Beruflich Dokumente

Kultur Dokumente

SZ7231-SZ7233 - Rev B

Hochgeladen von

Ruxandra AdrianaCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

SZ7231-SZ7233 - Rev B

Hochgeladen von

Ruxandra AdrianaCopyright:

Verfügbare Formate

UNI EN ISO 9001:2000

CERT. N. 9115 BCEL

INSTRUCTION MANUAL

SZ 7231 - SZ 7233

FLOW CELL

Option

REP N

SZ 7231

SZ 7233

Cod. 28019723 - Rev. B - 10/05

B&C Electronics Srl - Via per Villanova 3 - 20040 Carnate (Mi) - Italy - P.IVA 00729030965

Tel +39 039 63 1721 - Fax +39 039 607 6099 bc@bc-electronics.it - www.bc-electronics.it

B&C Electronics

SZ 7231 SZ 7233

Index

1

DESCRIPTION............................................................................................................................. 3

SPECIFICATIONS....................................................................................................................... 4

2.1

SZ 7231 Specifications ........................................................................................................ 4

2.2

SZ 7233 Specifications ........................................................................................................ 4

INSTALLATION ......................................................................................................................... 5

OPERATION ................................................................................................................................ 5

MAINTENANCE ......................................................................................................................... 6

Instruction Manual - Rev. B - 10/05

-2-

B&C Electronics

SZ 7231 SZ 7233

1 DESCRIPTION

This flow cell series is designed for the use with potentiostatic residual chlorine monitors.

The chlorine electrode is inserted in the cell position 9 .

The RTD Pt100 is inserted in position 10 .

The constant head flow cell controls the liquid speed over a wide variation of the feeding flow.

The cells are provided with a screw 4 suitable for the flow adjustment.

The package includes 2 m of 4 x 6 mm pipe for the cell connection to the water being measured.

The water inlet is through the fitting 3 .

The water outlet is through the fitting 5 on the bottom of the cell.

The cell SZ 7233 is designed for the insertion in the position 8 of the pH and ORP electrodes.

Electrodes must be inserted in the position suggested in this manual in order to have a correct

operation.

Instruction Manual - Rev. B - 10/05

-3-

B&C Electronics

SZ 7231 SZ 7233

2 SPECIFICATIONS

2.1 SZ 7231 SPECIFICATIONS

Body

Inlet

Overflow outlet

Dimensions

Fittings

Connection pipe

Water Flow

Temperature

Sensors

RTD sensor

transparent epoxy

1/4" fitting

10 x 14 mm diameter pipe

150 x 90 x 40 mm

1/4" for 4 x 6 mm pipe

2 m 4 x 6 mm (included)

approx. 10/30 l/hour

0/50 C

12 mm diameter

5 mm diameter

2.2 SZ 7233 SPECIFICATIONS

Body

Inlet

Overflow outlet

Dimensions

Fittings

Connection pipe

Water Flow

Temperature

Sensors

RTD sensor

Instruction Manual - Rev. B - 10/05

transparent epoxy

1/4" fitting

10 x 14 mm diameter pipe

150 x 120 x 40 mm

1/4" for 4 x 6 mm pipe

2 m 4 x 6 mm (included)

approx. 10/30 l/hour

0/50 C

12 mm diameter

5 mm diameter

-4-

B&C Electronics

SZ 7231 SZ 7233

3 INSTALLATION

The flow cell must be installed in vertical position close to the measuring instrument.

The flow assembly is wall mounted using the bolt holes 7 .

The overflow pipe connected to 5 must discharge in air, without any counter pressure (example into a

1" pipe).

4 OPERATION

-

Insert the chlorine electrode in position 9 .

Insert the RTD (if available) in position 10 .

Connect the measuring electrode (and RTD) to the instrument following the specific

connections instruction.

Adjust the screw 4 in order to have the over flow even in the minimum inlet water pressure

condition.

When the inlet flow adjustment is critical, install a supplementary tap on the feeding pipe.

Instruction Manual - Rev. B - 10/05

-5-

B&C Electronics

SZ 7231 SZ 7233

5 MAINTENANCE

The Chlorine electrode requires periodic maintenance.

When the platinum bands become fouled the sensitivity of the measuring decrease and it is necessary

to clean the platinum electrodes, pressing and rotating by hand a filter paper or similar.

Sensor maintenance should be performed every 4 weeks depending upon the severity of the sample

stream conditions.

Dirty applications will require more frequent maintenance, while high purity water applications will

require less frequent maintenance.

When some deposits or biological fouling are into the cell and internal holes, unscrew and remove the

cell cleaning screw 6 and the OR, clean the holes and reassembly the screw and the OR.

Instruction Manual - Rev. B - 10/05

-6-

B&C Electronics

SZ 7231 SZ 7233

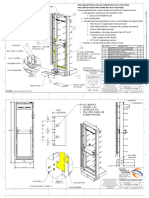

SZ 7231 CONNECTIONS

1.

2.

3.

4.

5.

6.

7.

9.

10.

Body

Drilled cover

Inlet

Flow control

Outlet

Cell cleaning screw

Fixing holes

Chlorine electrode

RTD sensor

Fig. 1

Instruction Manual - Rev. B - 10/05

-7-

B&C Electronics

SZ 7231 SZ 7233

SZ 7233 CONNECTIONS

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

Body

Drilled cover

Inlet

Flow control

Outlet

Cell cleaning screw

Fixing holes

pH / ORP electrode

Chlorine electrode

RTD sensor

Fig. 2

Instruction Manual - Rev. B - 10/05

-8-

B&C Electronics

SZ 7231 SZ 7233

NOTES

Instruction Manual - Rev. B - 10/05

-9-

Das könnte Ihnen auch gefallen

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5795)

- GrundfosliteratureDokument24 SeitenGrundfosliteratureRuxandra Adriana100% (1)

- SZ283 & SZ7231 Celula Si Senzor Cl2Dokument1 SeiteSZ283 & SZ7231 Celula Si Senzor Cl2Ruxandra AdrianaNoch keine Bewertungen

- Grundfosliterature 1665176Dokument24 SeitenGrundfosliterature 1665176Ruxandra AdrianaNoch keine Bewertungen

- Declaration of Conformity: Paradox SR120Dokument1 SeiteDeclaration of Conformity: Paradox SR120Ruxandra AdrianaNoch keine Bewertungen

- User'S ManualDokument4 SeitenUser'S ManualRuxandra AdrianaNoch keine Bewertungen

- Water Treatment Handbook - Ondeo Degremont IIDokument1.571 SeitenWater Treatment Handbook - Ondeo Degremont IIfaustino1@gmail91% (35)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Lec-7 Bus Switching Schemes Double Main & Transfer (DMT) One and Half CB Schemes in EnglishDokument6 SeitenLec-7 Bus Switching Schemes Double Main & Transfer (DMT) One and Half CB Schemes in EnglishTamjidNoch keine Bewertungen

- US2574551 (Electronic Tachometer)Dokument7 SeitenUS2574551 (Electronic Tachometer)Aaron Choco De GuzmanNoch keine Bewertungen

- TA35-40 G7 Steering AnimationDokument1 SeiteTA35-40 G7 Steering AnimationWalid AouiniNoch keine Bewertungen

- Accessories For 8 Oc's For TalkalDokument5 SeitenAccessories For 8 Oc's For Talkalhanu sunilNoch keine Bewertungen

- HMHIL-HWJ Brochure FinalDokument2 SeitenHMHIL-HWJ Brochure FinalKangkan Kishore DasNoch keine Bewertungen

- MediawebserverDokument52 SeitenMediawebserveralgubNoch keine Bewertungen

- Med-Linket Special OfferDokument45 SeitenMed-Linket Special OfferLogistica AquinoNoch keine Bewertungen

- CCT-10 Hub ControllerDokument12 SeitenCCT-10 Hub ControllerTamo NekoNoch keine Bewertungen

- HVAC Monthly Schedule - 2013Dokument6 SeitenHVAC Monthly Schedule - 2013MuhammadIqbalMughalNoch keine Bewertungen

- Single Motor Double Door MechanismDokument34 SeitenSingle Motor Double Door MechanismKanagarajan100% (1)

- CG Power and Industrial Solutions Limited: LT Motors Division AhmednagarDokument1 SeiteCG Power and Industrial Solutions Limited: LT Motors Division AhmednagarMohan BabuNoch keine Bewertungen

- PS1000 Maintenance GuideDokument42 SeitenPS1000 Maintenance GuideMumba KangwaNoch keine Bewertungen

- GL PRO Rid en 113Dokument27 SeitenGL PRO Rid en 113Radenko Skoro25% (4)

- Choke Valvess AOPDokument8 SeitenChoke Valvess AOPclaudio godinezNoch keine Bewertungen

- Cran Hybrid Rack Neq.17862 Fif-Pts3701-Xxxx-Rj-Tc1Dokument3 SeitenCran Hybrid Rack Neq.17862 Fif-Pts3701-Xxxx-Rj-Tc1Vince AceyNoch keine Bewertungen

- FRD Furukawa FDG40 Selector Grab Parts ListDokument18 SeitenFRD Furukawa FDG40 Selector Grab Parts ListDuncan ReedNoch keine Bewertungen

- ENGO 431 Lab 1 ReportDokument9 SeitenENGO 431 Lab 1 ReportwhatisthiswhyNoch keine Bewertungen

- Photovoltaic Plant Design: Presentation By, Jay Joshi (17MSE005)Dokument35 SeitenPhotovoltaic Plant Design: Presentation By, Jay Joshi (17MSE005)sagar paneliyaNoch keine Bewertungen

- AT2 ERT Installation GuideDokument3 SeitenAT2 ERT Installation GuideYordan Silva GomezNoch keine Bewertungen

- 97380-Wind Maker Elevation Motorized Treadmill ManualDokument20 Seiten97380-Wind Maker Elevation Motorized Treadmill ManualMuhannad InNoch keine Bewertungen

- PEB and PESB Series Valves: Durable Valves. Patented TechnologyDokument1 SeitePEB and PESB Series Valves: Durable Valves. Patented TechnologyUnited Construction Est. TechnicalNoch keine Bewertungen

- Fault Tracing: Checking The Starter Switch DiodeDokument1 SeiteFault Tracing: Checking The Starter Switch Diodeuser1Noch keine Bewertungen

- Voltmeters and Ammeters PDFDokument5 SeitenVoltmeters and Ammeters PDFYhonni IrwanNoch keine Bewertungen

- Vivace Brochure PDFDokument6 SeitenVivace Brochure PDFdediranduNoch keine Bewertungen

- DAILY SSS SURVEILLANCE April 17-18.totalDokument120 SeitenDAILY SSS SURVEILLANCE April 17-18.totalAldrich Ajang HenryNoch keine Bewertungen

- Test PanelsDokument20 SeitenTest PanelsumeshNoch keine Bewertungen

- High Mast CatalogueDokument16 SeitenHigh Mast CatalogueAliz BnNoch keine Bewertungen

- All Models PSU SVC BulletinDokument52 SeitenAll Models PSU SVC BulletinJim FordNoch keine Bewertungen

- GAC - Application Note Cummins PT Fuel Systems PIB1006Dokument12 SeitenGAC - Application Note Cummins PT Fuel Systems PIB1006gilizaniniNoch keine Bewertungen

- Kraftform Plus - Series 100 VDEDokument3 SeitenKraftform Plus - Series 100 VDEВладимир МалићNoch keine Bewertungen