Beruflich Dokumente

Kultur Dokumente

Model-Based Multirate Controllers Design: Julián Salt and Pedro Albertos, Senior Member, IEEE

Hochgeladen von

Will VegaOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Model-Based Multirate Controllers Design: Julián Salt and Pedro Albertos, Senior Member, IEEE

Hochgeladen von

Will VegaCopyright:

Verfügbare Formate

988

IEEE TRANSACTIONS ON CONTROL SYSTEMS TECHNOLOGY, VOL. 13, NO. 6, NOVEMBER 2005

Model-Based Multirate Controllers Design

Julin Salt and Pedro Albertos, Senior Member, IEEE

AbstractIn many industrial control applications the control action updating can be faster than the output measurement, leading

to multirate controllers. In this paper, some dual rate operations

are used to model the controller as well as the controlled plant.

The controller design is model-based and depends on the input to

be tracked. The controller is split into two parts acting at different

sampling rates and its design is approached based on the characteristics of each available sampling rate. The control target is to reach

the similar performances to those the faster single rate controller

would achieve. Model-based cancellation controllers are designed

using this approach and promising results are obtained.

Index TermsDigital control, modeling, model-based control,

multirate sampled data systems, proportionalintegral derivative

(PID) control.

NOMENCLATURE

CT

DT

DRDT

DRZOH

FSDT

MR

SSDT

Polynomial in

as defined in (5).

Continuous time.

Discrete time.

Dual rate discrete time.

Dual rate zero order hold.

Fast sampling discrete time.

DT transfer function of a CT plant with sample and

hold devices at -period.

Dual rate operator (input

-expanded sequence

and output -sequence).

DT controller designed to match the -period DT

model

.

Multirate.

Closed-loop transfer function of the plant with

controller.

Slow sampling discrete time.

Staircase signal from

.

Expanded polynomial (9).

Output of a DR controlled system.

sequence.

Z-transform of

sequence.

output of a plant with

controller.

-sequence expanded from an

-one.

-sequence obtained from a -one.

-unit operator

.

Manuscript received March 25, 2004; revised December 3, 2004. Manuscript received in final form July 29, 2005. Recommended by Associate

Editor K. Schlacher. This work was supported by the Plan Nacional de I+D,

Comisin Interministerial de Ciencia y Tecnologa (CICyT) under Program

DPI2003-01964.

The authors are with the Department of Systems Engineering and Control Universidad Politcnica de Valencia, Valencia 46022, Spain (e-mail:

julian@isa.upv.es; pedro@isa.upv.es).

Digital Object Identifier 10.1109/TCST.2005.857410

I. INTRODUCTION

ATA acquisition systems in industrial control applications

have, in general, more time constraints than actuators

and, as a result, different rates are used for control updating

and output sampling. Some process variables are difficult to be

directly measured and the measurement process requires some

time, enlarging the sampling period. This can be, for instance,

the case of chemical analyzers or offline measurements devices

where the sample should be prepared beforehand requiring

some preparation time, like in cement or ceramics applications

[1]. Also in robotics and manufacturing systems where the

measurement is got through a visual feedback [2], the image

processing will require a lot of time. In other cases, although

it could be possible, it is not convenient to have so many measurements and the resources are used for other purposes. This

is the case of the reader/writer header positioning in hard disk

drives servo systems. In the modern embedded sector servo

technique, the position signal is only available at the sectors,

improving the traditional option where an area was dedicated

to store the servo position. This results in a larger storage

capability without increasing the number of servo sectors [3].

In distributed computer controlled systems, as reported in [4],

a number of control loops are sharing the same communication

channels, and some conflicts in the use of the common resource

may appear. In this case, if the measurement sampling period is

large enough all the measurements can be processed, the network

is not so busy and the control actions can be applied on time. This

approach has been also used in robotics applications [5].

It is well known that the performances of a digitally controlled

plant could be degraded as far as the sampling period increases,

[6]. Thus, instead of using the same lowest sampling rate for all

the variables in the process, the multirate (MR) approach tries

to reach the fast sampling rate control performances but using

the available data, that is, data sampled at different rates.

Since the 1950s [7], [8], several techniques have been proposed and used for the modeling and design of MR systems.

A common feature in these approaches is the representation

of the MR system by means of an equivalent single-rate linear

time-invariant model with a sampling period (frame period),

which is the least common multiple of all sampling periods in

the system, and which contains more inputs and outputs than

the original system (this is the so-called lifting [9], [10] representation of the MR system). Several authors [11], [12] have

shown that this representation preserves many of the properties

of the original MR system (reachability, observability, stability).

The original idea of the switch decomposition method by Kranc

[13] could be used for understanding this kind of techniques

and procedures. The first work about the modeling of MR systems based on the statespace representation was introduced by

Kalman and Bertram [14].

1063-6536/$20.00 2005 IEEE

Authorized licensed use limited to: IEEE Xplore. Downloaded on January 14, 2009 at 07:20 from IEEE Xplore. Restrictions apply.

SALT AND ALBERTOS: MODEL-BASED MULTIRATE CONTROLLERS DESIGN

But the main difficulty is the design of MR control algorithms. Many approaches have been reported in the literature

[15], [16]. One simple and direct approach is proposed in [17]:

Given a continuous time (CT) controller and a fast discrete time

(DT) controller obtained by discretization, a DT controller is redesigned by using a dual-rate hold device.

If a model of the process is available, some other alternatives are possible. Most of them are based on the feedback of

a computed output, which is estimated based on the process

model. There are many options to get the computed output, as

reviewed in [18]. Any time a measurement is available, the feedback signal could be the actual output, like in the inferential control, [19]. But, in a more general case, the computed output is

a function of both, the actual output, if it is available, and the

estimated output.

The approach in this paper is to design a two steps controller

with a slow part computing the control error anytime an actual

measurement is available, and generating, also using a model

of the process, a fast control updating to get results similar to

those achievable with a faster controller. This reduces the computing load to evaluate the complete control algorithm. Now a

slow part (remote control in a networked control system environment with shared medium) is assumed complementing a fast

one (local control). In the case of the classical inferential control techniques, just a local fast control based on some estimated

output (only slow measurement is known) is considered.

The paper is structured as follows. In the next section a

number of input/output DT models are reviewed. Then, the

control problem is properly defined. Different controller design

techniques, such as PID or cancellation are considered. In any

case, the use of cancellation controllers is part of the design,

raising the issue of robustness of the controlled plant. A number

of examples illustrate the results.

989

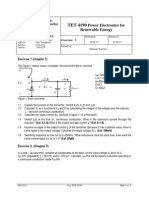

Fig. 1. Multirate system.

where the variable

represents the -unit delay operator. In a

similar way, if the sampling and updating periods were enlarged,

,

, the input and output

such that

sequences would have the following transforms:

(1b)

where the series on the right-hand side only present powers of

. Note that the physical meaning does not allow a

trivial substitution.

On these sequences, some operations can be defined, [20].

i) The expand (upsampling) operator creates a

-sequence, as follows:

from an

-sequence

(2a)

because a T-sequence

In this case it is correct to use

is actually obtained.

ii) The skip (downsampling) operator creates an

sequence from a -sequence, as follows:

II. MR SAMPLED-DATA MODELS

In order to deal with MR systems, some discrete-time

models attached to either an -order CT system represented

and the involved

by the strictly proper transfer function

variables are reviewed.

(2b)

The skip operation applied to the -transform of a signal can

be obtained using the expression (3), due to [21]:

A. Signals

From a CT signal, such as

in Fig. 1, a sequence of data

,

,

is represented by

.A

taken at rate

hold device

, operating at time periods , delivers a staircase signal

, from the input

. Ideally, a sequence, denoted by

, can be attached to the input of the hold device.

, the previous sequences are related to signal

For

values at the same time instant. Their -transforms can be expressed by

(3)

Some known [20] skip-expand properties usually considered

in this work are

(4a)

(4b)

(4c)

(1a)

that is, a) the skip operation does not commute, and b) the expand operation does. The third property is a clear rule with an

Authorized licensed use limited to: IEEE Xplore. Downloaded on January 14, 2009 at 07:20 from IEEE Xplore. Restrictions apply.

990

IEEE TRANSACTIONS ON CONTROL SYSTEMS TECHNOLOGY, VOL. 13, NO. 6, NOVEMBER 2005

easy proof that will be used in the following. If the signals considered in (1) were finite time signals, their Z-transforms will be

polynomials.

Assumption a) is required to avoid aliasing [15]. By assumption b), the notation is simplified.

The following useful relationship is easily derived:

B. Process

Assume the CT process in Fig. 1. For any pair of sequences

like those in (1), considered as process output and input, respectively, a DT transfer function of the process plus the hold device

can be written.

1) The fast sampling DT (FSDT) model is defined by

(5)

,

are polynomials in

. As previously

where

mentioned, following the notation in (1a), these polynomials

, realso represent finite sequences with -elements

, being

, and

. The

spectively, for

expand and skip operators, (2), can be also applied to polyno.

mials in

2) For the same process, a slow sampling DT (SSDT) model

can be similarly defined by

(6)

where

,

are polynomials in

and, math. A treatment similar to that expressed for

ematically, in

the skip and expand signal operations will be assumed for these

polynomials.

applied to a system is defined as the Z

The operator

transform of the -period discretized impulse response of that

system.

. That is

The FSDT transfer function poles are denoted by

(9)

that is

In the same way, for any polynomial

similar to (7),

, a transformation polynomial

can be

such that

defined.

The FSDT model may be also expressed by

(10)

where

.

, are distributed into

The parameters of the numerator,

groups of coefficients in such a way that the sum of each of

these groups leads to the slow single-rate numerator coefficient.

So, the SSDT model can be derived from the FSDT model, [22].

In the following, the arguments are omitted if their interpretation

is clear.

From (10), it yields (every variable expressed in )

(11)

If a skip operation is applied to the -time sequences, that is,

resampling, the result is

doing an

(12a)

(7)

whereas the SSDT poles are

where

is

, but expressed by means of the -varisamable. The physical meaning is the consideration of an

pler at the process output, that is, a slow output

, such that

(12b)

(8)

Note that, dealing with the same CT system,

.

Two very mild technical assumptions are taken.

a) If is a pole of

, then

,

, is not a pole of

.

b) All poles are different, i.e.,

;

In (12), the term

is indivisibleskip operation

does not commute (4a). This is clear and well known: It is not

possible to define a transfer function between a fast input and a

slow output.

3) Let us now consider the opposite situation: the transformation of a slow frequency DT sequence into a fast DT sequence.

The dual rate zero order hold (DRZOH) device is composed of

Authorized licensed use limited to: IEEE Xplore. Downloaded on January 14, 2009 at 07:20 from IEEE Xplore. Restrictions apply.

SALT AND ALBERTOS: MODEL-BASED MULTIRATE CONTROLLERS DESIGN

991

a slow rate ZOH, which input is such as

, followed by

. Altogether, it is represented by

a fast sampler delivering

(13)

where

. In this case, it is possible to obtain a

transfer function of the process plus the DRZOH device

(14)

because the expand operation commutes, (4b). Also, by using

(13)

(15)

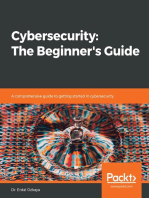

Fig. 2.

Basic MR control loop.

expand or up-sampling operation is needed in order to assure

the composition of two different frequency elements.

will be considered for

The CT fast sampled output

the purpose of the analysis. Let us first obtain some closed-loop

DRDT expressions of the controlled system.

Lemma 1: With the previous notation, the process output in

the MR controlled system, Fig. 2, is expressed by

Thus, a dual rate discrete time (DRDT) operator is defined

(18)

(16)

where

describes the transfer function from an exto a fast output

.

panded slow input

Using a similar notation, the DRZOH operation, (13), is rep.

resented by

Clearly, if the output is sampled with period

, it is obtained (see [22] for details)

Proof: For the system represented in Fig. 2, it is possible

to express

(19)

As the expand (upsampling) operation commutes, (4b), and

assuming some elementary block algebra considerations

(20)

(17)

that is, the SSDT model.

C. Closed-Loop MR controlled system

The basic MR control scheme assumed in this work is

shown in Fig. 2, where the plant is represented by a -order

single-inputsingle-output LTI CT system, with transfer func. The controller output is updated at a period

tion

through the fast hold device,

. The system output,

, is

, being represented by a fast sampler

measured at period

followed by an -sampler skip operation, and compared to

the reference

sampled at the slow rate,

. The MR

controller,

, processes the error. To simplify the computation, is assumed to be integer. The main issue now is how

to design the dual-rate controller. A nonconventional structure

composed by slow and fast parts is proposed; obviously an

Combining (20) and (19), (18) is obtained. Two remarks are

pertinent.

As previously said, the skip operation does not commute,

that is, although the fast transfer function

can be defined it is not possible to obtain a relation beand

.

tween

as part of a

It is necessary an expand operation

dual rate controller

.

Based on these models, the dual rate implementation of classical controllers is considered. The basic design approach is the

matching of the DRDT controlled plant behavior with that of

the FSDT controlled plant.

III. MULTIRATE CONTROLLER DESIGN

Given a CT process,

, the main goal is to design a

MR controller to obtain a closed-loop behavior as close as possible to that represented by the closed-loop transfer function

. In principle, to design a DT controller, two options can

Authorized licensed use limited to: IEEE Xplore. Downloaded on January 14, 2009 at 07:20 from IEEE Xplore. Restrictions apply.

992

IEEE TRANSACTIONS ON CONTROL SYSTEMS TECHNOLOGY, VOL. 13, NO. 6, NOVEMBER 2005

be followed: 1) To design a CT controller

to achieve

and discretize it, acthe closed-loop transfer function

cording to the sampling rate, for instance by using the ZOH DT

equivalent, or 2) To derive the DT controller to match the DT

closed-loop model, also with the corresponding sampling rate.

or

the DT

1) In the first case, let us denote by

, for sampling periods

or

,

equivalent of

respectively. The closed-loop controlled system transfer

function will be

part given by

part given by

and a fast

. That is

(22)

b) Moreover, if the skipped fast output

should be

the same that the slow single rate control-loop output

, then the parts of the controller should be

a fast part given by

or

(23a)

(21a)

a slow part given by

or

, the

None of them will match

, and thus, for

corresponding DT equivalents of

step reference changes, none of the output sequences will

match the CT response equivalent ones.

2) In this case, the single rate controllers will be

(23b)

a rate converter with the form

(23c)

or

(21b)

For a step reference change, the CT controlled system output

is denoted by

. Now, the controlled system discretized

output for step reference changes will coincide with the corresponding DT sequences taken from the initial CT system, i.e.,

;

. That is to say

(21c)

Our MR controller design goal is to achieve the fast controlled

system performances

based on the slow output measurement sequence. The MR controller is composed by three parts,

as depicted in Fig. 2. The low rate computed error is first proand passed through a rate concessed by the subcontroller

verter (upsampling block). The second and faster subcontroller,

, finally provides the control input to the plant. The result

can be expressed as follows.

, and

Main Result: Given a CT process

for the controlled system, assuming

a reference model

a control updating rate

, the output being sampled at rate

, Fig. 2, the following hold.

a) The output response of the dual rate controlled plant to the

, being

its -period discretized

reference input

representation, will match the fast single rate output response, if the dual-rate controller is composed of a slow

placed after the upsampling block.

Comments

1) For step changes in the reference, it achieves the same DT

response than the fast controller

does, but some ripple

could eventually appear.

,

2) To avoid the ripple, the fast part of the controller,

is changed by taking

as given by (21a) instead

, but the response does not match the FSDT

of

controlled plant response.

3) Similar results can be derived for other reference inputs

but the rate converter will be obviously different.

Proof:

a) Applying Lemma 1 and considering that

(24)

(25)

and identifying fast and expanded slow parts, we have:

the fast part

(26)

the expanded slow part

Authorized licensed use limited to: IEEE Xplore. Downloaded on January 14, 2009 at 07:20 from IEEE Xplore. Restrictions apply.

SALT AND ALBERTOS: MODEL-BASED MULTIRATE CONTROLLERS DESIGN

and without expand operator:

(27)

so, the main result a) is proved.

b) If the fast skipped output response and the slow single rate

loop output should match, that is

(28)

then,

(29)

it can be formulated that

993

units, as can be easily checked. A

introducing a delay of

similar approach can be followed for other kind of inputs.

Remark 1: The proposed approach is basically a digital direct design method. The main purpose is not the dual-rate digital

redesign of a continuous control loop. A cancellation controller

type has been introduced and some conditions (causality, stability, zero error regulation, etc.) similar to Ragazzini classical

method must be observed. In Section IV-B, some of them are

assumed.

Remark 2: The controller design depends on the considered

reference input, as it is the case in some other control design

approaches. Here, the rate converter is different for each kind

of input, as shown in (31). A general expression for the rate

converter (23c) can be derived for a generic polynomial input.

It is possible to introduce the use of interpolators.

Remark 3: If a real cancellation controller is designed, it

must be observed that in order to verify (28), that is the matching

between the slow skipped and fast output response, it is necessary that

(35)

(30)

and it is possible to express

(31)

hence, part b) has been proved.

Comment 1) is evident from the definitions of

,

,

.

To check 2), first realize that the fast controller, either (22)

or (23a), cancels the process dynamics, but the numerators of

and

are not the same. Thus, the intersampling

ripple could appear depending of

numerators roots,

[24]. If the fast controller is taken as

(32)

does not cancel the numerthe dual-rate controller

ator of the process transfer function, avoiding the ripple, but the

does not hold.

matching

With respect to comment 3), if the reference is a unitary step,

then

(33)

For a ramp input, that is

given by

, the rate converter (24) is

(34)

from

or simply

This could provide a way to obtain

to express a link condition between both rate transfer functions.

must be known or computed beforehand.

Evidently

Remark 4: In general, the stability margins of the DR controlled system are between those of the slow and fast single rate

discrete time schemes. Nevertheless, due to the cancellation features, the design strongly depends on the process model.

Remark 5: If the process is nonminimum phase, the cancellation of unstable pole-zero pairs must be avoided. Thus, the fast

part of the controller could be alternatively computed by (32). If

the slow part is maintained the output does not match the output

predicted by the closed loop transfer function. Nevertheless, if

is computed by using (35) the response will follow the

.

performance fixed by

Remark 6: The approach works for unstable processes, as

far as there is not pole cancellation in (22) and (23a). This is

avoided by using (32) instead.

Remark 7: The inputoutput stability of the designed controlled system is ensured because the output matches some given

references and the possible ripple can be avoided. On the other

hand, as any other control design approach based on (partial)

model cancellation, the robustness of the result should be analyzed. In general, [27], the system internal stability requires that

none of the four functions

the sensitivity (or output/output_disturbance transfer) function;

the control/reference transfer function;

the output/control_disturbance transfer

function;

the control/control_disturbance transfer

function;

should have unstable poles. In the MR setting, this is achieved

as far as the fast part of the controller is implemented by (32).

This result allows for a simple design of dual-rate controllers,

easy to be implemented. Also, the separation of the controller

Authorized licensed use limited to: IEEE Xplore. Downloaded on January 14, 2009 at 07:20 from IEEE Xplore. Restrictions apply.

994

IEEE TRANSACTIONS ON CONTROL SYSTEMS TECHNOLOGY, VOL. 13, NO. 6, NOVEMBER 2005

actions in different frequency ranges provides a more flexible

design. Currently this is a topic of our research activity.

As a conclusion, the following algorithm will concrete the

design approach.

MR Controller Design Algorithm

Given the model of the plant

,

the reference model of the controlled

, the reference input to be

plant

and

considered and the sampling

control updating

periods, design a

MR controller with three parts

a fast controller (23a);

a slow controller (23b);

a rate converter (23c);

using the discretized models of the

plant, the closed-loop controlled

plant and the reference.

If the plant is open-loop unstable,

nonminimum phase or some ripple appears due to the cancellations, some

additional computations should be carried out:

compute the CT cancellation

controller

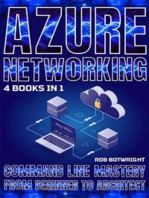

Fig. 3.

PID control.

Following the proposed design, the PID controlled plant

is assumed as the design target. In this

transfer function,

, adapts the process

case, the fast part of the MR controller,

dynamics in such a way that the new process can be controlled

.

by a slow DT part,

As an example, consider the process

An acceptable CT PID controller is given by

and discretize it to obtain

.

should be chosen such

Note that

that there are not unstable poles

cancellations in this controller;

proceed as before but substitute the

fast controller by (32).

for:

,

proximation for

,

, is given by

. A DT PID controller ap-

IV. APPLICATION DESIGNS

The proposed design approach can be used with different settings, always based on a desired closed-loop transfer function

model and some sort of cancellation. The main design option

is the selection of the closed-loop transfer function. It is well

known that ripple and hidden oscillation may occur if the selection is not appropriate. In the following, some options are

considered. In any case, this design methodology gives a rule of

thumb for other industrial controllers.

A. ProportionalIntegral Derivative (PID) Controlled Plants

For different sampling periods the controlled system response

is plotted in Fig. 3, becoming unstable for

s.

Assume that the output sampling period cannot be lower than

,

, is designed

0.3 s. A dual-rate controller, with

and implemented. The first solution is to implement a cancellation controller arranging a fast and a slow part given by (23):

Given a CT process

, a CT PID controller

is

designed. If a discretized PID is applied [24], the controlled

process dynamic performances are degraded if a slow sampling

period is chosen. Assume the DT behavior of the controlled

plant is acceptable for a sampling period , with the fast con, but too poor if it is taken as

,

. The question

troller

, is

in the MR setting is: if the input can be updated at rate

it possible to get similar performances if the output is measured

s?

any

The response matches the points of FSDT and SSDT controlled

system, as expressed by part b) of the main result, but the ripple

appears, as shown in Fig. 4, where is the discretized closed, corresponds to

and c is

loop response for

the multirate controlled plant step response.

Authorized licensed use limited to: IEEE Xplore. Downloaded on January 14, 2009 at 07:20 from IEEE Xplore. Restrictions apply.

SALT AND ALBERTOS: MODEL-BASED MULTIRATE CONTROLLERS DESIGN

995

B. Finite Settling Time Controller

In robotic applications, it would be very useful to achieve

model reference tracking with minimum time response, the control magnitude being bounded. If the process model is reliable

and robustness is not a critical issue, the cancellation controller

is the proper choice.

As is well known [25], the procedure for obtaining a finite

settling time behavior with prescribed steady-state requirements

leads to two diophantine equations

(36)

Fig. 4. Model-based multirate cancellation control.

being the order of the polynomial reference (for instance,

for step,

for ramp, ), where

and

are

polynomials to be determined. Note that, by this notation, the

polynomial (13) would be written as

.

To avoid the intersampling ripple, the last condition should

be expressed as

or, alternatively, taking into account (10)

(37)

which is easier to solve. Anyway, the solution of the proposed

equation system could require a sophisticated procedure, because there are discrete transfer functions at different periods.

An experimental example was developed on a portic robotics

environment. Assume a CT process model such as

Fig. 5. PID controlled plant.

To avoid the ripple, the fast part of the MR controller is computed as (32), that is

The excellent results are shown in Fig. 5, where the step responses for the PID controlled plant for a CT controller, the

and

s, as

single rate PID controllers for

well as the dual-rate model-based controlled plant are plotted

altogether. Using the perfect plant model, the initial part of the

dual rate controlled plant response follows that achieved by the

s. a new

fast rate controller. However, at time

measurement is taken and the response is improved.

Obviously, the full controller is much more complex than either of the two simply discretized single rate PID controllers. It

is also better than the slow rate cancellation controller design to

.

match the targeted discretized transfer function

It has been shown [26] that a single rate cancellation control,

with

s, introduces hidden oscillations.

A dual-rate controller to track a ramp, as usually required for

a robotic environment, is designed, according to (36).

The resulting controller with

,

, is given by the

following.

1) MT

As it can be seen in the output response, Fig. 6, some

hidden oscillations occur.

If the process numerator is included in the closed

loop dual rate model, following (37), a new controller is

designed.

2) FT

the response being ripple-free, as shown in Fig. 7.

Authorized licensed use limited to: IEEE Xplore. Downloaded on January 14, 2009 at 07:20 from IEEE Xplore. Restrictions apply.

996

IEEE TRANSACTIONS ON CONTROL SYSTEMS TECHNOLOGY, VOL. 13, NO. 6, NOVEMBER 2005

Fig. 6. Cancellation controller.

For instance in a shared medium distributed control environment, it is possible to have a central rough slow control and

best fast tuning after the information framepartial control actionhas traveled across the transmission medium.

The stability of the dual rate controlled plant can be assured

as the design is based on matching the reference responses obtained by the fast and slow rate predesigned (and stabilizing)

controllers.

Another relevant issue is the robustness against model uncertainty. This has not being used as a requirement in the design approach and will depend on how the desired closed loop transfer

function is defined. Anyway, the cancellation part of the controller will suffer from this internal disturbance.

By this approach it will be possible to extend the dual-rate

control design to a controller which is process-model independent by adjusting its fast and slow parts like a lag and lead phase

controllers, respectively.

Robustness of the design and frequency tuning of the controller, are currently issues under research.

V. CONCLUSION

Fig. 7. Ripple free MR control.

C. General Comments

In the proposed control design approach, the model of the

plant is assumed to be known, both in CT and the DT versions.

Thus, as previously stated, if the model of the plant is used for

implementing the controller, why not use the model to predict

the output? By means of an inferential control the fast model

can be used to estimate the intersample output, [19]. Of course,

this is an alternative approach leading, under ideal working conditions, to similar results. It depends very much on the specific

design to decide which result is better. However, if the computed

output is used, there is only one degree of freedom to design the

controller, just considering the faster sampling rate.

The new approach provides a better insight in the slow and

fast activities of the controller and it can be considered as a tool

to design a controller focusing on the requested frequency range.

Two different time scales have been considered with the consequent benefits in computational load and easy understanding.

Working under constraints in reducing the sampling rate of

the acquisition system, the design of MR controllers in order

to achieve with a slow output sampling the same performances

than a single rate fast sampling control system has been discussed. The main result is a simple design approach based on

the fast and slow controlled process behavior.

The controller implementation is straightforward, mainly for

stepwise references. It allows for a reduction in the measurement processing. It is also convenient in the case of slower sampling due to technical limitations and for distributed control systems, by splitting the control into a low frequency part to be sent

through the communication channel and a fast part to be locally

computed.

Different kinds of MR controllers with nonconventional

structure have been developed. Controllers designed to match

the PID controlled plant step response have been proposed,

with slight modifications to avoid the intersampling ripple.

Also, the finite time settling time design was revised and the

ripple is also cancelled.

Although the ideas behind the design are similar to those

used in the inferential control, the splitting of the controller into

two ranges of frequencies allows for a better understanding and

freedom in the design.

In any case, promising results are obtained when applied to

simple processes.

ACKNOWLEDGMENT

The authors would like to thank the Associate Editor and the

anonymous reviewers for their many helpful suggestions and

comments.

REFERENCES

[1] F. Morant, P. Albertos, and A. Crespo, Oxide composition control in

a raw material mill, in Proc. IFAC Symp. Microprocessor in Control,

Istambul, Turkey, 1986, pp. 127132.

Authorized licensed use limited to: IEEE Xplore. Downloaded on January 14, 2009 at 07:20 from IEEE Xplore. Restrictions apply.

SALT AND ALBERTOS: MODEL-BASED MULTIRATE CONTROLLERS DESIGN

[2] T. Tsao and S. Hutchinson, Multi-rate analysis and design of visual

feedback digital servo-control, J. Dyna. Syst. Measure. Control, vol.

116, no. 1, pp. 4555, 1994.

[3] S. Baek and S. Lee, Design of multi-rate estimator and its application

to a disk drive servo system, in Proc. Amer. Control Conf., San Diego,

CA, 1999, pp. 36403644.

[4] Y. Halevi and A. Ray, Integrated communication and control systems. Part Ianalysis, J. Dyna. Syst. Measure. Control, vol. 110, pp.

367373.

[5] A. Valera, J. Salt, V. Casanova, and S. Ferrus, Control of industrial

robot with a fieldbus, in Proc. IEEE Industry Applications Soc. Annu.

Meeting, Barcelona, Spain, 1999, pp. 12351241.

[6] P. Albertos and A. Crespo, Integrated design and implementation of

digital controllers, in In Lecture Notes in Computer Science CAST2001,

R. Moreno-Daz, B. Buchberger, and J. L. Freire, Eds. New York:

Springer-Verlag, 2001, pp. 385392.

[7] D. P. Glasson, Development anp application of multirate digital control

system, Control Syst. Mag., pp. 28, Nov. 1983.

[8] M. Araki, Recent development in digital control theory, in Proc. 12th

IFAC World Congr., vol. 9, 1993, pp. 951960.

[9] P. P. Khargonekar, K. Poola, and A. Tannenbaum, Robust control of

linear time-invariant plants using periodic compensation, IEEE Trans.

Autom. Control, vol. AC30, no. 11, pp. 10881096, Nov. 1985.

[10] B. Bamieh, J. B. Pearson, B. A. Francis, and A. Tannenbaum, A lifting

technique for linear periodic systems with applications to sampled-data

control, Syst. Control Lett., vol. 17, pp. 7988, 1991.

[11] S. Longhi, Structural properties of multirate sampled-data systems,

IEEE Trans. Autom. Control, vol. 39, no. 3, pp. 692696, Mar. 1994.

[12] D. G. Meyer, A new class of shift-varying operators, the shift-invariant

equivalents and multirate digital systems, IEEE Trans. Autom. Control,

vol. 35, no. 4, pp. 429433, Apr. 1990.

[13] G. M. Kranc, Input-output analysis of multirate feedback systems, IRE

Trans. Autom. Control, vol. 3, pp. 2128, 1957.

[14] R. E. Kalman and J. Bertram, A unified approach to the theory of sampling systems, J. Franklin Inst., vol. 267, pp. 405436, 1959.

[15] H. In and C. Zhang, A multirate digital controller for model matching,

Automatica, vol. 30, no. 6, pp. 10431050, 1994.

[16] D. Eckardt, Design of finite response controllers by pole assigment

in multirate sampled-data systems, Int. J. Control, vol. 49, no. 4, pp.

11851193, 1989.

[17] J. Tornero, Y. Gu, and M. Tomizuka, Analysis of multi-rate discrete

equivalent of continuous controller, in Proc. Amer. Control Conf., San

Diego, CA, 1999, pp. 27592763.

[18] P. Albertos, J. Sanchis, and A. Sala, Output prediction under scarce

data operation: Control applications, Automatica, vol. 35, no. 10, pp.

16711681, 1999.

[19] J. H. Lee and M. Morari, Robust inferential control of multi-rate sampled-data systems, Chem. Eng. Sci., vol. 47, no. 4, pp. 865885, 1992.

[20] T. C. Coffey and I. J. Williams, Stability analysis of multiloop, multirate

sampled systems, AIAA J. Guid. Control Dyna., no. 4, pp. 21782190,

1966.

[21] J. Sklansky and J. R. Ragazzini, Analysis of errors in sampled-data

feedback systems, AIEE Trans., pt. II, vol. 74, pp. 6571, 1955.

[22] P. Albertos and J. T. Salt, Dual rate adaptive control, Automatica, vol.

32, no. 7, pp. 10271030, 1996.

[23] P. T. Kabamba, Control of linear systems using generalized sample-data

hold functions, IEEE Trans. Autom. Control, vol. AC32, no. 9, pp.

772783, Sep. 1987.

[24] R. Isermann, Digital Control Systems. New York: Springer-Verlag,

1981.

997

[25] G. M. Kranc, Compensation of an error-sampled system by a multirate

controller, Trans. AIEE, pt. II, vol. 6, pp. 149155, 1957.

[26] R. Sanchis and P. Albertos, Design of ripple-free controllers, in Proc.

3rd Eur. Control Conf., Rome, Italy, 1995, pp. 36603664.

[27] P. Albertos and A. Sala, Multivariable Control Systems. An Engineering

Approach. New York: Springer-Verlag, 2004.

Julin Salt was born in Valencia, Spain, in 1960.

He received the M.Sc. degree in industrial engineering and the Ph.D. degree in control engineering

from Valencia Polytechnic University, Valencia,

Spain, in 1986 and 1992, respectively.

He is currently a Professor of Automatic Control,

Valencia Polytechnic University, teaching a wide

range of subjects in the area from continuous and

discrete simulation to automation and programmable

logic controllers applications. His research interests

include nonconventionally sampled control systems

and networked based control systems. He has taken part in research projects

funded by local industries, government and the European Science Foundation.

He has also been involved in educational projects and currently is Head of

the Systems Engineering and Control Department at UPV. He has been the

Director of eight Ph.D. dissertations and coauthor of about 60 technical papers

in journals and technical meetings.

Pedro Albertos (M81SM88) received the M.Sc.

degree in industrial engineering and the Ph.D. degree in control engineering from the Madrid Polytechnic University, Madrid, Spain, in 1968 and 1973,

respectively.

He has been a Professor in the Department of

Systems Engineering and Control, Polytechnic

University of Valencia, Valencia, Spain, since 1975.

He was the Director of the Department from 1979

to 1995, and in 1998. He has been teaching courses

on advanced control systems, intelligent control

systems and systems theory. He is an Honorary Professor at the Northwestern

University, Senhyang, China, and Doctor Honoris Causa at the Universities

of Oulu, Finland, and Polytechnic of Bucharest, Romania. He is an Invited

Professor at more than 20 Universities, all around the world, he has delivered

seminars at more than 30 universities and research centers. He has authored

more than 300 papers, book chapters, and congress communications, he is

a co-editor of seven books and coauthor of Multivariable Control Systems

(New York: Springer-Verlag, 2004). He has directed 16 Ph.D. dissertations

and is the Coordinator of the Ph.D. Program on Automatica and Industrial

Informatics, which has been implemented in Spain, Mexico, Columbia, and

Venezuela. He has participated in many national and international research

projects. Currently, he is involved in the ARTIST2 Node of Excellence on

Embedded Control Systems.

Dr. Albertos is an Associate Editor of Control Engineering Practice and Automatica and Editor-in-Chief of the Journal Revista RIAI (Revista Iberoamericana

de Automtica e Informtica Industrial). From 1999 to 2002, he was the IFAC

President.

Authorized licensed use limited to: IEEE Xplore. Downloaded on January 14, 2009 at 07:20 from IEEE Xplore. Restrictions apply.

Das könnte Ihnen auch gefallen

- Discrete-Time Control System Implementation Techniques: Advances in Theory and ApplicationsVon EverandDiscrete-Time Control System Implementation Techniques: Advances in Theory and ApplicationsNoch keine Bewertungen

- Introduction To Real-Time Control Using Labview With An Application To Distance LearningDokument18 SeitenIntroduction To Real-Time Control Using Labview With An Application To Distance LearningMarlon José Do CarmoNoch keine Bewertungen

- Digital Pid Controller Design For Delayed Multivariable SystemsDokument13 SeitenDigital Pid Controller Design For Delayed Multivariable SystemsssuthaaNoch keine Bewertungen

- Landau RSTDokument11 SeitenLandau RSTpbaculimaNoch keine Bewertungen

- Constraintoptimal Control For GyroscopeDokument7 SeitenConstraintoptimal Control For GyroscopeInternational Journal of Application or Innovation in Engineering & ManagementNoch keine Bewertungen

- A Simple Event-Based PID Controller: Årzén, Karl-ErikDokument7 SeitenA Simple Event-Based PID Controller: Årzén, Karl-ErikedroalNoch keine Bewertungen

- Lab 1Dokument7 SeitenLab 1MoapeNoch keine Bewertungen

- Modeling of A Queuing System Based On Cen Network in GPSS World Software EnvironmentDokument5 SeitenModeling of A Queuing System Based On Cen Network in GPSS World Software EnvironmentAlex HropatyiNoch keine Bewertungen

- Paper UksimDokument6 SeitenPaper Uksimsattanic666Noch keine Bewertungen

- Jurnal Proses ManufakturDokument6 SeitenJurnal Proses ManufakturNur RokhimNoch keine Bewertungen

- System Identification and Modeling For Interacting and Non-Interacting Tank Systems Using Intelligent TechniquesDokument15 SeitenSystem Identification and Modeling For Interacting and Non-Interacting Tank Systems Using Intelligent TechniquesMandy DiazNoch keine Bewertungen

- IMC Based Automatic Tuning Method For PID Controllers in A Smith Predictor ConfigurationDokument10 SeitenIMC Based Automatic Tuning Method For PID Controllers in A Smith Predictor ConfigurationAnonymous WkbmWCa8MNoch keine Bewertungen

- Identification of Longitudinal Aircraft Dynamics by Process Model Using Matlab/SimulinkDokument4 SeitenIdentification of Longitudinal Aircraft Dynamics by Process Model Using Matlab/SimulinkEditor IJSETNoch keine Bewertungen

- An Artificial Neural Network-Based Model Predictive Control For Three-Phase Flying Capacitor Multilevel Inverter (À Lire)Dokument12 SeitenAn Artificial Neural Network-Based Model Predictive Control For Three-Phase Flying Capacitor Multilevel Inverter (À Lire)maimouniahlamoNoch keine Bewertungen

- Digital Control Systems: Lecture NotesDokument61 SeitenDigital Control Systems: Lecture NotesHari Pavan0391Noch keine Bewertungen

- Weekly PP PDFDokument11 SeitenWeekly PP PDFDanielHaileNoch keine Bewertungen

- Design and Experimental Evaluation of A Time-Interleaved ADC Calibration Algorithm For Application in High-Speed Communication SystemsDokument12 SeitenDesign and Experimental Evaluation of A Time-Interleaved ADC Calibration Algorithm For Application in High-Speed Communication SystemsRahul ShandilyaNoch keine Bewertungen

- 146 562 1 PB PDFDokument5 Seiten146 562 1 PB PDFirqoviNoch keine Bewertungen

- Lastest Advancements in Process Control in RefineryDokument15 SeitenLastest Advancements in Process Control in Refinerydiazf2004Noch keine Bewertungen

- Simulation of UAV SystemsDokument5 SeitenSimulation of UAV SystemsZain Ul AabidinNoch keine Bewertungen

- Publication (P2) : On Computational Intelligence in Robotics and Automation (CIRA2005), EspooDokument7 SeitenPublication (P2) : On Computational Intelligence in Robotics and Automation (CIRA2005), Espoojosegarza92Noch keine Bewertungen

- Pipeline Architecture: C. V. RamamoorthyDokument42 SeitenPipeline Architecture: C. V. Ramamoorthykarunya.varmaNoch keine Bewertungen

- Chapter 2 Discrete Data Control SystemsDokument78 SeitenChapter 2 Discrete Data Control SystemsAmruth ThelkarNoch keine Bewertungen

- Fractional Order PID Controller Tuning Based On IMCDokument15 SeitenFractional Order PID Controller Tuning Based On IMCijitcajournalNoch keine Bewertungen

- Turbomachinery CFD On Parallel ComputersDokument20 SeitenTurbomachinery CFD On Parallel ComputersYoseth Jose Vasquez ParraNoch keine Bewertungen

- Stability Analysis of Digital Repetitive Control Systems Under Time-Varying Sampling PeriodDokument9 SeitenStability Analysis of Digital Repetitive Control Systems Under Time-Varying Sampling PeriodAyman IsmailNoch keine Bewertungen

- Optimization of Path Tracking RobotDokument5 SeitenOptimization of Path Tracking Robotsyclops3Noch keine Bewertungen

- O.dyer PIDDokument205 SeitenO.dyer PIDHemaNoch keine Bewertungen

- Imtc.1996.microcontroller-Based Measurement of Angular Position, Velocity and AccelerationDokument5 SeitenImtc.1996.microcontroller-Based Measurement of Angular Position, Velocity and AccelerationBorislavNoch keine Bewertungen

- Moving Horizon Model Based Control in The Presence of Feedback NoiseDokument3 SeitenMoving Horizon Model Based Control in The Presence of Feedback NoiseATSNoch keine Bewertungen

- Pipeline Architecture PDFDokument42 SeitenPipeline Architecture PDFChuang James100% (1)

- Discrete Event SimulationDokument140 SeitenDiscrete Event Simulationssfofo100% (1)

- Prediction of Critical Clearing Time Using Artificial Neural NetworkDokument5 SeitenPrediction of Critical Clearing Time Using Artificial Neural NetworkSaddam HussainNoch keine Bewertungen

- PIM Digital Redesign and Experiments of A Roll-Angle Controller For A VTOL-UAVDokument6 SeitenPIM Digital Redesign and Experiments of A Roll-Angle Controller For A VTOL-UAVYury PermiakovNoch keine Bewertungen

- Robo 1Dokument4 SeitenRobo 1Fernando PlazaNoch keine Bewertungen

- Scan Primitives For Vector ComputersDokument10 SeitenScan Primitives For Vector ComputersAnonymous RrGVQjNoch keine Bewertungen

- 255 - For Ubicc - 255Dokument6 Seiten255 - For Ubicc - 255Ubiquitous Computing and Communication JournalNoch keine Bewertungen

- Speed Control of A Real Time D.C. Shunt Motor Using SA Based Tuning of A PID ControllerDokument7 SeitenSpeed Control of A Real Time D.C. Shunt Motor Using SA Based Tuning of A PID Controllerprince1991kundraNoch keine Bewertungen

- Implementation of Induction Motor Drive Control Schemes in MATLAB/Simulink/dSPACE Environment For Educational PurposeDokument23 SeitenImplementation of Induction Motor Drive Control Schemes in MATLAB/Simulink/dSPACE Environment For Educational PurposeMos CraciunNoch keine Bewertungen

- DTC SVMDokument22 SeitenDTC SVMxeta123Noch keine Bewertungen

- Continuum Adapative ControlDokument14 SeitenContinuum Adapative Controlabdelhamid.ghoul93Noch keine Bewertungen

- Performance Assessment and Retuning of PID Controllers For Load Disturbance RejectionDokument6 SeitenPerformance Assessment and Retuning of PID Controllers For Load Disturbance RejectionAnonymous WkbmWCa8MNoch keine Bewertungen

- Jin 2013Dokument15 SeitenJin 2013Sidhant SharanNoch keine Bewertungen

- Sensors 15 12454 PDFDokument20 SeitenSensors 15 12454 PDFHussa 27Noch keine Bewertungen

- Controle Digital para Aviões Comparação Analógico Excelente Fala Também Sobre Monitoramento Texto TraduzidoDokument20 SeitenControle Digital para Aviões Comparação Analógico Excelente Fala Também Sobre Monitoramento Texto TraduzidoGardenia AndradeNoch keine Bewertungen

- PID Tuning For Improved Performance: Qing-Guo Wang, Tong-Heng Lee, Ho-Wang Fung, Qiang Bi, and Yu ZhangDokument9 SeitenPID Tuning For Improved Performance: Qing-Guo Wang, Tong-Heng Lee, Ho-Wang Fung, Qiang Bi, and Yu Zhangzub12345678Noch keine Bewertungen

- Closed Loop Time Domain For Smith Controller Using PI and Time Delay EstimationDokument56 SeitenClosed Loop Time Domain For Smith Controller Using PI and Time Delay Estimationashish88bhardwaj_314Noch keine Bewertungen

- Multicore & SimulinkDokument6 SeitenMulticore & SimulinkSalemHasnaouiNoch keine Bewertungen

- Paper 59-Marine Engine Room Alarm Monitoring SystemDokument9 SeitenPaper 59-Marine Engine Room Alarm Monitoring Systemthomas1313Noch keine Bewertungen

- Wind Turbine Condition Monitoring Based On SCADA Data Using Normal Behavior Models Part 1 System DescriptionDokument12 SeitenWind Turbine Condition Monitoring Based On SCADA Data Using Normal Behavior Models Part 1 System Descriptionbendiazz3430Noch keine Bewertungen

- Real-Time Aeroservoelastic Analysis of Wind-Turbines by Free Multibody SoftwareDokument18 SeitenReal-Time Aeroservoelastic Analysis of Wind-Turbines by Free Multibody SoftwareAbhishek PatilNoch keine Bewertungen

- Exact Tuning of PID ControllersDokument6 SeitenExact Tuning of PID Controllersmazaher karamiNoch keine Bewertungen

- 17 MPC - Distillation - Column PDFDokument15 Seiten17 MPC - Distillation - Column PDFneiljain421Noch keine Bewertungen

- Dead-Time Compensation and Model-Based Control: Wade04.book Page 291 Thursday, April 15, 2004 12:20 PMDokument20 SeitenDead-Time Compensation and Model-Based Control: Wade04.book Page 291 Thursday, April 15, 2004 12:20 PMsiamak001Noch keine Bewertungen

- Design of A Real-Time Inspection System For NDE of Reactor Vessels and Piping ComponentsDokument25 SeitenDesign of A Real-Time Inspection System For NDE of Reactor Vessels and Piping Componentsddaalayamoct313024Noch keine Bewertungen

- Effective Modeling and Simulation of Internal Combustion Engine Control SystemsDokument5 SeitenEffective Modeling and Simulation of Internal Combustion Engine Control SystemsShailesh JhaNoch keine Bewertungen

- Applications of Calculation Channel Function in Hybrid SimulationDokument11 SeitenApplications of Calculation Channel Function in Hybrid SimulationAlbaProyectoNoch keine Bewertungen

- Chapter 2 Discrete Data Control SystemsDokument70 SeitenChapter 2 Discrete Data Control SystemsAmruth Thelkar67% (3)

- Testing High-Performance Pipelined Circuits With Slow-Speed TestersDokument16 SeitenTesting High-Performance Pipelined Circuits With Slow-Speed Testersmingchiat88Noch keine Bewertungen

- Robust Fuzzy Fault Detection and Isolation Approach Applied To Surge in Centrifugal Compressor Modeling and ControlDokument25 SeitenRobust Fuzzy Fault Detection and Isolation Approach Applied To Surge in Centrifugal Compressor Modeling and Controlmehdipoor33Noch keine Bewertungen

- Milestone 5Dokument8 SeitenMilestone 5Koh Jiun HaoNoch keine Bewertungen

- Ficha Técnica Control de Alarmas y Dispositivos de EmergenciaDokument33 SeitenFicha Técnica Control de Alarmas y Dispositivos de EmergenciaLuis Garcia MartinezNoch keine Bewertungen

- Aviat E-Band Wireless Technology V1.0 PDFDokument11 SeitenAviat E-Band Wireless Technology V1.0 PDFtarreroNoch keine Bewertungen

- T2000 Data SheetDokument6 SeitenT2000 Data SheetRifaiNoch keine Bewertungen

- 4x1 MUXDokument6 Seiten4x1 MUXYash GuptaNoch keine Bewertungen

- Toshiba Small Form Factor Disk Drive White PaperDokument3 SeitenToshiba Small Form Factor Disk Drive White Papernjk19Noch keine Bewertungen

- PWM Signal GeneratorsDokument3 SeitenPWM Signal GeneratorsjalalhNoch keine Bewertungen

- Internet of Things: Jarrod Trevathan, PHD, Simon Schmidtke, Wayne Read, PHD, Tony Sharp, Abdul Sattar, PHDDokument18 SeitenInternet of Things: Jarrod Trevathan, PHD, Simon Schmidtke, Wayne Read, PHD, Tony Sharp, Abdul Sattar, PHDhighfive pologeeNoch keine Bewertungen

- A Low-Cost Extendable Framework For Embedded Smart Car Security SystemDokument17 SeitenA Low-Cost Extendable Framework For Embedded Smart Car Security Systemumaprakash111Noch keine Bewertungen

- FireNET Plus Install Manual V1.075 1127Dokument156 SeitenFireNET Plus Install Manual V1.075 1127Amada Barrera100% (1)

- Fiber Optics Connectors PDFDokument2 SeitenFiber Optics Connectors PDFJenniferNoch keine Bewertungen

- Sport & Fitness User Manual MultiDokument185 SeitenSport & Fitness User Manual MultibeoNoch keine Bewertungen

- Test Specification Number 5Dokument9 SeitenTest Specification Number 5tugba.yilmazNoch keine Bewertungen

- Thyristors, Triacs, DiacsDokument5 SeitenThyristors, Triacs, DiacsAnonymous n50GmJNoch keine Bewertungen

- Extinguishant Control Panel (SHC70002, SHC70003) Operation and Maintenance ManualDokument38 SeitenExtinguishant Control Panel (SHC70002, SHC70003) Operation and Maintenance ManualMersal AliraqiNoch keine Bewertungen

- Full Length Test - 60 Qs (60 Mins)Dokument6 SeitenFull Length Test - 60 Qs (60 Mins)Junaid MushtaqNoch keine Bewertungen

- Samsung MAX-DS750 PDFDokument38 SeitenSamsung MAX-DS750 PDFboroda2410100% (1)

- Hitachi - Energy - High K Dielectrics For SiC Power MOSFET TechnologyDokument8 SeitenHitachi - Energy - High K Dielectrics For SiC Power MOSFET TechnologyApe DieNoch keine Bewertungen

- Energies 12 01425 PDFDokument19 SeitenEnergies 12 01425 PDFArianit ZeqiriNoch keine Bewertungen

- FoEN Transient Analysis Color 1upDokument28 SeitenFoEN Transient Analysis Color 1upPruthvi NinganurNoch keine Bewertungen

- Sunpal 48V Lithium BatteryDokument2 SeitenSunpal 48V Lithium BatteryGeorge BillingNoch keine Bewertungen

- ETP48200-C5D1 V500R001 User Manual 01Dokument83 SeitenETP48200-C5D1 V500R001 User Manual 01Emre KayaNoch keine Bewertungen

- Westermo Ds md-45 PDFDokument2 SeitenWestermo Ds md-45 PDFPablo TeránNoch keine Bewertungen

- Mono 4Dokument193 SeitenMono 4Naveed ShoukatNoch keine Bewertungen

- CpuDokument14 SeitenCpuPranshu021Noch keine Bewertungen

- Fundamentals of Mixed Signals and SensorsDokument7 SeitenFundamentals of Mixed Signals and SensorsJayPeeJuradaNoch keine Bewertungen

- Spare Part List 7700 - SM - DOC2042197 - 1 PDFDokument139 SeitenSpare Part List 7700 - SM - DOC2042197 - 1 PDFd_abdosNoch keine Bewertungen

- Mst-1 Paper - BSC - Cs - II YearDokument2 SeitenMst-1 Paper - BSC - Cs - II YearPrabhat PandeyNoch keine Bewertungen

- BENZ Me97 Engine Programming-EnDokument15 SeitenBENZ Me97 Engine Programming-EnTaha NoamanNoch keine Bewertungen

- Exercise 3Dokument2 SeitenExercise 3Diogo Gonçalves OliveiraNoch keine Bewertungen

- Evaluation of Some Websites that Offer Virtual Phone Numbers for SMS Reception and Websites to Obtain Virtual Debit/Credit Cards for Online Accounts VerificationsVon EverandEvaluation of Some Websites that Offer Virtual Phone Numbers for SMS Reception and Websites to Obtain Virtual Debit/Credit Cards for Online Accounts VerificationsBewertung: 5 von 5 Sternen5/5 (1)

- Hacking: A Beginners Guide To Your First Computer Hack; Learn To Crack A Wireless Network, Basic Security Penetration Made Easy and Step By Step Kali LinuxVon EverandHacking: A Beginners Guide To Your First Computer Hack; Learn To Crack A Wireless Network, Basic Security Penetration Made Easy and Step By Step Kali LinuxBewertung: 4.5 von 5 Sternen4.5/5 (67)

- Cybersecurity: A Simple Beginner’s Guide to Cybersecurity, Computer Networks and Protecting Oneself from Hacking in the Form of Phishing, Malware, Ransomware, and Social EngineeringVon EverandCybersecurity: A Simple Beginner’s Guide to Cybersecurity, Computer Networks and Protecting Oneself from Hacking in the Form of Phishing, Malware, Ransomware, and Social EngineeringBewertung: 5 von 5 Sternen5/5 (40)

- Cybersecurity: The Beginner's Guide: A comprehensive guide to getting started in cybersecurityVon EverandCybersecurity: The Beginner's Guide: A comprehensive guide to getting started in cybersecurityBewertung: 5 von 5 Sternen5/5 (2)

- AWS Certified Solutions Architect Study Guide: Associate SAA-C02 ExamVon EverandAWS Certified Solutions Architect Study Guide: Associate SAA-C02 ExamNoch keine Bewertungen

- The Compete Ccna 200-301 Study Guide: Network Engineering EditionVon EverandThe Compete Ccna 200-301 Study Guide: Network Engineering EditionBewertung: 5 von 5 Sternen5/5 (4)

- Microsoft Azure Infrastructure Services for Architects: Designing Cloud SolutionsVon EverandMicrosoft Azure Infrastructure Services for Architects: Designing Cloud SolutionsNoch keine Bewertungen

- Microsoft Certified Azure Fundamentals Study Guide: Exam AZ-900Von EverandMicrosoft Certified Azure Fundamentals Study Guide: Exam AZ-900Noch keine Bewertungen

- Azure Networking: Command Line Mastery From Beginner To ArchitectVon EverandAzure Networking: Command Line Mastery From Beginner To ArchitectNoch keine Bewertungen

- ITIL® 4 Create, Deliver and Support (CDS): Your companion to the ITIL 4 Managing Professional CDS certificationVon EverandITIL® 4 Create, Deliver and Support (CDS): Your companion to the ITIL 4 Managing Professional CDS certificationBewertung: 5 von 5 Sternen5/5 (2)

- Palo Alto Networks: The Ultimate Guide To Quickly Pass All The Exams And Getting Certified. Real Practice Test With Detailed Screenshots, Answers And ExplanationsVon EverandPalo Alto Networks: The Ultimate Guide To Quickly Pass All The Exams And Getting Certified. Real Practice Test With Detailed Screenshots, Answers And ExplanationsNoch keine Bewertungen

- ITIL® 4 Create, Deliver and Support (CDS): Your companion to the ITIL 4 Managing Professional CDS certificationVon EverandITIL® 4 Create, Deliver and Support (CDS): Your companion to the ITIL 4 Managing Professional CDS certificationNoch keine Bewertungen

- Set Up Your Own IPsec VPN, OpenVPN and WireGuard Server: Build Your Own VPNVon EverandSet Up Your Own IPsec VPN, OpenVPN and WireGuard Server: Build Your Own VPNBewertung: 5 von 5 Sternen5/5 (1)

- Terraform for Developers: Essentials of Infrastructure Automation and ProvisioningVon EverandTerraform for Developers: Essentials of Infrastructure Automation and ProvisioningNoch keine Bewertungen

- Open Radio Access Network (O-RAN) Systems Architecture and DesignVon EverandOpen Radio Access Network (O-RAN) Systems Architecture and DesignNoch keine Bewertungen

- AWS Certified Cloud Practitioner Study Guide: CLF-C01 ExamVon EverandAWS Certified Cloud Practitioner Study Guide: CLF-C01 ExamBewertung: 5 von 5 Sternen5/5 (1)

- ITIL 4 : Drive Stakeholder Value: Reference and study guideVon EverandITIL 4 : Drive Stakeholder Value: Reference and study guideNoch keine Bewertungen