.4 mol H2

5.2 mol CH4

15 mol I

Process

The molar composition of the production gas

Components

Molar

composition

C2H6

C2H4

H2

CH4

100% x

(42.4/140)

100% x

(40/140)

100% x

(37.4/140)

100% x

(5.2/140)

100% x

(15/140)

= 30.3 %

= 28.6 %

= 26.7 %

= 3.7 %

= 10.7 %

Selectivity of C2H4 to CH4 = moles of desired product formed

moles of undesired product formed

= (40 mol C2H4) / (5.2 mol CH4) = 7.7

Dehydrogenation of Propane

C3H8 C3H6 + H2

Propane

propylene

The process is to be designed for a 95% overall conversion of

propane. The reaction products are separated into two streams; the

first, which contains H2, C3H6 and 0.555 % of the propane that leaves

the reactor, is taken off as product; the second stream, which

contains the balance of the unreacted propane and 5% of the

propylene in the product stream, is recycled to the reactor.

Required:composition of the product, the ratio (moles recycled)/(moles

fresh feed), and the single-pass conversion.

F mol

C3H8

Reactor

100 + Qr1 mol C3H8

Qr2 mol C3H6

P1 mol C3H8

P2 mol C3H6

P3 mol H2

Separator

Product

Q1 mol C3H8

Q2 mol C3H6

Q3 mol H2

Qr1 mol C3H8

Qr2 mol C3H6

33

2/12/15

Solution:

C3H8 C3H6+ H2

F mol

C3H8

= 100

Reactor

Separator

P1 mol C3H8

P2 mol C3H6

P3 mol H2

100 + Qr1 mol C3H8

Qr2 mol C3H6

Product

Q1 mol C3H8

Q2 mol C3H6

Q3 mol H2

Qr1 mol C3H8

Qr2 mol C3H6

Basis : 100 mol fresh feed

Overall Process:

100 - Q1

100

Q1 = 5 mol C3H8

moles of C3H8 reacted = 1() = 100 - 5 = 95 mol

foverall C3H8

100 mol

C3H8

Reactor

100 + Qr1 mol C3H8

Qr2 mol C3H6

= 0.95 =

C3H8 C3H6+ H2

= 95

P1 mol C3H8

P2 mol C3H6

P3 mol H2

Separator

Product

5 mol C3H8

Q2 mol C3H6

Q3 mol H2

Qr1 mol C3H8

Qr2 mol C3H6

Table of component amounts for the entire process

Components

Input (mol)

i mol

Output (mol)

C3H8

100

-1(95)

Q1 = 5

C3H6

+1(95)

Q2 = 95

H2

+1(95)

Q3 =95

34

2/12/15

C3H8 C3H6+ H2

100 mol

C3H8

Reactor

100 + Qr1 mol C3H8

Qr2 mol C3H6

P1 mol C3H8

P2 mol C3H6

P3 mol H2

Separator

195 moles

5 mol C3H8

95 mol C3H6

95 mol H2

Qr1 mol C3H8

Qr2 mol C3H6

The composition of the product:

C3H8 = 100%(5/195) = 2.6%

C3H6 = 100%(95/195) = 48.7%

H2 = 100%(95/195) = 48.7%

Given: 5% of C3H6 in the product stream is recycled.

Qr2 = 0.05(95) = 4.75 mol C3H6

C3H8 C3H6+ H2

100 mol

C3H8

Reactor

100 + Qr1 mol C3H8

Qr2 mol C3H6

P1 mol C3H8

P2 mol C3H6

P3 mol H2

Separator

195 moles

5 mol C3H8

95 mol C3H6

95 mol H2

Qr1 mol C3H8

4.75 mol C3H6

Given:

0.555% of C3H8 leaving the reactor is in the product stream.

0.555P1 = 5 mol C3H8

P1 = 900 mol C3H8

Separation Unit

H2 balance:

P3 = 95 mol H2

35

2/12/15

C3H8 C3H6+ H2

100 mol

C3H8

Reactor

100 + Qr1 mol C3H8

4.75 mol C3H6

900 mol C3H8 Separator

P2 mol C3H6

95 mol H2

195 moles

5 mol C3H8

95 mol C3H6

95 mol H2

Qr1 mol C3H8

4.75 mol C3H6

Table of component amounts for the reactor:

Components

Input (mol)

i mol

Output (mol)

C3H8

100 +Qr1

-1(95)

900

C3H6

4.75

+1(95)

P2 = 99.75

H2

+1(95)

95

C3H8 C3H6+ H2

100 mol

C3H8

Reactor

100 + Qr1 mol C3H8

4.75 mol C3H6

900 mol C3H8 Separator

P2 mol C3H6

95 mol H2

195 moles

5 mol C3H8

95 mol C3H6

95 mol H2

Qr1 mol C3H8

4.75 mol C3H6

Table of component amounts for the reactor:

Components

Input (mol)

i mol

Output (mol)

C3H8

100 +Qr1

-1(95)

900

C3H6

4.75

+1(95)

P2 = 99.75

H2

+1(95)

95

100 + Qr1 - 95 = 900

Qr1 = 895 mol

36

2/12/15

C3H8 C3H6+ H2

100 mol

C3H8

Reactor

100 + 895 mol C3H8

4.75 mol C3H6

900 mol C3H8 Separator

99.75 mol C3H6

95 mol H2

195 moles

5 mol C3H8

95 mol C3H6

95 mol H2

895 mol C3H8

4.75 mol C3H6

Ratio of

moles recycled

Q + Qr2 = 895 + 4.75 =9.0

= r1

moles fresh feed

100

100

Single-pass conversion = 100% (100 + Qr1) - 900

(100 +Qr1)

(100 + 895) - 900

= 100%

= 9.55%

(100 +895)

Combustion

Combustion reactions are one of the most

common and important classes of reactions

used in chemical processing due to the large

amounts of heat released by the reaction :

Heat

Fuel

O2

Flue Gas

37

2/12/15

The fuels are either coal, fuel oil, gaseous fuel (e.g.

natural gas) or liquefied petroleum gas. When

burned, the products are :

C + O2 CO2 (complete combustion)

C + O2 CO (incomplete combustion)

H + O2 H2O

S + O2 SO2

N + O2 NO (only T > 1800oC)

The composition of the flue / stack gas are given

either on a wet basis or a dry basis , depending

on whether water is included

Moles

Wet Basis

Dry Basis

50 mole CO2

33.3% CO2

50% CO2

50 mole N2

33.3% N2

50% N2

50 mole H2O

33.3% H2O

0% H2O

38

2/12/15

Air is the source of the oxygen for combustion and its

composition is simplified to 79% N2 and 21% O2.

Theoretical air (or theoretical oxygen)

Moles of air (or O2) needed for complete combustion of the

fuel and does not depend on how much is actually burned

Excess air (or excess oxygen)

Moles supplied beyond the theoretical requirements. It

depends only on the theoretical air (or O2) and the air (or O2)

feed rate, and not on how much is consumed in the reactor

or whether combustion is complete or partial.

% = (moles air or O2)fed - (moles air or O2)theo. x 100%

excess air

(moles air or O2)theo.

Combustion

Ethane (C2H6) is burned with 50% excess air. The

percentage conversion of the ethane is 90%; of the

ethane burned, 25% reacts to form CO and the

balance to form CO2. Calculate the composition of the

flue gas on a dry basis and the ratio of water to dry

flue gas.

Solution:

C2H6 + 7/2O2 2CO2 + 3H2O

C2H6 + 5/2O2 2CO + 3H2O

reaction 1

reaction

39

2/12/15

Solution:

C2H6 + 7/2O2 2CO2 + 3H2O

C2H6 + 5/2O2 2CO + 3H2O

50% excess air

Q mol O2

3.76Q mol N2

reaction (1)

reaction (2)

q1 mol C2H6

q2 mol O2

q3 mol N2

q4 mol CO

q5 mol CO2

q6 mol H2O

Process

100 mol C2H6

Basis : 100 mol ethane fed

Given: 50% excess air

0.5 = (moles O2)fed (moles O2)theo

(moles O2)theo

= Q (nO2)s

(nO2)s

C2H6 + 7/2O2 2CO2 + 3H2O

C2H6 + 5/2O2 2CO + 3H2O

50% excess air

Q mol O2

3.76Q mol N2

reaction (1)

reaction (2)

q1 mol C2H6

q2 mol O2

q3 mol N2

q4 mol CO

q5 mol CO2

q6 mol H2O

Process

100 mol C2H6

(nO2)s = 100 mol C2H6

0.5 =

3.5 mol O2

1 mol C2H6

(moles O2)fed (moles O2)theo

(moles O2)theo

= 350

Q 350

350

Moles O2 fed = 525 mol = Q

Moles N2 fed = 3.76(525) = 1974 mol

40

2/12/15

C2H6 + 7/2O2 2CO2 + 3H2O

C2H6 + 5/2O2 2CO + 3H2O

50% excess air

525 mol O2

1974 mol N2

reaction (1)

reaction (2)

75% C2H6

25% C2H6

q1 mol C2H6

q2 mol O2

q3 mol N2

q4 mol CO

q5 mol CO2

q6 mol H2O

Process

100 mol C2H6

Given: Percentage conversion of the ethane is 90%

0.9 = moles C2H6 reacted = moles C2H6 reacted

moles C2H6 fed

100

moles C2H6 reacted = 90 mol

0.25 (90) = 22.5 mol C2H6 reacts to form CO = 2

90 22.5 = 67.5 mol C2H6 reacts to form CO2 = 1

1 = 67.5 mol

2 = 22.5 mol

C2H6 + 7/2O2 2CO2 + 3H2O

C2H6 + 5/2O2 2CO + 3H2O

50% excess air

525 mol O2

1974 mol N2

Process

100 mol C2H6

1 =67.5 mol

2 = 22.5 mol

q1 mol C2H6

q2 mol O2

q3 mol N2

q4 mol CO

q5 mol CO2

q6 mol H2O

Table of amounts for all input and output component

Components

C2H6

O2

N2

CO

CO2

H2O

Input (mol)

100

525

1974

-1(67.5)

-3.5(67.5)

0(67.5)

2(67.5)

3(67.5)

-1(22.5)

-2.5(22.5)

0(22.5)

2(22.5)

3(22.5)

q1=10

q2=232.5

q3=1974

q4 = 45 q5=135

Generated/Consumed (+i 1 mol)

Generated/Consumed (+i 2 mol)

Output (mol)

q6=270

41

2/12/15

50% excess air

525 mol O2

1974 mol N2

Process

100 mol C2H6

10 mol

C2H6

232.5 mol O2

1974 mol N2

45 mol CO

135 mol CO2

270 mol H2O

Total moles on a dry basis

=10 + 232.5 + 1974 + 45 + 135

= 2396 mol dry gas

Hence the flue gas composition on a dry basis is

C2H6 = 10 / 2396 = 0.00417 mol C2H6 / mol

O2 = 232.5 / 2396 = 0.0970 mol O2 / mol

N2 = 1974 / 2396 = 0.824 mol N2 / mol

CO = 45 / 2396 = 0.019 mol CO / mol

CO2 = 135 / 2396 = 0.0563 mol CO2 / mol

And

Mole ratio of H2O to dry flue gas = 270 / 2396

= 0.113 mol H2O / mol

42

2/12/15

Ideal Gas

Ideal Gas Law :

PV = nRT

or

= RT

PV

where

P = absolute pressure of gas

V = volume of gas occupied by the gas

n = number of moles of the gas

R = gas constant

T = absolute temperature of gas

= molar volume (V/n) of the gas

V

Gas Constant

8.314 m3.Pa/mol.K

0.08314 liter.bar/mol.K

0.08206 liter.atm/mol.K

62.36 liter.mm Hg/mol.K

0.7302 ft3.atm/lb-mole.oR

10.73ft3.psia/lb-mole.oR

8.314 J/mol.K

1.987 cal/mol.K

1.987 Btu/ lb-mole.oR

43

2/12/15

Standard Conditions for Gases

System

Ts

Ps

Vs

ns

SI

273 K

1 atm 0.022415 m3

1 mol

CGS

273 K

1 atm 22.415 liter

1 mol

American

Engineering

492oR

1 atm

359.05 ft3

1 lb-mole

which leads to the abbreviations STP for

Standard Temperature and Pressure

Example:

o

o

10 ftn3 oflb-mole

air at 530

to 1070

air R and 1 atm are heated

n2 lb-mole

air R

1

and compressed to 2.5 atm. What volume does the gas

occupy

itsofinal

T1 =in530

R state

T2 = 1070oR

P1 = 1 atm

P2 = 2.5 atm

V1 = 10 ft3

V = ? ft3

Assume ideal gas behavior, n1 = n2

P2V2 = n2RT2

P1V1

n1RT1

V2 = V1P1T2 = 10.0 ft3 1.00 atm 1070 oR = 8.08 ft3

P2T1

2.50 atm 530 oR

44

2/12/15

Ideal Gas Mixtures

PV = ntotRT

ntot = total moles of all species in the ideal gas mixtures

pA +pB + = P

where pA = partial pressure of component A

yA =

PA

P

% mol = % vol.

Example:

A natural gas has the following composition :

CH4

C2H6

C3H8

87% mol

12% mol

1% mol

77.5 % wt.

20% wt.

2.5% wt.

Compute the volume occupied by 80kg of the gas

at 9oC (282.15K) and 600 kPa. The molecular

weight of the gas is 17.96 kg/kgmol.

45

2/12/15

Solution:

ntot =

80 kg kgmol

17.96 kg

= 4.45 kgmol

Using the ideal gas law:

PV = ntotRT

V=

V = 4.45 kgmol

ntotRT

P

282.15 K 8.314 kPa.m3

60 kPa

kgmol.K

= 174 m3

46

2/12/15

Real Gases

PV = znRT

or

= zRT

PV

where z = compressibility factor

= 1 (ideal gas behavior)

Generalized Compressibility Chart

47

2/12/15

Calculation Procedure

1. Look up the critical temperature Tc &

critical pressure Pc

2. Calculate reduced values

temperature,

Tr =to

T / Tc

3.Reduced

Use compressibility

chart

Reduced compressibility

pressure, Pr = P factor,

/ Pc z.

determine

Reduced volume, Vr = VPc / RTc

4. Solve for the unknown gas variable

For H2 and He,

(Tc) adjusted = Tc + 8 K

(Pc) adjusted = Pc + 8 atm

Example

100 mol of N2 are contained in a 5 liters vessel

at 20.6oC. Estimate the pressure in the

cyclinder

100 mol N2

5 liters

-20.6oC

P = ? atm

48

2/12/15

Solution:

Step 1: Critical value

Tc = 126.2K

Pc = 33.5 atm

Step 2: Reduced temperature

Tr = T/Tc

= (-20.6 + 273.2) K/ 126.2 K

=2

Reduce volume:

P /RT

Vr = V

c

c

100 mol N2

5 liters

-20.6oC

P = ? atm

= 5 liter 33.5 atm

mol.K

100 mol 126.2 K 0.08206 liter.atm

= 0.161

3. From the generalized

compressibility chart,

intersection Tr = 2.00 and Vr

= 0.161 occurs at z = 1.77

Tr = 2.00

Vr = 0.161

z = 1.77

49

2/12/15

100 mol N2

5 liters

-20.6oC

z = 1.77

Step 4: Calculate P = zRT/ V

P = zRT/ V

P = ? atm

= 1.77 0.08206 liter.atm

252.4 K

mol.K

0.05liter/mol

= 73.3 atm

Real Gas Mixtures

Kay s rule:

PV = zmnRT

or

= z RT

PV

m

Compressibility factor, zm, is found from the generalized

compressibility factor chart using pseudocritical

constants given by

Tc = yaTca + ybTcb + ycTcc +

Pc = yaPca + ybPcb + ycPcc +

where

ya,yb,yc..= mole fractions of a mixture of gases A,B,C

50

2/12/15

Example

A mixture of 75% H2 and 25% N2 (molar

basis) is contained in a tank at P=800 atm and

T=-70oC. Estimate the specific volume of the

mixture in liters/mol.

Solution:

H2:

Tc = 33K

Pc = 12.8 atm

N2:

Tc = 126.2K

Pc = 33.5 atm

Step 21

Pseudocritical

Look

H

Reduced

up T

values

2: Adjusted

c & Pc

values

for

critical values

mixture

(Tc)adj. = Tc +8K =33 + 8 = 41 K

(Pc)adj= Pc + 8 atm = 12.8 + 8 = 21.8 atm

Tc = yaTca + ybTcb = 0.75(41) + 0.25(126.2) = 62.3K

Pc = yaPca + ybPcb = 0.75(20.8) + 0.25(33.5) = 24.0 atm

Tr = T

Tc

= 203 = 3.26

62.3

Pr =

P

Pc

800

= 33.3

24.0

51

2/12/15

3. From the generalized

compressibility chart,

intersection Tr = 3.26 and Pr

= 33.3 occurs at zm = 1.86

Step 3

Zm from

compressibility

chart

zm = 1.86

Tr = 3.26

Pr = 33.3

Step 4

Using Kay s rule:

Solve for V

= z RT

PV

m

= zmRT

V

P

= 1.86 0.08206 liter.atm

mol. K

(-70+273)K

800 atm

= 0.0387 liter

mol

52

Das könnte Ihnen auch gefallen

- Chemical Engineering Tools: 1. Mass Balance (Neraca Massa)Dokument11 SeitenChemical Engineering Tools: 1. Mass Balance (Neraca Massa)muhammad tohaNoch keine Bewertungen

- 05-Chem Eng Tools 2016Dokument11 Seiten05-Chem Eng Tools 2016Hazel Raditya MizumareruNoch keine Bewertungen

- 05-Chem Eng Tools 2016Dokument11 Seiten05-Chem Eng Tools 2016arif thoha bariklanaNoch keine Bewertungen

- Chapter 1 (Part 2) Process VariablesDokument41 SeitenChapter 1 (Part 2) Process VariablesMuhammad FawwazNoch keine Bewertungen

- FL101Dokument64 SeitenFL101nhalieza10670% (1)

- Material Balances: Dr. M. ColeyDokument28 SeitenMaterial Balances: Dr. M. ColeyToanique HeadmanNoch keine Bewertungen

- University Questions (Two Marks With Answers)Dokument17 SeitenUniversity Questions (Two Marks With Answers)Uad100% (3)

- Introduction To Air Pollution - WorkbookDokument10 SeitenIntroduction To Air Pollution - Workbookrocky21stNoch keine Bewertungen

- Book 3Dokument21 SeitenBook 3Mequanint DemekeNoch keine Bewertungen

- 3.basics of CombustionDokument5 Seiten3.basics of CombustionVan Nguyen Huu VanNoch keine Bewertungen

- Units and Dimensions Key to Orbiter LossDokument41 SeitenUnits and Dimensions Key to Orbiter Lossbaseball604Noch keine Bewertungen

- Chemical Engineering Study GuideDokument26 SeitenChemical Engineering Study GuideGedion MelkieNoch keine Bewertungen

- ENVE 2001 Final Exam ReviewDokument53 SeitenENVE 2001 Final Exam ReviewXheikhKaleemNoch keine Bewertungen

- '16-'17-1T-CHEM 5 PtsDokument21 Seiten'16-'17-1T-CHEM 5 PtsLorenz BerroyaNoch keine Bewertungen

- Sample ProblemsDokument18 SeitenSample ProblemsEggy ThreekingsNoch keine Bewertungen

- Chloroalkali Process: Membrane Cell: Process Synthesis Term ProjectDokument14 SeitenChloroalkali Process: Membrane Cell: Process Synthesis Term ProjectAndrés Camilo Regino RamirezNoch keine Bewertungen

- Energy Conversion ES 832a: Eric SavoryDokument30 SeitenEnergy Conversion ES 832a: Eric SavoryMohamed Al-OdatNoch keine Bewertungen

- CPC Upto Aug14Dokument59 SeitenCPC Upto Aug14Nabayan SahaNoch keine Bewertungen

- Processes and Key VariablesDokument35 SeitenProcesses and Key VariablesAndrei Jose GilNoch keine Bewertungen

- 1 Units and Dimensions 54Dokument24 Seiten1 Units and Dimensions 54SSNoch keine Bewertungen

- MARTINEZ Ideal Gas and Polytropic ProblemDokument25 SeitenMARTINEZ Ideal Gas and Polytropic Problemyeng botz0% (1)

- CG5011 Balances Students VersionDokument21 SeitenCG5011 Balances Students VersionRRNoch keine Bewertungen

- A Fixed Quantity of Gas at 21Dokument8 SeitenA Fixed Quantity of Gas at 21nonoytagupa3Noch keine Bewertungen

- Lecture 3 StoichiometryDokument45 SeitenLecture 3 StoichiometryAndrew LeungNoch keine Bewertungen

- Chee Assignment 1Dokument13 SeitenChee Assignment 1TSHEGOFATSO GOTSILENGNoch keine Bewertungen

- Ejercicios Balance de Energia: TrabajoDokument11 SeitenEjercicios Balance de Energia: TrabajoDany DiazNoch keine Bewertungen

- Full Report Format For International Class MFR MarthaDokument8 SeitenFull Report Format For International Class MFR MarthadreamNoch keine Bewertungen

- Resumen CH05 FelderDokument43 SeitenResumen CH05 Feldercuberbill1980Noch keine Bewertungen

- Gases AnswersDokument8 SeitenGases AnswersSayNoch keine Bewertungen

- Mass and Energy Balance: ChapterDokument8 SeitenMass and Energy Balance: ChapterMohamed El-GoharyNoch keine Bewertungen

- Syme Ten U2 P2Dokument18 SeitenSyme Ten U2 P2nkmkm05Noch keine Bewertungen

- Concentrations and Other Units of Measure: (Nazaroff & Alvarez-Cohen, Section 1.C.1)Dokument7 SeitenConcentrations and Other Units of Measure: (Nazaroff & Alvarez-Cohen, Section 1.C.1)Vivian SolangonNoch keine Bewertungen

- S2 Mass Balance Slides PDFDokument68 SeitenS2 Mass Balance Slides PDFعقيل عبدالحسين جاسمNoch keine Bewertungen

- CHEMISTRY PROBLEMSDokument22 SeitenCHEMISTRY PROBLEMScarlNoch keine Bewertungen

- Combustion Chemical ReactionsDokument21 SeitenCombustion Chemical ReactionsBen LvNoch keine Bewertungen

- S2012 ChE234 S Exam - 2Dokument6 SeitenS2012 ChE234 S Exam - 2jrobs314Noch keine Bewertungen

- Lecture 2Dokument32 SeitenLecture 2api-292785878Noch keine Bewertungen

- Module 1 - CEE 335Dokument30 SeitenModule 1 - CEE 335Anonymous aE0YYlCOKNoch keine Bewertungen

- Assignment Thermal 2015Dokument22 SeitenAssignment Thermal 2015Syafiq MazlanNoch keine Bewertungen

- q m C ΔT: SolutionDokument7 Seitenq m C ΔT: SolutionMjhay Tanchiatco DavidNoch keine Bewertungen

- Material Balances for Humid Air Condenser ProblemDokument20 SeitenMaterial Balances for Humid Air Condenser ProblemToanique HeadmanNoch keine Bewertungen

- Chemical EquilibriaDokument28 SeitenChemical EquilibriasamuelolowohunwaNoch keine Bewertungen

- Fundamental Process VariablesDokument36 SeitenFundamental Process VariablesIfiok UsoroNoch keine Bewertungen

- Material and Energy BalanceDokument35 SeitenMaterial and Energy BalanceHammad KhanNoch keine Bewertungen

- Basic conceptDokument59 SeitenBasic conceptMinh HoàngNoch keine Bewertungen

- Material BalanceDokument29 SeitenMaterial Balancepeter-albert.danielNoch keine Bewertungen

- Topic 3 Stoichiometry and Solution Concentration-NEWDokument50 SeitenTopic 3 Stoichiometry and Solution Concentration-NEWPradebaNoch keine Bewertungen

- Chemical Reactions and Equations: Example: Conservation of MassDokument6 SeitenChemical Reactions and Equations: Example: Conservation of MassabharaNoch keine Bewertungen

- Ideal Gas LawDokument25 SeitenIdeal Gas LawAndreea Ella100% (1)

- Chaper 4 Non-Reactive Multi Units ProcessDokument48 SeitenChaper 4 Non-Reactive Multi Units Processجنات الغبيراءNoch keine Bewertungen

- Gas StoichiometryDokument17 SeitenGas StoichiometryJamless ChimChimNoch keine Bewertungen

- Chapter 1 - ContentDokument85 SeitenChapter 1 - ContentMalik KirbyNoch keine Bewertungen

- Tutorial 6 - Solution Mixtures Winardi Sani : CO N 2 O 2Dokument13 SeitenTutorial 6 - Solution Mixtures Winardi Sani : CO N 2 O 2wanpudinNoch keine Bewertungen

- Unit-1 Combustion Thermodynamics: - Vtu News - Vtu Notes - Question Papers - Forums - ResultsDokument18 SeitenUnit-1 Combustion Thermodynamics: - Vtu News - Vtu Notes - Question Papers - Forums - Resultsroad1212Noch keine Bewertungen

- Sample - Solution Manual For Principles of Chemical Engineering Processes 1st Edition - Nayef Ghasem, Redhouane HendaDokument4 SeitenSample - Solution Manual For Principles of Chemical Engineering Processes 1st Edition - Nayef Ghasem, Redhouane Hendaفراس الوافيNoch keine Bewertungen

- Complete Solution Manual for Principles of Chemical Engineering ProcessesDokument4 SeitenComplete Solution Manual for Principles of Chemical Engineering Processesفراس الوافيNoch keine Bewertungen

- Chapter 3 - Process Variables PDFDokument30 SeitenChapter 3 - Process Variables PDFLeon TanNoch keine Bewertungen

- Unit 7 - Equilibrium NotesDokument174 SeitenUnit 7 - Equilibrium NotesRahul Ghosh100% (1)

- Energy Balance of SolutionsDokument16 SeitenEnergy Balance of Solutionsnhalieza1067Noch keine Bewertungen

- Heat of Mixing/solution PDFDokument9 SeitenHeat of Mixing/solution PDFnhalieza1067Noch keine Bewertungen

- Energy Balance - HumidificationDokument13 SeitenEnergy Balance - Humidificationnhalieza1067Noch keine Bewertungen

- Fat HydrogenationDokument13 SeitenFat Hydrogenationnhalieza1067Noch keine Bewertungen

- Introduction to Energy Balance ConceptsDokument25 SeitenIntroduction to Energy Balance Conceptsnhalieza1067Noch keine Bewertungen

- Unsteady-State Heat and Mass TransferDokument19 SeitenUnsteady-State Heat and Mass Transfernhalieza1067Noch keine Bewertungen

- Appendix (Transport Processes and Separation Process Principles by Geankoplis)Dokument45 SeitenAppendix (Transport Processes and Separation Process Principles by Geankoplis)nhalieza106750% (2)

- Detergent and Solvent Fractionation of Palm OilDokument12 SeitenDetergent and Solvent Fractionation of Palm Oilnhalieza1067100% (1)

- Palm Oil Dry FractionationDokument19 SeitenPalm Oil Dry Fractionationnhalieza1067Noch keine Bewertungen

- Palm Oil InteresterificationDokument27 SeitenPalm Oil Interesterificationnhalieza1067Noch keine Bewertungen

- Material Balance On A 2 Unit DistillationsDokument6 SeitenMaterial Balance On A 2 Unit Distillationsnhalieza1067Noch keine Bewertungen

- Quality of Palm OIlDokument8 SeitenQuality of Palm OIlnhalieza1067Noch keine Bewertungen

- Palm Oil Solid BiomassDokument3 SeitenPalm Oil Solid Biomassnhalieza1067Noch keine Bewertungen

- Particle S: Size ReductionDokument16 SeitenParticle S: Size Reductionnhalieza1067Noch keine Bewertungen

- Cooling TowerDokument12 SeitenCooling Towernhalieza1067Noch keine Bewertungen

- Bubble Cap Distillation ColumnDokument3 SeitenBubble Cap Distillation Columnnhalieza1067Noch keine Bewertungen

- DryingDokument9 SeitenDryingnhalieza1067Noch keine Bewertungen

- Palm Oil BiomassDokument7 SeitenPalm Oil Biomassnhalieza1067Noch keine Bewertungen

- Parallel Plate Heat ExchangerDokument3 SeitenParallel Plate Heat Exchangernhalieza1067Noch keine Bewertungen

- Combustion Reactions & Flue Gas CompositionDokument11 SeitenCombustion Reactions & Flue Gas Compositionnhalieza1067Noch keine Bewertungen

- Heat ExchangerDokument7 SeitenHeat Exchangernhalieza1067Noch keine Bewertungen

- Size Reduction Methods and Equipment for Particle Size ReductionDokument2 SeitenSize Reduction Methods and Equipment for Particle Size Reductionnhalieza1067Noch keine Bewertungen

- LeachingDokument10 SeitenLeachingnhalieza1067Noch keine Bewertungen

- Packed Absorption ColumnDokument3 SeitenPacked Absorption Columnnhalieza1067Noch keine Bewertungen

- Size ReductionDokument9 SeitenSize Reductionnhalieza1067Noch keine Bewertungen

- Experiment: Packed Distillation ColumnDokument4 SeitenExperiment: Packed Distillation Columnnhalieza1067Noch keine Bewertungen

- Palm Oil and Global Oil & Fat - 2014Dokument14 SeitenPalm Oil and Global Oil & Fat - 2014nhalieza1067Noch keine Bewertungen

- Unsteady State Heat and Mass TransferDokument14 SeitenUnsteady State Heat and Mass Transfernhalieza1067Noch keine Bewertungen

- TriglyceridesDokument6 SeitenTriglyceridesnhalieza1067Noch keine Bewertungen

- Ch 7 and 8 Background Properties and ProcessesDokument25 SeitenCh 7 and 8 Background Properties and ProcessesMohamed Mo Galal Hassan-GharibaNoch keine Bewertungen

- Ch06 PsychrometricDokument17 SeitenCh06 PsychrometricCésar MoralesNoch keine Bewertungen

- Colligative Properties of SolutionsDokument31 SeitenColligative Properties of SolutionsKasandra AprestoNoch keine Bewertungen

- SPP3701 Formula Sheet and Steam Tables - 2021Dokument12 SeitenSPP3701 Formula Sheet and Steam Tables - 2021MNoch keine Bewertungen

- CLS Aipmt 16 17 XII Che Study Package 5 SET 1 Chapter 2Dokument8 SeitenCLS Aipmt 16 17 XII Che Study Package 5 SET 1 Chapter 2Kareena Gupta100% (3)

- Phase Changes and Thermodynamics Problems SolvedDokument35 SeitenPhase Changes and Thermodynamics Problems SolvedDiah Wulan AyuningtiasNoch keine Bewertungen

- Chemistry PPT SolutionDokument28 SeitenChemistry PPT Solutionnaukul rajNoch keine Bewertungen

- Appendix C Steam TablesDokument8 SeitenAppendix C Steam TablesWin Alfalah Nasution100% (1)

- Names and amounts associated with the mole conceptDokument16 SeitenNames and amounts associated with the mole conceptNicaliaNoch keine Bewertungen

- HelloDokument9 SeitenHelloPatxi LopezNoch keine Bewertungen

- Experiment 5 - Freezing Point DepressionDokument14 SeitenExperiment 5 - Freezing Point DepressionNabilah HairmanNoch keine Bewertungen

- 07 SolutionDokument72 Seiten07 SolutionsyammyNoch keine Bewertungen

- MolesDokument21 SeitenMolesAndre BirchNoch keine Bewertungen

- Steam Tables in Excel (By IIT, Mumbai)Dokument14 SeitenSteam Tables in Excel (By IIT, Mumbai)myself_riteshNoch keine Bewertungen

- Tutorial 14 Thermodynamics 18 May 2023Dokument20 SeitenTutorial 14 Thermodynamics 18 May 2023SNEHANSHU BANERJEENoch keine Bewertungen

- Gibbs free energy sample problemsDokument3 SeitenGibbs free energy sample problemsLeticia CarandangNoch keine Bewertungen

- Very Short Answer QuestionsDokument4 SeitenVery Short Answer Questionsashok pradhanNoch keine Bewertungen

- EYECON Price List 2022-2023Dokument1 SeiteEYECON Price List 2022-2023AMMU KAUSHIKNoch keine Bewertungen

- Molar Enthalpy WorksheetDokument2 SeitenMolar Enthalpy WorksheetRanNoch keine Bewertungen

- Las Melc 1 Week 3Dokument11 SeitenLas Melc 1 Week 3Evelyn AndosonNoch keine Bewertungen

- Solutions Anil HssliveDokument11 SeitenSolutions Anil HssliveRanit Mukherjee0% (1)

- Matlab CodeDokument5 SeitenMatlab CodeSri Varalakshmi MummidiNoch keine Bewertungen

- Physical Chemistry II - Review of Thermodynamics Chapter 3 The Second Law ExerciseDokument2 SeitenPhysical Chemistry II - Review of Thermodynamics Chapter 3 The Second Law ExerciseMary Daphne ButiNoch keine Bewertungen

- Simulation details of distillation process in DWSIM v5.8Dokument3 SeitenSimulation details of distillation process in DWSIM v5.8Deep SinojiyaNoch keine Bewertungen

- Play Tennis TreeDokument1 SeitePlay Tennis TreeSabi UllahNoch keine Bewertungen

- Sea Level: Ashrae Psychrometric Chart No.3Dokument7 SeitenSea Level: Ashrae Psychrometric Chart No.3TramAnh DuongNoch keine Bewertungen

- DPS Jalandhar Chapter 6 Thermodynamics QuestionsDokument2 SeitenDPS Jalandhar Chapter 6 Thermodynamics QuestionsUday VeerNoch keine Bewertungen

- Gas-Vapor Mixtures and Air-Conditioning: Çengel BolesDokument37 SeitenGas-Vapor Mixtures and Air-Conditioning: Çengel Boleskebaman1986Noch keine Bewertungen

- Colligative Properties of SolutionsDokument11 SeitenColligative Properties of SolutionsNelsonMoseM100% (1)