Beruflich Dokumente

Kultur Dokumente

Product Data: Beam Lintels Lengths

Hochgeladen von

Rakesh ParaliyaOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Product Data: Beam Lintels Lengths

Hochgeladen von

Rakesh ParaliyaCopyright:

Verfügbare Formate

Uniclass

L322

EPIC

F611

CI/SfB

(2-)

Ff5

2003

Product Data

PD9

Reinforced Beam and Trough Lintels

Lignacite Ltd produces two distinct types of lintel - the

conventional reinforced beam lintel and the trough lintel

block which is infilled with reinforced concrete. Each is

available in the standard colour range.

Description

Beam Lintels

Conventional reinforced beam lintels

are traditionally cast in a mould box

using the semi-dry method. The

concrete mixes used are Lignacite

(medium weight), Lignacrete or

Architectural Facing Masonry (dense

weight) types. Because of the

manufacturing method, shear

resistance limits maximum clear spans.

Trough Lintel Blocks

Trough lintel blocks (full or half

length) are cut from the same blocks

produced on the block-making

machine, enabling a close colour

match. The open core is filled with

reinforced concrete on site. Trough

lintels have increased performances

compared with beam lintels and

longer spans are possible.

Standards

Lintels do not conform to a defined

standard. Reinforcement conforms

to BS 4449 and tension bars are bent

to BS 4466. Trough lintel blocks

conform to BS 6073: 1981. Quality

is controlled at every stage, with

procedures assessed and certified

to BS EN ISO 9002 standards.

Lintel Range

Surface Texture and Colour

To match Lignacite, Lignacrete or

Architectural Facing Masonry blocks.

Refer to separate Data Sheets on

these products. Dummy perpends

can be incorporated into beam lintels.

Heights

215mm (standard) or 190mm

(metric modular).

Trough lintels may be designed

as a double height layer in order

to accommodate exceptional loads

or spans.

Lengths

Beam lintels

in any length within manufacturing

and performance limits - see table 2.

Trough lintels

440mm or 215mm (standard), or

390mm or 190mm (metric modular).

Widths

75mm to 215mm - see tables overleaf.

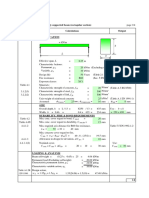

Structural Performance

Lintel design:

For use in masonry where no point

loads or openings occur within the

60 load triangle (Fig 2)

Application

The following alternative methods of

assessing the loads and checking the

suitability of lintels are suggested:

Method 1

Assess the total load (W) on

the lintel using the weights of

building Materials in BS 648.

Calculate the maximum Bending

Moment (BM) and Shear Force (SF)

for the different types of load

indicated on fig 1 and 2.

Uniformly Distributed Load

(UDL) - Fig 1

BM =

Checks: BM for UDL and

triangular load against

Safe Load table.

WL

8

SF =

W

2

Total load W

clear span + 180

Method 2

Obtain the equivalent UDL

from BS 5977: Part 1: 1981

and calculate the BM and SF

as Method 1.

Triangular Load - Fig 2

BM =

WL

6

SF =

W

2

load

triangle W

60

clear span + 180

L

High Street, Brandon, Suffolk IP27 0AX - Tel: 01842 810678 - Fax: 01842 814602 - E-mail: info@lignacite.co.uk - Website: www.li gnacite.co.uk

Meadgate Works, Nazeing, Waltham Abbey, Essex EN9 2PD - Tel: 01992 464441 - Fax: 01992 445713

33

Product Data

Reinforced Beam and Trough Lintels

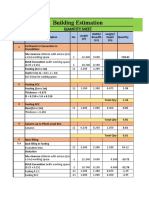

Reinforced Beam Lintels 215mm high

Resistances - Table 1

Unit Weights - Table 2

service values

Width

(mm)

Type

safe

Lengths (mm) 1115 1340 1565 1790 2015 2240 2465 2690

Clear Span (mm) 685 910 1135 1360 1585 1810 2035 2260

Resistance

moment

kNm

Shear

Resistance

kN

Maximum

UDL

kN

Width

(mm)

Type

Unit Weights

(kg)

75

Lignacite

1.52

0.92

1.84

75

Lignacite

30

36

42

48

54

60

75

Lignacrete

3.02

1.70

3.40

75

Lignacrete

40

48

56

64

72

80

90

Lignacite

1.52

0.92

1.84

90

Lignacite

36

43

50

58

65

72

90

Lignacrete

3.02

1.70

3.40

90

Lignacrete

48

57

67

77

86

95

100

Lignacite

2.19

1.83

3.66

100

Lignacite

40

48

56

64

72

80

100

Lignacrete

6.04

2.74

5.48

100 Lignacrete

53

64

75

86

96

107

140

Lignacite

3.08

2.75

5.50

140

56

68

79

91

102 114 125 137

140

Lignacrete

9.08

3.93

7.86

140 Lignacrete

74

89

104 119 134 149 164 179

150

Lignacite

3.27

2.75

5.50

150

59

72

84

150

Lignacrete

9.08

3.93

7.86

150 Lignacrete

79

95

111 127 143 159 175 191

77

93

109 124 140 155 171 187

Lignacite

Lignacite

190

Lignacite

4.16

3.66

7.32

190

190

Lignacrete

12.08

5.30

10.60

190 Lignacrete

Lignacite

200

Lignacite

4.37

3.66

7.32

200

200

Lignacrete

12.08

5.30

10.60

200 Lignacrete

Lignacite

215

Lignacite

4.70

4.14

8.28

215

215

Lignacrete

15.13

6.20

12.40

215 Lignacrete

Lignacite

96

108 120 132 145

101 121 141 162 182 202 223 243

81

98

115 131 147 164 180 197

106 129 151 173 194 216 237 259

87

106 124 142 159 177 195 213

115 139 163 186 209 232 256 279

R e i n f o r c e d S i n g l e Tr o u g h B l o c k L i n t e l s 2 1 5 m m h i g h

Performance Data - Table 3

Overall

Width

(mm)

Core

Height

Width

(mm)

Reinforcement

Bars*

Links

Maximum

clear span

(mm)

Shear

Resistance

(kN)

Ultimate moment capacities for Clear Spans (mm)

1810 2260

2710

3160

3610

4060

4510

(kN/m)

100

165

40

1x

T12

Single leg

R6 at

100mm c/s

2260

15

4.5

4.5

140

165

70

2x

T12

Two legs

R6 at

100mm c/s

4060

28

7.2

7.2

5.9

4.6

3.8

3.3

150

165

70

2x

T12

Two legs

R6 at

100mm c/s

4060

28

7.2

7.2

5.9

4.6

3.8

3.3

190

165

110

3x

T12

Two legs

R6 at

100mm c/s

4510

35

11.4

11.4

9.2

7.2

5.9

5.1

4.3

200

165

110

3x

T12

Two legs

R6 at

100mm c/s

4510

35

11.4

11.4

9.2

7.2

5.9

5.1

4.3

215

165

135

4x

T12

Two legs

R6 at

100mm c/s

4510

39

14.0

14.0

11.4

8.9

7.4

6.4

5.4

* Bars: Numbers of bars in top and bottom of lintel

Notes - Trough Lintels

1. Tabulated values for reinforced

cores to trough lintels have been

calculated to BS 8110: Part 1: 1985.

Maximum clear spans are based

on slenderness and/or deflection

limitations and are not to

be exceeded.

34

2. Allowable values do not include

self weight of lintel.

3. Applied moments and shear forces

to be calculated by applying factors

of 1.4 to Dead Load and 1.6 to

Imposed Load.

4. Cover to reinforcement to be

15mm. Bar ends to be bent to

BS 4466. Minimum end bearing

to be 215mm.

5. Concrete for reinforced in-situ

core to be minimum 35N/mm2

with 10mm maximum size

aggregate, thoroughly compacted.

Te l : 0 1 8 4 2 8 1 0 6 7 8 - W e b s i t e : w w w. l i g n a c i t e . c o . u k

Das könnte Ihnen auch gefallen

- Masonry Wall Design - 2Dokument3 SeitenMasonry Wall Design - 2Michael AbandeNoch keine Bewertungen

- Building EstimationDokument22 SeitenBuilding EstimationMelkamu AmusheNoch keine Bewertungen

- IESL Presentation by Ranjith12Dokument17 SeitenIESL Presentation by Ranjith12Surendra ElayathambyNoch keine Bewertungen

- Bison Hollow Core FloorsDokument16 SeitenBison Hollow Core FloorsJohn WoodsNoch keine Bewertungen

- Building Weather Cathedral Stadium Dwellings Rain Heat Sunlight Wind Conservatory VerandahDokument24 SeitenBuilding Weather Cathedral Stadium Dwellings Rain Heat Sunlight Wind Conservatory Verandahdudynayn100% (1)

- Reinforcement Detailing Guide for Concrete StructuresDokument4 SeitenReinforcement Detailing Guide for Concrete StructuresTina SanNoch keine Bewertungen

- Reinforcing Detailing of R.C.C Members - K.kaviTHADokument47 SeitenReinforcing Detailing of R.C.C Members - K.kaviTHAGurupriyaNoch keine Bewertungen

- Brick LintelsDokument17 SeitenBrick LintelsBharanidharan SelvanNoch keine Bewertungen

- Footing Design and AnalysisDokument5 SeitenFooting Design and AnalysisRichelle DandoNoch keine Bewertungen

- Sheer Wall PDFDokument142 SeitenSheer Wall PDFemrubel100% (1)

- Far Western University Civil Engineering CourseDokument5 SeitenFar Western University Civil Engineering Coursedinesh100% (1)

- Notes On Design of RCC ElementsDokument3 SeitenNotes On Design of RCC ElementsrangarajanNoch keine Bewertungen

- Design of Bracket for Supporting Waler BeamDokument4 SeitenDesign of Bracket for Supporting Waler BeamAhmed MohammedNoch keine Bewertungen

- Structural Analysis II Notes Rev1Dokument106 SeitenStructural Analysis II Notes Rev1Chris Jansen Van Rensburg100% (1)

- 16 Selection of Concrete Filled Steel Pipe Columns 23052014Dokument1 Seite16 Selection of Concrete Filled Steel Pipe Columns 23052014Ahmad Badsha QuadriNoch keine Bewertungen

- TC Debbie ReportDokument125 SeitenTC Debbie ReportphucNoch keine Bewertungen

- 425 Footing Design ExamplesDokument60 Seiten425 Footing Design ExamplesKakaNoch keine Bewertungen

- Beam to beam design with landingsDokument10 SeitenBeam to beam design with landingsUmesh ChamaraNoch keine Bewertungen

- MasterSeries Student Masonry Retaining EtcDokument21 SeitenMasterSeries Student Masonry Retaining EtcekaNoch keine Bewertungen

- Project MezzanineDokument2 SeitenProject Mezzaninepujan77Noch keine Bewertungen

- Sunita Limbu 15 Design ReportDokument19 SeitenSunita Limbu 15 Design ReportMishal LimbuNoch keine Bewertungen

- Steelwork Design Guide To BS 5950 Vol 1 Part B1 Dimensions & PropertiesDokument56 SeitenSteelwork Design Guide To BS 5950 Vol 1 Part B1 Dimensions & PropertiessubamanivelNoch keine Bewertungen

- Learn Flat Slab Software Step-by-Step GuideDokument128 SeitenLearn Flat Slab Software Step-by-Step GuideMohammad FawwazNoch keine Bewertungen

- Steel Plate Gate DesignDokument5 SeitenSteel Plate Gate DesignvsnsfbNoch keine Bewertungen

- Masonry Reinforcement and Windposts March 2015 V3Dokument14 SeitenMasonry Reinforcement and Windposts March 2015 V3witwatersrandNoch keine Bewertungen

- Structural Design Brief - Rev 0Dokument6 SeitenStructural Design Brief - Rev 0Umesh ChamaraNoch keine Bewertungen

- Learn Raft-RC Raft Foundation Analysis Design and Drawing SoftwareDokument108 SeitenLearn Raft-RC Raft Foundation Analysis Design and Drawing SoftwareRahul Kumar100% (2)

- Example 5.1-BeamDokument4 SeitenExample 5.1-BeamNur Alia NajwaNoch keine Bewertungen

- Base Plate Design Prokon PDFDokument8 SeitenBase Plate Design Prokon PDFmsiddiq1Noch keine Bewertungen

- RCCDokument16 SeitenRCCSyed Sirajul HaqNoch keine Bewertungen

- RCC Beams: Doubly Reinforced BeamDokument2 SeitenRCC Beams: Doubly Reinforced BeamSandeep ChavanNoch keine Bewertungen

- British Problem 5 PDFDokument5 SeitenBritish Problem 5 PDFelixnzNoch keine Bewertungen

- Estimating Deadloads On Timber CanopiesDokument1 SeiteEstimating Deadloads On Timber CanopiesConrad HarrisonNoch keine Bewertungen

- Reinforced Concrete Masonry Lintel Design ExampleDokument2 SeitenReinforced Concrete Masonry Lintel Design ExampleDilhan FernandoNoch keine Bewertungen

- HandBook of Structural SteelworkDokument57 SeitenHandBook of Structural SteelworkmakakamabamaNoch keine Bewertungen

- L&T TechnicalDokument5 SeitenL&T TechnicalvigneshwarimahamuniNoch keine Bewertungen

- Bondek I - Calculation Note - 1 Row of SupportDokument7 SeitenBondek I - Calculation Note - 1 Row of Supporttrung1983Noch keine Bewertungen

- Slab Design PDFDokument33 SeitenSlab Design PDF1NT14CV031 CivilNoch keine Bewertungen

- RC One Way Slab Design (ACI318-05)Dokument2 SeitenRC One Way Slab Design (ACI318-05)emoriderNoch keine Bewertungen

- Fig. 1: Types of Shear Wall, (A) Single Storey, (B) Multi-StoreyDokument3 SeitenFig. 1: Types of Shear Wall, (A) Single Storey, (B) Multi-StoreyAmer GonzalesNoch keine Bewertungen

- Example1 1-StraightsupportedDokument7 SeitenExample1 1-StraightsupportedOmar BayouNoch keine Bewertungen

- REPORTDokument49 SeitenREPORTSalin ShresthaNoch keine Bewertungen

- British Verification Problem 2Dokument7 SeitenBritish Verification Problem 2elixnzNoch keine Bewertungen

- DEEP BEAM DesignDokument2 SeitenDEEP BEAM DesignmangeshNoch keine Bewertungen

- Vertical Loads On Building Frames: Assumptions For The Analysis of Girders Using Approximate AnalysisDokument10 SeitenVertical Loads On Building Frames: Assumptions For The Analysis of Girders Using Approximate AnalysisNeven Ahmed HassanNoch keine Bewertungen

- Warehouse Design CalculationsDokument145 SeitenWarehouse Design CalculationsCHEA VANNAINoch keine Bewertungen

- Strip Footing Analysis & Design (BS8110)Dokument4 SeitenStrip Footing Analysis & Design (BS8110)shoebNoch keine Bewertungen

- UGWT DesignDokument2 SeitenUGWT DesignZain Saeed100% (1)

- Moment DistributionDokument153 SeitenMoment DistributionHerbert P. BacosaNoch keine Bewertungen

- Footing Design As Per BS 8110 PDFDokument1 SeiteFooting Design As Per BS 8110 PDFBobby A MathewNoch keine Bewertungen

- Openwell StaircaseDokument8 SeitenOpenwell StaircaseAbdul AzeemNoch keine Bewertungen

- Eurocode 6 Vertical Resistance 8-7-10Dokument8 SeitenEurocode 6 Vertical Resistance 8-7-10Rodrigo Sánchez Ferreira100% (1)

- Jenkins McCarthy Baweja FinalDokument7 SeitenJenkins McCarthy Baweja FinalPhú Trịnh ĐìnhNoch keine Bewertungen

- IS EN 1992 (Eurocode 2) Design of Concrete StructuresDokument64 SeitenIS EN 1992 (Eurocode 2) Design of Concrete Structuressanku_cidNoch keine Bewertungen

- Analysis of The One-Way Slab For Design Ultimate Loads Using The Software SAP-2000. VR 19.1.1Dokument19 SeitenAnalysis of The One-Way Slab For Design Ultimate Loads Using The Software SAP-2000. VR 19.1.1Alejandra AguilarNoch keine Bewertungen

- Tests on column bases validate Eurocode 3 compression modelDokument8 SeitenTests on column bases validate Eurocode 3 compression modelJose SilvaNoch keine Bewertungen

- CR 13045 PIER R00 Calculation ReportDokument11 SeitenCR 13045 PIER R00 Calculation Reportmusiomi2005Noch keine Bewertungen

- Reinforced Concrete Buildings: Behavior and DesignVon EverandReinforced Concrete Buildings: Behavior and DesignBewertung: 5 von 5 Sternen5/5 (1)

- ContractDokument11 SeitenContractMichellene TadleNoch keine Bewertungen

- Pricelist 2017Dokument133 SeitenPricelist 2017Ramkumar GunaNoch keine Bewertungen

- Sample Construction Contract SummaryDokument7 SeitenSample Construction Contract SummaryJer FortzNoch keine Bewertungen

- Anchored Sheet Pile Walls in Sandy Soil CalculatorDokument1 SeiteAnchored Sheet Pile Walls in Sandy Soil CalculatorAnin Kuwi UpinNoch keine Bewertungen

- Marble & Stones IndustriesDokument12 SeitenMarble & Stones IndustriesRakesh Paraliya100% (1)

- NitDokument4 SeitenNitRakesh ParaliyaNoch keine Bewertungen

- Class 9 - Road Infrastructure Development in India PDFDokument102 SeitenClass 9 - Road Infrastructure Development in India PDFRakesh Paraliya100% (1)

- Corrigendum updates tender dates and clarifies truck requirementsDokument11 SeitenCorrigendum updates tender dates and clarifies truck requirementsRakesh ParaliyaNoch keine Bewertungen

- Beam DetailsDokument1 SeiteBeam DetailsRakesh ParaliyaNoch keine Bewertungen

- Omex ModelDokument1 SeiteOmex ModelRakesh ParaliyaNoch keine Bewertungen

- C SSTSNJ Z2 TM Ibi 29Dokument4 SeitenC SSTSNJ Z2 TM Ibi 29Rakesh ParaliyaNoch keine Bewertungen

- Guidelines for Voluntary Surrender of AP RegistrationDokument4 SeitenGuidelines for Voluntary Surrender of AP RegistrationRakesh ParaliyaNoch keine Bewertungen

- Hostel Construction Project Bill of QuantitiesDokument9 SeitenHostel Construction Project Bill of QuantitiesRakesh ParaliyaNoch keine Bewertungen

- Rent Agreement Hindi PDFDokument4 SeitenRent Agreement Hindi PDFRakesh ParaliyaNoch keine Bewertungen

- Tenants Verification Form (Hindi) )Dokument1 SeiteTenants Verification Form (Hindi) )gajen_yadavNoch keine Bewertungen

- Alwer Railway TenderDokument82 SeitenAlwer Railway TenderRakesh ParaliyaNoch keine Bewertungen

- Chapter 09 BRICKDokument6 SeitenChapter 09 BRICKPawan Kumar SapraNoch keine Bewertungen

- Makalah Penelitian Tentang LingkunganDokument1 SeiteMakalah Penelitian Tentang LingkunganDedi IrhandiNoch keine Bewertungen

- Rewari Railway TenderDokument84 SeitenRewari Railway TenderRakesh ParaliyaNoch keine Bewertungen

- Buildings SoR 2014-15Dokument295 SeitenBuildings SoR 2014-15Madhu SayariNoch keine Bewertungen

- Analysis and Design of A Multi-Storey Reinforced ConcreteDokument61 SeitenAnalysis and Design of A Multi-Storey Reinforced Concretenour94% (18)

- 36 Bamboo - A - Material - For - Cost - EffDokument24 Seiten36 Bamboo - A - Material - For - Cost - EffSyahrilAbankArchNoch keine Bewertungen

- 15 Sec 1500 (Formwork)Dokument6 Seiten15 Sec 1500 (Formwork)Rakesh ParaliyaNoch keine Bewertungen

- 29.sec.2900 (Pipe Culverts)Dokument4 Seiten29.sec.2900 (Pipe Culverts)Rakesh ParaliyaNoch keine Bewertungen

- Connecticut's Deep Water Port Strategy StudyDokument198 SeitenConnecticut's Deep Water Port Strategy StudyPatricia DillonNoch keine Bewertungen

- Contractors HandbookDokument43 SeitenContractors HandbookVincent Mutambirwa100% (1)

- 11.sec.1100 (Pile Foundations)Dokument18 Seiten11.sec.1100 (Pile Foundations)Rakesh ParaliyaNoch keine Bewertungen

- Measuring and Estimating BrickworkDokument2 SeitenMeasuring and Estimating BrickworkRakesh Paraliya100% (1)

- Evaluation of Port Layout Alternatives: Pilbara Iron Ore and Infrastructure ProjectDokument41 SeitenEvaluation of Port Layout Alternatives: Pilbara Iron Ore and Infrastructure ProjectRakesh ParaliyaNoch keine Bewertungen

- Umri Road Work Done-1Dokument162 SeitenUmri Road Work Done-1DPRE PIU ADILABADNoch keine Bewertungen

- BtechhDokument7 SeitenBtechhcorbitecoNoch keine Bewertungen

- Basic Technical EnglishDokument8 SeitenBasic Technical EnglishAndreea AshuricaNoch keine Bewertungen

- Strength and Ductility of Reinforced Concrete Moment Frame Connections Strengthened With Quasi-Isotropic LaminatesDokument6 SeitenStrength and Ductility of Reinforced Concrete Moment Frame Connections Strengthened With Quasi-Isotropic LaminatesBadr AmmarNoch keine Bewertungen

- UnderpinningDokument32 SeitenUnderpinningkuruba saran rajNoch keine Bewertungen

- Strengthening of Bridge Beams and Similar Structures byDokument4 SeitenStrengthening of Bridge Beams and Similar Structures byArun KumarNoch keine Bewertungen

- Ci 31 Detallado Del Acero de Refuerzo PDFDokument6 SeitenCi 31 Detallado Del Acero de Refuerzo PDFflucayNoch keine Bewertungen

- Molds For Forming Concrete Test Cylinders VerticallyDokument5 SeitenMolds For Forming Concrete Test Cylinders VerticallyAquinoNoch keine Bewertungen

- Reinforced Cement Concrete - RCC - Ace Academy - GATE Material - Free Download PDF - CivilEnggForAll PDFDokument56 SeitenReinforced Cement Concrete - RCC - Ace Academy - GATE Material - Free Download PDF - CivilEnggForAll PDFprofamarNoch keine Bewertungen

- Manage Construction Costing System of ProjectsDokument53 SeitenManage Construction Costing System of ProjectsYihun abrahamNoch keine Bewertungen

- CD 358 Waterproofing and Surfacing of Concrete Bridge Decks-WebDokument63 SeitenCD 358 Waterproofing and Surfacing of Concrete Bridge Decks-WebJorge Baños LloredoNoch keine Bewertungen

- Guard House Bill of QuantitiesDokument2 SeitenGuard House Bill of QuantitiesMariya Mariya100% (2)

- Dricon Brochure July 2017 WebDokument17 SeitenDricon Brochure July 2017 WebAndrew PiNoch keine Bewertungen

- Concrete Trial Mix Calculations of Grade M-25 RCC: National Highway Authority of India (Nhai)Dokument13 SeitenConcrete Trial Mix Calculations of Grade M-25 RCC: National Highway Authority of India (Nhai)Ashok amlapureNoch keine Bewertungen

- Pradhan Manrti Gram Sadak Yojana (Pmgsy-Iii LSB Batch - I 2020-21) Chhattisgarh Rural Road Development Agency, Balod Bill of QuantityDokument6 SeitenPradhan Manrti Gram Sadak Yojana (Pmgsy-Iii LSB Batch - I 2020-21) Chhattisgarh Rural Road Development Agency, Balod Bill of QuantityLucky TraderNoch keine Bewertungen

- Design CaculationsDokument14 SeitenDesign Caculationsmkpasha55mpNoch keine Bewertungen

- Jurnal Markus Tanpa NamaDokument8 SeitenJurnal Markus Tanpa NamaMarkus Koko Nur BudiantoNoch keine Bewertungen

- Rawlplug XPT Throughbolt Technical DatasheetDokument7 SeitenRawlplug XPT Throughbolt Technical DatasheetAh MedNoch keine Bewertungen

- Neopor Documentation October 2011 English Version 12102011Dokument7 SeitenNeopor Documentation October 2011 English Version 12102011Santosh PayghanNoch keine Bewertungen

- 650 - Standard Sand For Testing CementDokument7 Seiten650 - Standard Sand For Testing CementDebabrata PalNoch keine Bewertungen

- SOR Volume 2 BuildingDokument266 SeitenSOR Volume 2 Buildingpankajsamiksha0% (1)

- Lab 2Dokument8 SeitenLab 2Flonja ShytiNoch keine Bewertungen

- Reinforced Concrete Building Seismic AssessmentDokument37 SeitenReinforced Concrete Building Seismic AssessmentRandolph BorgNoch keine Bewertungen

- Mrs Unit 6 STR Audit and BudgetDokument33 SeitenMrs Unit 6 STR Audit and BudgetSwati PatilNoch keine Bewertungen

- Task WorkDokument2 SeitenTask WorkSanta StraNoch keine Bewertungen

- Sika Ferrogard - 903+: Corrosion Inhibiting Impregnation (Improved Formulation)Dokument5 SeitenSika Ferrogard - 903+: Corrosion Inhibiting Impregnation (Improved Formulation)KpChuaNoch keine Bewertungen

- Self Healing 4Dokument9 SeitenSelf Healing 4Toni ArangelovskiNoch keine Bewertungen

- GRP 1 Building Tech.Dokument59 SeitenGRP 1 Building Tech.Kevin EdwinNoch keine Bewertungen

- U W Civil Utility Tunnels and Trenches: Facilities Service S Design GuideDokument9 SeitenU W Civil Utility Tunnels and Trenches: Facilities Service S Design GuideRamces AsisiNoch keine Bewertungen

- 5.1B Cost Annalysis SinkingFund MethodDokument2 Seiten5.1B Cost Annalysis SinkingFund MethodDiana RebeccaNoch keine Bewertungen