Beruflich Dokumente

Kultur Dokumente

Session 7

Hochgeladen von

DendeOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Session 7

Hochgeladen von

DendeCopyright:

Verfügbare Formate

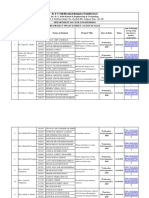

P.T.

INTI KARYA PERSADA TEHNIK

DEPARTMENTAL PROCEDURE

DP-EPD-302

VII.

7.1

TRAINING MANUAL

FOR PIPING DESIGNER

Page 185 of 206

PIPING LAYOUT AND ISOMETRIC DRAWING

PIPING LAYOUT DRAWING

The following general rules shall be followed to give consistent drawing

presentation :

Lower plans of areas must contain the Area M.L. indicated by coordinates.

Upper plans of areas should contain the Area M.L indicated by coordinates

only when piping, platforms, etc., extend through or are adjacent to the

M.L.

Where applicable, Battery Limit, Unit Limit and Drawing Limit lines shall

be shown and located.

Drawing numbers of piping plans above and below shall be indicate : i.e.,

for piping plan below EL. 112-6.

Use coordinates to locate vessels, equipment, and column lines (use the

same coordinate and points of reference as given on the Construction Issue

plot plan).

Identify each vessel or item of equipment by the number given on the plot

Plan. Place this number along the centerline in bold printing, to stand out

from the rest of the notes. Where a vessel or equipment item extends

vertically through more than one plan, identify it in the same way.

Tag instruments, relief valves, steam traps, column center lines, etc., with

appropriate numbers in a 7/16 Dia. Circle.

Tag nozzle designations and skirt openings, etc., within a square box.

Do not give the size and / or rating of nozzles.

Piping

Indicate all piping 12 and blow as single line and all piping 14 and

above as double line.

Originator: Wisnu S.

D:\Buku Pintar\Training Manual for Piping Designer\DP-EPD-302 PDsign_7c\Session_7.doc

Revision No.: 0

P.T. INTI KARYA PERSADA TEHNIK

DEPARTMENTAL PROCEDURE

DP-EPD-302

TRAINING MANUAL

FOR PIPING DESIGNER

Page 186 of 206

Give the bottom elevation of groups of lines such as in the yard,

established elevation for all other lines, and work point centerline for

sloping lines.

Locate every change of direction of a line, and every branch line into it,

even where this ascertainable from fitting to fitting dimensions.

The following apply for lines passing vertically through more than one

plan:

When the line appears in one drawing, indicate the line number,

centerline elevation and location at the origin.

When the line appears on two or more drawings, indicate the line

number, centerline elevation, and location at the origin. The line

number only should be repeated once on subsequent plans.

Give location, elevation, and line number of all lines leaving an area

outside the area match line, even though some of the information may be

repeated elsewhere on the drawing.

Locate, but do not give the length of, flanged piping components such as

separators, strainers, etc., even if these are specials. The isometric shall

give this information.

Show small by-passes around valves.

Indicate and locate branch lines to pumps from cooling water headers,

gland oil headers, etc., the continuation of this piping is detailed on the

isometric only.

At pumps with lube oil consoles and /or vacuum exhaust turbines, an

auxiliary plan should be made, indicating such piping as cooling water,

gland oil, lube oil, etc., with dimensions.

Increased line sizes, due to span purpose, are indicated as : LA-214-3/4

(1-1/2).

Do NOT call out reducing fittings.

Originator: Wisnu S.

D:\Buku Pintar\Training Manual for Piping Designer\DP-EPD-302 PDsign_7c\Session_7.doc

Revision No.: 0

P.T. INTI KARYA PERSADA TEHNIK

DEPARTMENTAL PROCEDURE

DP-EPD-302

TRAINING MANUAL

FOR PIPING DESIGNER

Page 187 of 206

Indicate and locate fire hydrants and hose monitors.

Indicate and locate fire hydrants and hose monitors.

Indicate handwheel orientation for socket weld, flanged, and butt welded

valves.

Partially indicate cold insulation over 3 thick.

Use dimensions to locate the following :

a) Pipe lines passing over matchlines, with respect t column centerlines

preferably, or equipment centerlines where there are no columns.

Make these lines locating dimensions continuous between column

lines, and include the closing dimension.

b) Piping within the area, i.e. the line runs, changes of direction,

branches, and piping items within a run, with respect to the

centerlines of vessels, equipment, nozzles or adjacent pipe runs.

c) Where a line crosses a matchline at horizontal angle, give the line

number and horizontal location only.

Coordinates under 1-0 to be given in feet and inches, i.e. 0-6.

Give dimensions up to but excluding 1-0 in inches, and round off to the

nearest 1/16.

Give metric dimensions in millimeters rounded off to the nearest 5mm,

except where dictated by equipment connections, fitting to fitting

arrangements or triangulations which shall be given to the nearest

millimeter.

Instruments/Electrical and Auxiliaries

Show, but do not dimension, level Controllers, Level Alarms, and Level

Gauges, along with connecting piping.

a) Tag every instrument with the primary identification number given on

the flow sheet.

b) Do NOT locate Tis, Pis, or Sample Points.

Originator: Wisnu S.

D:\Buku Pintar\Training Manual for Piping Designer\DP-EPD-302 PDsign_7c\Session_7.doc

Revision No.: 0

P.T. INTI KARYA PERSADA TEHNIK

DEPARTMENTAL PROCEDURE

DP-EPD-302

TRAINING MANUAL

FOR PIPING DESIGNER

Page 188 of 206

c) Do NOT show couplings or flanges on TIs, or valves on PIs and

Sample Points, when located in piping.

Indicate and identify instrument panels.

Indicate and identify electrical components which may affect the design

of piping, such as lighting panels, receptacle panels, pull boxes, etc.

Indicate, identify and locate by coordinate, flood light poles within the

area limits.

Draw in as a rectangle all control valve assemblies, using the instrument

number as identification, indicating those handwheels in vertical lines

which project out of the symbol rectangle. Locate a control valve set by

means of the attaching lines. The width of the rectangle shall be equal to

the O.D. of a line spec flange.

Orifice runs which are larger than the lines of which they form a part are

identified by line number and size, with the increased size in brackets :

e.g. 0-111-3 (40).

Give dimensions relative to horizontal orifice runs or position, and

elevation of vertical orifice flanges. Give the tag number of the orifice

and indicate the tap location (do not show valves).

a) Indicate and dimension the width of instrument and / or electrical

racks in yard

b) Indicate instrument and / or electrical racks in areas.

Steel and Concrete

The following items shall be indicated :

a) Davits (exchanger davits, MH davits, vessel davits, including support

bracket, etc.)

b) Ladders and cages

Originator: Wisnu S.

D:\Buku Pintar\Training Manual for Piping Designer\DP-EPD-302 PDsign_7c\Session_7.doc

Revision No.: 0

P.T. INTI KARYA PERSADA TEHNIK

DEPARTMENTAL PROCEDURE

DP-EPD-302

TRAINING MANUAL

FOR PIPING DESIGNER

Page 189 of 206

c) Double bracket pipe supports on vertical vessels (including those for

multiple lines)

d) Major support steel in structures, building, etc.

e) Trenches

f) Vessels supports

g) Platform brackets on vertical vessels

h) Trolley beams

The following items should be indicated and located as noted :

a). Yard supports (centerline)

b). Columns as noted on plot plan (centerline)

c). Concrete walls, curbs, etc. (inside wall plus height)

d). Earthen Dikes (centerline)

e). Platforms

1) Give platform elevation (Platform elevation is to the top of steel).

2) Do NOT dimension platforms.

3) Do NOT show handrail (s).

4) Platform outlines should be as shown below. Do not differentiate

between grating and plate.

f). Building, control houses, analyzer houses, etc. (edge of building per

plot plan)

Miscellaneous

Pulling Area

Indicate, but no NOT dimension or call out, tube or bundle pulling

areas for such items as exchangers, heating coils in lube oil reservoirs,

cylinders on reciprocating compressors, etc.

Originator: Wisnu S.

D:\Buku Pintar\Training Manual for Piping Designer\DP-EPD-302 PDsign_7c\Session_7.doc

Revision No.: 0

P.T. INTI KARYA PERSADA TEHNIK

DEPARTMENTAL PROCEDURE

DP-EPD-302

TRAINING MANUAL

FOR PIPING DESIGNER

Page 190 of 206

Drop Out Area

Indicate and call out, but do NOT dimension, drop out areas for towers

or reactors.

North Arrows

Descriptive north stanpats must be used on all piping plans. The arrow

should be placed in the upper right hand corner of the drawing.

On process unit piping plans, true north shall not be indicated unless

required by the client.

On offsite piping plans, plant north shall be indicated.

Preferably, all piping plans should be drawn in the same relative

direction as the plot plan.

Notes

The following notes shall appear on the main key plan of each area above

the revision box.

1. For General Notes

2. For Abbreviations

3. For additional piping plans in this area

Additional notes may be given by the work Group Leader as required.

Grade Elevations other than 100-0 or 100.000 MM should be so noted

on each piping plan @ grade.

Originator: Wisnu S.

D:\Buku Pintar\Training Manual for Piping Designer\DP-EPD-302 PDsign_7c\Session_7.doc

Revision No.: 0

P.T. INTI KARYA PERSADA TEHNIK

DEPARTMENTAL PROCEDURE

DP-EPD-302

7.2

TRAINING MANUAL

FOR PIPING DESIGNER

Page 191 of 206

PIPING ISOMETRIC DRAWING

Since the layout drawings do not contain piping details, the isometric is

required to present sufficient pipeline information for the field or shop

fabricator to produce detailed fabrication drawings. Isometrics shall be

drawn for all piping except as noted in the detail design highlights portion

of the project technology work plan.

Complicated and overcrowded isometrics shall be avoided since they

require excessive drafting and checking time and are more prove to

mistakes. The following rules shall be adhered to when preparing

isometrics :

Each isometric shall represent one line number

One line number can be on more than one isometric (sheet 1 of 2, etc.)

Shop lines from one adjacent area to another shall terminate at a

natural break point (no partial spools)

Isometric will be drawn per area breakdown

Field lines from one adjacent area to another shall terminate at the area

match line

Identical lines within an area shall be accounted for on individual

isometrics

No isometrics shall be issued with holds

The following should be required to be on separate isometrics. Check with

each project detail design highlights for direction.

Carbon steel 3 and larger

Carbon steel 2 and smaller

All stainless steel

All alloy

All aluminum

Originator: Wisnu S.

D:\Buku Pintar\Training Manual for Piping Designer\DP-EPD-302 PDsign_7c\Session_7.doc

Revision No.: 0

P.T. INTI KARYA PERSADA TEHNIK

DEPARTMENTAL PROCEDURE

DP-EPD-302

TRAINING MANUAL

FOR PIPING DESIGNER

All impact tested carbon steel

All lined pipe

All boiler code pipe

All large O.D. (26 and above)

Heavy wall carbon steel (900 and above)

Page 192 of 206

In general, Piping Design will be responsible for all isometrics on a

project. However, certain conditions may apply where piping Mechanical

is responsible for certain types of isometrics and details, such as, refractory

lined pipe or other specialty type items highlighted on the P & IDs or in

the design highlights.

The following general rules shall be followed :

The Work Group Leader will make available any special stamps or

notes required on the isometric with implementation directions

included in the design highlights. Any stamps or notes should be

placed in the area above the title block.

Hard piped underground isometrics shall generally extend above

ground from 1 (300 mm) to 3 (900 mm) above grade to the face of

flange, with the bolts and gaskets included with the A/G isometric.

When required, insulating kits will also be included with the A/G

isometric

N/S and E/W designations are to be used as a suffix to all coordinates.

COD isometric numbers shall be placed at the isometric match lines, as

well as at other continuation points, and shall include the line number,

centerline elevation and coordinate.

Place line number, size and direction of flow on the isometric pipeline.

Indicate personnel protection insulation breaks on the isometric 7

(2200 mm) above any operating level, including within 18 (450 mm)

from outside of platform.

Originator: Wisnu S.

D:\Buku Pintar\Training Manual for Piping Designer\DP-EPD-302 PDsign_7c\Session_7.doc

Revision No.: 0

P.T. INTI KARYA PERSADA TEHNIK

DEPARTMENTAL PROCEDURE

DP-EPD-302

TRAINING MANUAL

FOR PIPING DESIGNER

Page 193 of 206

For out of spec flanges, call-out the flange requirement (e.g. 3 300#

WNF) rather than indicating a spec break.

Identify item number for in-line and branch instruments, relief valves,

traps, specialty, item, in-line piping, mechanical items and structural

columns in diameter circles.

Indicate, but do not locate, the matchline where a line passes from one

plan drawing to another in the same area (horizontal and vertical).

Except for in spec flanges, 90 long radius elbows, equal tees and

standards bolts and gaskets all other piping material shall be called out

on the isometric using the pipe spec short codes. When both slip-on

and weld-neck flanges are in the spec, the slip-on should be called out

on the isometrics.

When the pipe spec schedule is calculated, the schedule must be

entered on the isometric and entered under miscellaneous material.

Figure 8s, blanks and spacers shall be indicated and called out on the

isometric.

Chain operators on valves shall be indicated and called out on the

isometric and listed under miscellaneous material.

When Y type strainer is not in the pipe spec it shall be called out and

listed under miscellaneous material.

When T type strainers are out of spec. It shall be indicated and called

out on the isometric and listed under miscellaneous material. When

strainer is in horizontal line and angled down at 45, a drain valve

must be tapped in the blind flange with adequate clearance for basket

removal.

Field welds shall be located for following conditions :

Shop to shop pieces

Shop to field pieces

Shop piece to welded equipment nozzle

At butt welded RV and CV in shop fab piping

Originator: Wisnu S.

D:\Buku Pintar\Training Manual for Piping Designer\DP-EPD-302 PDsign_7c\Session_7.doc

Revision No.: 0

P.T. INTI KARYA PERSADA TEHNIK

DEPARTMENTAL PROCEDURE

DP-EPD-302

TRAINING MANUAL

FOR PIPING DESIGNER

Page 194 of 206

Spool piece sizes shall normally be limited by the shipping

dimensions. Check with the design highlights for proper maximum

spool dimension requirements. Usually 40 (12000 mm) X 8 (2400

mm) for 3 to 24 pipe and 20 (6000 mm) X 4 (1200 mm) for 2 pipe

and below.

Use the outside of pipe to outside of pipe or fitting to calculate the

overall spool piece dimensions. Base supports, trunnions and welded

valve hand wheels should be included in the overall dimension.

Where possible, locate field welds accessible from platforms, beams,

etc. a minimum of 18 (450 mm) above platforms or grade if preferred.

Field welds should be arranged to eliminate difficult and tedious

alignment. These type of conditions should be done by the shop where

possible.

Field welds should not be located on in spec butt welded valves.

Field welds should not be located at branch welds, except where

header is field rum pipe.

Do not locate field welds at dissimilar material. Add 1 (300 mm) of

out of spec pipe in shop and then place field weld.

Do not locate field welds within 18 (450 mm) or flanges within 2

(600 mm) of main yard steel.

Spool piece mark numbers shall be indicated on the isometric in a

circle as described in the general notes section. Spool shall be

numbered with direction of flow.

No partial piece marks shall be used. The field weld should be placed

at the last natural break on the isometric with a dotted line continuing

to the match line and the piece mark assigned by the continuing

isometric.

Originator: Wisnu S.

D:\Buku Pintar\Training Manual for Piping Designer\DP-EPD-302 PDsign_7c\Session_7.doc

Revision No.: 0

P.T. INTI KARYA PERSADA TEHNIK

DEPARTMENTAL PROCEDURE

DP-EPD-302

TRAINING MANUAL

FOR PIPING DESIGNER

Page 195 of 206

For butt welds and in the vertical field welds shall preferably be in the

horizontal position for socketwelds. Check with design highlights for

Constructability preference.

Horizontal angles shall be drawn with the reference triangle in the

horizontal plane and vertical angles with the reference triangle in the

vertical plane. Indicate the angles as being slight angles rather than

steep. The linear and angular dimensions shall indicate the size of the

angle.

Indicate the short code on the body of the isometric for all in-spec

valves.

Indicate the handwheel for all flanged, butt welded and socket welded

valves. Give handwheel orientation if it is other than N, S, E, W or up.

Rotate flanged valves to standard bolt hole orientation where possible.

Otherwise, call out the required flange rotation.

Nipples shall be indicated on the isometric as NIP (in-line) and BRN

(branch). The standard length is 4 (100 mm). Out of spec nipples shall

have end conditions called out. All swage nipples shall be called as

CSW or ESW with end conditions specified an with FOB and

FOT designated for ESW. The end conditions are as follows :

OE = Thread one end (nipple only)

BB = Bevel both ends (nipple and swage)

TT = Thread both ends (nipple and swage)

TB = Large end threaded (swage only)

BT = Large end beveled (swage only)

(only use the above terms, no plain ends to be used)

The instrument tag number shall be the primary instrument number

shown on the P & ID. Piping will furnish through the primary valve on

the pressure connection and the olet or flange on the temperature

Originator: Wisnu S.

D:\Buku Pintar\Training Manual for Piping Designer\DP-EPD-302 PDsign_7c\Session_7.doc

Revision No.: 0

P.T. INTI KARYA PERSADA TEHNIK

DEPARTMENTAL PROCEDURE

DP-EPD-302

TRAINING MANUAL

FOR PIPING DESIGNER

Page 196 of 206

connection. The flanged projection shall be a long WNF 5 (125 mm)

from OD of pipe.

Orifice flanges shall be called out and shown per indicating tap

orientation, size and type from the following :

Tap size =

1/8 (3 mm) 8 and below

(7 mm) 10 14

3/8 (10 mm) 16 24

(12 mm) 26 30

Flanged extra length bolts shall not be called out. Usually is set up to

account for them with orifice flanges. Restriction orifices shall be

located and identified along with extra bolt lengths called out.

Branch connections for pipe to pipe branches shall be indicated by the

symbol (e.g. BRW for no pad or BRP with pad) per the pipe spec

or piping mechanical requirements.

Mitered elbows shall be identified with the required number of welds

and called out on the isometric as a 2 weld miter, etc.

Shop fabricated bends shall be called out as bend with prefix indicating

diameter i.e., 5 dia. Radius bend. Allow for tangent requirements per

the design highlights.

Trunnions should not be indicated with the original drafting of the

isometric. They will be added to the isometrics by piping from the

piping Mechanical comments to checked isometrics.

Presentation (Material Procedure)

All material shall be accounted for in the appropriate blocks on the

isometric form. The three digit short code should be used for all line

class piping items.

Originator: Wisnu S.

D:\Buku Pintar\Training Manual for Piping Designer\DP-EPD-302 PDsign_7c\Session_7.doc

Revision No.: 0

P.T. INTI KARYA PERSADA TEHNIK

DEPARTMENTAL PROCEDURE

DP-EPD-302

TRAINING MANUAL

FOR PIPING DESIGNER

Page 197 of 206

All specialty in-line items, such as SP, ST, RV, Instruments, Piping

Mechanical, Trunnions, etc. shall be listed in the miscellaneous

material section, under description column. Items, such as equipment

and branch type instruments should not be listed.

Reducing fittings, branch connections and nipples should be listed in

the column indicated on right side of sheet. Line class pipe, fittings,

and valves shall be completed with the appropriate short codes shown

along the bottom portion of the isometric.

Shop or field (S or F) must be assigned to all material, except for bolts

and gaskets and non-butt welded valves, which are indicated on the

isometric form as field. When butt-weld or socket weld valves are shop

fabricated, mark through the (field) call out.

The pipe schedule must be entered from the nomenclature when the

line class indicated calculate. The column shall not be filled in when

schedule is per spec. Standard bolts shall be entered as the number of

sets required, not individual bolts.

Extra length bolts shall be listed in 1/4: increments as miscellaneous

material by the individual number, non in sets, with the diameter X

length shown in the size column. Field butt welds shall be taken off as

a BUW short code in the fittings section. When an isometric breaks

at a FW, FW should not be taken off on both isometrics. All nipples

and swages shall have the proper end code listed.

Chain operators, extension stems, post indicators, etc. should be shown

in the miscellaneous material section. Insulating gasket kits should be

listed in the miscellaneous material section, not as a gasket set. Olets

shall indicate header size X branch size under the size column. The

description column is required for out of spec items with no short

codes, such as control valves, relief valves, SP items, etc.

Originator: Wisnu S.

D:\Buku Pintar\Training Manual for Piping Designer\DP-EPD-302 PDsign_7c\Session_7.doc

Revision No.: 0

P.T. INTI KARYA PERSADA TEHNIK

DEPARTMENTAL PROCEDURE

DP-EPD-302

TRAINING MANUAL

FOR PIPING DESIGNER

Page 198 of 206

All reducers and swages shall give both sizes under the size column.

When Y-strainers are in the line class, list the short code in the fittings

section. When not, list the strainer in the miscellaneous materials

section with description. Branch welds shall be listed in the fittings

section as BRW per size of the branch.

Orifice flanges shall be taken off as a set in the flange column along

with bolts and gaskets in field column. The bolts and gaskets (even

though 300 # and extra length) shall not be called out on the isometric

and will accounted for in special form sheet with the orifice flange.

When isometric require 300# flanges, bolts or gaskets that are in 150#

specs, they shall be listed in the miscellaneous column with the rating

shown under description. (except for orifice flanges)

Indicate nipple length under size column, only when 7 long nipple is

required, (1/2 X 7 ). Do not indicate standard 4 length. The Pipe

Spec, Temperature, Pressure, Insulation and Paint columns shall not be

repeated when the input data is the same. Pipe lengths shall be

determined from point to point dimensions, without deducting for

valves and fittings for 4 SS/10 CS and below. For 6 SS / 12 CS

and above the valves and fittings shall be deducted from the point to

point dimensions.

Trunnions shall be shown under miscellaneous materials and listed in

the size column as 3 X 4 (inches X feet), with the trunnion number in

the description column. Reinforcing pads shall be entered with short

code RPD under fittings as the branch size. The material shall be

accounted for in the miscellaneous column with size as header size,

schedule per spec, quantity per pad length in feet and pad listed under

description.

Originator: Wisnu S.

D:\Buku Pintar\Training Manual for Piping Designer\DP-EPD-302 PDsign_7c\Session_7.doc

Revision No.: 0

P.T. INTI KARYA PERSADA TEHNIK

DEPARTMENTAL PROCEDURE

DP-EPD-302

TRAINING MANUAL

FOR PIPING DESIGNER

Page 199 of 206

Personnel protection insulation shall be shown under miscellaneous

material with a certain code number and the pipe size / length insulated

under the size and quantity columns. Blind flanges (BLF) and field

welds (FW) should be shown on the same shop (S) line as other

material and will automatically be taken off as field.

Originator: Wisnu S.

D:\Buku Pintar\Training Manual for Piping Designer\DP-EPD-302 PDsign_7c\Session_7.doc

Revision No.: 0

P.T. INTI KARYA PERSADA TEHNIK

DEPARTMENTAL PROCEDURE

DP-EPD-302

TRAINING MANUAL

FOR PIPING DESIGNER

7.3. EXERCISES

Originator: Wisnu S.

D:\Buku Pintar\Training Manual for Piping Designer\DP-EPD-302 PDsign_7c\Session_7.doc

Revision No.: 0

Page 200 of 206

Das könnte Ihnen auch gefallen

- Production Engineering: Jig and Tool DesignVon EverandProduction Engineering: Jig and Tool DesignBewertung: 4 von 5 Sternen4/5 (9)

- Piping Drawings Basics: N.P.TodkarDokument37 SeitenPiping Drawings Basics: N.P.Todkaredgar_glezav100% (2)

- Piping Drawing Basics: Orthographic and Isometric ViewsDokument39 SeitenPiping Drawing Basics: Orthographic and Isometric Viewsprashant_dc_inNoch keine Bewertungen

- Piping Drawings Basics: Mr. T. N. GopinathDokument39 SeitenPiping Drawings Basics: Mr. T. N. Gopinathhirenkumar patel100% (1)

- Piping DrawingDokument36 SeitenPiping DrawingmansurNoch keine Bewertungen

- Piping Engineering - Piping Layout Procedure and Pipe Rack - XyntechDokument14 SeitenPiping Engineering - Piping Layout Procedure and Pipe Rack - XyntechKeiko DavilaNoch keine Bewertungen

- Equipment & Piping Layout T.N. GopinathDokument88 SeitenEquipment & Piping Layout T.N. Gopinathhirenkumar patelNoch keine Bewertungen

- P&id - 1Dokument5 SeitenP&id - 1dasubhai100% (1)

- Piping Layout PresentationDokument56 SeitenPiping Layout Presentationhirenkumar patel89% (9)

- Pipeline Design and Drafting GuideDokument32 SeitenPipeline Design and Drafting Guideravish ravindran90% (10)

- PROJECT STANDARDS and SPECIFICATIONS Offshore Piping and Instrumentation Diagrams Rev01Dokument7 SeitenPROJECT STANDARDS and SPECIFICATIONS Offshore Piping and Instrumentation Diagrams Rev01totongopNoch keine Bewertungen

- How To Make A P&IDDokument24 SeitenHow To Make A P&IDRinaBhattacharyaNoch keine Bewertungen

- An Overview Of: Plant Layout AND PipingDokument21 SeitenAn Overview Of: Plant Layout AND Pipingpuru55980Noch keine Bewertungen

- Rack DesignDokument8 SeitenRack DesignMayank Sethi100% (1)

- P&Id Related: Sr. No. Check Points DoneDokument5 SeitenP&Id Related: Sr. No. Check Points DoneSwapna Priya VattemNoch keine Bewertungen

- Equpment LayoutDokument6 SeitenEqupment LayoutdasubhaiNoch keine Bewertungen

- Eaton Port DimensionsDokument31 SeitenEaton Port DimensionsJas Sum100% (1)

- Check List For Piping GADokument2 SeitenCheck List For Piping GAmksk_23Noch keine Bewertungen

- Piping Drawings Guide: PFDs, P&IDs, Isometrics & GADsDokument89 SeitenPiping Drawings Guide: PFDs, P&IDs, Isometrics & GADsbey100% (2)

- An Overview Of: Plant Layout AND PipingDokument21 SeitenAn Overview Of: Plant Layout AND PipingRajkumar ANoch keine Bewertungen

- An Overview Of: Plant Layout AND PipingDokument21 SeitenAn Overview Of: Plant Layout AND Pipingmurali100% (1)

- P&IDDokument23 SeitenP&IDmagarciaprieto100% (2)

- Pipe RoutDokument10 SeitenPipe Routghkashyap1Noch keine Bewertungen

- Check List For Piping Unit Plot PlanDokument5 SeitenCheck List For Piping Unit Plot PlanVijay GaikwadNoch keine Bewertungen

- Pipe Rack PipingDokument28 SeitenPipe Rack Pipingardikurniawan100% (2)

- City of Newport Beach Standard Design RequirementsDokument9 SeitenCity of Newport Beach Standard Design Requirementsjeffreygonzales1yahoo.comNoch keine Bewertungen

- UGA PPD Electrical Design Standards and Guidelines.Dokument5 SeitenUGA PPD Electrical Design Standards and Guidelines.uddinnadeemNoch keine Bewertungen

- Isometrics Check ListDokument3 SeitenIsometrics Check Listvino2win100% (1)

- Check List For Piping LayoutsDokument3 SeitenCheck List For Piping LayoutsChris DE100% (1)

- Table of Contents and Piperack Design GuidelinesDokument20 SeitenTable of Contents and Piperack Design GuidelinesKehinde AdebayoNoch keine Bewertungen

- Overhead Sign Structure Design and Fabrication GuideDokument8 SeitenOverhead Sign Structure Design and Fabrication Guideleodegarioporral100% (1)

- Chapter 12 - Pipe Ra - 2018 - The Engineer S Guide To Plant Layout and Piping deDokument21 SeitenChapter 12 - Pipe Ra - 2018 - The Engineer S Guide To Plant Layout and Piping deezeabrilNoch keine Bewertungen

- SPC-0804.02-99.02 Rev D2 Preparation of P&I DDokument37 SeitenSPC-0804.02-99.02 Rev D2 Preparation of P&I DPadakandla Suman100% (1)

- EPF4802 - Chapter 7 (Part 1) Instrumentation and Control - NoteDokument27 SeitenEPF4802 - Chapter 7 (Part 1) Instrumentation and Control - NotehidayantiemNoch keine Bewertungen

- Pipe RackDokument25 SeitenPipe RackVernie SorianoNoch keine Bewertungen

- How To Make A P&IDDokument23 SeitenHow To Make A P&IDJawahar100% (1)

- Equipment Layout Drawing ChecklistDokument11 SeitenEquipment Layout Drawing ChecklistRené Luis Perez MagneNoch keine Bewertungen

- Alignment SheetDokument1 SeiteAlignment Sheetkhalid ahmedNoch keine Bewertungen

- NasbyG 2012 UsingFlowsheetsAsCommunicationTools AIChE-CEP Oct2012Dokument9 SeitenNasbyG 2012 UsingFlowsheetsAsCommunicationTools AIChE-CEP Oct2012Henry Arenas100% (1)

- Ags019 02Dokument22 SeitenAgs019 02Forbes KambaNoch keine Bewertungen

- PCB Unit 2Dokument62 SeitenPCB Unit 2shrimanNoch keine Bewertungen

- Engineering P&ID Technical TrainingDokument54 SeitenEngineering P&ID Technical TrainingSergio MartinezNoch keine Bewertungen

- 2-Plant Layout - Pipeway DesignDokument25 Seiten2-Plant Layout - Pipeway DesignLaxmikant SawleshwarkarNoch keine Bewertungen

- Guidelines For Piping Design & ErectionDokument55 SeitenGuidelines For Piping Design & ErectionKartik Varma Namburi100% (2)

- Line Stop Welded To Shoe CalculationDokument16 SeitenLine Stop Welded To Shoe CalculationmohdnazirNoch keine Bewertungen

- Orifice Plate Installation GuidelinesDokument24 SeitenOrifice Plate Installation Guidelineskhavihong100% (1)

- Along With There Piping Component Its Also Included The ProcessDokument1 SeiteAlong With There Piping Component Its Also Included The ProcessRahul MoottolikandyNoch keine Bewertungen

- Piping DesigningDokument28 SeitenPiping DesigningAnil PalNoch keine Bewertungen

- Design Guidelines for Surface Mount TechnologyVon EverandDesign Guidelines for Surface Mount TechnologyBewertung: 5 von 5 Sternen5/5 (1)

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsVon EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsBewertung: 4.5 von 5 Sternen4.5/5 (10)

- Complete PCB Design Using OrCAD Capture and PCB EditorVon EverandComplete PCB Design Using OrCAD Capture and PCB EditorBewertung: 5 von 5 Sternen5/5 (1)

- Radio Shack TRS-80 Expansion Interface: Operator's Manual: Catalog Numbers: 26-1140, 26-1141, 26-1142Von EverandRadio Shack TRS-80 Expansion Interface: Operator's Manual: Catalog Numbers: 26-1140, 26-1141, 26-1142Noch keine Bewertungen

- Linear IC Applications: A Designer's HandbookVon EverandLinear IC Applications: A Designer's HandbookBewertung: 4 von 5 Sternen4/5 (1)

- Structural Drafting - A Practical Presentation of Drafting and Detailed Methods used in Drawing up Specifications for Structural Steel WorkVon EverandStructural Drafting - A Practical Presentation of Drafting and Detailed Methods used in Drawing up Specifications for Structural Steel WorkBewertung: 3 von 5 Sternen3/5 (1)

- Applied Process Design for Chemical and Petrochemical Plants: Volume 1Von EverandApplied Process Design for Chemical and Petrochemical Plants: Volume 1Bewertung: 3.5 von 5 Sternen3.5/5 (3)

- Hazardous Area Classifications and ProtectionsDokument8 SeitenHazardous Area Classifications and ProtectionsUday GokhaleNoch keine Bewertungen

- Aga 10 2002 11 15 PDFDokument175 SeitenAga 10 2002 11 15 PDFjiesuaNoch keine Bewertungen

- USM GT400 Leaflet en 2014-10-28Dokument8 SeitenUSM GT400 Leaflet en 2014-10-28DendeNoch keine Bewertungen

- LNG Sampler VaporizerDokument4 SeitenLNG Sampler VaporizerDendeNoch keine Bewertungen

- Tutorial Gambit PDFDokument13 SeitenTutorial Gambit PDFNacera BenslimaneNoch keine Bewertungen

- Circuits BasicDokument11 SeitenCircuits BasicDendeNoch keine Bewertungen

- HYSYS Methanol ProductionDokument77 SeitenHYSYS Methanol ProductionGaukharAlzhanova100% (1)

- Tutorial Gambit PDFDokument13 SeitenTutorial Gambit PDFNacera BenslimaneNoch keine Bewertungen

- Leakage Class of Control ValvesDokument4 SeitenLeakage Class of Control Valvesg1232003gNoch keine Bewertungen

- IEC-60534-8-3 Standard For Noise Prediction in Control ValvesDokument12 SeitenIEC-60534-8-3 Standard For Noise Prediction in Control ValvesDende100% (2)

- Circuits BasicDokument11 SeitenCircuits BasicDendeNoch keine Bewertungen

- Gambit TutorialDokument305 SeitenGambit Tutorialvenkat4890100% (1)

- The specialist in efficient gas distribution regulatorsDokument6 SeitenThe specialist in efficient gas distribution regulatorsDendeNoch keine Bewertungen

- SafeNet Sentinel End User GuideDokument24 SeitenSafeNet Sentinel End User Guidelgskumar2010Noch keine Bewertungen

- Flo Calc Report TemplateDokument2 SeitenFlo Calc Report TemplateDendeNoch keine Bewertungen

- Flow and Level Measurement HandbookDokument100 SeitenFlow and Level Measurement Handbookmtayyab_786Noch keine Bewertungen

- Training Basic RoutingDokument4 SeitenTraining Basic RoutingDendeNoch keine Bewertungen

- DHCP Error SolveDokument1 SeiteDHCP Error SolveDendeNoch keine Bewertungen

- TocDokument13 SeitenTocDendeNoch keine Bewertungen

- 34pl4024 - I06 Default Views (1Dokument1 Seite34pl4024 - I06 Default Views (1DendeNoch keine Bewertungen

- Cable Size CalculationsDokument4 SeitenCable Size CalculationsSohail ANoch keine Bewertungen

- Excell VBA CrackDokument1 SeiteExcell VBA CrackDendeNoch keine Bewertungen

- CASE2Dokument1 SeiteCASE2DendeNoch keine Bewertungen

- Thermo Well Calculation PaperDokument7 SeitenThermo Well Calculation PaperessnelsonNoch keine Bewertungen

- Tutorial PV Elite 2005Dokument23 SeitenTutorial PV Elite 2005Fredy David Hutahaean100% (2)

- Junction Box (Wallsall)Dokument1 SeiteJunction Box (Wallsall)DendeNoch keine Bewertungen

- Astm A874Dokument3 SeitenAstm A874DendeNoch keine Bewertungen

- Insp Checklist - Piping ConnectionsDokument1 SeiteInsp Checklist - Piping ConnectionsDendeNoch keine Bewertungen

- AGA Calculations 1985 VS 1992 StandardsDokument26 SeitenAGA Calculations 1985 VS 1992 StandardsGeorge KasepNoch keine Bewertungen

- Specs-Stage 2& 3-TrackworksDokument76 SeitenSpecs-Stage 2& 3-Trackworksismail tp100% (2)

- Submersible Pumpsets - SpecificationDokument16 SeitenSubmersible Pumpsets - SpecificationP Ram MoorthyNoch keine Bewertungen

- Behaviour of Masonry StructuresDokument27 SeitenBehaviour of Masonry StructuresvarshaNoch keine Bewertungen

- WFDTH Waterflow Detector: Sprinkler Systems MonitoringDokument2 SeitenWFDTH Waterflow Detector: Sprinkler Systems MonitoringArgile-assholeNoch keine Bewertungen

- Flexible Pavement DesignDokument7 SeitenFlexible Pavement DesignMëñghëñg ŁïmNoch keine Bewertungen

- Dr. D. Y. Patil School of Engineering & Technology Department of Civil Engineering Be Project Phase Ii Sheet (Ay2019-20) Sem IiDokument3 SeitenDr. D. Y. Patil School of Engineering & Technology Department of Civil Engineering Be Project Phase Ii Sheet (Ay2019-20) Sem IiRao SahabNoch keine Bewertungen

- How To Control The Warping of Parts in Thin SheetDokument6 SeitenHow To Control The Warping of Parts in Thin SheetNeil WayneNoch keine Bewertungen

- SPEC SHEET 005 AeroGlass LensDokument1 SeiteSPEC SHEET 005 AeroGlass LensMarco GalindoNoch keine Bewertungen

- Spreadsheets To BS 8110: Advisory Group Ground Floor Columns at B1, B2 Etc 96Dokument14 SeitenSpreadsheets To BS 8110: Advisory Group Ground Floor Columns at B1, B2 Etc 96Quality ControlNoch keine Bewertungen

- Geosynthetics ApplicationsDokument51 SeitenGeosynthetics ApplicationsCharlotte TilburyNoch keine Bewertungen

- High Tensile Steel SpecificationDokument3 SeitenHigh Tensile Steel SpecificationRuano Andreola StumpfNoch keine Bewertungen

- SIMONA PVC-C CORZAN Engineered From Post-Chlorinated PVC For Exceptional PerformanceDokument6 SeitenSIMONA PVC-C CORZAN Engineered From Post-Chlorinated PVC For Exceptional PerformanceIsrael AristaNoch keine Bewertungen

- Solid State WeldingDokument14 SeitenSolid State WeldingRaju_pancal100% (1)

- GFCI Fact Sheet Explains Life-Saving Power of Ground Fault Circuit InterruptersDokument5 SeitenGFCI Fact Sheet Explains Life-Saving Power of Ground Fault Circuit InterruptersfaridunNoch keine Bewertungen

- Copy of Pending Pos MetalDokument112 SeitenCopy of Pending Pos MetalVijay OfficialNoch keine Bewertungen

- Experimental Behaviour of Steel Fiber Reinforced Concrete With Partial Replacement of Fly Ash and MetakaolinDokument4 SeitenExperimental Behaviour of Steel Fiber Reinforced Concrete With Partial Replacement of Fly Ash and MetakaolinEditor IJTSRDNoch keine Bewertungen

- Angle Style, Pressure Relief Valves For Steam, Gas, and Liquid ServicesDokument14 SeitenAngle Style, Pressure Relief Valves For Steam, Gas, and Liquid ServicesCHRISTIAN ZAVALANoch keine Bewertungen

- Prevent Negative Volume in Foam ModelsDokument9 SeitenPrevent Negative Volume in Foam ModelsGustavo Yippeekayyay GusNoch keine Bewertungen

- Special Advance Format For Project 2017 2020Dokument7 SeitenSpecial Advance Format For Project 2017 2020Dennis RojasNoch keine Bewertungen

- 28 Jan 2016 130451497MIDC9A4GAdditionalInformationDokument84 Seiten28 Jan 2016 130451497MIDC9A4GAdditionalInformationSankhyaNoch keine Bewertungen

- Roads Division KasaragodDokument142 SeitenRoads Division KasaragodShameer UppalaNoch keine Bewertungen

- Work Method Statement - Fireproofing PaintDokument4 SeitenWork Method Statement - Fireproofing Paintarrojak maksumNoch keine Bewertungen

- Quotation For G.I For The Sinar Sweet Factory Building at Kassla State V02Dokument4 SeitenQuotation For G.I For The Sinar Sweet Factory Building at Kassla State V02abdallah abdurhman aliNoch keine Bewertungen

- Check List For Installation and Incoming Materials For Pipe Sleeves (Sanitary & Plumbing Works)Dokument2 SeitenCheck List For Installation and Incoming Materials For Pipe Sleeves (Sanitary & Plumbing Works)Imho TepNoch keine Bewertungen

- The Electricity Wiring Regulations (Third EditionDokument139 SeitenThe Electricity Wiring Regulations (Third EditionAllen AnyayahanNoch keine Bewertungen

- Torrent Pumps: Deep Well Vertical Turbine Pumps 1/2Dokument1 SeiteTorrent Pumps: Deep Well Vertical Turbine Pumps 1/2g1ann1sNoch keine Bewertungen

- Serving The World in Pneumatic and Vacuum Conveying ProductsDokument8 SeitenServing The World in Pneumatic and Vacuum Conveying ProductsoganuluNoch keine Bewertungen

- Curing in ConstructionDokument7 SeitenCuring in ConstructionNgissah NketiahNoch keine Bewertungen

- JD - Internship at CyondDokument2 SeitenJD - Internship at CyondStupidity TalksNoch keine Bewertungen