Beruflich Dokumente

Kultur Dokumente

Pi New Functions 3 3 e

Hochgeladen von

hydrasearchOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Pi New Functions 3 3 e

Hochgeladen von

hydrasearchCopyright:

Verfügbare Formate

Table of Contents

MCOSMOS v3.3

New and Changed

Functions

This document provides information about

new or changed functions in MCOSMOS v3.3

Table of Contents

Table of Contents

MCOSMOS v3.3 ...................................................................... 1

New and Changed Functions ................................................ 1

1 Table of Contents ............................................................ 2

2 Hardware Configuration ................................................. 3

2.1

2.2

PartManager .................................................................... 4

3.1

4

5

Easy working with the info file ................................................... 4

Manual MCOSMOS Version ............................................ 5

MCOSMOS ....................................................................... 6

5.1

5.2

5.3

CARB functions for car body measurement ............................. 6

Head touch with PH20 and REVO RSP2 .................................... 6

Scanning with touch trigger probing system with I++ ............. 6

GEOPAK .......................................................................... 7

6.1

6.2

6.3

SpinArms ..................................................................................... 7

Knuckles/cranks with rotary probe heads ................................ 7

ProbeBuilder: Enhanced input of star probes .......................... 8

CAT1000........................................................................... 9

7.1

7.2

7.3

7.4

7.5

7.6

7.7

7.8

MCOSMOS Hardware (Minimum Configuration)....................... 3

MCOSMOS Software ................................................................... 3

Improvement of REVO "Scan on curve" ................................... 9

Contour comparison ................................................................... 9

Gasket Scan in CAT1000 ............................................................ 9

Section for nominal contour .................................................... 10

Supported CAD formats ........................................................... 10

Tolerance dialogue box for "Multiple circle measurement" .. 11

Element plane (circular): Additional option ............................ 11

Probing direction of picked model point................................. 11

GEARPAK ...................................................................... 12

8.1 Measure tip and root diameter (spur gear) ............................. 12

8.2 User-defined limits for profile and flank line diagrams (spur

gears) ................................................................................................... 12

Scanning ........................................................................ 13

9.1 Airfoil 3D probe radius compensation of turbine blade

sections ............................................................................................... 13

Table of Contents

2

2.1

Hardware Configuration

MCOSMOS Hardware (Minimum Configuration)

Processor

Multi-core processor (2.0 GHz)

Memory

3 GB of RAM (DDR2 RAM or higher)

Graphics card

NVIDIA Quadro 2000 (1024 MB of RAM)

2.2

MCOSMOS Software

Supported operating systems

Windows 7 (32-bit and 64-bit)

Windows Vista (32-bit)

Windows XP (32-bit)

Table of Contents

3

3.1

PartManager

Easy working with the info file

Up to now, the info file of a part has been stored under the fixed file name

"TXPO000X.doc". It has not been possible to determine the editor used to create

the info file.

With MCOSMOS version 3.3 the correct extension of the info file is stored (for

example ".docx", ".xlsx").

It is therefore always possible to open and to edit the info file with the correct

editor (for example Word, Excel).

Viewing and editing is thus independent of the editor specified in the

PartManager settings.

Table of Contents

Manual MCOSMOS Version

The manual version of MCOSMOS v3.0 is continued in MCOSMOS v3.3. The

manual version does not contain any CNC functionalities (neither CNC machines

nor CNC commands).

Further unavailable functions:

GEARPAK

CAT1000P and CAD simulation

Patch Scanning Generator

MAFIS

ROUNDPAK-CMM

SurfaceDeveloper and those GEOPAK functions that export data to

the SurfaceDeveloper

ASCII-GEOPAK converter (import and export of part programs)

Pure DMISPAK (import and export of part programs)

Manager programs

Q-PAK

CMM SystemManager including CNC CMMs

The manual version of MCOSMOS v3.3 is available as an independent

installation package. Both versions, however, are always made available at the

same time.

Table of Contents

5

5.1

MCOSMOS

CARB functions for car body measurement

MCOSMOS version 3.3 supports the CARB functions for car body measurement

with two CMMs.

Each CMM has its own PC. The PCs are connected via network. The main

advantage of car body measurement with two CMMs is the saving of time.

5.2

Head touch with PH20 and REVO RSP2

In MCOSMOS version 3.3, head touch with PH20 and REVO RSP2 is possible.

Essential to this functionality is I++ and a UCC control.

There are two different modes for head touch with PH20 and REVO RSP2:

Mode 1: Fixed quill. The points are measured without movement of

the CMM.

Mode 2: All axes. The points are measured during a 5 axis

movement of the CMM. Movement takes place in the three CMM

axes and the two probe axes.

5.3

Scanning with touch trigger probing system with

I++

The following functions are supported by MCOSMOS and the I++ DME client for

MCOSMOS version 3.3 or later:

"Scan CNC with touch trigger probing system

"Scan by leading contour" with touch trigger probing system

Table of Contents

6

6.1

GEOPAK

SpinArms

The following SpinArms can be supported:

Different types of the Mitutoyo SpinArm M series. These are

available in the CMM SystemManager.

Arms of third-party distributors such as FARO, Romer/CimCore and

Metris on request. These can be selected with the function

Universal CMM Designer of the CMM SystemManager.

6.2

Knuckles/cranks with rotary probe heads

Knuckles/cranks can be used with the following rotary probe heads:

PH9A

PH10M

PH10MQ

Restrictions for knuckles/cranks:

Star probes are not supported.

The probing system must be aligned along the spindle.

Table of Contents

6.3

ProbeBuilder: Enhanced input of star probes

With the new function "Resort" in the ProbeBuilder (CMM SystemManager) the

probe numbers can be easily modified.

The probe numbers can be directly modified.

Only probe number 1 cannot be modified.

Table of Contents

7

7.1

CAT1000

Improvement of REVO "Scan on curve"

The new function guide features provides an easy and effective way to edit

control point and control point orientations directly in 3D view to optimize the

CMM movement path.

The CMM movement path can be edited with or without collision check.

7.2

Contour comparison

Contour comparison commands can be created in CAT1000 via the GD&T wizard

and sent to GEOPAK.

7.3

Gasket Scan in CAT1000

Up to now, it has been possible to create planes automatically, either by grid

measurement or circular with CAT1000.

With the new functions "Create measurement path" and "Gasket Scan" of version

3.3 you can measure a plane with a measurement path that you have determined

on the plane before.

Thus, complex workpiece surfaces can be easily measured.

The same is valid for surface points.

CAT1000 offers two methods to create the measurement path used for "Gasket

Scan":

Create points through path: On the CAD model, click with the

mouse to determine several points. These points define the

measurement path.

Closed path: Create a measurement path by entering an offset for

the surface edge.

Measurement path for Gasket Scan

Table of Contents

7.4

Section for nominal contour

With this new function you can create sections for nominal contours (sections

with additional tolerance information) by means of the following tools:

Section with section plane

Section with edge offset

Section with cylinder or cone

For single sections it is necessary to define a start point and an end point. The

section for nominal contour is then adapted to this partial section.

It is also possible to create multiple sections. For multiple sections, independent

and closed sections for nominal contours are built from all sections.

7.5

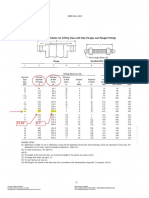

Supported CAD formats

CAD format

Supported

Versions

CATIA V4

Yes

4.1.9 - 4.2.4

CATIA V5

Yes

R6 - R21 (including PMI)

IGES

Yes

up to 5.3

Parasolid

Yes

10.0 - 24.0.133

1)

Pro/E

Yes

Sat

Yes

up to 22.0

Solidworks

Yes

98 - 2011

STEP

Yes

AP 203 and AP 214 (geometry only)

Unigraphic

Yes

11 - 18 and NX1 - NX7.5 (including PMI)

VDA-FS

Yes

Inventor

Yes

16 - Wildfire 5 (including PMI)

1.0 and 2.0

2)

6.0 - 11.0, 2008 - 2012

Supported CAD formats

1) The files have to be decompressed and unencrypted

2) New with optional CAD converter

10

Table of Contents

7.6

Tolerance dialogue box for "Multiple circle

measurement"

Within the new tolerance dialogue box "Multiple circle measurement", fast and

easy tolerancing of many circles in one single work step is possible.

7.7

Element plane (circular): Additional option

MCOSMOS 3.3 includes another option to measure a plane without having a

circle in the CAD model.

Simply select a point anywhere on the plane. This point is the center of the circle.

7.8

Probing direction of picked model point

From now on, the probing direction is displayed in the dialogue boxes "Picked

model point" and "Element point".

11

Table of Contents

8

8.1

GEARPAK

Measure tip and root diameter (spur gear)

Tip and root diameter can be measured automatically with GEARPAK-Cylindrical.

Either a scanning measurement or measurement with single points takes place.

Measurement with an indexable probe head is also supported.

8.2

User-defined limits for profile and flank line

diagrams (spur gears)

GEARPAK determines the diagram limits automatically by means of the

measurement points.

Now the user can define the diagram limits for profile and flank line diagrams.

12

Table of Contents

9

9.1

Scanning

Airfoil 3D probe radius compensation of turbine

blade sections

This function is part of the processing of contours in GEOPAK.

It allows to compensate a non-compensated contour on the surface of the

workpiece by means of a nominal contour (for example a section in a CAD

model).

The normal vectors of a nominal contour are set into relation with the measured

contour so that the measured contour can be moved to the contact points.

The form errors between nominal contour and measured contour are also taken

into consideration.

The measured contour can be moved in the plane of the nominal contour. Then,

a 2D tolerance comparison can be carried out.

13

Das könnte Ihnen auch gefallen

- 2020 McosmosDokument12 Seiten2020 McosmosKarthik Red100% (3)

- Reference Point System: Service InformationDokument11 SeitenReference Point System: Service Informationcmm5477Noch keine Bewertungen

- Mcosmos E4180 525Dokument28 SeitenMcosmos E4180 525Biljana UšćumlićNoch keine Bewertungen

- Cost Of Poor Quality A Complete Guide - 2021 EditionVon EverandCost Of Poor Quality A Complete Guide - 2021 EditionNoch keine Bewertungen

- Automotive Quality Management Systems A Complete Guide - 2020 EditionVon EverandAutomotive Quality Management Systems A Complete Guide - 2020 EditionNoch keine Bewertungen

- Project Manufacturing A Complete Guide - 2020 EditionVon EverandProject Manufacturing A Complete Guide - 2020 EditionNoch keine Bewertungen

- Manual KPM-QS Users Guide V2 2Dokument40 SeitenManual KPM-QS Users Guide V2 2EnriqueNoch keine Bewertungen

- Production Planning And Control A Complete Guide - 2020 EditionVon EverandProduction Planning And Control A Complete Guide - 2020 EditionNoch keine Bewertungen

- Redesigning Enterprise Process For E-BusinessDokument211 SeitenRedesigning Enterprise Process For E-BusinessMuarif AsdaNoch keine Bewertungen

- nx5 KeyboardcommandsDokument1 Seitenx5 KeyboardcommandsShaheen ArihaNoch keine Bewertungen

- Achieving Customer Experience Excellence through a Quality Management SystemVon EverandAchieving Customer Experience Excellence through a Quality Management SystemNoch keine Bewertungen

- Mvss206 Door LockDokument51 SeitenMvss206 Door LockPratik_rush2905Noch keine Bewertungen

- Vda4.1 Vda4.2 Vda4.3 Vda4.4 en 3rd 2021 最新版Dokument11 SeitenVda4.1 Vda4.2 Vda4.3 Vda4.4 en 3rd 2021 最新版cdmingNoch keine Bewertungen

- Quality Management System Process A Complete Guide - 2020 EditionVon EverandQuality Management System Process A Complete Guide - 2020 EditionNoch keine Bewertungen

- Delphi CSRDokument32 SeitenDelphi CSRecemericNoch keine Bewertungen

- SPC For MS Excel V2.0 Demo InstructionsDokument12 SeitenSPC For MS Excel V2.0 Demo InstructionsDanu MamlukatNoch keine Bewertungen

- Mil STD 1235-CDokument303 SeitenMil STD 1235-Cnenjijesus123100% (1)

- Calypso 127 True Position With Zeiss Calypso Part 3Dokument1 SeiteCalypso 127 True Position With Zeiss Calypso Part 3ferinoNoch keine Bewertungen

- Apis Iq v6 FeaturelistDokument2 SeitenApis Iq v6 Featurelistanon_812830553Noch keine Bewertungen

- Customer Satisfaction Levels A Complete Guide - 2020 EditionVon EverandCustomer Satisfaction Levels A Complete Guide - 2020 EditionBewertung: 1 von 5 Sternen1/5 (1)

- Mini - Tab For STADokument83 SeitenMini - Tab For STAmilanstr100% (1)

- Interface control document The Ultimate Step-By-Step GuideVon EverandInterface control document The Ultimate Step-By-Step GuideNoch keine Bewertungen

- Project Quality Management A Complete Guide - 2019 EditionVon EverandProject Quality Management A Complete Guide - 2019 EditionNoch keine Bewertungen

- Plato Scio Fmea Presentation 01Dokument22 SeitenPlato Scio Fmea Presentation 01Shree BiradarNoch keine Bewertungen

- Lect14r6oct 06 Pom World Class Manufacturing 110908135935 Phpapp01 PDFDokument80 SeitenLect14r6oct 06 Pom World Class Manufacturing 110908135935 Phpapp01 PDFVivek KumarNoch keine Bewertungen

- Calypso CAD FunctionsDokument19 SeitenCalypso CAD FunctionsRicardoVillanuevaCabreraNoch keine Bewertungen

- Manual ModusDokument410 SeitenManual ModusJuanillo100% (1)

- GM Customer Specifics - Rev 05-07-15Dokument34 SeitenGM Customer Specifics - Rev 05-07-15hugocronyNoch keine Bewertungen

- Supplier Performance Management Process A Complete Guide - 2019 EditionVon EverandSupplier Performance Management Process A Complete Guide - 2019 EditionNoch keine Bewertungen

- Process Improvement Simplified: A How-to-Book for Success in any OrganizationVon EverandProcess Improvement Simplified: A How-to-Book for Success in any OrganizationNoch keine Bewertungen

- Manufacturing Facilities A Complete Guide - 2019 EditionVon EverandManufacturing Facilities A Complete Guide - 2019 EditionNoch keine Bewertungen

- Vision: VDA Infosolutions Private LimitedDokument18 SeitenVision: VDA Infosolutions Private LimitedsudhakaremcNoch keine Bewertungen

- Design For Manufacture And Assembly A Complete Guide - 2020 EditionVon EverandDesign For Manufacture And Assembly A Complete Guide - 2020 EditionNoch keine Bewertungen

- Six Sigma Presentation FinalDokument38 SeitenSix Sigma Presentation FinalnayanvmNoch keine Bewertungen

- SQMS Manual For Suppliers: 1. General InformationDokument87 SeitenSQMS Manual For Suppliers: 1. General Informationlennad1Noch keine Bewertungen

- CMM CAD Programming 1Dokument9 SeitenCMM CAD Programming 1Supriya SahuNoch keine Bewertungen

- Template Q-Offer v1 2Dokument25 SeitenTemplate Q-Offer v1 2Krishna Mohan T.R100% (1)

- GQADokument26 SeitenGQARaduz HaduzNoch keine Bewertungen

- Engineering & Design Handbook EditedDokument140 SeitenEngineering & Design Handbook EditedHermanNoch keine Bewertungen

- Rollmaster TC InstDokument1 SeiteRollmaster TC InsthydrasearchNoch keine Bewertungen

- 600# Flange Modfication Check SheetDokument3 Seiten600# Flange Modfication Check SheethydrasearchNoch keine Bewertungen

- Engineering & Design Handbook EditedDokument140 SeitenEngineering & Design Handbook EditedHermanNoch keine Bewertungen

- Cause and Effect of Shutdown Issue.Dokument2 SeitenCause and Effect of Shutdown Issue.hydrasearchNoch keine Bewertungen

- Shutdown Issue Cause and EffectDokument2 SeitenShutdown Issue Cause and EffecthydrasearchNoch keine Bewertungen

- Care and Maintenance of HoseDokument3 SeitenCare and Maintenance of HosehydrasearchNoch keine Bewertungen

- Fun With Illustrator's Blend Tool - BittBoxDokument16 SeitenFun With Illustrator's Blend Tool - BittBoxhydrasearchNoch keine Bewertungen

- IK - Poster For Training of MultiplesDokument1 SeiteIK - Poster For Training of MultipleshydrasearchNoch keine Bewertungen

- Um String Code 2 0 eDokument46 SeitenUm String Code 2 0 ehydrasearchNoch keine Bewertungen

- Direction For The Kata WayDokument30 SeitenDirection For The Kata WayhydrasearchNoch keine Bewertungen

- Elk TempDokument1 SeiteElk TemphydrasearchNoch keine Bewertungen

- Robot Test FixtureDokument1 SeiteRobot Test FixturehydrasearchNoch keine Bewertungen

- Duet ManualDokument68 SeitenDuet ManualhydrasearchNoch keine Bewertungen

- Tripper ManualDokument1 SeiteTripper ManualhydrasearchNoch keine Bewertungen

- A3-PageWide F2F Deck 2 28 17 final-ENDokument129 SeitenA3-PageWide F2F Deck 2 28 17 final-ENkadirNoch keine Bewertungen

- Listening Test 25% Intento 1Dokument11 SeitenListening Test 25% Intento 1Adriana LoaizaNoch keine Bewertungen

- Braking Unit Braking Resistor Unit CDBR Lkeb Instructions (Toe-C726-2g)Dokument54 SeitenBraking Unit Braking Resistor Unit CDBR Lkeb Instructions (Toe-C726-2g)Pan TsapNoch keine Bewertungen

- Interview Question On Mobile Application Testing - Mobile Application TestingDokument10 SeitenInterview Question On Mobile Application Testing - Mobile Application TestingAnand DhanaNoch keine Bewertungen

- Forage Compactor 7700: Part of The FC7000 Series of Hay PressesDokument4 SeitenForage Compactor 7700: Part of The FC7000 Series of Hay PressesAbimelec TaipeNoch keine Bewertungen

- PlybooSound Collection CSI Specification - 100813Dokument5 SeitenPlybooSound Collection CSI Specification - 100813Nehru Valdenarro ValeraNoch keine Bewertungen

- Pmguru OnlineDokument167 SeitenPmguru OnlineGaurav KhamkarNoch keine Bewertungen

- NXC100 ControllerDokument2 SeitenNXC100 ControllermartinimartiiniNoch keine Bewertungen

- Dell and HP LaptopDokument74 SeitenDell and HP LaptopShobhit Goswami100% (5)

- Bs en 12Dokument10 SeitenBs en 12Alvin BadzNoch keine Bewertungen

- Clown - BD v0.81 ChangelogDokument13 SeitenClown - BD v0.81 ChangelogFaizurr HartmannNoch keine Bewertungen

- UDF & Powercopy of CATIA V5: About COE Membership Industries Events Content Center Partners ForumsDokument14 SeitenUDF & Powercopy of CATIA V5: About COE Membership Industries Events Content Center Partners ForumsRedondela DentalNoch keine Bewertungen

- 12 CS - SQPDokument5 Seiten12 CS - SQPkumaran mudNoch keine Bewertungen

- Android Application Development: Broadcast ReceiverDokument37 SeitenAndroid Application Development: Broadcast ReceiverAbdul RaoufNoch keine Bewertungen

- Downloaded From Manuals Search Engine: NOKIA 6820Dokument121 SeitenDownloaded From Manuals Search Engine: NOKIA 6820okamiotokoNoch keine Bewertungen

- DSBDA ORAL Question BankDokument6 SeitenDSBDA ORAL Question BankSUnny100% (1)

- Learning Docker - Sample ChapterDokument24 SeitenLearning Docker - Sample ChapterPackt PublishingNoch keine Bewertungen

- Argotlunar2 ReferenceDokument4 SeitenArgotlunar2 ReferenceronaldcopleyNoch keine Bewertungen

- Hype Cycle For The Telecommu 260996Dokument102 SeitenHype Cycle For The Telecommu 260996Enrique de la RosaNoch keine Bewertungen

- Motor Es CatDokument42 SeitenMotor Es CatfelixezamoraNoch keine Bewertungen

- PH 1Dokument22 SeitenPH 1Ricardo VelazquezNoch keine Bewertungen

- DS ERHARD ERK Titling Disc Check Valve ENDokument12 SeitenDS ERHARD ERK Titling Disc Check Valve ENkad-7Noch keine Bewertungen

- 01 - Introduction To PV Systems - NEWDokument35 Seiten01 - Introduction To PV Systems - NEWnoudjuhNoch keine Bewertungen

- Search: Skip To Content Using Gmail With Screen ReadersDokument11 SeitenSearch: Skip To Content Using Gmail With Screen ReadersKavitha100% (1)

- 3.5.5 Packet Tracer - Investigate The TCP-IP and OSI Models in ActionDokument4 Seiten3.5.5 Packet Tracer - Investigate The TCP-IP and OSI Models in Actionkds20850Noch keine Bewertungen

- Authentication GuideDokument60 SeitenAuthentication GuideCon CacNoch keine Bewertungen

- Fact Sheet CellD 300 en PDFDokument2 SeitenFact Sheet CellD 300 en PDFCharmer JiaNoch keine Bewertungen

- B230/B237/D042 Service ManualDokument1.312 SeitenB230/B237/D042 Service ManualSutan HarrymanNoch keine Bewertungen

- DriveCompatibility WikiDokument1 SeiteDriveCompatibility Wikishida67Noch keine Bewertungen

- 115E Pumps For NPPDokument16 Seiten115E Pumps For NPPONURNoch keine Bewertungen