Beruflich Dokumente

Kultur Dokumente

SPE 171519 MS - PDF Optimising Recovery in Gas Condensate Reservoirs

Hochgeladen von

swaala4realOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

SPE 171519 MS - PDF Optimising Recovery in Gas Condensate Reservoirs

Hochgeladen von

swaala4realCopyright:

Verfügbare Formate

SPE-171519-MS

Optimizing Recovery in Gas Condensate Reservoirs

Y. H. Seah, Schlumberger; A. C. Gringarten, Imperial College London; M. A. Giddins and K. Burton,

Schlumberger

Copyright 2014, Society of Petroleum Engineers

This paper was prepared for presentation at the SPE Asia Pacific Oil & Gas Conference and Exhibition held in Adelaide, Australia, 14 16 October 2014.

This paper was selected for presentation by an SPE program committee following review of information contained in an abstract submitted by the author(s). Contents

of the paper have not been reviewed by the Society of Petroleum Engineers and are subject to correction by the author(s). The material does not necessarily reflect

any position of the Society of Petroleum Engineers, its officers, or members. Electronic reproduction, distribution, or storage of any part of this paper without the written

consent of the Society of Petroleum Engineers is prohibited. Permission to reproduce in print is restricted to an abstract of not more than 300 words; illustrations may

not be copied. The abstract must contain conspicuous acknowledgment of SPE copyright.

Abstract

Gas condensate reservoirs exhibit complex flow behavior below the dewpoint pressure, caused by

compositional changes and the creation and growth of a condensate bank around the wellbore, which

effectively reduces the relative permeability to gas flow. As a result, gas production decreases and liquid

condensate, a valuable resource, is left behind in the reservoir.

Well deliverability impairment resulting from liquid dropout has been a main focus of gas condensate

studies for over 60 years. We have used compositional reservoir simulation, with representative lean- and

rich-condensate fluids and velocity-dependent relative permeability models, to predict condensate dropout

under typical operating conditions. The effectiveness of different production methods and remediation

solutions in minimizing condensate buildup below the dewpoint pressure was quantified, using first a

single-well model and then full-field models of tight and low-permeability gas condensate reservoirs in

which six vertical wells were compared with two horizontal wells.

We found that, although both horizontal wells and vertical well stimulation do improve well productivity, productivity enhancement depends greatly on well and reservoir parameters such as horizontal well

lengths, well placement, reservoir permeabilities, and gas condensate compositions. For gas condensate

production below the dewpoint pressure, it is possible to achieve an optimum balance between gas

production rate and pressure drawdown, thus minimizing condensate dropout effect while producing at a

reasonable rate. In a low-permeability gas condensate reservoir, the six vertical wells perform slightly

better than the two horizontal wells for the same amount of gas production. In a tight gas condensate

reservoir, on the contrary, gas recovery with two horizontal wells is significantly greater than with six

vertical wells. Although, in this model, well stimulation can increase the productivity of the vertical wells

in tight gas condensate reservoir, it is not as effective as using horizontal wells.

Introduction

Continuous developments in drilling and logging technologies have enabled deeper, higher pressure, and

higher temperature gas condensate reservoirs to be discovered and developed. In addition, most mature

gas condensate fields worldwide are at the later stage of their field life, gradually approaching their

dewpoint pressure below which liquid condensate drops out. Globally, the increasing demand for natural

gas liquids on world markets has stimulated interest in optimizing gas condensate resources (BP 2014).

SPE-171519-MS

Gas condensate reservoirs exhibit complex flow behavior as a result of retrograde condensation when

the bottomhole flowing pressure drops below the dewpoint pressure. Gas condensate dropout near the

wellbore must be considered, as changes in fluid saturations affect relative permeabilities. As a result, it

affects the final decision made in the production planning of a gas condensate field.

This has been the subject of many studies for over 60 years (Muskat 1949). It was discovered that three

concentric regions with different liquid saturations emerge around a gas condensate well producing below

the dewpoint pressure (Kniazeff and Naville 1965). Away from the well, an outer region contains the

initial liquid saturation. Next, an intermediate region shows a rapid increase in liquid saturation and a

corresponding reduction in gas relative permeability. Liquid in this region is still immobile because the

critical saturation has not been reached yet. Nearer to the well, an inner region forms where liquid

saturation exceeds the critical saturation and both the reservoir gas and liquid condensate flow into the

well with constant composition.

A fourth region in the immediate vicinity of the well with low interfacial tension resulting from high

flow rate yields lower liquid saturation and higher gas relative permeability (Gringarten et al. 2000). The

existence of this fourth region is important because it counters the productivity loss caused by liquid

dropout. This region is where the capillary number effect is dominant over the inertial resistance effect,

contributing to higher gas recovery.

Background and Theory

Muskat (1949) first suggested that liquid condensate builds up around the wellbore when bottomhole

pressure drops below the dewpoint pressure and explained mathematically the condensate saturation

profile around a producing well in a gas condensate reservoir. Eilerts et al. and Kniazeff and Naville

published papers in 1965, in which they modeled gas condensate well deliverability numerically with

respect to time and radial distance and studied the effects of non-Darcy flow. Two years later, Gondouin

et al. (1967) extended the work by Kniazeff and Naville (1965) and demonstrated the significance of

non-Darcy flow effects and condensate blockage by applying their formulations to the results data of

backpressure tests from Hassi Er RMel field, Algeria. ODell and Miller (1967), on the other hand,

applied Muskats solutions and presented a pseudopressure function to describe the gas condensate

blockage.

Fetkovich (1973) developed a rate- and time-dependent skin based on Muskats results and incorporated it into the standard gas flow equation. Subsequently, Fevang and Whitson (1996) applied the

modified form of the Evinger-Muskat pseudopressure (Evinger and Muskat 1942) to calculate gascondensate well deliverability and provided a simple method for calculating bottomhole flowing pressure

in coarse-grid models. A more recent study by Gringarten et al. (2000) established the use of a

three-region composite model to analyze gas condensate well test data.

Well productivity index (i.e., the relationship between pressure drop and flow rate) is complicated in

gas condensate reservoirs below the dewpoint pressure due to the existence of the fourth region with

lower interfacial tension and higher gas relative permeability. The two velocity-dependent relative

permeability effects contributing to the existence of the near-wellbore region are the capillary number

effect, also referred to as velocity stripping, viscous stripping, or positive coupling effect, and the

non-Darcy flow or inertial resistance effect introduced by Forchheimer (Belhaj et al. 2003).

A compositional reservoir simulator has been used to model the complex flow behavior of gas

condensates, with very fine grids near to the well, as pressure drawdown predominantly occurs within 10

ft of the wellbore (Mott et al. 2000).

Velocity-Dependent Relative Permeability Effects

The methods used in this study to model the two velocity-dependent relative permeability effects are

described below.

SPE-171519-MS

Capillary number effect Previous studies have reported that gas deliverability increases as a result of an

increase in the gas relative permeability at high velocity when the capillary number is high (Danesh et al.

1994; Henderson et al. 1995, 2000; Ali et al. 1997; Gringarten et al. 2000). Danesh et al. (1994) was the

first to address the improvements of relative permeability to gas flow in condensate systems with increases

in velocity or decreases in interfacial tension, through laboratory experimental results. Miscibility between

the flowing phases due to reduced interfacial tension at high velocities, which increases mobility for oil

and gas, can be modeled in compositional simulation using various different options for velocitydependent relative permeability.

Capillary number is the ratio of viscous to capillary forces and can be represented by a single

parameter, Nc. Production data from several fields have revealed that deliverability is higher than the

conventional simulated data because of the positive effect of capillary number (Mott 2002). It is essential

to incorporate the capillary number model into compositional simulations below the dewpoint pressure in

systems that exhibit retrograde condensation. Otherwise, well productivity will be underestimated

whereas pressure drops and condensate dropout will be overestimated.

The capillary number formulations applied in this study are after Henderson et al. (1995), as shown

below. In their model, the capillary number for both phases depends only on the gas properties.

(1)

The base capillary number Ncbp is defined as the lower threshold value below which Ncp has no effect

on phase relative permeabilities. This number is taken from input data and used to calculate a normalized

capillary number Ncnp:

(2)

At higher capillary numbers, the residual saturation is reduced by multiplying the phase residual

saturation Srp by a factor Xp:

(3)

The capillary number is also used to define the interpolation between the immiscible relative

permeability curves defined by input tables and the miscible curves that are constructed internally as

straight lines.

(4)

The immiscible relative permeability is krp, and the miscible relative permeability is calculated as

follows, giving a straight line with endpoints defined by the adjusted phase residual saturation:

(5)

where Xp is defined in Eq. 3. The interpolation factor f is calculated as

(6)

(7)

Non-Darcy Flow Effect Darcys law does not explain gas flow accurately when the flow rate is high,

especially near the wellbore. At high gas rate, pressure drop for flow into the well is no longer proportional

SPE-171519-MS

to the rate. Turbulence, which causes increased pressure drop, can be modeled in the simulator using the

Forchheimer correction to account for inertial effects:

(8)

Non-Darcy flow effect is typically modeled as a rate-dependent skin in most numerical simulators.

can be determined from multirate pressure test analysis or from theoretical or empirical correlations (Li

and Engler 2001). A typical empirical correlation for single-phase flow is:

(9)

Geertsma (1974) proposed an empirical correlation for two-phase flow, relating to the fluid saturation

and relative permeability:

(10)

In the case of two-phase gas condensate flow, inertial effects generate extra condensate dropout

because the inertial resistance in one phase is affected by the presence of the second phase.

Parameters Affecting Productivity of Horizontal Wells

The performance of horizontal wells in comparison with vertical wells has been investigated in previous

studies (Joshi 1988; Hashemi and Gringarten 2005). Results show that the relative productivity of a

horizontal well, compared to a vertical well in the same reservoir, depends on the producing horizontal

length and the ratio of vertical to horizontal permeability, kv/kh.

Methodology

This study was carried out in three stages: first, gas condensate compositional analysis; second, base

model study, and third, the full field model design. The following assumptions were made:

1. The near-well phase equilibrium and fluid flow interactions are accurately represented using a fine

radial grid model and a fine tartan grid, with fluid properties calculated from an equation of state

(EOS) model.

2. There is no limit on the tubing head flowing pressure, and only well bottomhole pressure limits

are considered.

3. The pressure drop due to condensate blockage is significant compared to the pressure drop in the

tubing.

4. No aquifer support was considered in this study.

Gas Condensate Compositional Analysis

Four gas condensate mixtures with different compositions have been studied to distinguish between rich

and lean gas condensates (TABLE 1). A typical lean gas condensate generates a small volume of liquid

(i.e., 30 to 50 stb/MMscf), whereas a rich gas condensate generates a relatively larger volume of liquid

(i.e., 50 to 300 stb/MMscf) (Zheng et al. 2006).

Referring to Table 1, gas condensate B was selected for use in single-well sensitivity studies and for

investigating production strategies in the full field model, because it represents a gas condensate with a

condensate/gas ratio (CGR) that is not too rich and not too lean (Fig. 1). All four gas condensates were

used in the comparison of rich versus lean gas condensate for the full field model study.

SPE-171519-MS

Table 1FLUID PROPERTIES FOR GAS CONDENSATE A, B, C, AND D

Gas condensate

CGR (stb/MMscf)

Dewpoint pressure (psia)

Reservoir temperature (F)

161

87

48

27

4767

4298

4028

3440

340

200

251

251

A

B

C

D

Figure 1Phase diagrams of gas condensate A (left) and B (right). Gas condensate B is leaner than gas condensate A and therefore its phase diagram

appears to be shifted to the left when compared to gas condensate A.

Base Model: Single Well

Compositional gas condensate simulation cases have been constructed to simulate fluid flow behavior and

to predict condensate dropout under typical operating conditions using single-well models.

Single-Well Model Gridding and Description The single-well models consisted of a five-layer homogeneous reservoir of 100-ft thickness with a drainage area of 891 acres, 10% porosity, horizontal

permeability of 1 md, and vertical-to-horizontal-permeability ratio (kv/kh) of 0.1 (typical of sandstone

reservoirs). Initially, the reservoir pressure is slightly above the dewpoint pressure.

Table 2SINGLE-WELL RADIAL GRID MODEL GRID PROPERTIES

Grid properties

Number of active cells

Innermost grid radius

Outermost grid radius

Cell spacing (ft)

Value

Unit

20

0.15

ft

3515

ft

Cell sizes increase geometrically

in radial direction away from the

center where the well is located.

Figure 2Single-well radial grid model.

SPE-171519-MS

Table 3SINGLE-WELL TARTAN GRID MODEL GRID PROPERTIES

Grid properties

Value

Unit

Number of active cells

Innermost grid size

Areal cell spacing

Uniform

Logarithmic, Central

Uniform

28125

2

Number of cells

30

15

30

ft

Average cell size (ft)

101.35

10

101.35

Figure 3Single-well tartan grid model.

A finely gridded 1D radial, fully compositional model was used, with no wellbore storage or

mechanical skin effect. A large outermost grid size of 1,335 ft was used to avoid boundary effects (Fig.

2; TABLE 2).

A tartan grid model was then designed to match the radial grid model, to be used in the full field model

studies at the later stage of the project (Fig. 3; TABLE 3).

Velocity-Dependent Relative Permeability Effect The same capillary number model and Forchheimers

non-Darcy model were incorporated into all the simulation cases for the compositional simulation runs.

The capillary number model introduced by Henderson et al. (1995) has been used to interpret the

difference between the base relative permeability and the miscible relative permeability models. A

multirate drawdown (200 Mscf/D for 1 day, 400 Mscf/D for 2 days, 800 Mscf/D for 3 days, and 1,600

Mscf/D for another 4 days) followed by 10 days of buildup were simulated to observe the positive effect

of the velocity-dependent relative permeability phenomenon.

The high capillary number and non-Darcy flow effects are both rate-dependent functions acting in

opposite directions. Fig. 4 shows a stronger capillary number effect over the inertial effect, resulting in

a positive velocity-dependent relative permeability effect. The pressure drawdown is lower than that

without velocity-dependent relative permeability models at the same designated flow rates.

Effect of Different Gas Production Rate The single-well radial grid model has been used to examine

the condensate dropout effect as production goes below the dewpoint pressure by operating at different

specified rates. Various scenario cases were run for 10 days of drawdown followed by another 10 days

of buildup to achieve an optimum balance between gas production rate and well bottomhole pressure. This

is important to minimize the condensate dropout effect in the reservoir.

The final operational decision was made after analyzing the results obtained from the scenario cases

at high and low rates whilst also taking into account the initial reservoir conditions.

Fig. 5 shows two options for operating this gas condensate model, yielding different amounts of

condensate dropout as the bottomhole pressure drops below the dewpoint pressure. For the well producing

at 2 MMscf/D, oil saturation as high as 37% was observed around the wellbore at the end of the 10-day

drawdown. For a production rate of 1 MMscf/D, about 26% oil saturation was observed around the well.

There is a trade-off between high production rate and small liquid dropout effect. The two operating

scenarios shown in Fig. 5 are both producing at reasonable rates. An operational decision can be made,

either aiming at reducing condensate dropout and therefore a lower production rate or aiming at producing

at a higher rate and accepting a higher liquid dropout around the wellbore.

For the next stage of the study, it was decided that the pressure drawdown will be allowed to go below

the dewpoint pressure, to allow the well to produce at a reasonable rate.

SPE-171519-MS

Figure 4 Effect of velocity-dependent relative permeability models on well bottomhole pressure.

Figure 5Gas production rate (GRAT) control mode at 1 MMscf/D and 2 MMscf/D, respectively, with a limiting bottomhole pressure (BHP) target

or lower limit at 3000 psia.

Full Field Model and Simulation Results

The full field simulation model consisted of a five-layer homogeneous reservoir of 300-ft thickness with

a drainage area of 4,768 acres, 10% porosity, horizontal permeability of 1 md, and kv/kh ratio of 0.1

(typical of sandstone reservoirs). A tartan grid was constructed with logarithmic cell spacing, with fine

grid cells near the wells for enhanced grid definition to capture the fluid flow movement. All the models

have the same initial gas in place. (Fig. 6)

Six vertical producing wells were placed equally apart from each other in the gas condensate field.

Capillary number and non-Darcy flow effects were taken into account, but frictional losses in the

wellbore, wellbore storage, and skin were neglected. The four main sensitivity studies conducted are gas

condensate composition, reservoir permeability, well configuration, and well stimulation. A sensitivity

study on rates was performed, and it was decided to produce at a field production daily contracted quantity

(DCQ) of 12 MMscf/D from the field; with each well producing at 2 MMscf/D to minimize the condensate

dropout effect around the wellbore. The condensate saturation profiles around well 1, well 2, and well 3

were plotted against the radial distance from the wellbores (i.e., along distance A from well 1, distance

B from well 2, and distance C from well 3. (Fig. 7) Different radial directions from the wells gave distinct

condensate saturation plots, but their saturation profiles generally follow the same trend.

SPE-171519-MS

Figure 6 Full field model with six vertical wells producing from the gas condensate reservoir. Tartan grid (right) was used for enhanced grid

definition.

Figure 7Comparison of condensate B saturation profile around the wellbores at different production rates (i.e., 2MMscf/D, 5 MMscf/D, and 10

MMscf/D).

Phase Diagram

As the well bottomhole flowing pressure falls below the dewpoint pressure, lighter components of gas

condensate B are produced as gas phase whereas the heavier components drop out as immobile liquid. The

produced gas becomes leaner as the near-wellbore region becomes richer in liquid condensate. As can be

seen in Fig. 8, the phase diagram of the gas condensate near the wellbore has shifted to the right at the

end of the drawdown, indicating that condensate dropout has occurred around the well.

Fig. 9 further confirms that the produced reservoir gas has become leaner at the end of the drawdown

period as condensate has dropped out in the reservoir. The CGR decreases rapidly from 87 stb/MMscf to

approximately 72.5 stb/MMscf during the first year of production; it then remains relatively constant at

a plateau CGR until the end of the production.

Rich versus Lean Gas Condensate

A first objective of the simulation runs was to compare the condensate saturation profile around the

wellbore for different gas condensate compositions, with all other parameters kept constant. The four gas

condensates shown in Table 1 were used in this study. Compositional simulation runs were made with

capillary number and inertial effects, at a constant gas flow rate of 2 MMscf/D per well.

A plot of condensate saturation profile against distance from well 1 at the end of the 5-year drawdown

is shown in Fig. 10. Gas condensate A (the richest gas condensate) exhibits the highest amount of liquid

SPE-171519-MS

Figure 8 Comparison of phase diagrams at the start and the end of the 5-year production from the full field model using six vertical wells.

Figure 9 Changes of CGR in the gas condensate field with respect to producing time.

dropout near the wellbore whereas gas condensate D (the leanest gas condensate) exhibits the least amount

of liquid dropout around the wellbore.

Gas condensate B, which has been used for all the simulation models, has about 31% of liquid

saturation within 2 ft of the wellbore; this increases gradually up to approximately 35% 10 ft away from

the wellbore and then eventually tails off farther away from the wellbore. Examination of the condensate

saturations and fluid properties near the wellbore indicates the existence of the fourth saturation region

due to capillary number effect (Gringarten et al. 2006). This was not observed in the simulation results

of the other three gas condensate types in this study.

Tight versus High-Permeability Gas Condensate Reservoir

A series of simulation runs was performed to compare the condensate saturation profile and gas and liquid

production rates for different reservoir permeabilities. Four different reservoir permeabilities were

studied, with each representing different types of gas condensate reservoir (i.e., ultratight reservoir (0.001

md), tight reservoir (0.1 md), low-permeability reservoir (1 md), and high-permeability reservoir (1,200

md). All four reservoirs have a kv/kh ratio of 0.1 and a porosity of 10%. Gas condensate B was used in

this study.

10

SPE-171519-MS

Figure 10 Comparison of condensate saturation profiles for different gas condensate compositions (A, B, C, and D).

Figure 11Comparison of condensate B saturation profiles in ultratight, tight, low-permeability, and high-permeability gas condensate reservoirs.

The condensate dropout effect is most significant in the tight reservoir, even more than in the ultratight

reservoir. Gas condensate production is lowest in the ultratight reservoir because the nature of the

reservoir inhibits the flow of the gas and condensates. There is no liquid dropout in the high-permeability

reservoir due to the very good formation connectivity, which enables both the gas and liquid phases to

flow easily into the producing wells and eventually up to the surface. (Fig. 11 and Fig. 12)

Well Configuration

Horizontal wells can enhance reservoir contact and improve well deliverability. The simulation model

used in this study is exactly the same as the full field model with six vertical wells discussed earlier, except

that two horizontal wells are used instead of the six vertical wells (Fig. 13). The two horizontal producing

wells were placed equally apart from each other in the gas condensate reservoir to minimize boundary

effects. Both of the horizontal wells are fully cased and perforated over their entire horizontal length.

Frictional losses in the wellbore, wellbore storage, and skin were neglected.

In this section, sensitivity studies were performed in the low-permeability gas condensate field (1 md)

and the tight gas condensate field (0.1 md). A series of simulation runs were performed to compare the

pressure drawdown and the condensate saturation profile when the flowing bottomhole pressure drops

below the dewpoint pressure. To match the field production DCQ at a rate of 12 MMscf/D, each of the

two horizontal wells was produced at 6 MMscf/D. The full field model was operated for 5-year drawdown

followed by 500 days of buildup period.

SPE-171519-MS

11

Figure 12Comparison of pressure drawdown, well gas cumulative production volume, well gas, and liquid production rates in ultratight, tight,

low-permeability, and high-permeability gas condensate reservoirs.

Figure 13Full field model with two horizontal wells producing from the gas condensate field. Tartan grid (right) was used for better runtime

performance and enhanced grid definition.

Low-Permeability Gas Condensate Field The liquid dropout effect in the low-permeability gas condensate field (1 md) is shown in Fig. 14. A plot of pressure against time is shown in Fig. 15 (left) for the

two horizontal wells with different completion lengths (1,000 ft, 2,000 ft, and 3,000 ft) and for the six

vertical wells (from the previous full field simulation) with 300 ft of completion length. Compositional

runs were made with capillary number and inertial effects at a constant gas flow rate of 6 MMscf/D.

12

SPE-171519-MS

Figure 14 Liquid condensate dropout effect from the first year to the fifth year of production.

Figure 15Comparison of pressure drawdowns (left) and of field gas and liquid cumulative production volume (right) for vertical and horizontal

wells in the low-permeability gas condensate field.

Figure 16 Comparison of condensate saturation profile for vertical and horizontal wells in the low-permeability reservoir.

As can be seen in Fig. 15 (left), the pressure drop in horizontal wells decreases as the horizontal well

length increases, although six vertical wells yield a smaller pressure drop than the two horizontal wells

(producing the same total amount). The horizontal well length of 3,000 ft was selected because it yields

a lower pressure drawdown, thus reducing the condensate dropout around the wellbore. Nonetheless, this

must be justified against the cost of using a longer horizontal well length. Fig. 15 (right) shows that for

the same field gas cumulative production, the six vertical wells produce approximately 10% more liquid

condensate compared with the two horizontal wells at the end of the drawdown.

SPE-171519-MS

13

Figure 17Comparison of pressure buildups (left) and of field gas and liquid cumulative production volume (right) for vertical and horizontal wells

in the tight gas condensate reservoir.

The condensate saturation profile around the vertical and horizontal wells in the field at the end of the

5-year drawdown is illustrated in Fig. 16. For the two horizontal wells, the condensate saturation is plotted

against the distance from the heel in the x-direction (perpendicular to the well). In this particular reservoir,

condensate saturation is fairly uniform because of the isotropic horizontal permeability throughout the

field. Fig. 16 also indicates that, as the horizontal well length increases from 1,000 ft to 3,000 ft, the

condensate saturation decreases.

Tight Gas Condensate Field To compare well productivities between vertical and horizontal wells and

to quantify the effectiveness of horizontal wells in tight gas condensate field (0.1 md), compositional

simulation runs of 5-year duration were made for different horizontal well lengths (1,000 ft, 2,000 ft and

3,000 ft). As for the low-permeability case, the runs were made with capillary number and inertial effects

at constant gas flow rate of 6 MMscf/D per well.

A plot of pressure against time for a 5-year drawdown followed by a 500-day buildup is shown in Fig.

17 (left) for the two horizontal wells with different completion lengths (1,000 ft, 2,000 ft, and 3,000 ft)

and for the six vertical wells with 300 ft of completion length. Due to the very low permeability of the

reservoir, it is difficult for the gas condensate to flow from the field into the wells. As can be seen in Fig.

17 (left), the bottomhole pressure limit of 400 psia for the vertical and horizontal wells has been reached

once the production was started.

Fig. 17 (right) shows that cumulative gas production from the two horizontal wells is approximately

4.7 Bscf more than production from the six vertical wells. In addition, it was found that the two horizontal

wells produce approximately 85 Mstb more liquid condensate than the six vertical wells.

The difference in well productivity between horizontal wells and vertical wells is very significant in a

tight gas condensate field. The cumulative gas production increases with the horizontal well length and

exceeds the production from the vertical wells for lengths over 2,000 ft (Fig. 18). Fig. 19 compares the

cumulative field liquid production for each horizontal well length and the vertical wells.

The condensate saturation profile around the vertical and horizontal wells in the tight gas condensate

reservoir at the end of the 5-year drawdown is illustrated in Fig. 20. The different horizontal well lengths

yield similar condensate saturation profiles around the wellbore. The vertical and horizontal wells showed

a maximum saturation of about 48%, which eventually tails off as it gets further away from the wellbore.

In the tight gas condensate field, horizontal wells yield higher total gas recovery than vertical wells.

This was not the case in the low-permeability gas condensate field, as discussed above.

14

SPE-171519-MS

Figure 18 Comparison of field gas cumulative production for vertical and horizontal wells in the tight gas condensate reservoir.

Figure 19 Comparison of field liquid cumulative production for vertical and horizontal wells in the tight gas condensate reservoir.

Figure 20 Comparison of condensate saturation profile for vertical and horizontal wells in the tight gas condensate reservoir.

Well Spacing between Horizontal Wells

Well spacing is generally defined as the maximum area of a reservoir that can be efficiently and

economically drained by one well (Keuengoua and Amorin 2011). Sensitivity studies were performed to

study the effects of well spacing between the horizontal wells. In this study, the low-permeability gas

condensate field was used to examine the boundary effects caused by the neighboring well when the two

horizontal wells were placed closer to each other. Fig. 21 shows another full field model having exactly

the same size and fluid properties as the original full field model, but with different well location and

SPE-171519-MS

15

Figure 21Horizontal wells placed closer to each other to observe boundary effects, where each well acts as a no-flow boundary against the other.

Figure 22Comparison of pressure drawdowns for the two horizontal wells being placed closer to each other and the two horizontal wells in the

original full field model.

smaller well spacing. As a result, the two horizontal wells acted as no-flow boundaries against each other,

leading to an increase in the pressure drawdown at a constant flow rate (Fig. 22).

Stimulation of Vertical Wells

Sensitivity analysis of well stimulation was performed to investigate the well productivity/deliverability

enhancement upon stimulating the six vertical wells in the tight gas condensate reservoir. The possible

effect of well stimulation was modeled by a productivity index (PI) multiplier in the simulation. The

resulting cumulative gas production is shown in Fig. 23.

Well (acid) stimulation enhances the productivity index and reduces the pressure drawdown at constant

flow rate, thus reducing the condensate dropout effect in the tight reservoir. However, in this study, as

shown in Fig. 23, localized well stimulation does not have a major impact on the productivity of the

vertical wells, compared to the use of two horizontal wells. Well stimulation yields an incremental field

gas recovery of 600 MMscf compared to the unstimulated vertical wells. However, the two horizontal

wells produce 4.1 Bscf more gas than the six stimulated vertical wells.

Neither hydraulic fracturing nor well stimulation on horizontal wells was investigated in this project

due to time constraints. Further study would be recommended to evaluate these options.

Discussion

In this study, well deliverability impairment due to liquid dropout in gas condensate fields was successfully represented in compositional simulation models. A sensitivity study on gas condensate compositions

16

SPE-171519-MS

Figure 23Productivity index enhancement after well stimulation (left) and the comparison of field gas cumulative production volume in vertical and

horizontal wells (right).

(rich versus lean) has been conducted to understand production behavior for different fluid characteristics.

A richer gas condensate yields higher liquid dropout in the field than a leaner gas condensate. A sensitivity

study on reservoir permeability was also performed to investigate the effects of formation permeability

around the wellbore on gas recovery and liquid dropout. This study assumes a homogeneous reservoir. In

real life, gas condensate reservoirs are complex and highly heterogeneous, resulting in more complicated

near-well flow behavior. Sensitivity studies on gas condensate reservoir properties are essential to confirm

the best production method for individual cases.

Good operational decisions in managing the gas condensate field yield higher recovery efficiency. The

production options considered in this study were production rates, well configuration, and well stimulation. In this study, for a low-permeability gas condensate reservoir, six vertical wells have a slightly better

performance than two horizontal wells (well length 3,000 ft), with both producing at the same DCQ.

On the other hand, the performance of two horizontal wells in a tight gas condensate reservoir is superior

to that of the six vertical wells, obtaining 47% more gas recovery.

Well stimulation (e.g., acid treatment) enhances the productivity of the vertical wells and yields 6%

more gas recovery than the unstimulated vertical wells in the tight gas condensate reservoir. Hydraulic

fracturing was not investigated in this particular work and is recommended for further study. Hashemi and

Gringarten (2005) compared horizontal wells and hydraulically fractured wells in single-well models and

showed that these well configurations are comparable and can improve productivity and reduce pressure

drop. The final choice between a horizontal well and an equivalent vertical well with a fracture can only

be determined from economic evaluation.

In practice, particularly in a gas condensate reservoir where reservoir pressure is close to dewpoint

pressure, there are two extreme options for operating the field. The first is to allow for very quick

depletion to produce most of the gas and condensates out of the field within the next few years of

production, without considering the effect of liquid dropout. Then, shut in the well for pressure buildup

for some time and produce from the field again, assuming the resulting pressure buildup plateau is above

the dewpoint pressure and the condensate bank will revaporize. The second option is to produce the field

at a lower rate by limiting the pressure drawdown above the dewpoint pressure. The optimum operating

decision for a specific field is likely to be between these two extremes, and it will require more simulation

studies to determine the best operating rates.

SPE-171519-MS

17

Conclusions

The results of this study demonstrate the critical importance of liquid dropout effects in a gas condensate

field. The main conclusions are as follows:

1. Well productivity index impairment due to liquid dropout in a gas condensate field will be

overestimated if the compositional simulation model ignores the velocity-dependent relative

permeability effects in the immediate vicinity of the wellbore.

2. For gas condensate production below the dewpoint pressure, simulation studies can be used to

achieve a balance between the gas production rate and the pressure drawdown, to minimize

condensate dropout effect while at the same time producing at a reasonable rate from the field.

3. The optimum well configuration and selection of vertical or horizontal wells for a gas condensate

field depend on the type of reservoir (low permeability versus tight reservoirs).

4. Horizontal well length affects gas production in gas condensate fields. A longer horizontal well

can increase reservoir contact and enable operation at a higher bottomhole pressure, thus reducing

condensate dropout in fields operated below the dewpoint pressure.

5. Well stimulation enhances the productivity of the vertical wells in the tight gas condensate

reservoir; however, in this study it is not as effective when compared to the use of horizontal wells.

Recommendations for Further Study

For this study, reservoir models with fine grids near the wellbore were successful, and the simulation

models ran in reasonable timescale. For a bigger field, it may be necessary to use coarser grids

incorporating methods of upscaling such as the generalized pseudopressure model proposed by Fevang

and Whitson (1996).

This work focuses on operational decisions and reservoir management of gas condensate fields. For a

more comprehensive understanding of the options available for field development, the following additional studies should be considered:

1. More detailed analysis of the costs and economic benefits of using horizontal wells compared to

vertical wells.

2. A study of hydraulic fracturing effects, before and after the formation of condensate bank.

3. Investigation of the effects of acid stimulation and hydraulic fracturing for horizontal wells.

4. Investigation of gas cycling, which can be used to maintain reservoir pressure above the dewpoint

pressure while producing at a reasonably high rate, thus avoiding condensate dropout in the

reservoir.

5. Research into solvent injection treatment to mitigate condensate banking.

6. Studies on the impact of aquifer drive and water encroachment for a gas condensate field with

aquifer support.

Nomenclature

a, b, c, d

Non-Darcy coefficients (experimental)

dp/dL

Pressure drop along distance L

f

Interpolation factor

Subscript g Phase (gas)

k

Absolute permeability (md)

Horizontal permeability (md)

kh

Miscible relative permeability of phase p

krmp

Immiscible relative permeability of phase p

krp

Interpolated (velocity-dependent) relative permeability of phase p

krvp

18

kv

LH

mp, n1p, n2p

Ncbp

Ncnp

Ncp

p

Subscript p

Sp

Srp

Xp

SPE-171519-MS

Vertical permeability (md)

Horizontal well length (ft)

Dimensionless user-defined input parameters

Base capillary number for phase p

Normalized capillary number for phase p

Capillary number for phase p

Pressure (psia)

Phase (oil, gas)

Saturation of phase p

Residual saturation of phase p

Residual saturation multiplying factor for phase p

Forchheimers non-Darcy coefficient

Viscosity (cp)

Interstitial velocity in the reservoir (ft/d)

Density

Interfacial tension

Porosity

References

Ali, J.K., McGauley, P.J., and Wilson, C.J. 1997. The Effects of High-Velocity Flow and PVT

Changes Near the Wellbore on Condensate Well Performance. Paper SPE 38923 presented at the SPE

Annual Technical Conference and Exhibition, San Antonio, Texas, USA, 5 8 October.

Belhaj, H.A., Agha, K.R., Nouri, A.M. et alet al. 2003. Numerical Simulation of Non-Darcy Flow

Utilizing the New Forchheimers Diffusivity Equation. Paper SPE 81499 presented at the SPE Middle

East Oil Show & Conference, Bahrain, 5 8 April.

BP Energy Outlook 2035, January 2014, pp. 2350. http://www.bp.com/en/global/corporate/aboutbp/energy-economics/energy-outlook/outlook-to-2035.html. Accessed 11 July 2014.

Danesh, A., Khazam, M., Henderson, G.D. et alet al. 1994. Gas Condensate Recovery Studies. Paper

presented at the DTI Improved Oil Recovery and Research Dissemination Seminar, London, June.

Eilerts, C.K., Sumner, E.F. and Potts, N.L. 1965. Integration of Partial Differential Equation for

Transient Radial Flow of Gas-Condensate Fluids in Porous Structures. SPE J. 5(2) 141152. SPE 716-PA.

Evinger, H.H. and Muskat, M. 1942. Calculation of Theoretical Productivity Factor. Trans AIME

146(1) 126 139. SPE-942126-G.

Fetkovich, M.J. 1973. The Isochronal Testing of Oil Wells. Paper SPE 4529 presented at the Fall

Meeting of the Society of Petroleum Engineers of AIME, Las Vegas, Nevada, USA, 30 September-3

October.

Fevang, . and Whitson, C. H. 1995. Modeling Gas-Condensate Well Deliverability. Paper SPE

30714 presented at the SPE Annual Technical Conference and Exhibition, Dallas, Texas, USA, 2225

October.

Geertsma, J. 1974. Estimating the Coefficient of Inertial Resistance in Fluid Flow through Porous

Media. SPE J. 14(5): 445450. SPE 4706-PA.

Gondouin, M., Iffly, R. and Husson, J. 1967. An Attempt to Predict the Time Dependence of Well

Deliverability in Gas Condensate Fields. SPE J. 7(2): 113124. SPE 1478-PA.

Gringarten, A.C., Al-Lamki, A., Daungkaew, S. et alet al. 2000. Well Test Analysis in Gas Condensate

Reservoirs. Paper SPE 62920 presented at the SPE Annual Technical Conference and Exhibition, Dallas,

Texas, USA, 1-4 October.

SPE-171519-MS

19

Gringarten, A.C., Bozorgzadeh, M., Daungkaew, S. and Hashemi, A. 2006. Well Test Analysis in

Lean Gas Condensate Reservoirs: Theory and Practice. Paper SPE 100993 presented at the SPE Russian

Oil and Gas Technical Conference and Exhibition, Moscow, Russia, 3 6 October.

Harisch, R.A., Bachman, R.C., Puchyr, P.J. and Strashok, G.W. 2001. Evaluation of a Horizontal

Gas-Condensate Well Using Numerical Pressure Transient Analysis. Paper SPE 71588 presented at the

SPE Annual Technical Conference and Exhibition, New Orleans, Louisiana, USA, 30 September3

October.

Hashemi, A. and Gringarten, A.C. 2005. Comparison of Well Productivity Between Vertical, Horizontal and Hydraulically Fractured Wells in Gas-Condensate Reservoirs. Paper SPE 94178 presented at

the 2005 SPE Europec/EAGE Annual Conference, Madrid, Spain, 1316 June.

Henderson, G.D., Danesh, A., Tehrani, D.H. et alet al. 1995. Measurement and Correlation of Gas

Condensate Relative Permeability by the Steady-State Method. Paper SPE 30777 presented at the SPE

Annual Technical Conference and Exhibition, Dallas, Texas, USA, 2225 October.

Henderson, G.D., Danesh, A., Tehrani, D.H. and Al-Kharusi, B. 2000. The Relative Significance of

Positive Coupling and Inertial Effects on Gas Condensate Relative Permeabilities at High Velocity. Paper

SPE 62933 presented at the SPE Annual Technical Conference and Exhibition, Dallas, Texas, USA, 1 4

October.

Joshi, S.D. 1988. Production Forecasting Methods for Horizontal Wells. Paper SPE 17580 presented

at the SPE International Meeting on Petroleum Engineering, Tianjin, China, 1 4 November.

Keuengoua, C.D.S. and Amorin, R. 2011. Well Spacing for Horizontal Wells. Research Journal of

Applied Sciences, Engineering and Technology 3(6): 486 493.

Kniazeff, V.J. and Naville, S.A. 1965. Two Phase Flow of Volatile Hydrocarbons. SPE J. 5(1): 3744.

Li, D. and Engler, T.W. 2001. Literature Review on Correlations of the Non-Darcy Coefficient. Paper

SPE 70015 presented at the SPE Permian Basin Oil and Gas Recovery Conference, Midland, Texas, USA,

1516 May.

Mott, R. 2002. Engineering Calculations of Gas-Condensate Well Productivity. Paper SPE 77551

presented at the SPE Annual Technical Conference and Exhibition, San Antonio, Texas, USA, 29

September2 October.

Mott, R., Cable, A., and Spearing, M. 2000. Measurements and Simulation of Inertial and High

Capillary Number Flow Phenomena in Gas-Condensate Relative Permeability. Paper SPE 62932 presented at the SPE Annual Technical Conference and Exhibition, Dallas, Texas, USA, 1 4 October.

Muskat, M. 1949. Condensate Reservoirs. In Physical Principles of Oil Production, Chap. 13, pages

738 800. McGraw-Hill.

ODell, H.G. and Miller, R.N. 1967. Successfully Cycling a Low-Permeability, High-Yield Gas

Condensate Reservoir. J Pet Tech 19(1): 4147. SPE 1495.

Zheng, S.Y., Zhiyenkulov, M. and Yi, T.C. 2006. Productivity Evaluation of Hydraulically Fractured

Gas-Condensate Reservoirs. Journal of Petroleum Geoscience 12(3): 275283.

Das könnte Ihnen auch gefallen

- Chapter 4 Heat Teacher's GuideDokument34 SeitenChapter 4 Heat Teacher's GuideAhmad Zaidi100% (9)

- Spe 151797 MSDokument9 SeitenSpe 151797 MSkpratik41Noch keine Bewertungen

- (Open Physics) Analysis of Impact Load On Tubing and Shock Absorption During PerforatingDokument8 Seiten(Open Physics) Analysis of Impact Load On Tubing and Shock Absorption During Perforatingjlbarretoa100% (1)

- A New Method To Predict The Performance of Gas Condensate ReservoirDokument13 SeitenA New Method To Predict The Performance of Gas Condensate Reservoirswaala4realNoch keine Bewertungen

- Managed Pressure Drilling MPD BrochureDokument5 SeitenManaged Pressure Drilling MPD Brochureswaala4realNoch keine Bewertungen

- Hydrate Plug in Oil Dominated Systems by OLGADokument10 SeitenHydrate Plug in Oil Dominated Systems by OLGAmahmoodnazeriNoch keine Bewertungen

- Basic Well Logging - CHAPTER 3Dokument45 SeitenBasic Well Logging - CHAPTER 3WSG SARIRNoch keine Bewertungen

- Foaming in Fractionation ColumnsDokument7 SeitenFoaming in Fractionation ColumnsAnonymous v5uipH100% (1)

- Spe 138275 MS PDFDokument9 SeitenSpe 138275 MS PDFSergio SaenzNoch keine Bewertungen

- Exploring Liquids Unit TestDokument6 SeitenExploring Liquids Unit Testapi-265908930100% (1)

- Artificial Lift: Making Your Electrical Submersible Pumps Talk To YouDokument19 SeitenArtificial Lift: Making Your Electrical Submersible Pumps Talk To Youamramazon88Noch keine Bewertungen

- Tubing and Casing ConnectionsDokument2 SeitenTubing and Casing ConnectionsYougchu LuanNoch keine Bewertungen

- Low Salinity Thesis 2014 Behruz Shaker ShiranDokument134 SeitenLow Salinity Thesis 2014 Behruz Shaker ShiranPondok Huda100% (1)

- Mechanism of An Asphaltene Inhibitor PDFDokument50 SeitenMechanism of An Asphaltene Inhibitor PDFTEXOPED Parsian KishNoch keine Bewertungen

- SPE 163085 Successfully Controlling Unwanted Gas Production in A Highly Naturally Fractured Carbonate ReservoirDokument5 SeitenSPE 163085 Successfully Controlling Unwanted Gas Production in A Highly Naturally Fractured Carbonate ReservoirLeopold Roj DomNoch keine Bewertungen

- Modelling LSWFDokument13 SeitenModelling LSWFChun YanNoch keine Bewertungen

- A Project Report On: High Pressure-High Temperature (HPHT) ChallengesDokument33 SeitenA Project Report On: High Pressure-High Temperature (HPHT) Challengesgaurav guptaNoch keine Bewertungen

- Co2 Injection Wells.009Dokument11 SeitenCo2 Injection Wells.009Shio WenzanNoch keine Bewertungen

- SPE-185428-MS Optimizing Cost and Effectiveness of Well Interventions: An Holistic ApproachDokument17 SeitenSPE-185428-MS Optimizing Cost and Effectiveness of Well Interventions: An Holistic ApproachQaiser HafeezNoch keine Bewertungen

- Spe 80945 MSDokument10 SeitenSpe 80945 MSLuciano FucelloNoch keine Bewertungen

- Biochemistry TymockzcoDokument315 SeitenBiochemistry Tymockzcoswaala4realNoch keine Bewertungen

- Biochemistry TymockzcoDokument315 SeitenBiochemistry Tymockzcoswaala4realNoch keine Bewertungen

- Method Predicts Well Bore ScaleDokument8 SeitenMethod Predicts Well Bore ScaleAnonymous JJ29r2oCNoch keine Bewertungen

- Flow Assurance Study: Wolfgang Böser, Stefan BelfroidDokument13 SeitenFlow Assurance Study: Wolfgang Böser, Stefan BelfroidAhmed RamadanNoch keine Bewertungen

- Minimum Miscibility Pressure From EOS: T. AhmedDokument12 SeitenMinimum Miscibility Pressure From EOS: T. AhmedArie IrNoch keine Bewertungen

- Flow Units From Conventional To Tight Gas To Shale Gas To Tight Oil To Shale Oil ReservoirsDokument31 SeitenFlow Units From Conventional To Tight Gas To Shale Gas To Tight Oil To Shale Oil ReservoirsKyle PongNoch keine Bewertungen

- SPE-57390-Underbalance or Extreme OverbalanceDokument10 SeitenSPE-57390-Underbalance or Extreme Overbalancecv sabiraNoch keine Bewertungen

- Spe 191575 PaDokument14 SeitenSpe 191575 PaNavneet SinghNoch keine Bewertungen

- A Review of The Status of Foam Applications in Enhaced Oil RecoveryDokument15 SeitenA Review of The Status of Foam Applications in Enhaced Oil RecoveryRosales DidierNoch keine Bewertungen

- How Formation Characterisitics Affect Acid JobsDokument44 SeitenHow Formation Characterisitics Affect Acid JobsLenin DiazNoch keine Bewertungen

- SPE 167698 Imbibition and Water Blockage in Unconventional Reservoirs: Well Management Implications During Flowback and Early ProductionDokument13 SeitenSPE 167698 Imbibition and Water Blockage in Unconventional Reservoirs: Well Management Implications During Flowback and Early ProductionsouthliNoch keine Bewertungen

- Chapter 2-B Well Performance AnalysisDokument33 SeitenChapter 2-B Well Performance AnalysisT CNoch keine Bewertungen

- Hole Cleaning StuffDokument33 SeitenHole Cleaning StuffANoch keine Bewertungen

- SPE-19545-MS Predicting Wellbore TrajectoryDokument13 SeitenSPE-19545-MS Predicting Wellbore Trajectoryswaala4realNoch keine Bewertungen

- SPE-35698-PA Kuparuk Large Scale Enhanced Oil Recovery ProjectDokument10 SeitenSPE-35698-PA Kuparuk Large Scale Enhanced Oil Recovery ProjectGilbert Omitta100% (1)

- SPEDokument16 SeitenSPEPablo Tapia100% (1)

- Maintaining Injectivity of Disposal Wells: From Water Quality To Formation PermeabilityDokument2 SeitenMaintaining Injectivity of Disposal Wells: From Water Quality To Formation PermeabilityEggi Septi YuliantoNoch keine Bewertungen

- PDFDokument11 SeitenPDFizzyguyNoch keine Bewertungen

- SPE 40036 Economic Eval of Logs For ConformanceDokument11 SeitenSPE 40036 Economic Eval of Logs For ConformanceLeo Rojas Dom100% (1)

- Curtis H. WhitsonDokument18 SeitenCurtis H. WhitsonglsancorNoch keine Bewertungen

- Confined Fluid Phase Behavior and CO2 Sequestration in Shale ReservoirsVon EverandConfined Fluid Phase Behavior and CO2 Sequestration in Shale ReservoirsNoch keine Bewertungen

- Spe 49165 MSDokument16 SeitenSpe 49165 MSamramazon88Noch keine Bewertungen

- Matrix Acidizing Using HCL and Other AicdsDokument9 SeitenMatrix Acidizing Using HCL and Other AicdsRamanamurthy PalliNoch keine Bewertungen

- Spe 175892 PaDokument17 SeitenSpe 175892 PaSSNoch keine Bewertungen

- Gas Well Deliverability Fetkovich PDFDokument33 SeitenGas Well Deliverability Fetkovich PDFBarbara_LFCNoch keine Bewertungen

- Spe 59537Dokument14 SeitenSpe 59537cmkohNoch keine Bewertungen

- Production SubjectDokument19 SeitenProduction SubjectFiena AzmiNoch keine Bewertungen

- Formation DamageDokument39 SeitenFormation DamagerikaNoch keine Bewertungen

- SPE 183676 Production Optimization of High Temperature Liquid Hold Up Gas WellDokument12 SeitenSPE 183676 Production Optimization of High Temperature Liquid Hold Up Gas WellEdgar GonzalezNoch keine Bewertungen

- Pro Tech 1 CH 8Dokument31 SeitenPro Tech 1 CH 8weldsvNoch keine Bewertungen

- From The Laboratory To The Field: Successful Multistage Horizontal Fracturing Design and Implementation in Tight Sandstones in The Anadarko BasinDokument25 SeitenFrom The Laboratory To The Field: Successful Multistage Horizontal Fracturing Design and Implementation in Tight Sandstones in The Anadarko BasinErdal AYDINNoch keine Bewertungen

- New and Novel Fracture Stimulation Technologies For The Revitalization of Existing Gas Storage Wells: Interim Project ResultsDokument87 SeitenNew and Novel Fracture Stimulation Technologies For The Revitalization of Existing Gas Storage Wells: Interim Project ResultsPinkesh ShahNoch keine Bewertungen

- 22 - Relative Permeability Effects On The Miscible CO2 WAG Injection SchemesDokument9 Seiten22 - Relative Permeability Effects On The Miscible CO2 WAG Injection SchemesheviNoch keine Bewertungen

- Spe 184869 MSDokument16 SeitenSpe 184869 MSSS100% (1)

- Crossplots: Fig. 2 - Neutron-Density Crossplot Showing Where The Common Lithologies in Fig. 1 FallDokument4 SeitenCrossplots: Fig. 2 - Neutron-Density Crossplot Showing Where The Common Lithologies in Fig. 1 Fallyuanita prastyoNoch keine Bewertungen

- D 4180Dokument3 SeitenD 4180JGD123Noch keine Bewertungen

- Sand Control in CSG WellsDokument28 SeitenSand Control in CSG WellsAli Hussein Al-JumahNoch keine Bewertungen

- IPM Flow Chart TempDokument1 SeiteIPM Flow Chart TempAnonymous U5t9NYzhLWNoch keine Bewertungen

- SPE-160127-MS Kuparuk River Unit Field - The First 30 YearsDokument13 SeitenSPE-160127-MS Kuparuk River Unit Field - The First 30 YearsGilbert OmittaNoch keine Bewertungen

- Chap 3 Core DamageDokument31 SeitenChap 3 Core DamageDaniel ViloriaNoch keine Bewertungen

- Talisman Energy Capillary Pressure Saturation Permeability and NMR Malay Basin Example PDFDokument60 SeitenTalisman Energy Capillary Pressure Saturation Permeability and NMR Malay Basin Example PDFRiccardo SNoch keine Bewertungen

- Buckley, S.E. and Leverett, M.C. Mechanism of Fluid Displacement in SandsDokument10 SeitenBuckley, S.E. and Leverett, M.C. Mechanism of Fluid Displacement in SandsSolenti D'nouNoch keine Bewertungen

- Paper Heavy Oil SamplingDokument6 SeitenPaper Heavy Oil SamplingLatorreMNoch keine Bewertungen

- SPE 59464 Full Field Model Study of A Dense Highly Fractured Carbonate ReservoirDokument5 SeitenSPE 59464 Full Field Model Study of A Dense Highly Fractured Carbonate ReservoircmkohNoch keine Bewertungen

- Spe 39437 MSDokument14 SeitenSpe 39437 MSAndrés Bojacá MatizNoch keine Bewertungen

- Hydrocarbon Fluid Inclusions in Petroliferous BasinsVon EverandHydrocarbon Fluid Inclusions in Petroliferous BasinsNoch keine Bewertungen

- PPDM TrainingProgramGuide 2016 10 PDFDokument8 SeitenPPDM TrainingProgramGuide 2016 10 PDFswaala4realNoch keine Bewertungen

- Brainy: Effective Selection of Data StructuresDokument20 SeitenBrainy: Effective Selection of Data Structuresswaala4realNoch keine Bewertungen

- Spe 29363 MSDokument11 SeitenSpe 29363 MSswaala4realNoch keine Bewertungen

- SPE 0608 0079 JPT CT ApplicationsDokument3 SeitenSPE 0608 0079 JPT CT Applicationsswaala4realNoch keine Bewertungen

- Hole Cleaning Performance of Light-Weight Drilling Fluids During Horizontal Underbalanced DrillingDokument6 SeitenHole Cleaning Performance of Light-Weight Drilling Fluids During Horizontal Underbalanced Drillingswaala4realNoch keine Bewertungen

- SPE 87242 Underbalanced Drilling With Coiled TubingDokument6 SeitenSPE 87242 Underbalanced Drilling With Coiled Tubingswaala4realNoch keine Bewertungen

- Design and Evaluation of Acid Fracturing Treatments: by Kamel Ben-Naceur and Michael EconomidesDokument10 SeitenDesign and Evaluation of Acid Fracturing Treatments: by Kamel Ben-Naceur and Michael Economidesswaala4realNoch keine Bewertungen

- SPE 18885 On The Design of Fracture Acidizing TreatmentsDokument8 SeitenSPE 18885 On The Design of Fracture Acidizing Treatmentsswaala4realNoch keine Bewertungen

- Fluid Lecture 1 2017 PDFDokument88 SeitenFluid Lecture 1 2017 PDFThana AsradNoch keine Bewertungen

- FLUID I CH 1 Fluid Statics Tut 2 ADokument5 SeitenFLUID I CH 1 Fluid Statics Tut 2 ANaser KhalidNoch keine Bewertungen

- Rac Lab ManualDokument69 SeitenRac Lab ManualHrshita SinghNoch keine Bewertungen

- Aws4538z-Xg XGDokument2 SeitenAws4538z-Xg XGGiovani RodriguesNoch keine Bewertungen

- GEO 387 W4 Thermodynamics Dry MyDokument38 SeitenGEO 387 W4 Thermodynamics Dry MyLmaoNoch keine Bewertungen

- SHS Sy2021-2022 Q3law W1-2 General-Chemistry-ValidatedDokument8 SeitenSHS Sy2021-2022 Q3law W1-2 General-Chemistry-Validatedjohnrobertdeocampo84Noch keine Bewertungen

- Determination of Vapor PressureDokument5 SeitenDetermination of Vapor PressureAbhinav AnandNoch keine Bewertungen

- Feed Water Tanks PDFDokument4 SeitenFeed Water Tanks PDFAleksei SukhovNoch keine Bewertungen

- Quiz On Unit 3Dokument3 SeitenQuiz On Unit 3Er Amarsinh RNoch keine Bewertungen

- Line Designation Table - Pre-TreatmentDokument7 SeitenLine Designation Table - Pre-TreatmentNDTInstructorNoch keine Bewertungen

- Lecture 01c - QuestDistexDokument74 SeitenLecture 01c - QuestDistexsdsNoch keine Bewertungen

- Wetted Wall Column Experiment and Set UPDokument4 SeitenWetted Wall Column Experiment and Set UPvarun kumarNoch keine Bewertungen

- Project Module 4Dokument12 SeitenProject Module 4fishatsion09Noch keine Bewertungen

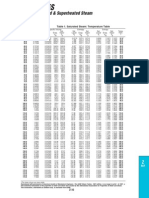

- Steam TablesDokument11 SeitenSteam TablesARNOUXNoch keine Bewertungen

- Experimental Investigation On Cascade Refrigeration System With and Without Phase Change MaterialDokument8 SeitenExperimental Investigation On Cascade Refrigeration System With and Without Phase Change MaterialijsretNoch keine Bewertungen

- Deposition (PVD and CVD)Dokument34 SeitenDeposition (PVD and CVD)Faraj HaiderNoch keine Bewertungen

- Pressure Build-Up in A Diesel Tank Exposed To Fire: C H E M I C A L E N G I N E E R I N GDokument6 SeitenPressure Build-Up in A Diesel Tank Exposed To Fire: C H E M I C A L E N G I N E E R I N GHenda PutraNoch keine Bewertungen

- U1L1Dokument19 SeitenU1L1tegnap16 tegnap1316Noch keine Bewertungen

- TheoryDokument3 SeitenTheoryAhmad SyamilNoch keine Bewertungen

- Major Losses: Due To Friction, Significant Head Loss Is Associated With The StraightDokument2 SeitenMajor Losses: Due To Friction, Significant Head Loss Is Associated With The StraightVarun ShastryNoch keine Bewertungen

- RefrgiratiobnDokument36 SeitenRefrgiratiobnfekadeNoch keine Bewertungen

- Ideal Gas LawDokument1 SeiteIdeal Gas LawLarry BugaringNoch keine Bewertungen

- Gas Laws Cheat SheetDokument1 SeiteGas Laws Cheat SheetWeljun GallardoNoch keine Bewertungen

- HANDOUT in PHYSICS - Heat, Specific Heat Phase Change, and CalorimetryDokument5 SeitenHANDOUT in PHYSICS - Heat, Specific Heat Phase Change, and CalorimetryJonathan Briones Mses MsphyNoch keine Bewertungen

- Mass BalanceDokument30 SeitenMass BalanceThe PieonicBritzNoch keine Bewertungen

- Worksheet-Sources of Water - Water Cycle - Where Is The Water StoredDokument2 SeitenWorksheet-Sources of Water - Water Cycle - Where Is The Water StoredEeshaalNoch keine Bewertungen

- Welding Report Sem3Dokument11 SeitenWelding Report Sem3hakimNoch keine Bewertungen