Beruflich Dokumente

Kultur Dokumente

Lecture # 6, Measurment of Zero Sequence Impedance, Harmonics of No-Load Current & OLTC Tests

Hochgeladen von

raza239Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Lecture # 6, Measurment of Zero Sequence Impedance, Harmonics of No-Load Current & OLTC Tests

Hochgeladen von

raza239Copyright:

Verfügbare Formate

CERTIFIED QUALITY CONTROL

PROFESSIONALS

Presented By Supported By

JAHANZEB

RAZA AFTAB

AHMED

Special Thanks to

HR Department

MODULE-1 TRANSFORMER

TESTING

CERTIFIED QUALITY CONTROL

PROFESSIONALS

CONTENTS

1.

2.

3.

4.

5.

6.

7.

8.

Measurement of No-Load Loss & Acoustic Sound Level

Measurement of Impedance Voltage & Load Loss

Separate Source & Induce Over-voltage withstand test (with

measurement of Partial Discharges)

Lightning impulse over-voltage withstand test

Heat run (temperature rise test)

Measurement of zero-sequence impedance

Measurement of voltage & current harmonics

Tests on OLTC & Insulating Oil

MODULE-1 TRANSFORMER

TESTING

CERTIFIED QUALITY CONTROL

PROFESSIONALS

Measurement of Zero Sequence Impedance

PURPOSE

The purpose of this test is to measure the zero sequence impedance for all

star connected windings of the transformer needed for earth fault protection

and earth fault current calculations

Applicable to star or zigzag interconnected star connections with neutral

brought out.

CLASS

IEC declare it as a special test.

MODULE-1 TRANSFORMER

TESTING

CERTIFIED QUALITY CONTROL

PROFESSIONALS

Measurement of Zero Sequence Impedance

APPLICABLE STANDARD

IEC 60076-1, Clause 10.7, Measurement of zero sequence impedance on

three phase transformers.

DEFINITION OF ZERO SEQUENCE IMPEDANCE

The impedance expressed in /Phase at rated frequency between the line

terminals of a three phase star connected or zigzag connected winding

connected together and its neutral terminal.

Zo = 3 V/I

MODULE-1 TRANSFORMER

TESTING

/Phase

CERTIFIED QUALITY CONTROL

PROFESSIONALS

Measurement of Zero Sequence Impedance

TOLERANCES

According to IEC 60076-8, Clause # 4, Zero Sequence Properties.

CALCULATIONS

Net impedance (Zo/3 ohms) = measured voltage / measured current

Zero sequence impedance per phase (Zo) = 3 * net impedance

MODULE-1 TRANSFORMER

TESTING

CERTIFIED QUALITY CONTROL

PROFESSIONALS

Measurement of Zero Sequence Impedance

EQUIPMENTS/INSTRUMENTS

Following equipments/instruments are required to perform this test:

Motor-Generator Set

Power Analyzer

Current Transformer

Potential Transformer

MODULE-1 TRANSFORMER

TESTING

CERTIFIED QUALITY CONTROL

PROFESSIONALS

Measurement of Zero Sequence Impedance

TEST CIRCUIT

MODULE-1 TRANSFORMER

TESTING

CERTIFIED QUALITY CONTROL

PROFESSIONALS

Measurement of Zero Sequence Impedance

PROCEDURE

The measurement is carried out by supplying a current of rated frequency

between parallel connected phase terminals and the neutral terminal. The zero

sequence impedance per phase is three times the impedance measured in this

way.

The zero sequence impedance for a star-star connected transformer, having a

tertiary winding in open delta connection, can be measured in the following four

ways.

Supply on HV side, with LV open and tertiary short circuited.

MODULE-1 TRANSFORMER

TESTING

CERTIFIED QUALITY CONTROL

PROFESSIONALS

Measurement of Zero Sequence Impedance

PROCEDURE.Continued

Supply on HV side, with LV shorted and tertiary open circuited.

MODULE-1 TRANSFORMER

TESTING

CERTIFIED QUALITY CONTROL

PROFESSIONALS

Measurement of Zero Sequence Impedance

PROCEDURE.Continued

Supply on LV side, with HV open and tertiary short circuited.

MODULE-1 TRANSFORMER

TESTING

CERTIFIED QUALITY CONTROL

PROFESSIONALS

Measurement of Zero Sequence Impedance

PROCEDURE.Continued

Supply on LV side, with HV shorted and tertiary open circuited.

MODULE-1 TRANSFORMER

TESTING

CERTIFIED QUALITY CONTROL

PROFESSIONALS

Measurement of Zero Sequence Impedance

PROCEDURE.Continued

MODULE-1 TRANSFORMER

TESTING

CERTIFIED QUALITY CONTROL

PROFESSIONALS

Measurement of Zero Sequence Impedance

TEST RESULTS

Following items are recorded in the test reports:

1.

Zero sequence impedance value.

2.

Corresponding test condition.

MODULE-1 TRANSFORMER

TESTING

CERTIFIED QUALITY CONTROL

PROFESSIONALS

Measurement of Zero Sequence Impedance

PRECAUTIONS

1. Current flowing in the windings should be according to their current

carrying capacity.

2.

Measurements should be performed quickly.

MODULE-1 TRANSFORMER

TESTING

CERTIFIED QUALITY CONTROL

PROFESSIONALS

Measurement of Harmonics of the no-load current

PURPOSE

The purpose of this test is to determine the extent of distortion of the no-load

current waveform.

CLASS

IEC declare it as a special test.

APPLICABLE STANDARD

IEC 60076-1, Clause 10.6, Measurement of harmonics of the no-load

current.

MODULE-1 TRANSFORMER

TESTING

CERTIFIED QUALITY CONTROL

PROFESSIONALS

Measurement of Harmonics of the no-load current

BACKGROUND

The magnetizing current of transformers contains harmonics due to the nonlinear magnetizing characteristic. The magnetizing current is in normal

operation small, in the order of 1% of the rated current of the transformers, and

the influence of harmonics is negligible. However, if the transformer core is

saturated due to an applied voltage higher than the rated voltage, the

magnetizing current and its harmonics will dramatically increase.

MODULE-1 TRANSFORMER

TESTING

CERTIFIED QUALITY CONTROL

PROFESSIONALS

Measurement of Harmonics of the no-load current

CALCULATIONS

VTHD (%) = 100 * SQRT [(V22 + V32 + V42 + ... + Vn2)] / Vt

ITHD (%) = 100 * SQRT [(I22 + I32 + I42 + ... + In2)] / It

MODULE-1 TRANSFORMER

TESTING

CERTIFIED QUALITY CONTROL

PROFESSIONALS

Measurement of Harmonics of the no-load current

EQUIPMENTS/INSTRUMENTS

Following equipments/instruments are required to perform this test:

Motor-Generator Set

Step-up Adapter Transformer

Power Analyzer

Current Transformer

Potential Transformer

MODULE-1 TRANSFORMER

TESTING

CERTIFIED QUALITY CONTROL

PROFESSIONALS

Measurement of Harmonics of the no-load current

TEST CIRCUIT

MODULE-1 TRANSFORMER

TESTING

CERTIFIED QUALITY CONTROL

PROFESSIONALS

Measurement of Harmonics of the no-load current

PROCEDURE

Rated voltage is generally supplied to the low voltage winding and all the other

windings are open circuited. Other windings, which can be connected in open

delta, should have the delta closed.

The voltage across the windings should be symmetrical and sinusoidal, as far

as possible. The test voltage should be adjusted according to a voltmeter

responsive to mean value of voltage.

The harmonic analyzer directly gives the harmonics and their corresponding

magnitudes in volts, from which percentage harmonic voltages can be found

out, with reference to the fundamental component.

MODULE-1 TRANSFORMER

TESTING

CERTIFIED QUALITY CONTROL

PROFESSIONALS

Measurement of Harmonics of the no-load current

TEST RESULTS

Following items are recorded in the test reports:

1. Applied voltage.

2. Fundamental and harmonic components in volts.

3. Fundamental and harmonic components in percentages

MODULE-1 TRANSFORMER

TESTING

CERTIFIED QUALITY CONTROL

PROFESSIONALS

Measurement of Harmonics of the no-load current

PRECAUTIONS

Readings of current and power should be taken at the exact rated voltage of

the winding

MODULE-1 TRANSFORMER

TESTING

CERTIFIED QUALITY CONTROL

PROFESSIONALS

TESTS ON ON-LOAD TAP CHANGER

PURPOSE

The purpose of this test is to verify the operation of the on-load tap changer

at various conditions of the transformer i.e. un-energized, unloaded, loaded &

reduced conditions.

CLASS

IEC declare it as a Routine test.

APPLICABLE STANDARD

IEC 60076-1, Clause 10.8, Tests on OLTC.

MODULE-1 TRANSFORMER

TESTING

CERTIFIED QUALITY CONTROL

PROFESSIONALS

TESTS ON ON-LOAD TAP CHANGER

DEFINITION

On-Load Tap Changer

A device for changing the tapping connections of a winding, suitable for

operation while the transformer is energized or on load.

MODULE-1 TRANSFORMER

TESTING

CERTIFIED QUALITY CONTROL

PROFESSIONALS

TESTS ON ON-LOAD TAP CHANGER

EQUIPMENTS/INSTRUMENTS

Following equipments/instruments are required to perform this test:

Motor-Generator Set

Step-up Adaptor Transformer

Power Analyzer

Current Transformer

Potential Transformer

Compensation Capacitors

MODULE-1 TRANSFORMER

TESTING

CERTIFIED QUALITY CONTROL

PROFESSIONALS

TESTS ON ON-LOAD TAP CHANGER

PROCEDURE

With the tap changer fully assembled on the transformer the following sequence of

operations shall be performed without failure.

1. With the transformer un-energized, eight complete cycles of operation (a

cycle of operation goes from one end of the tapping range to the other, and

back again).

2. With the transformer un-energized, and with the auxiliary voltage reduced to

85% of its rated value, one complete cycle of operation.

MODULE-1 TRANSFORMER

TESTING

CERTIFIED QUALITY CONTROL

PROFESSIONALS

TESTS ON ON-LOAD TAP CHANGER

PROCEDURE

3. With the transformer energized at rated voltage and frequency at no load,

one complete cycle of operation. This test may be performed after

performing the no load test.

4. With one winding short circuited and, as far as practicable, rated current in

the tapped winding, 10 tap change operations across the range of two steps

on each side from where a coarse or reversing changeover selector

operates, or otherwise from the middle tapping.

MODULE-1 TRANSFORMER

TESTING

CERTIFIED QUALITY CONTROL

PROFESSIONALS

TESTS ON ON-LOAD TAP CHANGER

PRECAUTIONS

1. All connections should be tight.

2. Proper clearances should be observed.

3. Proper alignment between the tap changer indicator and the motor drive

indicator should be ascertained.

MODULE-1 TRANSFORMER

TESTING

CERTIFIED QUALITY CONTROL

PROFESSIONALS

THANK

YOU

MODULE-1 TRANSFORMER

TESTING

Das könnte Ihnen auch gefallen

- Into Grade 7 English - AssessorDokument6 SeitenInto Grade 7 English - Assessorraza239Noch keine Bewertungen

- Year 7 Literary Terms Worksheet AnswersDokument2 SeitenYear 7 Literary Terms Worksheet Answersraza239Noch keine Bewertungen

- Year 7 Conflict Worksheet QuestionsDokument1 SeiteYear 7 Conflict Worksheet Questionsraza239Noch keine Bewertungen

- Year 6 Writing Prompts Worksheet 3 AnswersDokument2 SeitenYear 6 Writing Prompts Worksheet 3 Answersraza239Noch keine Bewertungen

- Into Grade 7 English - StudentDokument5 SeitenInto Grade 7 English - Studentraza239Noch keine Bewertungen

- Year 6 Writing Prompts Worksheet 3 AnswersDokument2 SeitenYear 6 Writing Prompts Worksheet 3 Answersraza239Noch keine Bewertungen

- Year 7 Writing Prompts Worksheet 2 QuestionsDokument2 SeitenYear 7 Writing Prompts Worksheet 2 Questionsraza239Noch keine Bewertungen

- Year 6 Writing Prompts Worksheet 3 AnswersDokument2 SeitenYear 6 Writing Prompts Worksheet 3 Answersraza239Noch keine Bewertungen

- P5 Excel Secondary TimetableDokument1 SeiteP5 Excel Secondary Timetableraza239Noch keine Bewertungen

- Excel Essential Skills Grammar and Punctuation Workbook Years 7 8Dokument28 SeitenExcel Essential Skills Grammar and Punctuation Workbook Years 7 8raza239100% (1)

- Year 7 Writing Prompts Worksheet QuestionsDokument2 SeitenYear 7 Writing Prompts Worksheet Questionsraza239Noch keine Bewertungen

- Protective Relay RS 2001: Operating Instructions BA59/07Dokument12 SeitenProtective Relay RS 2001: Operating Instructions BA59/07raza239Noch keine Bewertungen

- SPIDA and ELLIPSEDokument1 SeiteSPIDA and ELLIPSEraza239Noch keine Bewertungen

- Year 7 Writing Prompts Worksheet 3 QuestionsDokument2 SeitenYear 7 Writing Prompts Worksheet 3 Questionsraza239Noch keine Bewertungen

- Excitation Current Test On Power TransformersDokument4 SeitenExcitation Current Test On Power Transformersraza239Noch keine Bewertungen

- DIN 127 Spring Lock WasherDokument3 SeitenDIN 127 Spring Lock Washerraza239Noch keine Bewertungen

- Simple Agelesss Methods For Field Testing Power TransformersDokument13 SeitenSimple Agelesss Methods For Field Testing Power Transformersraza239Noch keine Bewertungen

- DIN 440 R Washer For Wood ConstructionsDokument1 SeiteDIN 440 R Washer For Wood Constructionsraza239Noch keine Bewertungen

- DIN 125 Plain Washers Brass WashersDokument3 SeitenDIN 125 Plain Washers Brass Washersraza239Noch keine Bewertungen

- DIN 933-931 HEX HEAD M33 M48 BOLTSDokument3 SeitenDIN 933-931 HEX HEAD M33 M48 BOLTSraza239Noch keine Bewertungen

- Ansi C57.12.25-1990Dokument19 SeitenAnsi C57.12.25-1990IngJGMNoch keine Bewertungen

- PPT-Availability of HV Power EquipmentDokument23 SeitenPPT-Availability of HV Power Equipmentraza239Noch keine Bewertungen

- Din 975 Brass Threaded RodsDokument2 SeitenDin 975 Brass Threaded Rodsraza239Noch keine Bewertungen

- Din 933Dokument3 SeitenDin 933raza239Noch keine Bewertungen

- 3 Phase Short Circuit CalculationDokument7 Seiten3 Phase Short Circuit Calculationcherif yahyaouiNoch keine Bewertungen

- C57 12 24-2000Dokument18 SeitenC57 12 24-2000raza239Noch keine Bewertungen

- Ansi C57.12.22-1993 PDFDokument24 SeitenAnsi C57.12.22-1993 PDFEdwin CapdepomtNoch keine Bewertungen

- CT Burden Ans Sec Voltage CalculatorDokument1 SeiteCT Burden Ans Sec Voltage Calculatorraza239Noch keine Bewertungen

- IEEE STD C57.12.23 - 2002: AbstractDokument15 SeitenIEEE STD C57.12.23 - 2002: AbstractCarlos Enrique DíazNoch keine Bewertungen

- Ansi C57.12.26-1992 PDFDokument31 SeitenAnsi C57.12.26-1992 PDFEdwin CapdepomtNoch keine Bewertungen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (120)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Mercom Energy Storage Report Apr2023Dokument10 SeitenMercom Energy Storage Report Apr2023aakashNoch keine Bewertungen

- Permanent Magnet Motor: Instruction Manual and Experiment Guide For The PASCO Scientific Model SE-8658ADokument34 SeitenPermanent Magnet Motor: Instruction Manual and Experiment Guide For The PASCO Scientific Model SE-8658AAbhijeet SinhaNoch keine Bewertungen

- ABB Motor Protection and Control 2016Dokument332 SeitenABB Motor Protection and Control 2016DeanLefebvreNoch keine Bewertungen

- Um1r483500e3 Rev B 48v 3500w Rectifier 2022Dokument26 SeitenUm1r483500e3 Rev B 48v 3500w Rectifier 2022Yu MaNoch keine Bewertungen

- Maintenance of Transformers (A Detailed Checklist) - Electrical4UDokument11 SeitenMaintenance of Transformers (A Detailed Checklist) - Electrical4Umadantiwari2000% (1)

- Satec EM 920 MeterDokument39 SeitenSatec EM 920 MeterAnonymous BBX2E87aHNoch keine Bewertungen

- Exelon: Exelon Corporation Is An American Fortune 100 EnergyDokument11 SeitenExelon: Exelon Corporation Is An American Fortune 100 EnergyYuvaraj BhaduryNoch keine Bewertungen

- Hoja Tecnica Control de NivelDokument3 SeitenHoja Tecnica Control de NivelpawerxlNoch keine Bewertungen

- CH3 TransformerDokument57 SeitenCH3 TransformerDoktor CintaNoch keine Bewertungen

- Generation Protection FinalDokument44 SeitenGeneration Protection FinalclegenceNoch keine Bewertungen

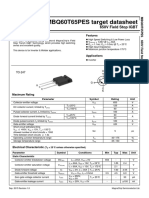

- MBQ60T65PES Target Datasheet: 650V Field Stop IGBTDokument1 SeiteMBQ60T65PES Target Datasheet: 650V Field Stop IGBTamrNoch keine Bewertungen

- Battery Charger Parts ListDokument2 SeitenBattery Charger Parts ListvivsencoNoch keine Bewertungen

- Bushing Insulators: Other Medium Voltage EquipmentDokument4 SeitenBushing Insulators: Other Medium Voltage EquipmentjalilemadiNoch keine Bewertungen

- SPECIFICATION SHEET - Li2800QC TWIN PACDokument2 SeitenSPECIFICATION SHEET - Li2800QC TWIN PACElias ZabanehNoch keine Bewertungen

- Manual for Phoenix Inverter CompactDokument110 SeitenManual for Phoenix Inverter CompactAlba Car MarNoch keine Bewertungen

- Zelio Logic SR2 - SR3 - SR2B121FUDokument6 SeitenZelio Logic SR2 - SR3 - SR2B121FUabdul kadirNoch keine Bewertungen

- Inverter - Solaredge - Installation-Manual - SE3800A-US InstallationDokument7 SeitenInverter - Solaredge - Installation-Manual - SE3800A-US InstallationAl0% (1)

- OT1600KLUU3BZ Encl. Switch DisconnectorDokument3 SeitenOT1600KLUU3BZ Encl. Switch DisconnectorMohamed AlhadidyNoch keine Bewertungen

- Dual Display Digital Multimeter User ManualDokument15 SeitenDual Display Digital Multimeter User ManualEric CostaNoch keine Bewertungen

- 2sk3673 MosfetDokument4 Seiten2sk3673 Mosfetagus2kNoch keine Bewertungen

- G.A.L. Manufacturing Encoderless Closed Loop Door Operator Q&ADokument2 SeitenG.A.L. Manufacturing Encoderless Closed Loop Door Operator Q&APabloNoch keine Bewertungen

- Acme 9comDokument6 SeitenAcme 9comLouie Angelo LaoNoch keine Bewertungen

- Ejee - 2021 - 23.01 - 01Dokument7 SeitenEjee - 2021 - 23.01 - 01Henok AyeleNoch keine Bewertungen

- Ismail Hamza-Saudi Grid CodeDokument35 SeitenIsmail Hamza-Saudi Grid CodeboopelectraNoch keine Bewertungen

- Basic panel-mounted fault annunciator configurationDokument16 SeitenBasic panel-mounted fault annunciator configurationraulNoch keine Bewertungen

- Datasheet 587962 (80-6360-A0) en 120V 60HzDokument4 SeitenDatasheet 587962 (80-6360-A0) en 120V 60HzBenja TCNoch keine Bewertungen

- AC & DC WindingDokument29 SeitenAC & DC WindingSattar BalochNoch keine Bewertungen

- Protection Devices and Systems For High Voltage Applications PDFDokument308 SeitenProtection Devices and Systems For High Voltage Applications PDFsqrt3Noch keine Bewertungen

- Designing Air-Cored Axial Flux Permanent Magnet GeDokument6 SeitenDesigning Air-Cored Axial Flux Permanent Magnet GeSaleem AbbasNoch keine Bewertungen

- Saudi Electricity RegulationDokument103 SeitenSaudi Electricity Regulationvijay babu100% (1)