Beruflich Dokumente

Kultur Dokumente

CamryShiftFlare TSIB

Hochgeladen von

Vadim UrupaOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

CamryShiftFlare TSIB

Hochgeladen von

Vadim UrupaCopyright:

Verfügbare Formate

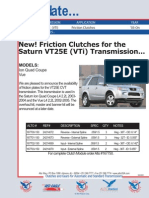

Technical Service

BULLETIN

3RD - 4TH GEAR SHIFT FLARE

Models:

07 Camry (V6)

August 2, 2006

TSB REVISION NOTICE:

S August 7, 2006: The OFP has been updated in Warranty Information. Applicable

Warranty has been changed from Comprehensive to Powertrain.

Previous versions of this TSB should be discarded.

Introduction

Some customers may experience a sharp increase in RPM between the 3rd to 4th

gear shift point during the first ten minutes of operation after a cold start. A revised

transmission valve body has been developed to address this concern.

NOTE:

This TSB ONLY applies to vehicles that have been confirmed to have the customer

concerns listed above.

Applicable

Vehicles

Parts

Information

Required

Tools &

Material

Warranty

Information

S 2007 model year Camry vehicles equipped with the V6 engine.

PREVIOUS

PART NUMBER

CURRENT

PART NUMBER

PART NAME

QTY

3541033170

Same

Body Assembly, Transmission Valve

9030127010

Same

Oring, Oil Strainer

3516833080

Same

Gasket, Transmission Oil Pan

0888602305

Same

ATF WS

3.4 qts (3.2 liters,

2.8 Imp. qts)

9043012008

Same

Gasket, Overflow Plug

TOOLS & MATERIAL

QUANTITY

Toyota Genuine Adhesive 1344, Three Bond 1344, or equivalent

As Needed

OP CODE

DESCRIPTION

ENGINE

TIME

OFP

369251

R & R Valve Body Assembly

2GRFE

2.2

3541033170

T1

T2

91 99

Applicable Warranty*:

This repair is covered under the Toyota Powertrain Warranty. This warranty is in

effect for 60 months or 60,000 miles, whichever occurs first, from the vehicles

in-service date.

* Warranty application is limited to correction of a problem based upon a customers specific complaint.

Toyota Supports ASE Certification

Page 1 of 6

TRANSMISSION & CLUTCH

TC008-06

Title:

3RD 4TH GEAR SHIFT FLARE TC008-06 Revised

Required

SSTs

ITEM

NO.

SPECIAL SERVICE TOOLS (SSTs)

August 2, 2006

PART NUMBER

QTY

DRW**

TOY220036

01002744

Toyota Diagnostic Tester Kit*

1

NOTE:

S All components from this kit/set are required.

S 12 Megabyte Diagnostic Tester Program Card

(P/N 01002593005) with version 13.3a Software

(or later) is required.

CAN Interface Module Kit*

NOTE:

S All components from this kit/set are required.

* Essential SSTs.

** Refers to drawer number in SST Storage System.

NOTE:

Additional Diagnostic Tester Kits, CAN Interface Modules, Program Cards, or other

SSTs may be ordered by calling SPX/OTC at 1-800-933-8335.

Repair

Procedure

1. Allow the vehicle to cold soak for a minimum of 4 hours.

2. Connect the Diagnostic Tester to DLC3.

3. Turn the engine switch ON.

4. Turn the Diagnostic Tester ON.

5. Enter the following menus on the tester:

DIAGNOSIS / OBDMOBD / ECT / DATA LIST.

6. Start the engine.

7. Monitor SHIFT position and ENGINE SPD while driving the vehicle with light throttle

application (under 40% throttle angle).

8. If shift flare is experienced when shifting from 3rd to 4th gear, remove and replace the

transmission valve body.

A. Remove the automatic transaxle

oil pan subassembly.

a. Remove the 18 bolts and oil

pan from the transaxle.

NOTE:

Some fluid will remain in the oil pan.

Remove all the pan bolts, and carefully

remove the oil pan assembly.

b. Remove the gasket from the

oil pan.

Page 2 of 6

3RD 4TH GEAR SHIFT FLARE TC008-06 Revised

Repair

Procedure

(Continued)

August 2, 2006

B. Remove the valve body oil

strainer assembly.

a. Remove the 2 bolts and oil

strainer from the valve body.

b. Remove the Oring from the

oil strainer.

ORing

C. Remove the transmission valve

body assembly.

Remove the 11 bolts and valve

body from the transaxle.

NOTE:

When removing the transmission

valve body assembly, be careful NOT

to allow the transmission revolution

sensor and the transaxle case to

interfere with each other.

D. Remove the manual valve from

the valve body.

E. Coat the manual valve with ATF

and install it into the NEW

valve body.

F. Install the transmission valve

body assembly.

a. Coat the Oring of the

transmission wire with ATF.

Page 3 of 6

3RD 4TH GEAR SHIFT FLARE TC008-06 Revised

Repair

Procedure

(Continued)

b. Confirm that the manual valve

lever is positioned as shown in

the illustration and install the

valve body assembly to the

transaxle case with the

11 bolts.

August 2, 2006

Torque: 11 NSm

(112 kgfScm, 8 ftSlbf)

Bolt length:

Bolt

Bolt

Bolt

Bolt

Bolt

A:

B:

C:

D:

E:

25 mm (0.98 in.)

30 mm (1.18 in.)

35 mm (1.38 in.)

45 mm (1.77 in.)

55 mm (2.17 in.)

*1

*1

B

E

B

NOTE:

S First, temporarily tighten the bolts

marked by (*1) in the illustration

because they are positioning bolts.

S When installing the transmission

valve body assembly, be careful NOT

to allow the transmission revolution

sensor and transaxle case to

interfere with each other.

S Be sure to insert the pin of the

manual valve lever into the groove

on the end of the manual valve.

G. Install the valve body oil

strainer assembly.

a. Coat a NEW Oring with ATF

and install it to the oil strainer.

NOTE:

Ensure that the Oring is NOT twisted

or pinched.

Page 4 of 6

ORing

3RD 4TH GEAR SHIFT FLARE TC008-06 Revised

Repair

Procedure

(Continued)

August 2, 2006

b. Install the oil strainer to the

valve body with the 2 bolts.

Torque: 11 NSm

(112 kgfScm, 8 ftSlbf)

H. Install the automatic transaxle oil

pan subassembly.

Magnet

a. Confirm the position of the

2 magnets in the oil pan.

b. Install a NEW gasket to the

oil pan.

c. Apply adhesive to the

18 bolts.

Adhesive:

Toyota Genuine Adhesive 1344,

Three Bond 1344, or equivalent

d. Install the oil pan to the

automatic transaxle with the

18 bolts.

Torque: 7.5 NSm

(76 kgfScm, 66 in.Slbf)

NOTE:

S In order to ensure proper sealing of

the transmission oil pan bolts,

apply adhesive to the bolts and

install them within 10 minutes of

adhesive application.

S Completely remove any oil or

grease from the contact surface of

the transaxle case and oil pan

subassembly with the gasket

before installation.

I.

Fill transaxle with automatic transaxle fluid.

Automatic Transaxle Fluid: Genuine ATF WS Transmission Fluid

Refer to the Technical Information System (TIS), 2007 model year Camry Repair

Manual: U660E Automatic Transaxle: Automatic Transaxle Assembly: Installation.

Page 5 of 6

3RD 4TH GEAR SHIFT FLARE TC008-06 Revised

Repair

Procedure

(Continued)

August 2, 2006

9. After replacement of the transmission valve body:

A. Connect the Diagnostic Tester to DLC3.

B. Turn the engine switch ON and turn the Diagnostic Tester ON.

C. Enter the following menus on the tester:

DIAGNOSIS / OBDMOBD / ECT / AT CODE UTILITY.

D. Select AT CODE RESET on the tester.

E. Press ENTER.

10. Perform a road test to allow the TCM to learn.

NOTE:

Perform the following procedures while strictly observing all traffic laws and

speed limits.

A. Warm up the engine.

B. From a standstill, achieve the highest possible speed with the accelerator pedal

opened 15% or less. Keep the accelerator pedal angle steady while driving

the vehicle.

C. Repeat the previous step until shift shock no longer occurs.

D. From a standstill, achieve the highest possible speed with the accelerator pedal

opened 25% or more. Keep the accelerator pedal angle steady while driving

the vehicle.

E. Repeat the previous step until shift shock no longer occurs.

NOTE:

If valve body replacement does NOT correct the condition, continue diagnosis

following the Repair Manual Problem Symptoms Table. If necessary, contact Technical

Assistance for further support.

Page 6 of 6

Das könnte Ihnen auch gefallen

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceVon EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNoch keine Bewertungen

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementVon EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNoch keine Bewertungen

- A960e VB BreakdownDokument15 SeitenA960e VB BreakdownDavid Chalker0% (2)

- On-Vehicle InspectionDokument5 SeitenOn-Vehicle InspectionEdson CRNoch keine Bewertungen

- Compressor WabcoDokument6 SeitenCompressor Wabcoruben_cruz_34Noch keine Bewertungen

- M.I.L. On DTC p1349 - Vvti Actuator T-Eg007-03Dokument3 SeitenM.I.L. On DTC p1349 - Vvti Actuator T-Eg007-03asdref100% (1)

- Engine Mechanical PDFDokument115 SeitenEngine Mechanical PDFAndrey GladyshevNoch keine Bewertungen

- Hyundai AT ErrorDokument10 SeitenHyundai AT ErrorPerminov SergeyNoch keine Bewertungen

- Engine Identification: 1998-2000 ENGINES 3.0L V6 1998-2000 ENGINES 3.0L V6Dokument49 SeitenEngine Identification: 1998-2000 ENGINES 3.0L V6 1998-2000 ENGINES 3.0L V6Rafael Enrique Grijalva GarciaNoch keine Bewertungen

- 1986 Landcruiser Maintenance ProceduresDokument40 Seiten1986 Landcruiser Maintenance ProceduresnapobNoch keine Bewertungen

- B&M Transpak Kit TH700Dokument14 SeitenB&M Transpak Kit TH700Ghostrider1100% (1)

- Holden VT 2000 Service TechlinesDokument177 SeitenHolden VT 2000 Service Techlinescosky071% (7)

- February 9, 2009 S-B-18.00/40a S-B-18.00/40 Dated October 28, 2008 18Dokument9 SeitenFebruary 9, 2009 S-B-18.00/40a S-B-18.00/40 Dated October 28, 2008 18kevin gradinNoch keine Bewertungen

- 4756 Civic 96-2000 D16y8 Performer XDokument3 Seiten4756 Civic 96-2000 D16y8 Performer XRafael Isaac Lòpez Vargas100% (1)

- 11 - FuelDokument33 Seiten11 - FuelJen-Yung ChangNoch keine Bewertungen

- Engine IdentificationDokument47 SeitenEngine Identificationgerber damianNoch keine Bewertungen

- Banks SidewinderDokument20 SeitenBanks Sidewinderpino2234Noch keine Bewertungen

- NissanDokument7 SeitenNissanTun Tun Win KseNoch keine Bewertungen

- Yamaha BR250 Bravo Snowmobile Service ManualDokument191 SeitenYamaha BR250 Bravo Snowmobile Service ManualSmedlowNoch keine Bewertungen

- XJS 3.6 Service EngineDokument192 SeitenXJS 3.6 Service Enginessinokrot100% (1)

- 2GR-FSE - Engine - On Vehicle InspectionDokument8 Seiten2GR-FSE - Engine - On Vehicle InspectionJohn Locke0% (1)

- Article Beginning: 2.4L 4-CYL Article TextDokument65 SeitenArticle Beginning: 2.4L 4-CYL Article TextEdU RECTIFICANoch keine Bewertungen

- TSB 2100306Dokument13 SeitenTSB 2100306ossoskiNoch keine Bewertungen

- Hyundai Exel 89 1.5l.mantenimientoDokument18 SeitenHyundai Exel 89 1.5l.mantenimientoAlexander cesar neyra sotoNoch keine Bewertungen

- 2az Fe Engine Mechanical-1Dokument290 Seiten2az Fe Engine Mechanical-1Diego Falconi100% (2)

- Mitsubishi-Lancer 2008 EN Manual de Taller Service Sistema de Enfriamiento 2bb88f178fDokument1 SeiteMitsubishi-Lancer 2008 EN Manual de Taller Service Sistema de Enfriamiento 2bb88f178fMAXI666418Noch keine Bewertungen

- Corolla CVT T-SB-0150-16Dokument12 SeitenCorolla CVT T-SB-0150-16ossoski100% (3)

- Pole Position 14 VKMC 01250 1 EN Highres PDFDokument6 SeitenPole Position 14 VKMC 01250 1 EN Highres PDFRita PcomputerNoch keine Bewertungen

- GM 6t70 UpdatesDokument45 SeitenGM 6t70 UpdatesThePokeOne100% (9)

- D - Adjustments: 1991 Mitsubishi MonteroDokument10 SeitenD - Adjustments: 1991 Mitsubishi MonteronadaNoch keine Bewertungen

- Yamaha DS7 (72) RD250 (73) R5C (72) RD350Dokument113 SeitenYamaha DS7 (72) RD250 (73) R5C (72) RD350Igor Majksner100% (5)

- Rcrit 14V647 9581Dokument43 SeitenRcrit 14V647 9581Eko PurwantoNoch keine Bewertungen

- Eaton Clutch Service Bulletin Clib0035Dokument8 SeitenEaton Clutch Service Bulletin Clib0035Levarda Bogdan100% (1)

- 1995 Toyota T100 DX 1 TON 2.7L 3RZ-FE PDFDokument60 Seiten1995 Toyota T100 DX 1 TON 2.7L 3RZ-FE PDFManuel TerrazaNoch keine Bewertungen

- 41TE Accumulator PositionDokument10 Seiten41TE Accumulator PositionLula MarquesNoch keine Bewertungen

- 7.5L EngineDokument32 Seiten7.5L EngineSalvador Gasca100% (1)

- 06T Semihermetic Screw CompressorDokument8 Seiten06T Semihermetic Screw CompressorAbu Malak CiprianoNoch keine Bewertungen

- Tribute S Sport 2008Dokument219 SeitenTribute S Sport 2008AlirioNoch keine Bewertungen

- John Deere PowerTech 10.5L Diesel Engines Level 6 Electronic Fuel Systems With Lucas EUIs Service Repair Manual (CTM188)Dokument17 SeitenJohn Deere PowerTech 10.5L Diesel Engines Level 6 Electronic Fuel Systems With Lucas EUIs Service Repair Manual (CTM188)laopaodunNoch keine Bewertungen

- TCM InjectorSID05 7Dokument7 SeitenTCM InjectorSID05 7leather_nunNoch keine Bewertungen

- Spark T4 Engine1 (0-30)Dokument31 SeitenSpark T4 Engine1 (0-30)Çàřļōş Ǡǹȡȓȇș Preciado100% (1)

- 2GR-FE Engine MechanicalDokument156 Seiten2GR-FE Engine MechanicalLuks Fernandez100% (7)

- 3007a Je0m f9q Special FeaturesDokument101 Seiten3007a Je0m f9q Special FeaturesAdam JohnsonNoch keine Bewertungen

- AFC Sensor de Presion PDFDokument10 SeitenAFC Sensor de Presion PDFCharlie BrownNoch keine Bewertungen

- 2.0l 4 Cyl Nissan b13Dokument52 Seiten2.0l 4 Cyl Nissan b1325912530Noch keine Bewertungen

- Engine Identification: Removal (Carbureted Models)Dokument18 SeitenEngine Identification: Removal (Carbureted Models)(Obr-Bto) Francisco Antonio Lizardo SalasNoch keine Bewertungen

- 1NZ-FXE Engine Mechanical On Toyota PriusDokument160 Seiten1NZ-FXE Engine Mechanical On Toyota PriusOana Molocea100% (2)

- 78 Dt400e DT250E ManualDokument18 Seiten78 Dt400e DT250E Manualdisgustipate0% (1)

- 1991 Ford Technical Service BulletinsDokument147 Seiten1991 Ford Technical Service Bulletinsalexander pintoNoch keine Bewertungen

- ZFDokument3 SeitenZFMohammed MochrifNoch keine Bewertungen

- Syskey 1234172&from SMDokument20 SeitenSyskey 1234172&from SMHeber G. La RosaNoch keine Bewertungen

- Subaru - Impreza - Workshop Manual - 1999 - 2002Dokument8.373 SeitenSubaru - Impreza - Workshop Manual - 1999 - 2002bart3omiej3boguszewiNoch keine Bewertungen

- NTB15 037dDokument36 SeitenNTB15 037dALVARO ALATORRE ANoch keine Bewertungen

- Automatic Transmission - TransDokument145 SeitenAutomatic Transmission - TransJoel R. ChanNoch keine Bewertungen

- Technical Service BulletinDokument8 SeitenTechnical Service Bulletinfishhunter18Noch keine Bewertungen

- 4runner Limited 2009 2UZ FEDokument314 Seiten4runner Limited 2009 2UZ FEarmotrixmecNoch keine Bewertungen

- A/T - No Reverse/3rd or 5th Gear/MIL ON/DTC P0776Dokument6 SeitenA/T - No Reverse/3rd or 5th Gear/MIL ON/DTC P0776Carlos CuellarNoch keine Bewertungen

- 350z Procharger Install ManualDokument52 Seiten350z Procharger Install Manualr3belzNoch keine Bewertungen

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitVon EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNoch keine Bewertungen

- VW Volkswagen Transporter T4 [ Powered By 1.8, 2.4 & 2.9 Diesel engines ]: Workshop Manual Diesel Models Years 2000-2004Von EverandVW Volkswagen Transporter T4 [ Powered By 1.8, 2.4 & 2.9 Diesel engines ]: Workshop Manual Diesel Models Years 2000-2004Bewertung: 3 von 5 Sternen3/5 (1)

- R4A51Dokument1 SeiteR4A51Vadim Urupa0% (1)

- 5HP24Dokument4 Seiten5HP24Vadim UrupaNoch keine Bewertungen

- F 4 A 45Dokument18 SeitenF 4 A 45Vadim UrupaNoch keine Bewertungen

- Lepelletier GearsetDokument18 SeitenLepelletier GearsetVadim UrupaNoch keine Bewertungen

- Aw 5550 VBDokument4 SeitenAw 5550 VBVadim Urupa0% (1)

- Honda SwraDokument3 SeitenHonda SwraVadim Urupa100% (5)

- VT 25Dokument1 SeiteVT 25Vadim UrupaNoch keine Bewertungen

- TB NV 235Dokument2 SeitenTB NV 235Vadim UrupaNoch keine Bewertungen

- MechaDokument6 SeitenMechaVadim UrupaNoch keine Bewertungen

- 1Dokument4 Seiten1Bodhayan PrasadNoch keine Bewertungen

- ATC700 (BMW X5 2007-Up BMW X6 2007-Up) : Revision 10/2011Dokument2 SeitenATC700 (BMW X5 2007-Up BMW X6 2007-Up) : Revision 10/2011Vadim UrupaNoch keine Bewertungen

- ZF 6 HP 19Dokument5 SeitenZF 6 HP 19Vadim UrupaNoch keine Bewertungen

- ATC300 (BMW 3 Series 2000-On) : Full Time AWD Gear Driven (No Chain)Dokument2 SeitenATC300 (BMW 3 Series 2000-On) : Full Time AWD Gear Driven (No Chain)Vadim UrupaNoch keine Bewertungen

- Chrysler Specific Diagnostic Trouble CodesDokument8 SeitenChrysler Specific Diagnostic Trouble CodesVadim UrupaNoch keine Bewertungen

- BMW Instrument Cluster LanguageDokument2 SeitenBMW Instrument Cluster LanguageVadim UrupaNoch keine Bewertungen

- CVTFluid Application ChartDokument1 SeiteCVTFluid Application ChartNiculae AlexandruNoch keine Bewertungen

- TF-80 Af-40 6 SpeedDokument53 SeitenTF-80 Af-40 6 Speedsanya7289% (37)

- Adaptation BMWDokument3 SeitenAdaptation BMWVadim UrupaNoch keine Bewertungen

- Cleaning of Contact Points and Wiring HarnessesDokument3 SeitenCleaning of Contact Points and Wiring HarnessesRafa Montes MOralesNoch keine Bewertungen

- Datasheet MEC MPS200 v1 2018Dokument4 SeitenDatasheet MEC MPS200 v1 2018Cepi Sindang KamulanNoch keine Bewertungen

- AGIP STD - Valves Specification SheetDokument1 SeiteAGIP STD - Valves Specification Sheethalim_kaNoch keine Bewertungen

- Unknown Facts About Physicians Email List - AverickMediaDokument13 SeitenUnknown Facts About Physicians Email List - AverickMediaJames AndersonNoch keine Bewertungen

- DR Hoon Park III - Indigenous Microorganism (IMO)Dokument33 SeitenDR Hoon Park III - Indigenous Microorganism (IMO)neofrieda79100% (1)

- INTP Parents - 16personalitiesDokument4 SeitenINTP Parents - 16personalitiescelinelbNoch keine Bewertungen

- Plumbing Breakup M 01Dokument29 SeitenPlumbing Breakup M 01Nicholas SmithNoch keine Bewertungen

- Aromatic Electrophilic SubstitutionDokument71 SeitenAromatic Electrophilic SubstitutionsridharancNoch keine Bewertungen

- User Manual: 3603807 CONTACT US - 09501447202,8070690001Dokument1 SeiteUser Manual: 3603807 CONTACT US - 09501447202,8070690001Arokiaraj RajNoch keine Bewertungen

- Missoula County Fairgrounds Phase 2Dokument10 SeitenMissoula County Fairgrounds Phase 2Olivia IversonNoch keine Bewertungen

- Dissertation Topics Forensic BiologyDokument7 SeitenDissertation Topics Forensic BiologyHelpMeWriteMyPaperPortSaintLucie100% (1)

- PPC Production PlantDokument106 SeitenPPC Production PlantAljay Neeson Imperial100% (1)

- Doingwell Coaching ServicesDokument4 SeitenDoingwell Coaching ServicesPaweł PawełNoch keine Bewertungen

- EF4e Beg Quicktest 05Dokument3 SeitenEF4e Beg Quicktest 05terrenoruralcamboriuNoch keine Bewertungen

- Mdx-40a Use en R1 PDFDokument100 SeitenMdx-40a Use en R1 PDFMarcos BustamanteNoch keine Bewertungen

- Case StudyDokument7 SeitenCase StudyLeighvan PapasinNoch keine Bewertungen

- 3 Ways To Take Isabgol - WikiHowDokument6 Seiten3 Ways To Take Isabgol - WikiHownasirNoch keine Bewertungen

- 99 AutomaticDokument6 Seiten99 AutomaticDustin BrownNoch keine Bewertungen

- AERO241 Example 10Dokument4 SeitenAERO241 Example 10Eunice CameroNoch keine Bewertungen

- Variance AnalysisDokument22 SeitenVariance AnalysisFrederick GbliNoch keine Bewertungen

- CP 1Dokument22 SeitenCP 1api-3757791100% (1)

- DR K.M.NAIR - GEOSCIENTIST EXEMPLARDokument4 SeitenDR K.M.NAIR - GEOSCIENTIST EXEMPLARDrThrivikramji KythNoch keine Bewertungen

- General Session Two - Work Life BalanceDokument35 SeitenGeneral Session Two - Work Life BalanceHiba AfandiNoch keine Bewertungen

- Biology Q PDFDokument9 SeitenBiology Q PDFsumon chowdhuryNoch keine Bewertungen

- LECTURE NOTES-EAT 359 (Water Resources Engineering) - Lecture 1 - StudentDokument32 SeitenLECTURE NOTES-EAT 359 (Water Resources Engineering) - Lecture 1 - StudentmusabNoch keine Bewertungen

- As Level Chemistry Practical Paper 3 - GCE GuideDokument1 SeiteAs Level Chemistry Practical Paper 3 - GCE GuideJamal AldaliNoch keine Bewertungen

- Olivares VsDokument2 SeitenOlivares VsDebbie YrreverreNoch keine Bewertungen

- Dabur Vs PatanjaliDokument4 SeitenDabur Vs PatanjalirangarajanNoch keine Bewertungen

- Complaint: Employment Sexual Harassment Discrimination Against Omnicom & DDB NYDokument38 SeitenComplaint: Employment Sexual Harassment Discrimination Against Omnicom & DDB NYscl1116953Noch keine Bewertungen

- Intentions and Results ASFA and Incarcerated ParentsDokument10 SeitenIntentions and Results ASFA and Incarcerated Parentsaflee123Noch keine Bewertungen

![VW Volkswagen Transporter T4 [ Powered By 1.8, 2.4 & 2.9 Diesel engines ]: Workshop Manual Diesel Models Years 2000-2004](https://imgv2-2-f.scribdassets.com/img/word_document/282876773/149x198/5fb74bd6e1/1675169638?v=1)