Beruflich Dokumente

Kultur Dokumente

2010 MMEP Res Hydraulics

Hochgeladen von

lalinda0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

38 Ansichten5 SeitenHydraulic Question and nswers

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenHydraulic Question and nswers

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

38 Ansichten5 Seiten2010 MMEP Res Hydraulics

Hochgeladen von

lalindaHydraulic Question and nswers

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 5

Martins Marine Engineering Page www.dieselduck.

net

Marine Engineering Exam Resource Review of Hydraulics

1. What is Pascals law?

Pressure confined on a confined fluid will transmit the pressure in all directions and act with

equal force on all areas at right angles.

2. How does the law pertain to hydraulics?

In an enclosed hydraulic system pressure can be transmitted through hydraulic pipes and hoses.

3. What is Bernoullis principal?

When over the velocity (speed) of a liquid is increase at any point the pressure will decrease at

that point.

4. What types of flow can be present in a hydraulic system?

Laminar flow (strait). Turbulent (around bends)

5. What is the formula for force?

Force = pressure x area, f = p x a, p = f / a, a = f / p,

system 2000 lb. Piston area 20

Lb./sq. In. Output force equals 2000 x 20 = a force of 40000 lbs.

6. What types of pumps are used in hydraulic systems?

Positive displacement. (An amount of fluid has to move each stroke.)

7. How are most hydraulic pumps rated?

Gallons per minute.

8. What types of gears can be used in a gear pump and why?

Herringbone, - quiet and no thrust. Spur, - economical. Helical, - smooth flow.

9. What is a vane pump?

Positive displacement pump which uses vanes to push the liquid around the housing to the

outlet.

10. What is a balanced vane?

Has two inlet ports and two outlet ports. Reduces the side loading on the rotor.

11. Which type of pump would you find a half moon shaped part?

an internal gear pump. (Crescent pump)

12. What is meant by the term variable displacement pump?

The output from the pump can be varied (flow rate) by changing the area of the pumping

chamber.

13. What is meant by the term pressure compensated?

As pressure is increased to maximize the output flow rate will automatically decrease. (Pressure

regulator)

14. Which pumps produce the highest pressures in a hydraulic system?

Axial - pistons are parallel with axis. Piston pumps up to 10,000 psi.

Source : Paul V.

May 2010

Page 1 of 5

Martins Marine Engineering Page www.dieselduck.net

Marine Engineering Exam Resource Review of Hydraulics

15. What is the difference between an axial and a radial piston pump?

Axial - is parallel to shaft (pistons working)

Radial - piston working 90 degrees to shaft axis.

16. How can the displacement of piston pumps be changed?

By lengthening or shortening piston stroke.

17. What is the rating system used on hydraulic filtering?

Microns. 1 micron = 1 millionth of a meter or = .000039 of an inch. Filters are usually 5

microns.

18. What are the three main families of valves used in hydraulic systems?

Pressure control, counter balance relief.

Directional control, controls cylinder movement

Flow control, controls speed of operation.

19. What type of valve do we use to control the pressure in a system?

Pressure control valve. Pressure relief valve.

20. What is the purpose of a vent in the reservoir?

No pressure in tank is built up just atmospheric pressure. Regardless of fluid level.

21. Where in the system does the valve in question 19 go?

After the pump and before any other component in the system. (System safety valve) even

before filter.

22. What is the pressure reducing valve and what is it used for?

Reduces pressure like a relief valve but to a different direction to a secondary circuit at a lower

setting than the relief valve.

23. What is an unloading valve and where is it used?

A valve used top unload a low-pressure pump when the h.p. pump is the only one required in

the system.

24. What is a sequence valve and where is it used?

Controls the operation of two cylinders when one has to operate before the other. Ie clamp and

drill operation..

25. What is a counterbalance valve and where is it used? What is a break valve?

Pressure control valve that maintains backpressure to prevent a load from falling.

26. How does a flow control valve work?

(Needle valve) by changing the area through which the flow passes. Used to control the speed

on a cylinder or motor.

Source : Paul V.

May 2010

Page 2 of 5

Martins Marine Engineering Page www.dieselduck.net

Marine Engineering Exam Resource Review of Hydraulics

27. What is another name for a flow control valve?

Volume control valve.

28. What is a check valve?

A valve that allows flow only one way.

29. What type of valve normally controls cylinder movement?

Directional control valve. Page 252

30. What is the different center ports available?

Closed

float

Open

tandem

page 253- 255

31. A three position, four-way d.c.v. is connected to a cylinder with a pressure gauge on the b port.

When the cylinder extends, pressure is applied to the A port. The gauge shows and increase in

pressure but the cylinder does not move, what is wrong?

B port is blocked. The directional control valve is blocked.

32. What is the most common type of cylinder used in hydraulics? What is another name for it?

Double action cylinder or a linear activator. Page 294

33. What type of controls are used to activate directional control valves?

Solenoid (electrical impulse)

Pilot pressure

Mechanical (lever) page 303

34. What type of component is used to store hydraulic energy?

Accumulator pre-charged to half the working pressure. Page 298

35. What type of gas is used?

Nitrogen. Page 301

36. How is pipe measured?

Inside dimensions

37. How is tubing measured?

Outside diameter

38. When hydraulic pressure is used to shift a valve, the valve is said to be?

Pivot activated.

39. The outside diameter of tubing with a dash number of 8/16 would be?

8/16 or inch outside diameter.

40. The inside of a hydraulic hose with a dash number of 8/16 would be?

8/16 or inch inside diameter.

Source : Paul V.

May 2010

Page 3 of 5

Martins Marine Engineering Page www.dieselduck.net

Marine Engineering Exam Resource Review of Hydraulics

41. The pipe with the heaviest wall thickness is?

Double extra heavy strength.

42. At a given pressure setting the force exerted by a hydraulic cylinder depends on?

Affect over piston flow

43. Fluid under pressure passing through a restricted passage shows?

Lower pressure or a pressure drop. Bernolles principal.

44. The difference between cracking pressure and full flow pressure is called?

Cracking when a valve first starts to open. Full flow, valve full open. Pressure override, the

difference between the two.

45. When velocity of a fluid is increased, pressure does what?

Drops. Bernolles principal.

46. Where is a pressure line located?

After the system relief valve. Before any other components on pressure side. Page 272

47. Where would you place a vacuum gauge on a hydraulic pump?

On the suction side of pump.

48. If you install a new gear pump on a system and it did not deliver oil, what would be the mostly

likely problem?

Direction of rotation. Lack of oil. Plugged in tank. Air leak in suction.

49. What is the most important consideration when installing a pump above the surface of the oil

to be pumped.?

The distance between the oil and pump level. As short as possible. Less bends and Corners as

possible.

50. When pressure testing a cylinder under no load conditions, an increase in pressure indicates?

Internal bending in cylinder piston.

51. If you found a hydraulic pump with a restricted suction line, what problems could occur if it is

not repaired?

Damage do to cavitation or (vapor or air bubbles)

52. How is the working pressure usually increased in a hydraulic system?

Changing the settings on the relief valve.

53. If you replaced the sleeve or cam ring in a vane pump, what else should you replace?

You should replace the vanes.

Source : Paul V.

May 2010

Page 4 of 5

Martins Marine Engineering Page www.dieselduck.net

Marine Engineering Exam Resource Review of Hydraulics

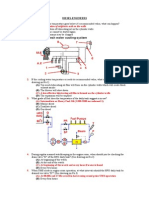

54. What is the graphical symbol for the following:

A. Relief valve

B. Sequence valve

C. Counterbalance valve

D. Unloading valve

E. Four way valve two position

F. Three way valve tandem centre

G. Double acting cylinder

H. Accumulator

I.

Variable displacement, pressure compensated pump, pump variable motor variable

J.

Filter reservoir vented pressurized pages 311 - 312

Source : Paul V.

May 2010

Page 5 of 5

Das könnte Ihnen auch gefallen

- AhpDokument7 SeitenAhpsuresh2kbNoch keine Bewertungen

- Me55 - Applied Hydraulics & Pneumatics PDFDokument12 SeitenMe55 - Applied Hydraulics & Pneumatics PDFPandiya RajanNoch keine Bewertungen

- ME 1305 - Applied Hydraulics and PneumaticsDokument7 SeitenME 1305 - Applied Hydraulics and PneumaticsUva ShruthikaNoch keine Bewertungen

- Unit 3Dokument6 SeitenUnit 3hariharanbookNoch keine Bewertungen

- FM Lab VivaDokument20 SeitenFM Lab VivaXanely D'souza50% (2)

- Links To This Post First Year QP Mechanical QB Mechnical: Posted by N R Rejin Paul LabelsDokument8 SeitenLinks To This Post First Year QP Mechanical QB Mechnical: Posted by N R Rejin Paul LabelsSuresh KumarNoch keine Bewertungen

- automative control system.Dokument9 Seitenautomative control system.appujalal326Noch keine Bewertungen

- Applied Hydraulics and Pneumatics ME1305Dokument8 SeitenApplied Hydraulics and Pneumatics ME1305kv19852009Noch keine Bewertungen

- Unit - I: Two Mark Questions & AnswersDokument8 SeitenUnit - I: Two Mark Questions & Answerssmg26thmayNoch keine Bewertungen

- Hydraulic Drive System - WikipediaDokument20 SeitenHydraulic Drive System - WikipediaLAliNoch keine Bewertungen

- (Oto-Hui - Com) Doosan Hydraulic BasicDokument76 Seiten(Oto-Hui - Com) Doosan Hydraulic Basiceng_ebrahim_2000100% (2)

- Unit 2Dokument6 SeitenUnit 2hariharanbookNoch keine Bewertungen

- (123doc) Thuy Luc Tren May BayDokument50 Seiten(123doc) Thuy Luc Tren May Bayty3919883665Noch keine Bewertungen

- AircraftSystems Lesson-4-5Dokument7 SeitenAircraftSystems Lesson-4-5Yves CaraangNoch keine Bewertungen

- Applied Hydralics and Pneumatics 2 MarksDokument10 SeitenApplied Hydralics and Pneumatics 2 MarksVignesh VickyNoch keine Bewertungen

- Define Cavitation Phenomena in PumpDokument8 SeitenDefine Cavitation Phenomena in PumpB Mahendar ReddyNoch keine Bewertungen

- Mod 2Dokument27 SeitenMod 2Ameen SalimNoch keine Bewertungen

- Centrifugal PumpsDokument30 SeitenCentrifugal PumpsNitish NairNoch keine Bewertungen

- Steam Turbine QuestionsDokument56 SeitenSteam Turbine QuestionsNivas Ssv50% (2)

- Manual Cm-760 - 780 InglesDokument121 SeitenManual Cm-760 - 780 InglesULISCHAP100% (1)

- Detailed Notes - All Valves - Pumps - Design CirciutsDokument63 SeitenDetailed Notes - All Valves - Pumps - Design CirciutsJimmy KariukiNoch keine Bewertungen

- Basic HydraulicsDokument22 SeitenBasic HydraulicsGorge SoroNoch keine Bewertungen

- Hydraulic & Pneumatic Two Mark QuestionsDokument7 SeitenHydraulic & Pneumatic Two Mark QuestionsVVCET - MechNoch keine Bewertungen

- Basic Civil and Mechanical Engineering Unit III Pumps and TurbinesDokument10 SeitenBasic Civil and Mechanical Engineering Unit III Pumps and TurbinesA.R. Pradeep Kumar100% (1)

- Hydraulics by MakinoDokument112 SeitenHydraulics by Makinopreetish123456100% (1)

- Robotics Unit2 SlidesDokument104 SeitenRobotics Unit2 SlidesJanarthanan BalakrishnasamyNoch keine Bewertungen

- Hydraulic PumpsDokument6 SeitenHydraulic PumpsSriram SastryNoch keine Bewertungen

- Hydraulic Drive SystemDokument21 SeitenHydraulic Drive SystemAnkit SrivastavaNoch keine Bewertungen

- Hydraulic MachineryDokument13 SeitenHydraulic MachineryCarlito PantalunanNoch keine Bewertungen

- Hydraulic System Hydraulics: An Area of Engineering Science That Deals With andDokument19 SeitenHydraulic System Hydraulics: An Area of Engineering Science That Deals With andArun Kumar JhaNoch keine Bewertungen

- Training On Industrial HydraulicsDokument72 SeitenTraining On Industrial HydraulicsTO HaioceankNoch keine Bewertungen

- Study of A Centrifugal Pump, Pipe Fittings and Valves - Ch.E 206Dokument30 SeitenStudy of A Centrifugal Pump, Pipe Fittings and Valves - Ch.E 206Synthia100% (1)

- Hydraulic System:-: Chapter-2 Hydraulic, Pneumatic and Electrical Telemetry SystemsDokument7 SeitenHydraulic System:-: Chapter-2 Hydraulic, Pneumatic and Electrical Telemetry SystemsMayur ParmarNoch keine Bewertungen

- Hydraulic pumps explainedDokument22 SeitenHydraulic pumps explainedSiraj BusseNoch keine Bewertungen

- Basic Hydraulics GuideDokument20 SeitenBasic Hydraulics GuideTEPU MSOSA100% (4)

- Applied Hydraulics and Pneumatics 2 Mark QuestionsDokument5 SeitenApplied Hydraulics and Pneumatics 2 Mark QuestionsChandni DayakarNoch keine Bewertungen

- Pump BasicsDokument96 SeitenPump BasicsDhanasekaran SivasamyNoch keine Bewertungen

- ME/ECE 4710 Motion and Control Lab #2: Hydraulic Cylinder CircuitsDokument4 SeitenME/ECE 4710 Motion and Control Lab #2: Hydraulic Cylinder CircuitsVishal PipavatNoch keine Bewertungen

- Hydraulic drive system basicsDokument6 SeitenHydraulic drive system basicsyamnul khairNoch keine Bewertungen

- Hydraulic TrainingDokument32 SeitenHydraulic TrainingbadralislamNoch keine Bewertungen

- Hydraulic and Pneumatic Question PaperDokument24 SeitenHydraulic and Pneumatic Question PaperAbdihamid bin-mohamoudNoch keine Bewertungen

- Sheet 3Dokument6 SeitenSheet 3alexandra owNoch keine Bewertungen

- Mechatronics - Unit-Iii (Iv B.Tech I Sem Mech) : (Hydraulic Systems)Dokument36 SeitenMechatronics - Unit-Iii (Iv B.Tech I Sem Mech) : (Hydraulic Systems)Radha KrishnaNoch keine Bewertungen

- Ivan-Mac Ivan MagbatocDokument16 SeitenIvan-Mac Ivan MagbatocJayjay MonterdeNoch keine Bewertungen

- CFDDokument3 SeitenCFDhazratNoch keine Bewertungen

- Hyd Micro ProjectDokument20 SeitenHyd Micro ProjectOmkar Moze CE - J1 - 88Noch keine Bewertungen

- Reciprocating Pump With Air VesselDokument19 SeitenReciprocating Pump With Air VesselKrunal Patil93% (15)

- Class 4 Hydraulic PumpsDokument75 SeitenClass 4 Hydraulic PumpsSoheilDarvishMotavalliNoch keine Bewertungen

- Hydraulic Machinery: Force and Torque MultiplicationDokument10 SeitenHydraulic Machinery: Force and Torque MultiplicationNezar Amin Ali ElfadilNoch keine Bewertungen

- Introduction To FPSDokument32 SeitenIntroduction To FPStmohanrajkecNoch keine Bewertungen

- Hydraulic Components and SystemsDokument31 SeitenHydraulic Components and SystemsPrasad ChamarajanagarNoch keine Bewertungen

- Hydraulic Powerpack DesignDokument18 SeitenHydraulic Powerpack DesignChandrahas ReddyNoch keine Bewertungen

- AHP NotesDokument26 SeitenAHP NotesDr.R.Pugazhenthi Associate Prof.Noch keine Bewertungen

- HydraulicDokument12 SeitenHydraulicNitu Sharma100% (1)

- Schedule and topicsDokument61 SeitenSchedule and topicsRonal MaharajNoch keine Bewertungen

- Hydraulic SystemDokument28 SeitenHydraulic SystemSamiha Maysoon Nooria0% (1)

- Prevention of Actuator Emissions in the Oil and Gas IndustryVon EverandPrevention of Actuator Emissions in the Oil and Gas IndustryNoch keine Bewertungen

- How to Select the Right Centrifugal Pump: A Brief Survey of Centrifugal Pump Selection Best PracticesVon EverandHow to Select the Right Centrifugal Pump: A Brief Survey of Centrifugal Pump Selection Best PracticesBewertung: 5 von 5 Sternen5/5 (1)

- Hydraulics and Pneumatics: A Technician's and Engineer's GuideVon EverandHydraulics and Pneumatics: A Technician's and Engineer's GuideBewertung: 4 von 5 Sternen4/5 (8)

- Diesel EngineersDokument18 SeitenDiesel EngineerslalindaNoch keine Bewertungen

- Electricity For EngineersDokument15 SeitenElectricity For Engineerslalinda100% (3)

- British MallardDokument42 SeitenBritish MallardlalindaNoch keine Bewertungen

- AutomationDokument57 SeitenAutomationlalinda100% (4)

- Corrosion - February 2010Dokument15 SeitenCorrosion - February 2010lalindaNoch keine Bewertungen

- Cu Carry Over To BoilerDokument8 SeitenCu Carry Over To BoilerlalindaNoch keine Bewertungen

- Introduction To Fuels and Lubricants - Feb 2010Dokument14 SeitenIntroduction To Fuels and Lubricants - Feb 2010lalindaNoch keine Bewertungen

- Water Testing-January 2010Dokument19 SeitenWater Testing-January 2010lalindaNoch keine Bewertungen

- Alpha Lubricator System OperationDokument190 SeitenAlpha Lubricator System Operationlalinda67% (3)

- Meo Class IV Orals Ques Bank - Mumbai MMDDokument66 SeitenMeo Class IV Orals Ques Bank - Mumbai MMDlalindaNoch keine Bewertungen

- Solas For TankerDokument25 SeitenSolas For TankerlalindaNoch keine Bewertungen

- Solas For TankerDokument25 SeitenSolas For TankerlalindaNoch keine Bewertungen

- AVRDokument3 SeitenAVRlalindaNoch keine Bewertungen

- EMERGENCY POWERDokument8 SeitenEMERGENCY POWERlalinda100% (1)

- Air CompressorsDokument7 SeitenAir Compressorsherobpo13373Noch keine Bewertungen

- Air Coolers: Air Cooler Grid Type Water SeparatorDokument1 SeiteAir Coolers: Air Cooler Grid Type Water Separatorherobpo13373Noch keine Bewertungen

- AR-5061/AR-5061u ADSL2+ Ethernet Router User Manual: Version A1.0, March 18, 2009Dokument86 SeitenAR-5061/AR-5061u ADSL2+ Ethernet Router User Manual: Version A1.0, March 18, 2009lalindaNoch keine Bewertungen

- Air Starting SystemsDokument9 SeitenAir Starting SystemslalindaNoch keine Bewertungen

- Electrical Work ShopDokument5 SeitenElectrical Work ShoplalindaNoch keine Bewertungen

- Construction Training ReportDokument3 SeitenConstruction Training ReportlalindaNoch keine Bewertungen

- 07 Fitting ShopDokument9 Seiten07 Fitting ShoplalindaNoch keine Bewertungen

- Lecture 8 of Tropical MeteorologyDokument22 SeitenLecture 8 of Tropical MeteorologyMelvin BadonNoch keine Bewertungen

- PHY369 Thermodynamics Solutions to Homework Set #1Dokument10 SeitenPHY369 Thermodynamics Solutions to Homework Set #1alyxs_1Noch keine Bewertungen

- Solution Manual Gas Dynamics 3rd Edition James Ea John Theo GDokument10 SeitenSolution Manual Gas Dynamics 3rd Edition James Ea John Theo Gsuthur27Noch keine Bewertungen

- For Combined Gas LawDokument44 SeitenFor Combined Gas LawApril Bartolome Flores100% (1)

- IS 13920 - 1993vs2016Dokument14 SeitenIS 13920 - 1993vs2016RonakShahNoch keine Bewertungen

- Dynamics of Bubbles, Drops and Rigid Particles (1999) Springer - Z. Zapryanov, S. TabakovaDokument526 SeitenDynamics of Bubbles, Drops and Rigid Particles (1999) Springer - Z. Zapryanov, S. TabakovaHarold Valle ReyesNoch keine Bewertungen

- Hydraulic Design of BPT-1Dokument11 SeitenHydraulic Design of BPT-1rajkumarpritimaniNoch keine Bewertungen

- Haftom ReddaDokument96 SeitenHaftom ReddaThaung Myint OoNoch keine Bewertungen

- Specific heat values of foods and materialsDokument1 SeiteSpecific heat values of foods and materialslucasNoch keine Bewertungen

- Phase Diagram Heating and Cooling CurvesDokument30 SeitenPhase Diagram Heating and Cooling CurvesAnirudhNoch keine Bewertungen

- Reinforced Concrete Wall Design Report: Material and Design DataDokument4 SeitenReinforced Concrete Wall Design Report: Material and Design DataazwanNoch keine Bewertungen

- Psychrometric Chart - Us and Si UnitsDokument1 SeitePsychrometric Chart - Us and Si UnitsRaden_Rici_Abi_1914Noch keine Bewertungen

- Proposal Title: Design and Analysis of A Simply Supported Beam For A Steel Structure Under Uniformly Distributed LoadDokument9 SeitenProposal Title: Design and Analysis of A Simply Supported Beam For A Steel Structure Under Uniformly Distributed LoadAmeer saidNoch keine Bewertungen

- A Realizable Reynolds Stress Algebric Equation Model - ShihDokument38 SeitenA Realizable Reynolds Stress Algebric Equation Model - ShihDanielRobertoFerreiraNoch keine Bewertungen

- Stress Transformtion ProblemsDokument33 SeitenStress Transformtion ProblemsG Sri SoumyaNoch keine Bewertungen

- Kutateladze NumberDokument20 SeitenKutateladze NumberDiego1980bNoch keine Bewertungen

- UAS Jan 2022 - Analisa Struktur 1 - ISTNDokument2 SeitenUAS Jan 2022 - Analisa Struktur 1 - ISTNSyh TfkNoch keine Bewertungen

- Backward Calculation For Bearing Capacity Estimation of Geogrid Reinforced Foundation by Finite Element MethodDokument13 SeitenBackward Calculation For Bearing Capacity Estimation of Geogrid Reinforced Foundation by Finite Element MethodFoolad GharbNoch keine Bewertungen

- KULIAH3 EC3 UNRESTRAINED BEAM-kl PDFDokument66 SeitenKULIAH3 EC3 UNRESTRAINED BEAM-kl PDFZazliana Izatti100% (1)

- Expansion & Contraction Demo Expansion Tube: DisclaimerDokument3 SeitenExpansion & Contraction Demo Expansion Tube: DisclaimerMrsriyansyahNoch keine Bewertungen

- Sterling Sihi GMBH: Product Identification Folder PT Sihi MSLDokument3 SeitenSterling Sihi GMBH: Product Identification Folder PT Sihi MSLRini Yuni SaraNoch keine Bewertungen

- Shallow Foundation Design Guide in 40 CharactersDokument27 SeitenShallow Foundation Design Guide in 40 CharactersMoses HonNoch keine Bewertungen

- Worksheet: - Earthquake P-Wave & S-Wave Travel Time Chart TutorialDokument31 SeitenWorksheet: - Earthquake P-Wave & S-Wave Travel Time Chart TutorialJoanna Nicole MercadoNoch keine Bewertungen

- Soil Exploration and Foundation SettlementDokument4 SeitenSoil Exploration and Foundation SettlementSuryakant MangajNoch keine Bewertungen

- Bms SystemDokument13 SeitenBms SystemgaineyskNoch keine Bewertungen

- Finite Element Method Terminology and ConceptsDokument11 SeitenFinite Element Method Terminology and ConceptsSudhakar UppalapatiNoch keine Bewertungen

- CE 302 - Conc - Lecture 1 - Wk1 PDFDokument18 SeitenCE 302 - Conc - Lecture 1 - Wk1 PDFIsraelNoch keine Bewertungen

- Geoconsult India Pvt Ltd designs tunnel segment lining for Ahmedabad Metro projectDokument36 SeitenGeoconsult India Pvt Ltd designs tunnel segment lining for Ahmedabad Metro projectStructural Spreadsheets0% (1)

- Non-Linear Analysis of Composite Beams by A Displacement ApproachDokument12 SeitenNon-Linear Analysis of Composite Beams by A Displacement ApproachCharles WongNoch keine Bewertungen

- Fluid Mechanics Advanced Lab Proposal - EnglishDokument6 SeitenFluid Mechanics Advanced Lab Proposal - EnglishtanveeruzzamanqureshiNoch keine Bewertungen