Beruflich Dokumente

Kultur Dokumente

Observatorynano Briefing No 28 Sensor

Hochgeladen von

Shobhit GuptaCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Observatorynano Briefing No 28 Sensor

Hochgeladen von

Shobhit GuptaCopyright:

Verfügbare Formate

BRIEFING No.

28

ObservatoryNANO Briefing March 2012

AGRIFOOD

Sensors in Food Production & Processing

With a world population expected to reach 9.3 billion by 2050 1 there is an ever increasing demand for

more efficient food production. The agricultural industry must also reduce its environmental impact

while facing the many challenges of a changing climate, such as increased water stress and new pests.

Food safety and quality control is a major issue in food processing, and food borne illnesses remain a

major public health concern; in 2009 there were 5550 reported food borne outbreaks in the EU2.

Existing sensor technologies provide important information to farmers concerning environmental conditions, plant and animal health, and growth parameters allowing for remedial action. In food processing

sensors detect contaminants including biologicals and chemicals which would impact on human health.

Nanotechnologies offer the potential for increasingly sensitive sensors with reduced time to results,

which can be used on-the-spot, and do not require high levels of technical expertise. This BRIEFING outlines challenges to be addressed, describes a selection of promising nanotechnologies which offer improvements over current technologies, provides a view on research and industrial activity within this

sector in the EU, and looks at some of the issues being faced in the development of these technologies.

The Challenge

To feed the growing world population while reducing the environmental impact of food production

the following requirements must be addressed:

Closer monitoring of environmental conditions, plant and animal health, and growth

for optimal output and efficient use of resources (pest identification has been identified as a particular need which cannot be

achieved with current technologies3);

Precision farming leading to more targeted

and earlier intervention to increase productivity and reduce the requirement for agrochemicals (fertilisers, pesticides, and antibiotics); and

Accurate measurement of the environmental impact of the agricultural process,

particularly in terms of pesticide and fertiliser levels in soil and run off.

In the food processing industry it is vital to detect

the presence of agro-chemicals, other chemical

contaminants (such as heavy metals), and pathogens that lead to food borne illnesses including

salmonella, listeria, and campolybacter. In addition, measurement of food quality is also required

in terms of colour, smell, taste and mouth feel.

How can nanotechnologies help?

Current sensor technologies are able to measure

all required variables; however, they may lack sensitivity, rapidity of detection, portability or a combination of these factors. The much increased surface area of nanomaterials allows for a greater

number of molecular interactions and therefore

potentially much higher sensitivity and faster detection times.

With current technologies, in general, an individual

has to collect a physical sample, which is analysed

at a different location (usually a central laboratory). This requires technical expertise, is labourintensive and can take a number of days, by which

time the opportunity for optimal intervention

could be missed (for example, the industry standard for chemical detection is gas or liquid chromatography followed by mass spectrometry).

Nano-enabled sensor developments may allow for

portable or in-situ continuous monitoring, leading

to farmer led intervention for improved outcomes

including increased and better quality and yields of

food. Additionally the potential reduction in use of

agro-chemicals will reduce the environmental impact.

For food quality control, nanotechnology applications again offer greater sensitivity and real-time

(on the spot) detection, with smaller samples being required. This would lead to more effective

detection of contaminants that lead to food borne

Box 1: Sniffing out quality

In the past, manufacturers used highly trained individuals to measure quality of foodstuffs; however, this is

obviously not suitable in the modern high volume food

processing industry! One answer is to use an electronic

nose or electronic tongue.

FP7 project Bioelectronic Olfactory Neuron Device

(BOND) is developing a new kind of bioelectronic nose,

based on olfactory receptors, which mimic the way an

animals nose detects odour. It is hoped that the resultant sensor will have extremely high sensitivity and selectivity for detecting very small quantities of odorants.

Together with a real time response, low expertise requirement, portability and affordability of the system

compared with existing biosensors, the capabilities required by end users such as the food processing industry

will be met5.

AGRIFOOD: Sensors in Food Production & Processing

ObservatoryNANO Briefing March 2012

outbreaks or other harm to human health, and

additionally could determine whether food is still

safe to eat even after it has reached its expiry date,

thus reducing waste.

The nano way

The field of nano-enabled sensors is largely driven

by their application in the medical sector; however, a variety of nano-enabled sensor technologies show potential for use in food production and

processing. Both are summarised in Table 1.

Biosensors, such as uni-molecular sensors or bioarrays, utilise biomolecules to detect targets such as

pesticides or gases relevant to agricultural growth.

Nanotechnology impacts on these technologies by

improving sensitivity (due to a greater surface

area), increased miniaturisation, and faster detection rates. Array technologies can detect multiple

target substances and can be used at different

stages of the food chain. Examples are 1. detecting

the presence of pathogens in livestock or crops; 2.

measuring the levels of toxins or nutrients in soils;

and 3. monitoring the quality of processed food

(Box 1).

Impacts

Economic/Industry

The biosensor market has been historically driven

by medical biosensors rather than applications in

food production and processing. The food market,

although very large, has, in general, low profit margins and there is huge competition. Consequently,

the food industry cannot afford to invest in modern analytical methods at the same level as other

hi-tech sectors such as clinical or pharmaceutical

areas. Additionally the application of biosensors in

the food industry still has to compete with other

analytical methods in terms of cost, performance,

and reliability.

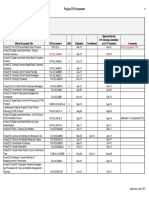

Market analysts have estimated that the global

revenue for the biosensors market will continue to

exhibit strong growth and will exceed the 10 billion mark in the next seven years6 (Figure 1). These

revenues are estimated to grow at a CAGR

(compound annual growth rate) of 11.5% from

2009 to 2016. Annual revenue growth rates are

likely to be in the region of 12 to 14% by 2016.

Biosensors have been recently used in more than

47 different end-user applications in contrast to

just over 32 applications seven years ago. This

growth in end-user applications and expansion into

other markets is strongly aided by innovations

within the biosensor market.

As to the application of sensors in food industry,

the strongest growth potential has been suggested

for intelligent packaging with radio frequency identification data tags (RFIDs). This category is expected to grow at almost 19 % annually by 20147.

Some companies active in the field include Israeli

MS Tech whose sensors utilising High-Frequency

Quartz Crystal Microbalance (HF-QCM) detection

method (Electronic nose/tongue). Sensors using

the HF-QCM detection method can also be recalled

as "Electronic-Nose" and "Electronic-Tongue". Attophotonics, an Austrian company, is a producer of

smart humidity indicators (SHIs), with the next

generation products based on nanostructural

changes, for use in food quality monitoring. In

terms of agricultural sensors Syngenta, formed in

2000 from the merger of AstraZeneca and Novartis

crop science businesses, has invested in the Sygenta Sensor University Innovation Centre at the

University of Manchester in the UK. Here new

sensing technologies are being investigated for use

in the agricultural sector.

Societal/Impact on European Citizen

Nano-enabled sensors in food production and

processing offer a number of benefits to the EU

citizen including:

Technology

Description

Target

Uni-molecular sensors

Single biomolecule enclosed or attached to nanomaterials

(liposomes, nanoparticles, nanorods, or carbon nanotubes).

Pesticides, gases such as CO2.

Bioarrays (including electronic noses/tongues)

Multiple biomolecules enclosed or attached to nanostructured

materials.

Multiple chemicals & microbes.

Solid state sensors

Thin film or nanowire (carbon nanotube, silicon, metal oxide,

metal alloy or conducting polymer) sensors.

Gases.

Optical & spectrographic

sensors

CCD, lasers and spectrometers.

Plant growth, presence of different

chemicals.

Radio Frequency Identification (RFID) tags

Sensor networks

Monitoring of produce condition

during transit.

Individual sensor nodes that can be dispersed over an area,

measure local variables, and report to a central processing unit.

All aspects of crop and livestock

monitoring for precision farming.

Table 1: Examples of nano-enabled sensor technologies relevant to food production and processing (adapted from 4 )

AGRIFOOD: Sensors in Food Production & Processing

ObservatoryNANO Briefing March 2012

Increased food production ensuring food

security and reduced food inflation;

Reduced use of agrochemicals reducing the

environmental impact of and ultimately human exposure to the agricultural industry;

Improved livestock monitoring limiting the

threat of disease and allowing more effective control (e.g. limited use of veterinary

medicines).

Improved monitoring of growth conditions for

crops will optimize and reduce the use of nitraterich fertilisers (which are a major source of water

pollution in the EU, and at high concentrations are

harmful to both the environment and humans8).

Increasingly, sensitive sensors in the food processing industry will have important implications in

terms of protecting the general public from food

borne pathogens and other contaminants that can

lead to illness and death. They can also offer the

prospect of superior food quality in terms of taste,

smell, appearance and mouth feel.

In packaging they can improve consumer confidence in the condition of food, leading to less

waste.

EU Competitive Position

The biosensors market as a whole is highly competitive but as previously mentioned this is driven

by the medical and pharmaceutical sector. However, there are a number of European initiatives

relevant to the use of sensors in food production

and processing. The University of Manchesters

School of Electronic and Electrical Engineering has

launched the e-Agri research cluster to integrate

advanced research in ICT, sensing, electronics, control and power systems to help enable a new future for global agriculture and food security; this is

in response to current efforts being seen as biocentric.

In the field of RFID technology European efforts

include the RACE networkRFlD, an EU project

which has been established to position the EU as a

Figure 1: Global revenue forecast for the biosensors market

until 2016 (with baseline year as 2009).

world leader in RFID. Also, the platform developed

through the LOTUS EU project reinforces the leading position of European Industry in flexible RFIDs.

The technologies and materials generated through

this project enables the EU to be competitive with

Asia and North America and provides new technologies to address societal needs. The overall

strategy addresses both common needs and the

specific requirements of any flexible electronics

and food protection or food freshness applications.

Challenges

Technological

Many nano-enabled sensor technologies remain at

an early stage of development and therefore have

a number of technological challenges to be addressed. One of the key issues is the stability and

longevity of the sensing biomolecule under conditions in the field, for example, how it is affected by

temperature ranges, presence of other chemicals

and particulates. Other aspects of the sensor such

as signal conduction and processing also require

improvement. For example, conductive polymer

nanowires are mechanically weak and likely to

break easily9.

Ethical & Societal Concerns

The involvement of nanotechnologies at any stage

of the food chain is sensitive and raises concerns

among the general public and some NGOs, particularly with regard to environment, health and safety

implications (see below). However, as nanoenabled sensors will not be consumed they are

expected to meet less consumer resistance than

some other nano-enabled developments for the

Agrifood sector. RFID tags in particular raise privacy issues, e.g. for cattle owners or for consumers10. Biosensors used for livestock disease control could be ethically preferable to other methods

such as large scale vaccinations or eradicating diseases by culling animals11.

Environment, Health & Safety

According to the exposure analysis conducted by

the ObservatoryNANO12, solid state sensors for gas

measurement near crops have low exposure potential for the user (farmer) or consumer. In addition, the variety of sensors utilised during food

processing have been deemed to have a low exposure potential for both professional user and consumer.

At the disposal stage, the environment may be exposed when applications containing nanosensors

are incinerated (air), landfilled (soil), or released

from the sewage treatment plant (water). Both soil

and water may be exposed through litter (e.g. discharge from food packages).

ObservatoryNANO Briefing March 2012

AGRIFOOD: Sensors in Food Production & Processing

Regulations & Standards

There are general regulations and standards challenges facing all nanotechnology developments

and these have been assessed within the ObservatoryNANO13. Focusing on the Agrifood sector, the

European Food Standards Agency (EFSA) was

asked by the EC to provide a scientific opinion on

the potential risks of application of nanoscience

and nanotechnologies (particularly engineered

nanomaterials) in the food and feed (animal food)

chain. The EFSA Scientific Committee concluded

that current international regulations for risk assessment may be applied but a case-by-case approach should be adopted due to the current limitations in the risk assessment of nanomaterials

and the associated uncertainty14.

Recommendations

Any successful application of nanotechnology in

the food production and food processing industry

requires the combined effort of academia, industry, NGOs, general public and public policy-makers

to understand the fundamental knowledge of

nanospecific features and establish the benefit-risk

balance. According to the recommendations of

JRC-EASAC Working Group15 a more effective

translation of this knowledge into best practice

and final product, will require closer collaboration

between primary producers, downstream users

and consumers. This is consistent with multisectoral and safety research as an essential part of

the innovation of food production and processing

directed by nano-enabled sensors.

Figure 2: Technology readiness levels for selected sensor

technologies in food production and processing

Summary

With a rapidly growing world population

there is a pressing need to improve the productivity and reduce the impact of the agricultural industry on people and the environment.

Nano-enabled sensors may allow for greater

sensitivity than conventional sensors and

potential for on-site, continuous, untrained

analysis allowing for precision farming.

Considerable technological challenges remain to be addressed before nano-enabled

sensors are commercialised and effectively

compete with existing technologies.

The use of nano-enabled developments

within the food chain is a sensitive issue in

terms of public acceptance and this, together with potential exposure of man and

the environment and lack of specific regulation, represents a significant barrier to full

scale commercialisation.

Contact information

Technical: Mark Morrison, Institute of Nanotechnology, mark.morrison@nano.org.uk

Economic: Gabriela Salejova, Czech Liaison Office

for R&D, TCASCR, salejova@tc.cz

References

1

http://esa.un.org/unpd/wpp/Other-Information

Press_Release_WPP2010.pdf

2

http://www.efsa.europa.eu/en/efsajournal/doc/2090.pdf

3

https://ktn.innovateuk.org/c/document_library/get_file?

uuid=b2d9d533-0c95-4283-8be7-44b9153f305a&groupId=3460325

4

http://www.observatorynano.eu/project/filesystem/files/Full%

20Report%20Nanotechnology%20in%20Agrifood%20May%

202009.pdf

5

http://bondproject.org/

6

Thusu, R. Strong Growth Predicted for Biosensors Market, 2010,

Frost & Sullivan Sensors.

7

Nano-Enabled Packaging for the Food and Beverage Industry - A

Global Technology, Industry and Market Analysis. 2009, iRAP, Inc.,

www.azonano.com

8

http://europa.eu/rapid/pressReleasesAction.do?

reference=IP/10/154&format=HTML

9

http://www.engr.ucr.edu/~myung/Publications/ja031.pdf

10

David, K. & Thompson, P.B., (eds), What can nanotechnology learn

from biotechnology? Social and ethical lessons for nanoscience from

the debate over agrifood biotechnology and GMOs, Food science and

technology series, Academic Press, 2008, http://books.google.nl/

books?id=DljpjLEjCM0C&source=gbs_navlinks_s

11

Evers, J., Aerts, S., De Tavernier, J. An Ethical Argument in Favour of

Nano-enabled Diagnostics in Livestock Disease Control, in Nanoethics

Vol 2, No 2, August 2008, http://www.springerlink.com/content/

t1871473wx614047/?p=d70ba4115d0a4a8fa341cd957c99a405&pi=3

12

http://www.observatorynano.eu/project/filesystem/files/

AgrifoodEHSanalysis_Aug10.pdf

13

http://www.observatorynano.eu/project/filesystem/files/

DevelopmentsInNanotechnologiesRegulationandStandards_2011.pdf

14

http://www.efsa.europa.eu/en/faqs/faqnanotechnology.htm

15

European Commission, EASAC and JRC. Impact of engineered nanomaterials on health: considerations for benefit-risk assessment, 2011,

ISBN 978-92-79-20446-3

Das könnte Ihnen auch gefallen

- Nanotechnology Research Methods for Food and BioproductsVon EverandNanotechnology Research Methods for Food and BioproductsNoch keine Bewertungen

- Advanced Food Analysis Tools: Biosensors and NanotechnologyVon EverandAdvanced Food Analysis Tools: Biosensors and NanotechnologyRovina KobunNoch keine Bewertungen

- Nano-Food Regulatory Issues in The European Union: Articles You May Be Interested inDokument8 SeitenNano-Food Regulatory Issues in The European Union: Articles You May Be Interested inTOCHUKWU VINCENTNoch keine Bewertungen

- Nanotechnology For The Food and Bioprocessing IndustriesDokument9 SeitenNanotechnology For The Food and Bioprocessing IndustriesvikashvermaiitkgpNoch keine Bewertungen

- Nanomaterials in FoodDokument8 SeitenNanomaterials in FoodLindo PulgosoNoch keine Bewertungen

- Nanotechnology ApplicationDokument38 SeitenNanotechnology ApplicationMadhulika Bhati100% (1)

- 10.1016/j.foodres.2014.03.022: Food Research InternationalDokument25 Seiten10.1016/j.foodres.2014.03.022: Food Research InternationalIrshaan SyedNoch keine Bewertungen

- Nanotechnologyin Food Processingand PackagingDokument25 SeitenNanotechnologyin Food Processingand PackagingSam HunterNoch keine Bewertungen

- Biosensor Development in Agri ManagementDokument21 SeitenBiosensor Development in Agri ManagementSendhilNoch keine Bewertungen

- Soceital Implication of Nanotechnology EssayDokument9 SeitenSoceital Implication of Nanotechnology EssayJyothish DevadasNoch keine Bewertungen

- Nanoagri 2010Dokument145 SeitenNanoagri 2010wasousky10Noch keine Bewertungen

- Application of Nanotechnology in Food Packaging: September 2016Dokument8 SeitenApplication of Nanotechnology in Food Packaging: September 2016Mumtahin Ul KousarNoch keine Bewertungen

- Nanotechnology An Innovative Approach For Smart AgricultureDokument6 SeitenNanotechnology An Innovative Approach For Smart AgricultureEditor IJTSRDNoch keine Bewertungen

- 1 s2.0 S102194981830173X MainDokument21 Seiten1 s2.0 S102194981830173X MainZafar IqbalNoch keine Bewertungen

- Badhos SMNRDokument7 SeitenBadhos SMNRTäð Œvê MîðNoch keine Bewertungen

- Nano and AgricultureDokument14 SeitenNano and AgricultureJorge Steban Moreno LozanoNoch keine Bewertungen

- Biosensors and Nanomaterials-Mycotoxin Determination-2011Dokument30 SeitenBiosensors and Nanomaterials-Mycotoxin Determination-2011fikerykNoch keine Bewertungen

- Marinedrugs 19 00061Dokument35 SeitenMarinedrugs 19 00061Fadly IrmawanNoch keine Bewertungen

- OSU NanoAgDokument2 SeitenOSU NanoAgJason FromerNoch keine Bewertungen

- Nanoparticulas LipidicasDokument4 SeitenNanoparticulas LipidicasIrving GarciaNoch keine Bewertungen

- Foods 07 00072Dokument29 SeitenFoods 07 00072viktraNoch keine Bewertungen

- GMO New Technologies 2011Dokument220 SeitenGMO New Technologies 2011Tedi PremtiNoch keine Bewertungen

- Nanobiotechnology, Bioproducts and Sustainability: Where Is Agriculture Going??Dokument28 SeitenNanobiotechnology, Bioproducts and Sustainability: Where Is Agriculture Going??anirbanmanna88320Noch keine Bewertungen

- NanotechnologyDokument3 SeitenNanotechnologyfintastellaNoch keine Bewertungen

- Bio SensorDokument2 SeitenBio SensorSahil GuptaNoch keine Bewertungen

- Nanomateriales para ProductosDokument10 SeitenNanomateriales para ProductosYARITZA DEL CARMEN COTRINA QUINTANANoch keine Bewertungen

- BEENISH, BAZILA NASEER, FARHEENA IFTIKHAR, 2021 - Nanotechnology in Food Sector - A ReviewDokument8 SeitenBEENISH, BAZILA NASEER, FARHEENA IFTIKHAR, 2021 - Nanotechnology in Food Sector - A ReviewDana NicutaNoch keine Bewertungen

- Food Technology DisruptionsDokument2 SeitenFood Technology Disruptionsfernando MurciaNoch keine Bewertungen

- Nanotechnology Applications in Food and Food Processing Innovative Green Approaches Opportunities and Uncertainties For Global MarketDokument26 SeitenNanotechnology Applications in Food and Food Processing Innovative Green Approaches Opportunities and Uncertainties For Global MarketDivya DivyachilaNoch keine Bewertungen

- Assignment Biotch 405Dokument9 SeitenAssignment Biotch 405Syed Ali HadiNoch keine Bewertungen

- Nanomaterials and Their Application Possible Toxic EffectsDokument18 SeitenNanomaterials and Their Application Possible Toxic EffectsJesus TurradoNoch keine Bewertungen

- Embedded Based Food Quality Detection With Sensor TechnologyDokument5 SeitenEmbedded Based Food Quality Detection With Sensor TechnologyIJRASETPublicationsNoch keine Bewertungen

- International Journal of Green Nanotechnology: Physics and ChemistryDokument26 SeitenInternational Journal of Green Nanotechnology: Physics and ChemistryAndrea GuzmánNoch keine Bewertungen

- Vegetable Tracing Using IOTDokument64 SeitenVegetable Tracing Using IOTSampath TNoch keine Bewertungen

- Wireless Passive Sensors For Food Quality Monitoring Improving The Safety of Food ProductsDokument14 SeitenWireless Passive Sensors For Food Quality Monitoring Improving The Safety of Food ProductsChun HuiNoch keine Bewertungen

- Nanotechnology Based Biosensors and Its Application: Suravi Pandit, Debaprotim Dasgupta, Nazneen Dewan and Prince AhmedDokument8 SeitenNanotechnology Based Biosensors and Its Application: Suravi Pandit, Debaprotim Dasgupta, Nazneen Dewan and Prince AhmedANTHONY GABRIEL ALBARRACIN ALARCONNoch keine Bewertungen

- Nanotechnology Can Increase Agricultural Production, and Its Applications IncludeDokument4 SeitenNanotechnology Can Increase Agricultural Production, and Its Applications Includedivyansh raiNoch keine Bewertungen

- Shimadzu: Food Safety and Environmental Analyses and More..Dokument26 SeitenShimadzu: Food Safety and Environmental Analyses and More..marcelloairesNoch keine Bewertungen

- Biological TracersDokument6 SeitenBiological TracersAlexandre Marostica NetoNoch keine Bewertungen

- Detection of Foodborne Pathogens by QPCR A Practical Approach For Food Industry ApplicationsDokument20 SeitenDetection of Foodborne Pathogens by QPCR A Practical Approach For Food Industry ApplicationsicrgNoch keine Bewertungen

- Food Industry 4Dokument20 SeitenFood Industry 415041168Noch keine Bewertungen

- Mary Eleftheriadou Microbiological Food 2016Dokument29 SeitenMary Eleftheriadou Microbiological Food 2016Cristina MaldurNoch keine Bewertungen

- Potential Uses of Nano Technology in Dairy IndustryDokument28 SeitenPotential Uses of Nano Technology in Dairy Industryloay2008Noch keine Bewertungen

- Conveyer Belt Vegetable Cleaner and SorterDokument10 SeitenConveyer Belt Vegetable Cleaner and Sorterpiabalmores669Noch keine Bewertungen

- Utilization of It in Food ProcessingDokument12 SeitenUtilization of It in Food ProcessingPavithra VNoch keine Bewertungen

- Application of Nanotechnology in AgriculDokument9 SeitenApplication of Nanotechnology in AgriculDavid TorresNoch keine Bewertungen

- Biosensors Applications in Agri-Food Industry: Liliana Serna-Cock and Jeyson G. Perenguez-VerdugoDokument24 SeitenBiosensors Applications in Agri-Food Industry: Liliana Serna-Cock and Jeyson G. Perenguez-VerdugoARATHI PMPMNoch keine Bewertungen

- Industrial BiotechnologyDokument9 SeitenIndustrial BiotechnologyRohailNoch keine Bewertungen

- Article in Introduction SlidesDokument5 SeitenArticle in Introduction SlidesNoemí SánchezNoch keine Bewertungen

- Applied SciencesDokument11 SeitenApplied SciencesAswad ZEllzNoch keine Bewertungen

- CH9Dokument4 SeitenCH9Raniel RomNoch keine Bewertungen

- Jovanovic 2021 IOP Conf. Ser. Earth Environ. Sci. 854 012041Dokument5 SeitenJovanovic 2021 IOP Conf. Ser. Earth Environ. Sci. 854 012041jensayuswantoro20Noch keine Bewertungen

- An Overview On Use of Biosensor in AgricultureDokument4 SeitenAn Overview On Use of Biosensor in AgricultureAldrienNoch keine Bewertungen

- Agri en ICSDokument2 SeitenAgri en ICSsenthil kumarNoch keine Bewertungen

- Applications of BiosensorsDokument7 SeitenApplications of Biosensorspradeep kumarNoch keine Bewertungen

- 1 Nanotecnology in Agri-Food ProductionDokument23 Seiten1 Nanotecnology in Agri-Food Productionsondang nadapdapNoch keine Bewertungen

- Application of Nanotechnology in Agriculture Future ProspectsDokument12 SeitenApplication of Nanotechnology in Agriculture Future ProspectsZhanarNoch keine Bewertungen

- Priyadarshini Et Al. (2018)Dokument57 SeitenPriyadarshini Et Al. (2018)Santiago DangerNoch keine Bewertungen

- Navigating The Valley of Death Perceptions of Industry and Academia On Production Platforms and Opportunities in BiotechnologyDokument11 SeitenNavigating The Valley of Death Perceptions of Industry and Academia On Production Platforms and Opportunities in BiotechnologyGRAÇAS PERFUMARIANoch keine Bewertungen

- Esfaf 438Dokument6 SeitenEsfaf 438Pew PewNoch keine Bewertungen

- Binder 3 of 4 Dec-2018Dokument1.169 SeitenBinder 3 of 4 Dec-2018Anonymous OEmUQuNoch keine Bewertungen

- Abnormalities of Placenta, Amniotic Fluid and Cord: Prepared By, B. Ezhilarasi, Nursing TutorDokument21 SeitenAbnormalities of Placenta, Amniotic Fluid and Cord: Prepared By, B. Ezhilarasi, Nursing TutorGopala KrishnanNoch keine Bewertungen

- Convection Concentric Annulus Vertical Cylinders Filling Porous MediaDokument17 SeitenConvection Concentric Annulus Vertical Cylinders Filling Porous MediakarthikeyanNoch keine Bewertungen

- L2 Biostatistics ProbabilityDokument84 SeitenL2 Biostatistics ProbabilityAaron CiudadNoch keine Bewertungen

- Upaam 1135891 202105060749199700Dokument18 SeitenUpaam 1135891 202105060749199700Kartik KapoorNoch keine Bewertungen

- Microbiology Part 3Dokument74 SeitenMicrobiology Part 3Authentic IdiotNoch keine Bewertungen

- Maths All FormulasDokument5 SeitenMaths All FormulasVishnuNoch keine Bewertungen

- RhythmDokument10 SeitenRhythmSalcedo NoelNoch keine Bewertungen

- Pref - 2 - Grammar 1.2 - Revisión Del IntentoDokument2 SeitenPref - 2 - Grammar 1.2 - Revisión Del IntentoJuan M. Suarez ArevaloNoch keine Bewertungen

- Iron Ore ProcessDokument52 SeitenIron Ore Processjafary448067% (3)

- Antoine Constants PDFDokument3 SeitenAntoine Constants PDFsofiaNoch keine Bewertungen

- Comparative Performance of Some Cattle Breeds Under Barani Conditions of PakistanDokument4 SeitenComparative Performance of Some Cattle Breeds Under Barani Conditions of PakistanMasood HassanNoch keine Bewertungen

- Class 12 Maths Project On Prime NumbersDokument13 SeitenClass 12 Maths Project On Prime Numbersanon_3835245630% (1)

- LJ-V7080 DatasheetDokument2 SeitenLJ-V7080 DatasheetOrhan DenizliNoch keine Bewertungen

- Math 202 Syllabus-Spring18 PDFDokument2 SeitenMath 202 Syllabus-Spring18 PDFvonacoc49Noch keine Bewertungen

- Communication Models in Internet of Things: A SurveyDokument5 SeitenCommunication Models in Internet of Things: A SurveyIJSTENoch keine Bewertungen

- Intel Stratix 10 Avalon - MM Interface For PCI Express Solutions User GuideDokument173 SeitenIntel Stratix 10 Avalon - MM Interface For PCI Express Solutions User Guideenoch richardNoch keine Bewertungen

- Texto CuritibaDokument1 SeiteTexto CuritibaMargarida GuimaraesNoch keine Bewertungen

- Generalized Anxiety DisorderDokument24 SeitenGeneralized Anxiety DisorderEula Angelica OcoNoch keine Bewertungen

- Uji Efektivitas Mikroba Rumpun BambuDokument7 SeitenUji Efektivitas Mikroba Rumpun BambuUse Real ProjectNoch keine Bewertungen

- Me8072 Renewable Sources of EnergyDokument13 SeitenMe8072 Renewable Sources of EnergyNallappan Rajj ANoch keine Bewertungen

- Understanding Bernoulli's Principle Through Simulations PDFDokument4 SeitenUnderstanding Bernoulli's Principle Through Simulations PDFIoannis GaroufalidisNoch keine Bewertungen

- Efficient Rice Based Cropping SystemDokument24 SeitenEfficient Rice Based Cropping Systemsenthilnathan100% (1)

- Industrial Internet of Things: Presented To-Presented byDokument18 SeitenIndustrial Internet of Things: Presented To-Presented byGaurav RaturiNoch keine Bewertungen

- Southwest Airlines Final ReportDokument16 SeitenSouthwest Airlines Final Reportapi-427311067Noch keine Bewertungen

- Arts6,4, Week2, Module 2V4Dokument24 SeitenArts6,4, Week2, Module 2V4Loreen Pearl MarlaNoch keine Bewertungen

- Approved Project 25 StandardsDokument5 SeitenApproved Project 25 StandardsepidavriosNoch keine Bewertungen

- Food Biotechnology in Ethical PerspectiveDokument340 SeitenFood Biotechnology in Ethical Perspectivemojtaba2500100% (2)

- Quarter 4 English As Grade 4Dokument28 SeitenQuarter 4 English As Grade 4rubyneil cabuangNoch keine Bewertungen