Beruflich Dokumente

Kultur Dokumente

17.00 P Rajendran & KP Vasudevan, Chemtrols Group

Hochgeladen von

Mohd AliCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

17.00 P Rajendran & KP Vasudevan, Chemtrols Group

Hochgeladen von

Mohd AliCopyright:

Verfügbare Formate

14/03/2011

7th March 2011

Cemtech Dubai - 2011

Presentation by Chemtrols Group of Companies

Updations in Gas Cooling Technology

Continuous Emission Monitoring Systems

UPDATIONS IN GAS COOLING GAS CONDITIONING

IN THE TOP CYCLONES

Worldwide References

Principle of Operation

Case Studies

UPDATIONS IN GAS COOLING HYBRID GAS

CONDITIONING SYSTEMS

Worldwide References

Principle of Operation

14/03/2011

Lets remember the application areas

Drilling

Rig

Raw Mix

Component

Bins

Gas cooling

in GCT

Chimney

Quarry

Gas cooling

in Top Cyclone

Gas

Conditioning in

Downcomer

Duct

Limestone

bin

Seperator

Crusher

Clinker

silos

Pre-Blending

dome

Water

Injection to

Cement Mill

GCT

Gas Cooling Tower

Raw Mill

Cement Mill

Seperator

Homogenizing

silos

Pre-Heating Tower and

Pre-Calciner

Cement

silos

Kiln

Coal Storage

Cement

Dispatch

Coal Mill

application

areas

Clinker Cooler Bed

Gas cooling

in Cooler Bed

REFERENCES FOR GAS

COOLING IN TOP CYCLONES

WORLDWIDE REFERENCES

ALCEMENT KUWAIT

BUZZIUNICEM BARLETTA PLANT ITALY

QUINN CEMENT, IRELAND

REFERENCES IN INDIA

1.

VIKRAM CEMENT, KHOR 3 SYSTEMS

2.

ITALCHEMENTI, VISHNU CEMENT UNIT

3.

ULTRATECH CEMENT, AWARPUR CEMENT WORKS - 4 SYSTEMS

4.

ULTRATECH CEMENT, ADITYA CEMENT WORKS

5.

ULTRATECH CEMENT, NARMADA CEMENT WORKS

6.

MADRAS CEMENT, ALATHIYUR CEMENT WORKS 2 SYSTEMS

7.

MADRAS CEMENT, ARIYALUR CEMENT WORKS 2 SYSTEMS

8.

SANGHI CEMENT, SANGHIPURAM

9.

CHETTINAD CEMENT, PULIYUR CEMENT WORKS

10. CHETTINAD CEMENT, KARIKKALI CEMENT WORKS

11. J.K.LAKSHMI CEMENT , UNIT 1

12. SANGHI CEMENT, SANGHIPURAM 2 SYSTEMS (UNDER

MANUFACTURE)

14/03/2011

GAS COOLING IN THE TOP CYCLONES PRINCIPLE

14/03/2011

GAS COOLING IN THE TOP CYCLONES PRINCIPLE

In the Cyclone Water Spray

System cooling water is

injected close to the dip tube

against the gas flow in an

absolute fine mist form to cool

down the hot gas.

While the high pressure

water mist spray enables to

condition & cool the hot gas,

it also agglomerates & forces

the dust downwards back in

to the system, thus improving

the collection ratio &

efficiency.

The cooled gas leaving the Cyclone occupies less volume, enabling substantial

power savings for the PH fan.

LANCE LOCATIONS GAS COOLING IN THE

TOP CYCLONES

14/03/2011

THE MAJOR COMPONENTS OF GAS

COOLING SYSTEM IN THE TOP CYCLONES

PUMP STATION : pumps are VFD controlled. ENERGY SAVING

Use of vertical pumps where ever possible again Power Savings

THE MAJOR COMPONENTS GAS COOLING

IN THE TOP CYCLONES

LANCES & SPRAY NOZZLES : HIGH PERFORMACE HIGH PRESSURE LANCES, NO

COMPRESSED AIR IS NEEDED TO MAKE ULTRA FINE SPRAY. ENERGY SAVING

14/03/2011

Calculations for

GAS COOLING IN THE TOP CYCLONES

CHEMTROLS USES THEIR OWN SOFTWARE FOR

HEAT TRANSFER CALCULATIONS IN GAS COOLING

Calculations for

GAS COOLING IN THE TOP CYCLONES

CHEMTROLS USES THEIR OWN SOFTWARE FOR

HEAT TRANSFER CALCULATIONS IN GAS COOLING

14/03/2011

THE CONTROLS OF GAS COOLING IN THE TOP

CYCLONES

The overall control of whole system is conducted by PLC incorporating upto-date technological advances where microprocessors enable

incomparable control of the system, user friendly operation, reability, close

loop control and managing almost all components automatically.

4 CASE STUDIES & APPLIED

INSTALLATIONS

CASE STUDY 1

J.K.LAKSMI CEMENT

CASE STUDY 2

KUWAIT CEMENT

CASE STUDY 3

CHETTINAD CEMENT

CASE STUDY 4

SANGHI CEMENT

14/03/2011

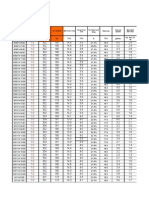

CASE STUDY 1 : J. K. LAKSMI CEMENT

WITHOUT WATER SPRAY

CASE STUDY 1 : J. K. LAKSMI CEMENT

WITH WATER SPRAY

14/03/2011

CASE STUDY 1 : J. K. LAKSMI CEMENT

BEFORE

COOLING SYSTEM

INSTALLATION

AFTER

COOLING

SYSTEM

INSTALLATION

REMARKS

167,3 t/h

199,58 t/h

19,3% capacity

increase

Cylone Exit Temp

(C)

322C

214C

108C

temperature drop

O Content

6,94%

5,21%

ID Fan (rpm)

786,85

686,43

Less 12,7%

ID Fan (KW)

918,24

711,87

Less by 206 KW

Hybrid Bag DP

mmWC

199,36

180,94

Less DP

PARAMETERS

Kiln Feed

CASE STUDY 2 : KUWAIT CEMENT

WITHOUT GAS

COOLING SYSTEM

14/03/2011

CASE STUDY 2 : KUWAIT CEMENT

WITH GAS COOLING

SYSTEM

CASE STUDY 2 : KUWAIT CEMENT

WITHOUT GAS

COOLING SYSTEM

10

14/03/2011

CASE STUDY 2 : KUWAIT CEMENT

WITH GAS COOLING

SYSTEM

CASE STUDY 2 : KUWAIT CEMENT

BEFORE

GAS COOLING

SYSTEM

INSTALLATION

AFTER

GAS COOLING

SYSTEM

INSTALLATION

405 t/h

437 t/h

327 C / 345 C

274 C/271 C

3.8% / 3.6%

3.8% / 3.9%

99% open

20% open

ID Fan (rpm)

982

961

ID Fan (KW)

1321

1326

Bag filter discharge

Screw conveyor

Load

15A

14A

PARAMETERS

Kiln Feed

Cylone Exit Temp

(C)

O Content

Dilution Damper pos.

REMARKS

8% capacity

increase

53 / 74 C

Improved

collection in

the Cyclone

11

14/03/2011

CASE STUDY 3 : CHETTINAD CEMENT

GENERAL PROCESS

LAYOUT

CASE STUDY 3 : CHETTINAD CEMENT

THESE FIGURES HAS BEEN REPORTED IN THEIR WEBSITE

NO

BEFORE

AFTER

GAS COOLING

SYSTEM

INSTALLATION

GAS COOLING

SYSTEM

INSTALLATION

Preheater Temp.

(C)

342

290

Preheater Fan

(KW)

995

965

30 KW savings

Bag House Fan

(KW)

650

450

200 KW

savings

Reverse Air Fan

3 hrs savings

164

102,5

61.5 KW

savings

30

30 KW

additional

power

PARAMETERS

REMARKS

52C

Temperature drop

(Running Hrs)

Reverse Air Fan

(KW)

Pumps Power

Consp (KW)

12

14/03/2011

CASE STUDY 4 SANGHI CEMENT

ILC STRING

FRESH AIR

RM

Bag-filter

SLC STRING

Junction

BH Fan 1,288,000

m3/hr@2600C

CM-1

C2 STRING

CM-2

CASE STUDY 4 SANGHI CEMENT

1

Raw Mill Bag house

Design capacity

1,280,000 provided by

Dilution air

SIL

PRESENT

CONDITION

Calculated water flow rate for cooling

in m3/hr

Resultant temperature due to mixing of gas

streams 123 & 4 = 1234

Resultant volume of gas Nm3/hr - 1234

Resultant volume of gas Am3/hr - 1234

Gas drawn for one Coal Mill

1,010,967

Volume of gas at Bag.House inlet with 1 Coal mill running

1,754,130

Volume of gas at Bag.House inlet with 2 Coal mills running

1,574,130

Moisture addition %

0.00

Total water requred

m3/hr

Temperature drop

considered

Case-1: Plant operation at 9500 TPD without water spray - RM Stopped

Heat Balance Calculation

249

1,934,130

180,000

Note: The junction duct gets pressurised even after operation of both coal mill as baghouse gas

handling capacity is 1,288,000 m3/hr @ 2600C and available gas at inlet is 1,574,000 m3/hr @

2500C

13

14/03/2011

CASE STUDY 4 SANGHI CEMENT

Heat Balance Calculation

Raw Mill Bag house

Design capacity 1,280,000 provided by

Dilution air

SIL

Present Fan

Operating flow rate

Calculated water flow rate for cooling

in m 3/hr

Resultant temperature due to mixing of gas streams 123 & 4 =

1234

248

Resultant volume of gas Nm3/hr - 1234

933,731

Resultant volume of gas Am3/hr - 1234

1,782,818

Gas drawn for one Coal Mill

180,000

Volume of gas at Bag.House inlet with 1 Coal mill running

1,602,818

Volume of gas at Bag.House inlet with 2 Coal mills running

1,422,818

Moisture addition %

1.07

Total water requred

m3/hr

Temperature drop

considered

Case-2: Plant operation at 9500 TPD with water spray in ILC top stage cyclone (present

operating condition)- RM Stopped

Note: The junction duct gets pressurised even after operation of both coal mill as baghouse gas handling

capacity is 1,288,000 m3/hr @ 2600C and available gas at inlet is 1,422,818 m3/hr @ 2500C

CASE STUDY 4 SANGHI CEMENT

Heat Balance Calculation

Dilution

air

Calculated water flow rate for cooling in m3/hr

Resultant temperature due to mixing of gas streams

123 & 4 = 1234

Resultant volume of gas Nm3/hr - 1234

Resultant volume of gas Am3/hr - 1234

Gas drawn for one Coal Mill

Volume of gas at Bag.House inlet with 1 Coal mill running

Volume of gas at Bag.House inlet with 2 Coal mills running

Moisture addition %

12

13

Raw Mill Bag

house Design

capacity

1,280,000

provided by SIL

Present Fan

Operating

conditions

Total water

requred m3/hr

Temperature drop

considered

Case-3: Plant operation at 9500 TPD with water spray in ILC, SLC & C2 string top cyclone - RM

Stopped

32

251

683,870

1,312,258

180,000

1,132,258

952,258

5.74

Note: The junction duct will not get pressurised after installation of the water spray system in SLC

& C2 string and operation of both coal mills.

14

14/03/2011

CASE STUDY 4 SANGHI CEMENT

Heat Balance Calculation

Raw Mill Bag house fan

Design capacity 1,280,000 m3/hr @

Dilution air

2600C

Maximum Operaring

conditions

Calculated water flow rate for cooling in m 3/hr

Resultant temperature due to mixing of gas streams 123 & 4 =

1234

Resultant volume of gas Nm3/hr - 1234

Resultant volume of gas Am3/hr - 1234

Gas drawn for one Coal Mill

802,138

1,506,384

180,000

Volume of gas at Bag.House inlet with 1 Coal mill running

1,326,384

Volume of gas at Bag.House inlet with 2 Coal mills running

1,146,384

Moisture addition %

2.98

Total water requred

m3/hr

Temperature drop

considered

Case-5: Plant operation at 10,500 TPD with water spray in ILC, SLC & C-2 (Maximum

Operating capacity)- RM Stopped

19

240

Note: The junction duct will not get pressurised by operating both coal mills as baghouse gas handling capacity

is 1,288,000 m3/hr @ 2600C and available gas at inlet is 1,146,385 m3/hr @ 2400C

SUMMARY GAS COOLING IN TOP CYCLONE

ENERGY SAVING IN ID FAN= YES

ENERGY SAVING IN THE FOLLOWING FANS IN DOWNSTREAM

PROCESS = YES

PRODUCTION INCREASE = YES

REDUCTION IN THE RECYCLING RATIO IN THE LINE = YES

INCREASED CYCLONE RETENTION EFFICIENCY = YES

THE ONLY MANUFACTURER IN THE

WORLDCALCULATIONS, ENGINEERING, DESIGN,

MANUFACTURING, AUTOMATION,

INSTALLATION & COMMSSIONING

15

14/03/2011

HYBRID GAS COOLING SYSTEMS

CALCULATIONS, ENGINEERING,

DESIGN, MANUFACTURING, AUTOMATION,

INSTALLATION & COMMSSIONING

GAS CONDITIONING IN GCT

HIGH PRESSURE

PRINCIPLE I

SPILLBACK SYSTEM

Single fluid

water ~38 bars

SPILLBACK LANCES

No atomising air

PRINCIPLE-II

New generation

HYBRID SYSTEM

Single fluid

water ~38 bar

SPILLBACK LANCES +

HIGH PRESSURE

LANCES

No atomising air

DUAL FLUID

PRINCIPLE

DOUBLE FLUID SYSTEM

Double fluid

water + air mixture

~5-7 bar

AIRMIST LANCES

Atomising air required

Full automation

HYBRID SYSTEMS LOWEST ENERGY

CONSUMPTION

REFERENCES

HYBRID GAS COOLING

SYSTEMS

WORLDWIDE REFERENCES

SET BALIKESIR, ISTANBUL

DENZILI CEMENT, ISTANBUL 2 SYSTEMS

1.

2.

3.

4.

5.

REFERENCES IN INDIA

ITALCEMENTI, ZUARI CEMENT , YERUGUNTALA

MAIHAR CEMENT, SARALANAGAR 2 SYSTEMS

ORIENT CEMENT , DEVAPUR WORKS 3 SYSTEMS

ULTRATECH CEMENT, HIRMI CEMENT WORKS 2 SYSTEMS

KANORIA CEMENT, BAGALKOT CEMENT WORKS

16

14/03/2011

HYBRID GAS COOLING SYSTEM

This is a combination of Spillback & High Pressure lances in the tower

replacing the conventional Single nozzle or cluster lances.

These can be fitted in the same protection pipe of the Chemtrols High

performance single nozzle lance.

50% to 70% lances will be high pressure fixed volume spray No returnflow control The lances are with 5 nozzles.

Balance lances are spillback with return-flow control -These lances are

cluster with 3 nozzles.

This combination allows better atomization and performance of the

system.

The flow control of water will be from 50% to 100% of the total water

injection rate. During the stable plant operation this variation is sufficient

for control.

If higher rangability is required, the high pressure lances can be arranged

in 2 or 3 stages with ON/OFF valves for each stage.

HIGH PERFORMANCE LANCES

In-built

non-return

valve

return

line

zero leakage tongue

& groove connection

protection

pipe

FILTER ELEMENT

feed line

butterfly bolts

Integral MINIBASKET FILTER

1.

2.

3.

The most important component in the gas conditioning system is the New generation high

performance lances, which has an inbuilt filter and an NRV as integral part of the lance.

These are user friendly, light and robust for the application.

The inbuilt filter ensures non-clogging feature to the nozzle & increases the nozzle life doublefold.

17

14/03/2011

HIGH PERFORMANCE LANCES

HIGH PERFORMANCE RETURN-FLOW

LANCES

18

14/03/2011

COOLING LANCES HIGH PRESSURE - UCC

HIGH PRESSURE

LANCE SPRAY

19

14/03/2011

CLUSTER LANCE

SPRAY

HYBRID SYSTEM

20

14/03/2011

HYBRID GAS COOLING TOWER OUTSIDE VIEW

OTHER ACTIVITIES OF CHEMTROLS

Dust Suppression Systems, Plain water &

Dryfog for Raw material Preparation section

DeNOx Systems for Cement plants by

CHEMTROLS-ERC a Joint venture with ERC

Germany.

CEMS Continuous Emission Monitoring

Systems for Cement Plants by Chemtrols

Industries Ltd.

21

14/03/2011

Continuous Emission Monitoring Systems

List of Process Applications in Cement Plants

22

14/03/2011

Operation condition at various measurement points

CEMS Typical layout

Analyzer

Cabinet with

air conditioning

23

14/03/2011

CEMS Typical layout

Gas Analysis KILN Stack

Due to various types of

Alternate Fuels, the

following Gases are

generated and are to be

measured.

SO2

NOx

NH3

HCl

Hydrocarbons

24

14/03/2011

THANK YOU & WELCOME YOUR

QUESTIONS

25

Das könnte Ihnen auch gefallen

- Nox TestDokument10 SeitenNox TestMohd AliNoch keine Bewertungen

- 1.9 Global Env - ConcernsDokument6 Seiten1.9 Global Env - ConcernsDharsan SathyaNoch keine Bewertungen

- House Value 8,000,000 Initial Payment 20% Loan Value 6,400,000 Launch Project Initial Amount 1,600,000 Monthly 133,333Dokument1 SeiteHouse Value 8,000,000 Initial Payment 20% Loan Value 6,400,000 Launch Project Initial Amount 1,600,000 Monthly 133,333Mohd AliNoch keine Bewertungen

- HOT AIR VOLUME ESTIMATION BASED ON OXYGEN LEVELSDokument4 SeitenHOT AIR VOLUME ESTIMATION BASED ON OXYGEN LEVELSMohd AliNoch keine Bewertungen

- 12.00 Thomas Marx, ABBDokument16 Seiten12.00 Thomas Marx, ABBMohd AliNoch keine Bewertungen

- 09.30 Cemengal Tanger BK6 FDDokument18 Seiten09.30 Cemengal Tanger BK6 FDMohd AliNoch keine Bewertungen

- KünneDokument28 SeitenKünneMohd AliNoch keine Bewertungen

- Writing Energy Audit ReportsDokument4 SeitenWriting Energy Audit ReportsWin JoseNoch keine Bewertungen

- Raw Mill Nozzle Ring Area AnalysisDokument6 SeitenRaw Mill Nozzle Ring Area AnalysisMohd Ali100% (7)

- 11.00 Ahmed Hussein, Cairo Financial HoldingDokument18 Seiten11.00 Ahmed Hussein, Cairo Financial HoldingMohd AliNoch keine Bewertungen

- Notes On Cemtech 2011 Dubai PresentationsDokument8 SeitenNotes On Cemtech 2011 Dubai PresentationsMohd AliNoch keine Bewertungen

- Cemtech Dubai Dry Bulk Freight Market & Cement Trading Trends OutlookDokument7 SeitenCemtech Dubai Dry Bulk Freight Market & Cement Trading Trends OutlookMohd AliNoch keine Bewertungen

- 15.00 Paolo Bossi, MD, Sinai White CementDokument38 Seiten15.00 Paolo Bossi, MD, Sinai White CementMohd AliNoch keine Bewertungen

- 16.00 Luc Rudowski, PolysiusDokument14 Seiten16.00 Luc Rudowski, PolysiusMohd AliNoch keine Bewertungen

- 09.30 Hettish Karmani, Global Investment HouseDokument10 Seiten09.30 Hettish Karmani, Global Investment HouseMohd AliNoch keine Bewertungen

- 11.30 DR Stefan Seemann, KHD Humboldt Wedag GMBHDokument15 Seiten11.30 DR Stefan Seemann, KHD Humboldt Wedag GMBHMohd AliNoch keine Bewertungen

- 16.30 Ferdinand Pecson, NLSupervisionDokument9 Seiten16.30 Ferdinand Pecson, NLSupervisionMohd AliNoch keine Bewertungen

- 12.00 Thomas Marx, ABBDokument16 Seiten12.00 Thomas Marx, ABBMohd AliNoch keine Bewertungen

- 11.30 Michel Folliet, International Finance CorporationDokument11 Seiten11.30 Michel Folliet, International Finance CorporationMohd AliNoch keine Bewertungen

- 10.00 Heinrich Höse, Aumund Fördertechnik GMBHDokument25 Seiten10.00 Heinrich Höse, Aumund Fördertechnik GMBHMohd Ali100% (1)

- 17.00 Loïc Pottier, Fives FCBDokument11 Seiten17.00 Loïc Pottier, Fives FCBMohd AliNoch keine Bewertungen

- 10.00 Ankur Agarwal, Nomura International PLCDokument11 Seiten10.00 Ankur Agarwal, Nomura International PLCMohd AliNoch keine Bewertungen

- Process Control FundamentalsDokument73 SeitenProcess Control Fundamentalsshashank715100% (1)

- Engineering Terms and DefinationsDokument79 SeitenEngineering Terms and DefinationsROHAN DESAINoch keine Bewertungen

- Stand-alone Grinding Plants Results from IndiaDokument16 SeitenStand-alone Grinding Plants Results from IndiaMohd Ali100% (1)

- High Efficiency Dynamic ClassifierDokument21 SeitenHigh Efficiency Dynamic ClassifierchandantuNoch keine Bewertungen

- Energy Efficient Motor SystemsDokument28 SeitenEnergy Efficient Motor SystemsMohd AliNoch keine Bewertungen

- Thermal Energy Efficiency in Cement IndustryDokument105 SeitenThermal Energy Efficiency in Cement IndustryHoang Nguyen100% (6)

- Cement EmissionsDokument41 SeitenCement EmissionsMohd Ali100% (1)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5782)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (72)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- LA City Plan Check List for Plumbing/Mechanical PlansDokument12 SeitenLA City Plan Check List for Plumbing/Mechanical PlanshusanwongNoch keine Bewertungen

- VAV BrochureDokument28 SeitenVAV BrochureMuralidharan SudhakarNoch keine Bewertungen

- Diagraph PA6000Dokument34 SeitenDiagraph PA6000walakadah100% (1)

- Outdoor Unit SpecificationsDokument322 SeitenOutdoor Unit Specificationsgstathisg100% (1)

- 600M.W.Plant C&I CourseDokument91 Seiten600M.W.Plant C&I Courseknx175Noch keine Bewertungen

- Air Conditioner Service Manual (PHA-AG0701011A2Dokument17 SeitenAir Conditioner Service Manual (PHA-AG0701011A2Nikolai_Dimitr_7781Noch keine Bewertungen

- Alarko Fcu İngDokument16 SeitenAlarko Fcu İngcalavera83Noch keine Bewertungen

- Senthil ResumeDokument4 SeitenSenthil ResumesatheeshNoch keine Bewertungen

- Briefing Paper - IceDokument62 SeitenBriefing Paper - IcePanagiotis RappasNoch keine Bewertungen

- Air Systems R 01Dokument120 SeitenAir Systems R 01Rasta MastaNoch keine Bewertungen

- As 1359 106 IEC 34 6 Rotating Machines Method of CoolingDokument22 SeitenAs 1359 106 IEC 34 6 Rotating Machines Method of CoolingIvan GarciaNoch keine Bewertungen

- Complete Guide to Home Ventilation SystemsDokument15 SeitenComplete Guide to Home Ventilation SystemsfuzzyroNoch keine Bewertungen

- Catalogo de Reductores de VelocidadDokument74 SeitenCatalogo de Reductores de VelocidadAnonymous Nyv3dRNoch keine Bewertungen

- Daikin - RXYQ-PBTJ VRVIII 208-230 Heat Pump PDFDokument64 SeitenDaikin - RXYQ-PBTJ VRVIII 208-230 Heat Pump PDFLuis DomdNoch keine Bewertungen

- Installation Method of The M&e WorksDokument27 SeitenInstallation Method of The M&e WorksMạnh Hùng100% (2)

- Door Air CurtainsDokument6 SeitenDoor Air CurtainsjationonaNoch keine Bewertungen

- Wet Scrubber ManualDokument15 SeitenWet Scrubber ManualYusak Santoso Use100% (1)

- Catalogo de Aire Acondicionado Compacto Carrier 50TC-17-30-V-02PD (17 A 30 T.R)Dokument98 SeitenCatalogo de Aire Acondicionado Compacto Carrier 50TC-17-30-V-02PD (17 A 30 T.R)Luis Eduardo Carmona VasquezNoch keine Bewertungen

- Building Automation Data SummaryDokument2 SeitenBuilding Automation Data SummaryAmol Bengiri75% (8)

- Sadiq Poultry PVT Limited Internship Report (Sheikhupura Hatchery) by Dr. Adnan Yousaf 03005662008Dokument37 SeitenSadiq Poultry PVT Limited Internship Report (Sheikhupura Hatchery) by Dr. Adnan Yousaf 03005662008IOSR0% (1)

- The History of The Leaf BlowerDokument3 SeitenThe History of The Leaf BlowerscottleafblowersNoch keine Bewertungen

- Calculator Centrifugal Fan - Google SearchDokument2 SeitenCalculator Centrifugal Fan - Google SearchJebDesNoch keine Bewertungen

- Centrifugal FansDokument19 SeitenCentrifugal FansMark John Santos60% (5)

- VENTUS Born in The USA - CatalogueDokument23 SeitenVENTUS Born in The USA - CataloguekksajjanamNoch keine Bewertungen

- Plant Shut Down Procedure - BHELCOMMDokument27 SeitenPlant Shut Down Procedure - BHELCOMMNishali SamNoch keine Bewertungen

- Thermal Power Plant BathindaDokument58 SeitenThermal Power Plant Bathindadeepzsohl100% (1)

- Thermal Applications: Cooling Systems GuideDokument32 SeitenThermal Applications: Cooling Systems GuideTinu Paul JepinNoch keine Bewertungen

- Chris Bickerstaff - Reducing Footprint Power Water UseDokument15 SeitenChris Bickerstaff - Reducing Footprint Power Water UseCorina GonzalezNoch keine Bewertungen