Beruflich Dokumente

Kultur Dokumente

Dawson, Cellulosic Ethanol Production From Sugarcane

Hochgeladen von

animaniax666Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Dawson, Cellulosic Ethanol Production From Sugarcane

Hochgeladen von

animaniax666Copyright:

Verfügbare Formate

PEER-REVIEWED ARTICLE

ncsu.edu/

bioresources

CELLULOSIC ETHANOL PRODUCTION FROM SUGARCANE

BAGASSE WITHOUT ENZYMATIC SACCHARIFICATION

Letha Dawson and Raj Boopathy*

Sugarcane processing generates a large volume of bagasse. Disposal

of bagasse is critical for both agricultural profitability and environmental

protection. Sugarcane bagasse is a renewable resource that can be

used to produce ethanol and many other value-added products. In this

study, we demonstrate that cane processed bagasse could be used to

produce fuel grade ethanol without saccharification. A chemical pretreatment process using alkaline peroxide and acid hydrolysis was

applied to remove lignin, which acts as physical barrier to cellulolytic

enzymes. Yeast Saccharomyces cerevisiae ATCC, strain 765, was used

in the experiment. The pre-treatment process effectively removed lignin.

Ethanol production in the culture sample was monitored using high

performance liquid chromatography. The results indicate that ethanol

can be made from the sugarcane bagasse.

Keywords: Bagasse; Ethanol: Lignin; Acid hydrolysis; Alkaline hydrolysis; Yeast

Contact information: Department of Biological Sciences; Nicholls State University;

Thibodaux, LA 70310, USA

*Corresponding Author Telephone 985 448 4716; Fax 985 493 2496; Email: biol-rrb@nicholls.edu

INTRODUCTION

The sugarcane stalk consists of two parts, an inner pith containing most of the

sucrose and an outer rind with lignocellulosic fibers. During sugar processing, the

sugarcane stalk is crushed to extract sucrose (Boopathy 2004). This procedure produces

a large volume of residue, the bagasse, which contains both crushed rind and pith fibers.

In Louisiana there are 16 sugar mills that produce approximately five million tons of

bagasse every year (LSU Ag Center 2003). Most of this bagasse (approximately 75%) is

used as in-house fuel for power generation or as raw material for producing low-value

products such as mulch or ceiling tiles (Boopathy 2004). The remaining 25% is

considered as waste that goes to landfill or is allowed to decay (LSU Ag Center 2003).

This 25% accounts for 1.25 million tons of bagasse, which could be used as a raw

material for cellulosic ethanol production. Ethanol is a clean-burning renewable resource

that can be produced from fermented cellulosic biomass (Yu and Zhang 2004). In many

parts of the world, demand for ethanol as an alternative fuel source has steadily increased

(Sheoran et al. 1998) due to dwindling fossil fuel resources and increased gasoline prices.

The growing demand for gas and oil was not been met domestically in the U.S. Recently

the U.S government showed serious concern for developing renewable energy sources in

an effort to ease the severity of unexpected energy shortages. One possibility is the

conversion of agricultural wastes such as sugarcane bagasse into liquid and gaseous fuels.

Dawson and Boopathy (2008). Cellulosic ethanol, bagasse, BioResources 3(2), 452-460. 452

PEER-REVIEWED ARTICLE

ncsu.edu/

bioresources

Currently, the U.S produces approximately three billion gallons of ethanol from corn

annually (Potera 2004).

There are major limitations to efficient ethanol production from agricultural

residues (Krishna and Chowdary 2000; Martin et al. 2002). These limitations include the

close physical and chemical associations between lignin and plant cell wall

polysaccharides, together with cellulose crystallinity (Gould 1984). Lignin forms a

protective shield around cellulose and hemicellulose, protecting the polysaccharides from

enzymatic degradation. To convert the biomass into ethanol, the cellulose must be

readily available for cellulase enzymes (Krishna and Choudary 2000). Thus, by removing

the lignin, the cellulose becomes vulnerable to enzymes and allows the yeast to covert the

glucose into ethanol during fermentation (Wyman 1996). Therefore, a pretreatment must

be applied to remove lignin in the bagasse, decrease cellulose crystallinity, and increase

the surface area for enzymatic activity. Most reports on lignocellulosic ethanol

production involve acid hydrolysis followed by enzymatic saccharification using

cellulase enzyme (Krishna and Choudary 2000; Gould 1984; Martin et al. 2002). The

enzymatic saccharification step is cost-prohibitive because of the high cost of the

commercial cellulase enzyme. Ethanol has been produced without enzymatic sachharification using recombinant and mutant bacteria and yeast (Ho et al. 1998; Dien et al.

2003; Kim et al. 2007; van Maris et al. 2006).

The present study was conducted to determine the optimal pretreatment

conditions for high efficiency ethanol production from sugarcane bagasse. The major

components of sugarcane bagasse are lignin (22%), cellulose (30%), and hemicellulose

(23%) (Dawson 2005). The bagasse was subjected to alkaline hydrogen peroxide

pretreatment and sulfuric acid pretreatments, followed by three weeks of fermentation

using ATCC yeast, Saccharomyces cerevisiae, strain 765. We did not use the enzymatic

saccharification step in this study. The results indicated that ethanol can be made from

sugarcane bagasse, but the ethanol yield was eight times less than the theoretical yield.

MATERIALS AND METHODS

Microbial Source

The yeast Saccharamyces cerevisiae, strain 765, was obtained from the American

Type Culture Collection (ATCC), Manassas, VA, USA. This strain is known to produce

ethanol from cellulosic material, specifically, from the bark of trees (Boopathy 2005).

The role of this yeast strain producing ethanol without saccharification using sugarcane

leaf was reported earlier by Dawson and Boopathy (2007). S. cerevisiae culture was

maintained in tryptic soy broth (TSB) and a fresh one week old culture grown on TSB

was used in the fermentation experiment.

Alkaline Pretreatment

The purpose of the alkaline pretreatment was delignification. The removal of

lignin is necessary for cellulose to become readily available for the enzymes, which

permit the yeast to convert the glucose into ethanol (Wyman 1996). The amount of

weight lost following chemical pretreatment of residue was due to lignin removal

Dawson and Boopathy (2008). Cellulosic ethanol, bagasse, BioResources 3(2), 452-460. 453

ncsu.edu/

PEER-REVIEWED ARTICLE

bioresources

(Wyman 1996). Greater weight loss indicates more lignin loss. The percent weight lost

was used to compare pretreatment effects on lignin removal. Delignification was tested

by soaking bagasse in various concentrations (0, 1, 2, and 5%) of household hydrogen

peroxide at various pHs (8, 11.5, and 13), for various time intervals (8, 24, and 48 hours).

Initially, dry sugarcane bagasse (supplied by the United States Department of

Agriculture office in Houma, Louisiana) was weighed to approximately 3 g and placed in

flasks. Then, three 1% H2O2 solutions were made. The pH of a 1% H2O2 solution was

adjusted to 8, 11.5, or 13 by adding NaOH tablets. The treatment solution was added to

individual flasks to submerge the sugarcane residue and allowed to soak for 8, 24, or 48

hours. Each flask was placed in a shaker at 100 rpm to ensure that all of the bagasse

came into contact with the treatment solution. This experiment was repeated for H2O2

concentrations of 0, 2, and 5%. DI water was substituted for H2O2 for the 0% H2O2

treatment level. In addition, a DI water control without the pH adjustment was used in

the experiment. Each H2O2, pH, and time treatment combination was repeated four

times. After the required time for soaking, the residue was removed from the solutions

by filtering through cheesecloth and then triple-rinsed for thirty minutes in DI water. The

residue was then dried in an oven at 100C for approximately 12 hours. Finally, the

residue was re-weighed. The weight difference was equated to the amount of lignin

removed. Upon conclusion of the alkaline pretreatments, analysis of variance was used to

determine the pretreatment conditions that removed the most lignin. The best pretreatment was then used for further fermentation experiments. Fermentation experiments

were conducted using the yeast S. cerevisiae, strain 765.

The pretreatment with 2% H2O2, pH 11.5, and soaking for 48 hours removed the

most lignin most efficiently (Table 1) and was chosen for the fermentation experiment.

In this experiment, 2 g of the pretreated bagasse residue was placed into anaerobic bottles

that contained 100 mL of sterile tap water and 5% (v/v) of the yeast S. cerevisiae, strain

765. This experiment was run in triplicates along with triplicate controls. Samples were

taken on days 0, 6, 12, 18, and 21 using a 5 mL syringe and needle. Samples were

microcentrifuged at 10,000 rpm for 6 minutes. The supernatant, transferred to HPLC

vials, was used to monitor ethanol production using HPLC analysis as described below.

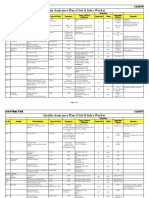

Table 1. Alkaline Pretreatments of Sugarcane Bagasse Shown to Remove the

Most Weight. (Treatments denoted by the same letters are not significantly

different from each other)

H2O2

Concentration

Time

(hours)

pH

% Weight

Loss

2%

48

11.5

60.45A

5%

48

13

56.04AB

1%

48

13

55.70AB

2%

48

13

51.45B

1%

24

13

51.32B

Dawson and Boopathy (2008). Cellulosic ethanol, bagasse, BioResources 3(2), 452-460. 454

PEER-REVIEWED ARTICLE

ncsu.edu/

bioresources

Acid Pretreatment

The purpose of acid hydrolysis was to break up lignin and make cellulose

available for yeast fermentation. Dilute sulfuric acid (H2SO4) concentrations (0.0, 0.2,

0.4, and 0.8M) were used in this pretreatment. For the acid hydrolysis pretreatment,

approximately 3 g of bagasse residue was placed into anaerobic bottles containing 100

mL of DI water and 0.2 M H2SO4 and allowed to soak for 24 hours, based on our

previous study (Dawson 2005). The bottles were subsequently autoclaved and allowed to

cool before 5% (v/v) of the yeast S. cerevisiae, strain 765, was added. Samples were

taken on days 0, 6, 12, 18, and 21 using a 5 mL syringe, microcentrifuged at 10,000 rpm

for 6 minutes, and transferred to HPLC vials. Ethanol production was monitored using

HPLC analysis as described below. This experiment was repeated using 0.0, 0.4, and 0.8

M H2SO4, and each treatment had three replicates.

Analytical Techniques

Ethanol production was analyzed by high performance liquid chromatography

(HPLC) on a Varian Pro Star Autosampler Model 410 liquid chromatograph equipped

with two solvent pumps, a model 210 programmable multiwavelength refractive index

detector set at 210 nm, a data module, and a model 320 system controller. The mobile

phase was 0.0025 N H2SO4. Aliquots of 10 L were injected into an organic acid column

(Varian organic acid column, Cat # SN 035061) at 22C. The flow rate of the mobile

phase was 0.6 mL/min, and the analysis was done under isocratic mode. Quantification

of ethanol was done by using standard ethanol.

Statistical Analysis

Data were subjected to analysis of variance (ANOVA) followed by a Tukey posthoc range test (p 0.05; Neter et al. 1990).

RESULTS AND DISCUSSION

Alkaline Pretreatment

The alkaline pretreatment with 2% H2O2 (pH 11.5) and soaking for 48 hours

removed the most lignin in bagasse, compared to other treatment combinations (Table 1).

Therefore, this treatment was chosen for the fermentation experiments. Results of

treatment combinations consisting of pH 8 soaking for 48 hours did not show significant

effects (p = 0.9) (data not shown).

Lignocellulosic biomass cannot be saccharified by enzymes to high yields without

a pretreatment, mainly because the lignin in plant cell walls forms a barrier against

enzymatic attack (Sewalt et al. 1997). An ideal pretreatment would reduce the lignin

content and crystallinity of the cellulose and increase the surface area (Krishna and

Chowdary 2000). Lignin is degraded in nature by various organisms, but the mechanism

of natural degradation is largely unknown. It is thought that oxidants such as H2O2 may

play an important role. Under certain conditions, H2O2 is known to react with lignin and

has been widely used to bleach high-lignin pulps (Gould and Freer 1984). Gould (1984)

recently reported that under suitable conditions H2O2 will delignify wheat straw and other

Dawson and Boopathy (2008). Cellulosic ethanol, bagasse, BioResources 3(2), 452-460. 455

ncsu.edu/

PEER-REVIEWED ARTICLE

bioresources

crop residues to a point where the cellulose can be enzymatically converted to glucose

with near-quantitative yield. According to Gould and Freer (1984), H2O2-treated

lignocellulosic materials can be rapidly fermented to ethanol with greater than 90%

efficiency in the presence of cellulase. In the present study, sugarcane bagasse residue

pretreated with 2% H2O2 at a pH of 11.5 and soaked for 48 hours (Table 1) removed

60.45% of the total weight of the sample; therefore, this treatment removed more lignin

than any other pretreatment option evaluated.

These results were similar to those concluded from other research. Maximum

delignification of wheat straw occurred at a pH of 11.5 or higher and the increase in

saccharification efficiency was nearly complete after 8 hours at room temperature (Gould

1984). Krishna and Chowdary (2000) concluded that alkaline peroxide pretreatments

were effective in providing fractionation of the hemicellulose and lignin components and

resulted in efficient hydrolysis in linn leaves.

In another study by Gould and Freer (1984), wheat straw treated for several hours

at room temperature with 1% H2O2 at a pH of 11.5 released slightly more than one-half of

its lignin as water-soluble degradation products. They found that increased concentrations of H2O2, more alkaline pH, or repeated H2O2 treatments did not alter the total

amount of lignin solubilized. However, based upon the present research, increased pH

levels did remove more lignin than lower pHs. Furthermore, Gould and Freer (1984)

concluded that in the absence of H2O2 only a very small fraction of the lignin present in

the straw was released. Boopathy (2005) also obtained similar results in research

conducted on sugarcane leaf.

Sugarcane bagasse pretreated in 2% H2O2 (pH 11.5) for 48 hours was subjected to

fermentation. Sugarcane bagasse was fermented for 21 days and sampled periodically.

Optimum fermentation condition for pretreated bagasse was determined to occur on day

21, producing a mean of 140.5 mg/L ethanol (Fig. 1).

Ethanol Produced (mg/L)

200

150

Control

100

Treated

50

0

0

12

18

21

Day of Experiment

Figure 1. Mean ( standard deviation) ethanol production from alkaline pretreated sugarcane

bagasse residue, 2% H2O2 at a pH of 11.5 for 48 hours, after fermentation over time.

Dawson and Boopathy (2008). Cellulosic ethanol, bagasse, BioResources 3(2), 452-460. 456

ncsu.edu/

PEER-REVIEWED ARTICLE

bioresources

Results from this research were slightly higher than those reported by Boopathy

(2005), where ethanol production was 118 mg/L. However, Gould and Freer (1984)

reported that alkaline pretreated corn cobs, corn husks, and corn stalks produced ethanol

with an overall 90% efficiency, while kenaf and oak shavings produced enhanced ethanol

yields, although significantly below the theoretical maximum. It must be noted that

Gould and Freer (1984) added cellulase enzyme prior to fermentation.

Acid Hydrolysis

The sugarcane bagasse acid treatment of 0.8 M H2SO4, with fermenting for 18

days, produced more ethanol than any other treatment combination up to day 18.

Fermentation for more than 18 days did not increase ethanol production (Fig. 2).

Fermentation of bagasse showed the most efficient acid hydrolysis treatment with 0.8 M

H2SO4, producing 395.5 mg/L ethanol (Fig. 3). In acid hydrolyzed experiments of waste

cotton conducted by Yu and Zhang (2004), 0.2 mol/L H2SO4 was the optimal acid

treatment, producing 14.2 g/L of ethanol in 24 hours.

Ethanol Produced (mg/L)

500

400

Control

300

0.2 M

0.4 M

200

0.8 M

100

0

0

12

18

21

Day of Experiment

Figure 2. Mean ( standard deviation) ethanol production (mg/L) over time from sugarcane

bagasse residue soaking in different acid hydrolysis treatments

After comparing alkaline H2O2 and H2SO4 acid treatments, it was shown that acid

hydrolysis produced the most ethanol from the residue. More ethanol was produced from

bagasse treated with 0.8M H2SO4 for 18 days, compared to alkaline pretreated residue at

2% H2O2 (pH 11.5) for 48 hours and fermented for 21 days (Fig. 3).

This preliminary study showed that ethanol production from post-harvest

sugarcane residue such as bagasse is possible without the addition of cellulase enzyme.

The ethanol yield in our study was eight times lower than the theoretical yield as per

National Renewable Energy Laboratory (NREL) calculation, which can be seen at

(http://www1.eere.energy.gov/biomass/ethanol_yield_calculator.html).

Dawson and Boopathy (2008). Cellulosic ethanol, bagasse, BioResources 3(2), 452-460. 457

ncsu.edu/

PEER-REVIEWED ARTICLE

bioresources

Ethanol Produced

500

400

300

200

100

0

Alkaline

Acid

Treatment

Figure 3. Mean ( standard deviation) ethanol production from the alkaline pretreated bagasse

residue, 2% H2O2 (pH 11.5) 48 hours, and the acid treated residue, 0.8 H2SO4, 18 days. The

asterisk denotes a significant difference at p = 0.05

Lignin prevents the degradation of cellulose mainly by acting as a physical barrier

between the cellulolytic enzyme and its substrate. Consequently, the rate and extent of

enzymatic cellulose degradation in lignocellulosic materials is inversely related to the

lignin content (Gould 1984) with maximum cellulose degradation occurring only after

50% or more of the lignin has been removed. In the present study we did not see any

inhibition from potential inhibitors such as acetic acid and furfural. This may be due to

the more dilute acid used in this study compared to other reports (Klinke et al. 2004;

Palmarola-Adrados et al. 2005; Hahn-Hagerdal et al. 2007). In this study, we achieved a

significant removal of lignin from the bagasse, which resulted in higher production of

ethanol. Further research is needed to optimize the conditions for maximum production

of ethanol from bagasse.

ACKNOWLEDGMENTS

Funding for this work was provided by Louisiana Board of Regents through the

Clean Power Energy Research Consortium (CPERC) and the American Sugarcane

League. The authors would like to thank Dr. Quenton Fontenot for the statistical

analysis.

REFERENCES CITED

Boopathy, R. (2004). Use of post-harvest sugarcane residue in coastal reclamation: A

feasibility study, Sugar Cane International. Jan/Feb, 9-13.

Boopathy, R. (2005). Use of microbes in managing post-harvest crop residues:

Sugarcane residue as a case study, In: Microbial Biotechnology in Agriculture and

Aquaculture. R. C. Ray (ed). Science Publishers Inc., Plymouth, UK, 433-446.

Dawson and Boopathy (2008). Cellulosic ethanol, bagasse, BioResources 3(2), 452-460. 458

PEER-REVIEWED ARTICLE

ncsu.edu/

bioresources

Dawson, L. (2005). Optimization of pretreatment conditions for high efficiency ethanol

production from post-harvest sugarcane residue, M.S. Thesis submitted to Nicholls

State University, Thibodaux, LA.

Dawson, L., and Boopathy, R. (2007). Use of post-harvest sugarcane residue for ethanol

production, Bioresource Technology 98, 1695-1699.

Dien, B. S., Cotta, M. A., and Jeffries, T. W. (2003). Bacteria engineered for fuel

ethanol production: Current status, Applied Microbiology and Biotechnology 63,

258-266.

Gould, J. M. (1984). Alkaline peroxide delignification of agricultural residues to

enhance enzymatic saccharification, Biotechnology and Bioengineering 26, 46-52.

Gould, J. M., and Freer, S. N. (1984). High-efficiency ethanol production from

lignocellulosic residues pretreated with alkaline H2O2, Biotechnology and

Bioengineering 26, 628-631.

Hahn-Hagerdal, B., Karhumaa, K., Fonseca, C., Martins, I. S., and Gorwa-Grauslund, M.

F. (2007). Towards industrial pentose-fermenting yeast strains, Applied

Microbiology and Biotechnology 74, 937-953.

Ho, N. W. Y., Chen, Z., and Brainard, A. P. (1998). Genetically engineered

Saccharomyces yeast capable of effective cofermentation of glucose and xylose,

Applied Environmental Microbiology 64, 1852-1859.

Kim, Y., Ingram, L. O., and Shanmugam, K. T. (2007). Construction of an Escherichia

coli K-12 mutant for homoethanologenic fermentation of glucose or xylose without

foreign genes, Applied Environmental Microbiology 73, 1766-1771.

Klinke, H. B., Thomsen, A. B., and Ahring, B. K. (2004). Inhibition of ethanolproducing yeast and bacteria by degradation products produced during pre-treatment

of biomass, Applied Microbiology and Bioechnology 66, 10-26.

Krishna, S. H. and Chowdary, G. V. (2000). Optimization of simultaneous

saccharification and fermentation for the production of ethanol from lignocellulosic

biomass, Journal of Agricultural and Food Chemistry 48, 1971-1976.

LSU Ag Center. (2003). Annual Report, Baton Rouge, LA.

Martn, C., Galbe, M., Wahlbom, C. F., Hahn-Hgerdal, B., and Jnsson, L. J. (2002).

Ethanol production from enzymatic hydrolysates of sugarcane bagasse using

recombinant xylose-utilizing Saccharomyces cerevisiae, Enzyme and Microbial

Technology 31, 274-282.

Neter, J., Wasserman, W., and Kutner, M. H. (1990). Applied Linear Statistical Models:

Regression, Analysis of Variance, and Experimental Designs, 3rd Ed. IRWIN. Burr

Ridge, Illinois.

Palmarola_Adrados, B., Choteborska, P., Galbe, M., and Zacchi, G. (2005). Ethanol

production from non-starch carbohydrates of wheat bran, Bioresource Technology

96, 843-850.

Potera, C. (2004). Efficient recombinant yeast yields ethanol from straw residues,

ASM News. 70, 442-443.

Sewalt, V. J. H., Glasser, W. G., and Beauchemin, K. A. (1997). Lignin impact on fiber

degradation: Reversal of inhibition on enzymatic hydrolysis by chemical modification

of lignin and by additives, Journal of Agricultural and Food Chemistry 45, 18231828.

Dawson and Boopathy (2008). Cellulosic ethanol, bagasse, BioResources 3(2), 452-460. 459

PEER-REVIEWED ARTICLE

ncsu.edu/

bioresources

Sheoran, A., Yadav, B. S., Nigam, P., and Singh, D. (1998). Continuous ethanol

production from sugarcane molasses using a column reactor of immobilized

Saccharomyces cerevisiae HAU-1, Journal of Basic Microbiology 38, 123-128.

Van Maris, A. J. A., Abbot, D. A., Bellissimi, E., van den Brink, J., Kuyper, M., Luttik,

M. A. H., Wisselink, H. W., Scheffers, W. A., van Dijken, J. P., and Pronk, J. T.

(2006). Alcoholic fermentation of carbon sources in biomass hydrolysates by

Saccharomyces cerevisiae: Current status, Antonie van Leeuwenhoek 90, 391-418.

Wyman, C. E. (1996). Ethanol production from lignocellulosic biomass: Overview,

Handbook on Bioethanol: Production and Utilization, C. E. Wyman (ed)., Taylor &

Francis, Washington, DC, Chapter 1, 11-12.

Yu, Z., and Zhang, H. (2004). Ethanol fermentation of acid-hydrolyzed cellulosic

pryolysate with Saccharomyces cerevisiae, Bioresource Technology 93, 199-204.

Article submitted: Feb. 13, 2008; Peer review completed: March 26, 2008; Revised

version received and accepted: March 27, 2008; Published: March 29, 2008.

Dawson and Boopathy (2008). Cellulosic ethanol, bagasse, BioResources 3(2), 452-460. 460

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- ASTM D 4437-99 Standard Practice For Determining The Integrity of Fiel Seams Used in Joining Flexible Polymeric Sheet GeomembranesDokument3 SeitenASTM D 4437-99 Standard Practice For Determining The Integrity of Fiel Seams Used in Joining Flexible Polymeric Sheet GeomembranesPablo Antonio Valcárcel Vargas100% (2)

- BQ - Structural Works - CompressedDokument163 SeitenBQ - Structural Works - CompressedLee YuxuanNoch keine Bewertungen

- D2E133AM4701 Operating Instruction UsDokument9 SeitenD2E133AM4701 Operating Instruction UsMohamed AlkharashyNoch keine Bewertungen

- MJDF Mcqs - Mixed - PDFDokument19 SeitenMJDF Mcqs - Mixed - PDFAyesha Awan0% (3)

- Week 1-2 Module 1 Chapter 1 Action RseearchDokument18 SeitenWeek 1-2 Module 1 Chapter 1 Action RseearchJustine Kyle BasilanNoch keine Bewertungen

- (LaSalle Initiative) 0Dokument4 Seiten(LaSalle Initiative) 0Ann DwyerNoch keine Bewertungen

- 3114 Entrance-Door-Sensor 10 18 18Dokument5 Seiten3114 Entrance-Door-Sensor 10 18 18Hamilton Amilcar MirandaNoch keine Bewertungen

- Management of StutteringDokument182 SeitenManagement of Stutteringpappu713100% (2)

- Feature Glance - How To Differentiate HoVPN and H-VPNDokument1 SeiteFeature Glance - How To Differentiate HoVPN and H-VPNKroco gameNoch keine Bewertungen

- Embedded System Lab ManualDokument67 SeitenEmbedded System Lab Manualsaim100% (1)

- MBA 2nd Sem SyllabusDokument6 SeitenMBA 2nd Sem SyllabusMohammad Ameen Ul HaqNoch keine Bewertungen

- SchedulingDokument47 SeitenSchedulingKonark PatelNoch keine Bewertungen

- Jurnal KORELASI ANTARA STATUS GIZI IBU MENYUSUI DENGAN KECUKUPAN ASIDokument9 SeitenJurnal KORELASI ANTARA STATUS GIZI IBU MENYUSUI DENGAN KECUKUPAN ASIMarsaidNoch keine Bewertungen

- Jurnal Direct and Indirect Pulp CappingDokument9 SeitenJurnal Direct and Indirect Pulp Cappingninis anisaNoch keine Bewertungen

- Case-Based Learning Guide (A)Dokument19 SeitenCase-Based Learning Guide (A)pentagon 5Noch keine Bewertungen

- Matter Around Me: SC1 - Teaching Science in ElementaryDokument27 SeitenMatter Around Me: SC1 - Teaching Science in ElementaryYanna Marie Porlucas Macaraeg50% (2)

- Introduction To Human MovementDokument5 SeitenIntroduction To Human MovementNiema Tejano FloroNoch keine Bewertungen

- NHD Process PaperDokument2 SeitenNHD Process Paperapi-122116050Noch keine Bewertungen

- Lenovo S340-15iwl Compal LA-H101P SchematicDokument53 SeitenLenovo S340-15iwl Compal LA-H101P SchematicYetawa Guaviare100% (4)

- Mystakidis2022 MetaverseDokument13 SeitenMystakidis2022 MetaverseVennela NandikondaNoch keine Bewertungen

- MultiZone Limitations and HintsDokument2 SeitenMultiZone Limitations and HintsRubén Darío Becerra GalindoNoch keine Bewertungen

- CMS156Dokument64 SeitenCMS156Andres RaymondNoch keine Bewertungen

- Quadratic SDokument20 SeitenQuadratic SAnubastNoch keine Bewertungen

- INDUSTRIAL PHD POSITION - Sensor Fusion Enabled Indoor PositioningDokument8 SeitenINDUSTRIAL PHD POSITION - Sensor Fusion Enabled Indoor Positioningzeeshan ahmedNoch keine Bewertungen

- 1000 Base - T Magnetics Modules P/N: Gst5009 LF Data Sheet: Bothhand USA Tel: 978-887-8050Dokument2 Seiten1000 Base - T Magnetics Modules P/N: Gst5009 LF Data Sheet: Bothhand USA Tel: 978-887-8050DennisSendoyaNoch keine Bewertungen

- Quality Assurance Plan - CivilDokument11 SeitenQuality Assurance Plan - CivilDeviPrasadNathNoch keine Bewertungen

- Promotion of Coconut in The Production of YoghurtDokument4 SeitenPromotion of Coconut in The Production of YoghurtԱբրենիկա ՖերլինNoch keine Bewertungen

- La La Mei Seaside Resto BAR: Final PlateDokument4 SeitenLa La Mei Seaside Resto BAR: Final PlateMichael Ken FurioNoch keine Bewertungen

- Electronic Waste Management in Sri Lanka Performance and Environmental Aiudit Report 1 EDokument41 SeitenElectronic Waste Management in Sri Lanka Performance and Environmental Aiudit Report 1 ESupun KahawaththaNoch keine Bewertungen

- Cultural AnthropologyDokument12 SeitenCultural AnthropologyTRISH BOCANoch keine Bewertungen