Beruflich Dokumente

Kultur Dokumente

Delta Tau NC

Hochgeladen von

Mohsin AhmadOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Delta Tau NC

Hochgeladen von

Mohsin AhmadCopyright:

Verfügbare Formate

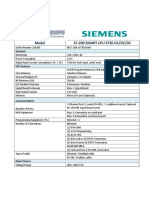

Advantage 900

PMAC-NC Pro2 CNC AutoPilot Utility

PMAC-NC Pro2 CNC AutoPilot Utility

The CNC AutoPilot program is a part of the

NCUI32 installation. It is available from the NC

folder.

Verify the installation of the CNC AutoPilot. By

default it is installed under C:\Program

Files\Delta Tau\ADV900 NC \NC Setup.

PMAC-NC Pro2 CNC AutoPilot Utility

The CNC AutoPilot was developed to assist in setting up basic NC

functionality, allowing the integrator to concentrate on custom

machine software (e.g., tool logic development, ESTOP logic

development, etc.).

This program works as a Wizard to generate the CNC project files,

configuration of the axis motor relations, machining parameters,

and the standard PLCs for the Advantage 900, 810 and 600

hardware.

CNC AutoPilot also creates a modular file template, the Project

Workspace used by PEWIN32Pro. This helps in documentation

and control of the machine software.

This program sets up the default NC registry entries for MILL or

LATHE applications.

CNC AutoPilot is for setting the NC related parameters, not

PMAC setup (motor phasing and servo tuning). The appropriate

PMAC Setup program is used for this.

PMAC-NC Pro2 CNC AutoPilot Utility

Select the CNC AutoPilot application from NCUI folder or the

Start Menu. At the start of the

application,

the

introduction

window will be displayed

This dialog box will display the

Software Release date (APR 28

2005 or greater), version number

and build number (4.0 or greater).

This is important for any technical

support issues. The default setting

for Application Type is MILL.

Select the type of application depending upon your machine type.

PMAC-NC Pro2 CNC AutoPilot Utility

Click Start to continue. The PMAC Devices dialog box will be

displayed. Select the appropriate device from the list. Click the

Properties button to set up dual port RAM communication (necessary

for NC software). The following dialogs will be the same for USB,

Ethernet and PCI.

PMAC-NC Pro2 CNC AutoPilot Utility

Select the DPR RT Buffers

Button first. Mark the check

box for DPRAM Real-Time

Update

and

enter

an

appropriate update rate (the

default of 20 servo cycles

should be OK for most users).

Then select the motors for the

application. For example, in a

typical MILL application there

are 4 axes, X, Y, Z, and spindle

i.e. 4 motors these may

correspond to motors #1, #2, #3

and #4.

PMAC-NC Pro2 CNC AutoPilot Utility

Next select the DPR BG

Buffers Button. Mark the

check box for DPRAM

BackGround Update and

enter an appropriate update rate

(the default of 20 servo cycles

should be OK for most users).

This will determine the

minimum rate for display

update. Also select the number

of coordinate systems the

application requires (usually

one). Click the OK button to go

back to the PMAC Device

dialog box.

PMAC-NC Pro2 CNC AutoPilot Utility

Press OK to exit from the PMAC Devices

dialog box. The PcommServer dialog should

appear with the message The PMAC was

successfully detected, select OK.

PMAC-NC Pro2 CNC AutoPilot Utility

At this point, the AutoPilot program will check the

application type with (Mill or LATHE A, B or C) and will

ask for confirmation to set the NC user interface registry.

This pop-up message will not be displayed on a fresh

installation If you to run AutoPilot again, then this pop-up

message will be displayed.

PMAC-NC Pro2 CNC AutoPilot Utility

By clicking the YES button, all previous NC settings will be lost. Clicking

the No button presents the first AutoPilot main setup screen. There are four

tabs.

Axis Motor Assigns

axis to motor

Std PLC Select and

configure standard NC

PLC

Machine Setup Set up

machine parameters like

Jog speed, Rapid(G0)

speed etc.

NCUI Registry Set up

default.

PMAC-NC Pro2 CNC AutoPilot Utility

Axis-Motor tab

Axis-Motor Definitions:

The first step will be assigning

Motors to the axis. Select the

Axis-Motor tab. There are three

columns under Axis-Motor

Definitions:

Axis (Name)

Mtr No.

Pulses Per Unit.

Axis Names are fixed (X, Y, Z

etc.), Mtr No. and Pulses Per

Unit entries are user assigned

values.

PMAC-NC Pro2 CNC AutoPilot Utility

Mtr No.

Any motor can be assigned to any axis. For

example, motor 2 can be assigned to axis X or 3 to

axis Y, etc. The motor number cannot be

duplicated, i.e., assignment of motor 1 to axis X

and Y will result in an Invalid Motor Number

error.

The range for Motor Number is 1 to 8.

PMAC-NC Pro2 CNC AutoPilot Utility

Pulses Per Unit

This is the encoder counts per unit. If the machine unit is inch, then it

is the number of encoder counts per inch. To calculate this value, use

this formula:

PPU =

Decode Control * Encoder Lines * Screw Pitch * Unit conversion factor

Decode Control = Turbo PMAC I7mn0 parameter resultant decode

multiplier value (x1, x2, or x4). Default is 4.

Encoder Lines = The number of lines specified by the Encoder

manufacturer used for the feedback. Units are lines/rev.

Screw Pitch is specified rev/pitch length the units are usually revs/mm.

Unit conversion factor is the conversion of pitch length units to

machine units. For a machine in inches this is usually mm/inch.

PMAC-NC Pro2 CNC AutoPilot Utility

Pulses Per Unit

Example: For standard 5mm-pitch ballscrew and

8192 line encoders, the pulses per unit value is:

Pulses Per Unit = 4 cts/Line * 8192 lines/rev *

rev/5mm *25.4 mm/inch = 166461.48 pulses per

inch. Where 4 cts /line is decode control I7mn0

variable of PMAC

PMAC-NC Pro2 CNC AutoPilot Utility

Reset All

Click this button to set all definitions to 0 (zero).

Zero indicates that the axis is not connected, this

function clears the axis motor definitions quickly.

PMAC-NC Pro2 CNC AutoPilot Utility

Position Units and Display Format

Position Units

This defines the position units of the machine in either

English or Metric (inches or milimeters). This setting is for

the complete machine, not for individual motors.

The first time the program is started, this value defaults to

English (Inch), and English (Inch) is checked on the window.

Select Metric (mm) and the program will start in Metric

thereafter until switched back to English.

Display Format

This defines the display format for different position units.

This display format is used by NCUI 32 to display the axis

position. The convention of the format is {total number of

digits}.{digits after the decimal point}. Default format is 9.4

which mean total width is nine digits with four digits after

the decimal point.

PMAC-NC Pro2 CNC AutoPilot Utility

Std PLC tab

Use the Std PLC function to

configure, create, and download

PLCs to PMAC and start the basic

function of the NC. The basic

functionality includes:

Mode selection (including Home Mode)

Axis selection

Jog

Speed selection

Hand-wheel operation

All function keys from the Control

panel (single step, optional stop,

block del, etc.)

PMAC-NC Pro2 CNC AutoPilot Utility

Machine Name and PLC Path

Machine Name

Enter a machine name up to 15 characters in the Machine Name field. This name is used for generating the .CFG file

as well as for creating the directory. The default machine name is Adv 600, which is one of Delta Taus available

control panels. .For example, if the machine is MyMachine, then CNCAutoPilot will create the directory MyMachine

under C:\Program Files\Delta Tau\. All of the PLCs, headers, etc. files are stored in this folder.

PLC Path

The PLC Path field indicates where the PLC files are stored. The standard base path C:\Program Files\Delta Tau . The

\<Machine Name> will be appended to base path to create folder for storing PLC. The Browse button is used to set

PLC base path. As soon as a machine name is entered, the PLC path is updated automatically.

PMAC-NC Pro2 CNC AutoPilot Utility

Cntl Panel Function

In the Cntl Panel group of fields, enter the values to create

the Control Panel PLC.

PMAC-NC Pro2 supports different types of Control

Panels. Currently this software supports Adv 600, Adv 810,

Adv 900 and Software Panel. For details of these control

panels see the hardware reference documents. The Control

Panel PLC outputs changes according to the selection of

the control panel. Select the appropriate panel. By default,

Adv 600 control panel is selected.

The Software Control Panel is selected when NC4.x will

be running without a hardware control panel.

The Control Panel PLCs support NC4.x and NC5.x

software. These control panel PLCs will not work with

older NC software such as NC2.36 or NC3.x.

To support old NC software, use the Autopilot that came

with the installation of the old NC software

PMAC-NC Pro2 CNC AutoPilot Utility

Adv. Settings

If the Adv. Settings function is clicked, the window shown below displays.

Advance Settings is useful for ADV600 style control panel and ACC34 style

PMAC I/O boards.

No. of I/O Cards

This box is for adding I/O cards.

Default control panel PLC reads and

writes one I/O card. When the control

panel type is Adv 810, then these

settings are not available. For Adv 810,

use I/O M-Variables defined in the

IO810.H file. The file can be found at

C:\Program

Files\Delta

Tau

Shared\IO810.h. This file is already

included in the .CFG file output of Auto

Pilot.

PMAC-NC Pro2 CNC AutoPilot Utility

Override

Enter the values for the machine override parameters in this group of fields. ADV 810 and

ADV900 control panels supports only ANALOG type overrides.

% Spindle Override

Enter the values to set the Spindle Override percentages in this group of fields. The

value in the % Speed Min field sets the minimum percentage spindle override and the

value in the Speed Max field sets the maximum percentage spindle override.

The Digital and Analog options set the type of switch used for setting spindle

override.

Range: Default 50 to 110

Allowed 0 to 200

% Feedrate Override

This group of fields is used to set the feedrate override percentages. The value in the

% Feed Min field sets the minimum percentage feedrate override and the value in the

% Feed Max field sets the maximum percentage feedrate override.

The Digital and Analog options set the type of switch used for setting spindle

override.

Range: Default 0 to 150

Allowed 0 to 200

PMAC-NC Pro2 CNC AutoPilot Utility

Home

Enter the value for the Home PLC in

this group of fields. When Command is

selected, the #{motor number}HM

commands are issued through the

Control Panel PLC. If selected, this

button resets the Enable option.

When PLC is selected, the HOME

commands are issued through the

HOME PLC. This is set automatically if

Enable is checked.

Currently, Home using the motion

program feature is not available.

PMAC-NC Pro2 CNC AutoPilot Utility

Handle

Enter the value for the Handle PLC in this group of

fields. The value in the Max field sets the limit for

the maximum handwheel increment per one

revolution. By default, this increment is one unit.

The value in the Min field sets the minimum

handwheel increment per division.

Default settings are:

Hand Wheel Revs Speed Selection Position Increment

1

High (Max)

1 unit

1

Medium

0.1 unit

1

Low (Min)

0.01 unit

In this group, Max is set to 0.01 by default. A typical

pulse generator has 100 divisions. Thus in High

setting, the motor will move 0.01 *100 = 1 Unit.

PMAC-NC Pro2 CNC AutoPilot Utility

Spindle

Enable the Spindle PLC in this group of

fields.

Type: This parameter allows selection of the

spindle type as Close Loop or Open Loop. The

Close Loop spindle requires a feedback to

PMAC; Open Loop does not (the spindle

drive may still require feedback).

Max RPM: This parameter defines the

maximum spindle RPM. The Spindle PLC

uses this input to set the proper RPM. The

program will not accept an RPM command

greater than the value in the Max RPM field;

it will clamp it to Max RPM.

PMAC-NC Pro2 CNC AutoPilot Utility

PMAC Type

The program detects the type of the PMAC automatically and displays it here.

Enable PLC

If Enable PLC is checked, then all of the generated PLCs are enabled by

issuing ENABLE PLC command to PMAC after download.

Save PLC

If Save PLC is checked, then the SAVE command is issued to PMAC after

download. This saves all of the PLCs and I-Variables in the PMAC memory.

PMAC-NC Pro2 CNC AutoPilot Utility

Machine Setup tab

Enter the values of all the

machine related settings

for NC, such as speed,

following error, etc., in this

group of fields.

The menu window is selfexplanatory. The Axis

Name is displayed only if

axes are assigned to the

motor as displayed on the

Axis Motor tab.

PMAC-NC Pro2 CNC AutoPilot Utility

Jog Speed

This sets the maximum axis jog speed in user-selected units. The speed setting

can be different for different motors.

Rapid Speed

This sets the maximum axis rapid speed (G0 speed in NC terms) in user-selected

units. This setting can be different for different motors.

Positive S/W Limit

This sets the positive software limit in user-selected units. This setting can be

different for each motor.

Negative S/W Limit

This sets the negative software limit in user-selected units. This setting can be

different for each motor.

PMAC-NC Pro2 CNC AutoPilot Utility

Home Offset

This sets the distance in user-selected units to move after a HOME completes. This is a signed

quantity. This setting can be different for each motor.

Home Speed (and direction)

This sets the maximum machine home speed in user-selected units. This setting can be different for

each motor. Speed can be positive or negative.

Positive Limit Switch

Negative Limit Switch

Home Switch

This group of buttons per axis sets the basic condition for homing. For example, if Positive Limit

Switch is selected, then homing will be done on the rising edge of the positive limit switch and the

rising edge of C channel. This is the same for the other two switches. This setting can be different for

each motor.

Home on C Channel

Home on C Channel is used if the homing is to be done on the rising edge of C channel only. Only

one type of condition is selected (Rising Edge). This setting can be different for each motor.

PMAC-NC Pro2 CNC AutoPilot Utility

CS Setup

This group of fields contains the settings related to the NC coordinate system.

Feed Rate

This sets the maximum axis feed rate in user-selected units. This setting is for all machine axes. This

is G1, G2, G3 speed, in NC terms.

Following Error

This sets the maximum following error in user-selected units. This setting is for all machine axes.

In Position Band

This sets the In Position band in user-selected units. This setting is for all machine axes.

LookAhead ON

This option is checked if the PMAC type is a Turbo. This sets the basic starting parameters for the

look ahead mode for the NC. These settings depend upon the PMAC CPU frequency. The following

I-Variables will be set for NC Coordinate System 1:

I5113 = Move segmentation time in ms

I5187 = Acceleration time in ms

I5120 = Number of segments

For details on these parameters, refer to the PMAC Turbo User Manual.

PMAC-NC Pro2 CNC AutoPilot Utility

Update

This option updates the Windows registry values used by the NC. Registry values must be updated

after the configuration of axes is complete for the NC to reflect the setup configuration. Update will

work only if the NC application is not running. In addition, registry values will not be updated if the

registry key for that parameter is not present. In this case an error will be displayed.

Build

When selected, this function generates the PLCs that are marked enable. All the PLCs are stored in

the selected <PLC PATH>.

The next step is to download these PLCs manually, using PEWIN Executive software. Use the

{Machine Name}.CFG file for the download.

Build and Download

This function generates the PLCs that are marked enable. All the PLCs are stored in selected <PLC

PATH>. This downloads the {Machine Name}.CFG file to PMAC automatically. If selecting

ENABLE PLC and SAVE PLC, it issues the appropriate commands to PMAC.

PMAC-NC Pro2 CNC AutoPilot Utility

Configuring the NCUI Registry tab.

PMAC-NC Pro2 CNC AutoPilot Utility

File Management

NC Events Log File: This sets the path for storing NC events log.

NC Program to Load: This stores the NC file with path to be loaded in the NC interface on start-up of the

application.

NC Program Folder: This sets the default NC file path. PMAC-NC will use this path as the default to open machine

files.(.NC) .

NC Error File: This sets the path for storing the Errors data file. PMAC-NC will use this file to show user errors.

NC Variable File: This sets the path for storing the Parametric variables data file.

PMAC-NC Pro2 CNC AutoPilot Utility

NC Buffers

Lookahead Buffer: This defines the number segments stored in the lookahead buffer.

Rotary Buffer: This defines the size of the rotary buffer used by NC program

Synchronous M Buffer: This defines the size of the Stack to hold synchronous M-variables.

The following commands for the coordinate system will be issued to PMAC:

DEFINE ROTARY {Rotary Buffer}

DEFINE LOOKAHEAD {Lookahead Buffer},{Synchronous M Buffer}

For details on these parameters, refer to the Turbo PMAC Users and Software Reference Manual

PMAC-NC Pro2 CNC AutoPilot Utility

Miscellaneous

User_Position_Reporting: If this check box is

selected, then Autopilot will generate the default

Position Reporting PLC. Users can alter this PLC

and write their own calculation for position display.

This is useful for displaying positions when inverse

kinematics is used or for position displays using non

conventional feedback devices. The feature will only

work for Turbo PMAC Firmware V1.942 and above.

WirelessPendentOn: If this check box is selected,

then Autopilot will update the NC registry which will

allow to use WIRELESS PENDENT with ADV900

Control panel.

Velocity Scale X, Velocity Scale Y, Velocity Scale

Z: These values are used as scale factor in Feed Rate

calculation. HMI NC uses these values to display

Feed Rate. Typically used when Dual feedback is

used. The default is 1.

PMAC-NC Pro2 CNC AutoPilot Utility

Tool

This will allow the user to

configure the Tool page columns

in the NC as Geometry, Wear etc.

The Maximum number of tools is

99. A number entry more than 99

will reset this field back to the

default of 50 tools.

PMAC-NC Pro2 CNC AutoPilot Utility

This section will give an example of the CNC AutoPilot Program. Refer to the

different screen pictures which show the input for generating the standard PLCs

for Adv 900 CNC control. On completion of these steps, the Build or Build &

Download options can be clicked. If Build & Download is selected, make sure to

check the ENABLE PLC and SAVE PLC option.

Step 1: Run NC_Setup.EXE and select MILL option.

Step 2: Set the Axis- Motor definition as shown in the next slide

Step 3: Set machine Name for this example set it as MyMachine. Select ADV900

as control panel.

Step 4: Set all the machine parameters (Jog Speed, Homing condition, following

error etc.).

Step 5: Set the NC default File path and Buffer sizes.

Step 6: Check ENABLE PLC and SAVE PLC check boxes and click Build &

Download. This will generate the PLC code and download it to PMAC. The PLCs

are generated in a folder specified by PLC Path in Std PLC tab.

PMAC-NC Pro2 CNC AutoPilot Utility

Axis - Motor definitions, Position Units and Display Format

PMAC-NC Pro2 CNC AutoPilot Utility

The ADV900 type control panel

is selected.

Control Panel, Override, Handle

and spindle close loop PLC are

selected.

PMAC Type is UMAC.

Home command is issued from

Control panel PLC.

Override controls are type

Analog.

Initialize PLC is not selected so

all the initialize part is done in

Control panel plc.

PMAC-NC Pro2 CNC AutoPilot Utility

The maximum Feed Rate, Following

Error, and In Position band settings

are coordinate system-specific and

are in USER UNITS. (inches as

specified in previous screen).

Lookahead mode is ON.

Homing is based on HOME Switch.

Radio Button is selected for this

option.

All motor specific (Mtr#1, Mtr#2)

settings are in User units, INCH.

In our Axis- Motor definition, we

have 4 motors assigned to X, Y, Z

and spindle so only 4 motors settings

are enabled on Machine Setup page.

PMAC-NC Pro2 CNC AutoPilot Utility

For good integration practice,

create a Machine folder

(CNC_Program) on the hard

drive. Use this folder to store all

the Machine specific files.

This folder has been created so

that all the default path settings

and default files will be stored

here.

NC Buffers setting specifies the

PMAC buffer sizes. In our

example, the lookahead and

rotary buffers will be defined as

follows:

Def Rot 8192

Def Look 400,400

PMAC-NC Pro2 CNC AutoPilot Utility

The Auto Pilot program creates the

MyMachine folder and stores all of the

PLCs in this folder.

*.PLC PMAC PLC files to be used with

Adv 900 control panel

*.H Header files to be used in download

Mill.* Machine GMT code files

(Mill.G, Mill.M and Mill.T)

*.IVR PMAC I variable file

*.CFG Configuration file to be used in

downloading the PLC manually by using

Pewin 32 software.

Updates and modifies a project workspace

file. This will create MyMachine as a

project in PEWIN32 PRO.

To download, use MyMachine.CFG file

from PEWIN32 Executive software.

MyMachine.Log will be created as output

file after download to check for errors.

PMAC-NC Pro2 CNC AutoPilot Utility

MyMachine.CFG

This file is the template file created by

AutoPilot to be used in case of manual

download. This file can be used in the

future for further downloads. The sample

file is displayed here.

File names can be added, deleted in the

#include files field for additional PLCs

(e.g., Lube, Coolant, etc.) and this file can

be downloaded manually using the

PEWIN utility.

As a good integration practice, always use

this file to download to PMAC. Add

additional PLCs to this file.

PMAC-NC Pro2 CNC AutoPilot Utility

AutoPilot Files

MyMachine_UserDefins.H: This is a blank file created by the AutoPilot program. The

machine related Macros (#defines ) can be written in this file for better document control

and maintainability. As a good integration practice do not alter or modify Address.h or

OEM.h etc files. Use this file to add machine specific code.

NC_I_VAR.IVR: This file stores all the I-Variables generated by AutoPilot program using

the Machine Setup input.

INITIALIZE.PLC: This is a one-time execution PLC. This is used to initialize the NC

system variables or I/O. Additional variables can be placed in this file.

CNTLPANEL.PLC: This is the control panel PLC for Adv 600/810/900.

OVERRIDE.PLC: This is the override control PLC used for spindle speed and feed rate.

HOME.PLC: This is the home PLC for all axes.

PMAC-NC Pro2 CNC AutoPilot Utility

AutoPilot Files cont.

HANDLE.PLC: This PLC is for the handwheel functions.

SPINDLE.PLC: This PLC is for the spindle functions. It can be open or closed loop.

Reset.PLC: This is a template PLC for Reset action. User can add a RESET sequence or

any other Reset related actions in this PLC.

GPTimer.PLC: This PLC provides additional Timers. This PLC uses a PMAC free memory

location to create additional TIMERS.

POSITION_REPORT.PLC: This is the user position reporting PLC generated only if the

User Position Reporting check box is selected from miscellaneous group box. In our

example we did not selected this check box so this PLC will not be generated.

OEM.H: This header file is created by the AutoPilot program based on user input and

should not be altered. The MyMachine.H file is for general use.

PMAC-NC Pro2 CNC AutoPilot Utility

AutoPilot Files cont.

NCPLC.H: The AutoPilot program generates this file. It consist of the

#defines constant based on the user input.

MILL.G, MILL.M, and MILL.T: These are the G, M, and T code files

used in the application.

ADVCNTLU.H: This file is in C:\Program Files\Common Files\Delta

Tau Shared folder and should not be altered. This will be used for

assigning user buttons on the Adv 810/900 control panel.

IO810.H or IO600.H: This is the I/O header file. The IO810 file is for

the Adv 810 and IO600 is for an Adv 600 type controller. These files can

be modified as needed and are found in C:\Program Files\Delta

Tau\PmacNC\Mill.

PMAC-NC Pro2 CNC AutoPilot Utility

MyMachine Project

Workspace

The NC Setup updates the default >INI

file used by PEWIN32 pro and creates

MyMachine as a project. This is a very

useful feature for controlling

integrated Machine Source code.

In this screen, the PEWIN32 PRO

executive software shows MyMachine

as a project with all the files built by

AutoPilot.

PMAC-NC Pro2 CNC AutoPilot Utility

These are the P, Q and M variable Resources used by the

CNC Program:

Advantage 900

PMAC-NC Registry BackUp Utility

PMAC-NC Registry BackUp Utility

The PMAC-NC Registry BackUp is a utility included in the

PMAC-NC Pro2 suite of software applications for saving

and restoring the Windows Registry parameters which

determine the configuration of the PMAC-NC Pro2 CNC

software interface. The PMAC-NC Registry Backup creates

a Windows Registry backup file with all the necessary

parameters to restore the PMAC-NC Pro2 environment in the

event of a PC crash, or allows OEM machine builders to

quickly duplicate machine configurations.

PMAC-NC Registry BackUp Utility

The PMAC-NC Registry BackUp can be started by double clicking the

executable file in the folder location where the PMAC-NC Pro2 Software

was installed or from the Windows Start menu. The default installation

will place the application in the Start menu as shown below.

PMAC-NC Registry BackUp Utility

Once the PMAC-NC Registry BackUp is launched you

should see the application as shown below:

Follow the onscreen instructions

to either save or restore the

PMAC-NC Pro2 registry settings.

Save PMAC-NC - Registry

Settings - Saves your backup

Registry file in text format to a

location and name of your

choice.

Restore PMAC-NC - Registry

Settings - Restores your PMACNC Pro2 GUI parameters

Das könnte Ihnen auch gefallen

- Kinetix Servo Drive Specifications Technical Data Knx-td003 - En-PDokument200 SeitenKinetix Servo Drive Specifications Technical Data Knx-td003 - En-PvuNoch keine Bewertungen

- Simotion SCOUT CamTool - ProgrammingDokument114 SeitenSimotion SCOUT CamTool - ProgrammingBobWhalerNoch keine Bewertungen

- EPower 029669 5 PDFDokument14 SeitenEPower 029669 5 PDFrajabharath12Noch keine Bewertungen

- Gefran GTF Xtra ManualDokument29 SeitenGefran GTF Xtra ManualjilfNoch keine Bewertungen

- b04 Data BlocksDokument18 Seitenb04 Data BlocksvarunshyamNoch keine Bewertungen

- Introduction To Profibus & ProfinetDokument15 SeitenIntroduction To Profibus & ProfinetAshish PatwardhanNoch keine Bewertungen

- 1 2 3 4 5 CP 343-2 / CP 343-2 P AS-Interface Master Simatic NetDokument134 Seiten1 2 3 4 5 CP 343-2 / CP 343-2 P AS-Interface Master Simatic NetMike LeeNoch keine Bewertungen

- Service On Sinamics ConvertersDokument16 SeitenService On Sinamics Converterssiva kumarNoch keine Bewertungen

- TIA PRO1 16 Integrating Drive enDokument38 SeitenTIA PRO1 16 Integrating Drive enEmilio MonterichelNoch keine Bewertungen

- Active Disturbance Rejection Control for Nonlinear Systems: An IntroductionVon EverandActive Disturbance Rejection Control for Nonlinear Systems: An IntroductionNoch keine Bewertungen

- Schneider Electric Altivar Process ATV9xx DTM Library V3.8.2 ReleaseNotesDokument9 SeitenSchneider Electric Altivar Process ATV9xx DTM Library V3.8.2 ReleaseNotesAna MosiashviliNoch keine Bewertungen

- Guide WizconDokument125 SeitenGuide WizconlettolimaNoch keine Bewertungen

- SIMATIC S7-1200 - Sinamics Blocks TIA PortalDokument91 SeitenSIMATIC S7-1200 - Sinamics Blocks TIA Portalantonio pedroNoch keine Bewertungen

- Debug and Start-Up: Simatic S7Dokument24 SeitenDebug and Start-Up: Simatic S7Ahmed KhairyNoch keine Bewertungen

- Eurotherm 2704 PDFDokument2 SeitenEurotherm 2704 PDFKirkNoch keine Bewertungen

- VBScripting Manual - Rev 2013Dokument42 SeitenVBScripting Manual - Rev 2013basamvenkatNoch keine Bewertungen

- KNX sg001 - en PDokument234 SeitenKNX sg001 - en PNelsonNoch keine Bewertungen

- Automating With STEP 7 in LAD and FB1Dokument1 SeiteAutomating With STEP 7 in LAD and FB1Mario Compagnoni0% (1)

- 6ra70 PDFDokument232 Seiten6ra70 PDFChowdary MnchowdaryNoch keine Bewertungen

- 1222041-20 Modular Angle Encoders Optical en PDFDokument88 Seiten1222041-20 Modular Angle Encoders Optical en PDFSigh BalaNoch keine Bewertungen

- PRO1 13E Organzation BlocksDokument14 SeitenPRO1 13E Organzation BlocksLộc QuangNoch keine Bewertungen

- 5 Axis Arm Robot Trainer Ed 7255 1390040798Dokument2 Seiten5 Axis Arm Robot Trainer Ed 7255 1390040798Gabriel Aparecido FonsecaNoch keine Bewertungen

- Distributed Safety: Sensor-Actuator Interfacing: SITRAIN Training ForDokument23 SeitenDistributed Safety: Sensor-Actuator Interfacing: SITRAIN Training Forcarsan87Noch keine Bewertungen

- PCS 7 V8.2 PC Configuration and Authorization - 03 - 2016Dokument156 SeitenPCS 7 V8.2 PC Configuration and Authorization - 03 - 2016Ecaterina IrimiaNoch keine Bewertungen

- #1. SmartStruxure Lite Training - Introduction Ver 1.1.0 - 0Dokument55 Seiten#1. SmartStruxure Lite Training - Introduction Ver 1.1.0 - 0cosmin_butanescuNoch keine Bewertungen

- TIA Pro1 PDFDokument29 SeitenTIA Pro1 PDFKerwin GrapaNoch keine Bewertungen

- FQ2-SiemensPLC PROFINET Eng 20140213Dokument12 SeitenFQ2-SiemensPLC PROFINET Eng 20140213Djebbi SamiNoch keine Bewertungen

- S7-PLCSIM - Testing Your S7-CPU Programs - ManualDokument93 SeitenS7-PLCSIM - Testing Your S7-CPU Programs - Manualchaubinhkhang110686Noch keine Bewertungen

- PRO2 01eDokument14 SeitenPRO2 01eghita_gabrielNoch keine Bewertungen

- TIA PRO1 15 Troubleshooting enDokument62 SeitenTIA PRO1 15 Troubleshooting enEmilio MonterichelNoch keine Bewertungen

- 0 1 2 3 4 5 6 Simatic Hmi: ManualDokument120 Seiten0 1 2 3 4 5 6 Simatic Hmi: Manualyukaokto2Noch keine Bewertungen

- Multiprog Proconos eDokument11 SeitenMultiprog Proconos eLuciano Cardoso VasconcelosNoch keine Bewertungen

- Siemens Sinamics V20 Getting StartedDokument34 SeitenSiemens Sinamics V20 Getting StartedRolando QuirozNoch keine Bewertungen

- Modicon M221: General PresentationDokument1 SeiteModicon M221: General PresentationS DNoch keine Bewertungen

- IPE Typical Ex PZ Schematic Diagram (Rev.1)Dokument1 SeiteIPE Typical Ex PZ Schematic Diagram (Rev.1)Ikhtiander IkhtianderNoch keine Bewertungen

- Simotion DDokument3 SeitenSimotion DHernan GardiazabalNoch keine Bewertungen

- Simotion Scout DocumentDokument5 SeitenSimotion Scout Documentthanh_cdt01100% (1)

- PRO2 - 03e Instructions With REAL NumbersDokument7 SeitenPRO2 - 03e Instructions With REAL NumbersSamehibrahemNoch keine Bewertungen

- PC Panel 670 PDFDokument195 SeitenPC Panel 670 PDFkillers201493Noch keine Bewertungen

- Basic Adroit Ignite Training Manual 2021 - Rev06Dokument184 SeitenBasic Adroit Ignite Training Manual 2021 - Rev06ArkitectNoch keine Bewertungen

- NetToPLCSim - A Network Interface To PLCSim PDFDokument2 SeitenNetToPLCSim - A Network Interface To PLCSim PDFAlex JimenezNoch keine Bewertungen

- 10 Working With SCL PDFDokument16 Seiten10 Working With SCL PDFAZMNoch keine Bewertungen

- 14.2 Apendix 05 Distributed IODokument56 Seiten14.2 Apendix 05 Distributed IOIsai Anguiano100% (1)

- 07 - Modular - Machine - ConceptsDokument158 Seiten07 - Modular - Machine - ConceptsislamooovNoch keine Bewertungen

- Csharp OPC Client DOKU v10 eDokument117 SeitenCsharp OPC Client DOKU v10 eÖzkan KayacanNoch keine Bewertungen

- Configuring Sequences With SFC: Simatic Pcs 7Dokument20 SeitenConfiguring Sequences With SFC: Simatic Pcs 7jriwohd jriwohd100% (1)

- Wizcon 9.2 - OPC User Guide (English) PDFDokument69 SeitenWizcon 9.2 - OPC User Guide (English) PDFAline VenturaNoch keine Bewertungen

- 01 # S7-200 OverviewDokument20 Seiten01 # S7-200 OverviewRaj ChavanNoch keine Bewertungen

- Preliminary Man Sinamics-Simotion v1 7 EngDokument153 SeitenPreliminary Man Sinamics-Simotion v1 7 EngJacob B ChackoNoch keine Bewertungen

- Sinumerik OPC UA Device DriverDokument9 SeitenSinumerik OPC UA Device DriverMartinNoch keine Bewertungen

- RS232 DNCDokument21 SeitenRS232 DNChungNoch keine Bewertungen

- Sinumerik OPC DA Device DriverDokument8 SeitenSinumerik OPC DA Device DriverMartinNoch keine Bewertungen

- Aromat 10-40 HMI ManualDokument24 SeitenAromat 10-40 HMI ManualJederVieiraNoch keine Bewertungen

- Atm-10 40 ManualDokument21 SeitenAtm-10 40 ManualmarivapopNoch keine Bewertungen

- Ajax CNC Installation ManualDokument27 SeitenAjax CNC Installation ManualsunhuynhNoch keine Bewertungen

- Heidenhain Device DriverDokument12 SeitenHeidenhain Device DriverMartinNoch keine Bewertungen

- V22LatheInstalling-Editing Post ProcessorsDokument36 SeitenV22LatheInstalling-Editing Post ProcessorsCreo ParametricNoch keine Bewertungen

- M100711D MAI Memory Upgrade For Fanuc 15B2Dokument32 SeitenM100711D MAI Memory Upgrade For Fanuc 15B2323ciNoch keine Bewertungen

- Eaton Cutler-Hammer - Operator Interface ProductsDokument44 SeitenEaton Cutler-Hammer - Operator Interface ProductsChina BrownNoch keine Bewertungen

- Anwendungsbericht LinMot Toelke Closure ENDokument4 SeitenAnwendungsbericht LinMot Toelke Closure ENMohsin AhmadNoch keine Bewertungen

- Linear Motor Stage (EN)Dokument27 SeitenLinear Motor Stage (EN)Mohsin AhmadNoch keine Bewertungen

- Cpu st30 PDFDokument1 SeiteCpu st30 PDFMohsin AhmadNoch keine Bewertungen

- What Is Economics?: Scarce AlternativeDokument3 SeitenWhat Is Economics?: Scarce AlternativeMohsin AhmadNoch keine Bewertungen

- Powerboss Data Center EnergyAdvantageDokument22 SeitenPowerboss Data Center EnergyAdvantageMohsin AhmadNoch keine Bewertungen

- Datasheet 7805Dokument34 SeitenDatasheet 7805Mohsin AhmadNoch keine Bewertungen

- MOST BusDokument3 SeitenMOST BusMohsin AhmadNoch keine Bewertungen

- 3 Lab Cache StudioDokument166 Seiten3 Lab Cache Studioaman singhNoch keine Bewertungen

- Ada in Action: (With Practical Programming Examples)Dokument153 SeitenAda in Action: (With Practical Programming Examples)Gabriel Hi100% (1)

- Getting Started Guide Switch v4.00 (WW) 130x183Dokument56 SeitenGetting Started Guide Switch v4.00 (WW) 130x183ravikkotaNoch keine Bewertungen

- Fortiadc: Application Delivery ControllersDokument16 SeitenFortiadc: Application Delivery ControllersKunalNoch keine Bewertungen

- CFF Explorer Scripting LanguageDokument43 SeitenCFF Explorer Scripting Languagenight_shade88Noch keine Bewertungen

- Making Custom Modifications To PDF TemplatesDokument13 SeitenMaking Custom Modifications To PDF TemplatesacastroyNoch keine Bewertungen

- Nutanix - API-Ref-AOS-v51Dokument677 SeitenNutanix - API-Ref-AOS-v51pkjk07Noch keine Bewertungen

- Test Cases On Login PageDokument10 SeitenTest Cases On Login Pagedips13286Noch keine Bewertungen

- Error en Created - at en Valor Datetime y DateDokument10 SeitenError en Created - at en Valor Datetime y DateRayNoch keine Bewertungen

- Check Your English Vocabulary For ComputingDokument37 SeitenCheck Your English Vocabulary For Computingan kapNoch keine Bewertungen

- 13-Rfi-001-Lj Workforce Information Technology Procurement Project - A Florida Workforce Saas (Software As A Service)Dokument36 Seiten13-Rfi-001-Lj Workforce Information Technology Procurement Project - A Florida Workforce Saas (Software As A Service)Sanjay JagdaleNoch keine Bewertungen

- Project Case Study of Spare Part Management System (1) ..Dokument47 SeitenProject Case Study of Spare Part Management System (1) ..Vipul Sharma100% (1)

- FYP - Gantt ChartDokument1 SeiteFYP - Gantt Chartzhi enNoch keine Bewertungen

- 11-DS Agile Management - Rev GDokument16 Seiten11-DS Agile Management - Rev GrpshvjuNoch keine Bewertungen

- Jenkins 2 Up & Running Tutorial-Chapter01Dokument13 SeitenJenkins 2 Up & Running Tutorial-Chapter01abhi gargNoch keine Bewertungen

- Implementation and Comparison of Recommender Systems Using Various ModelsDokument13 SeitenImplementation and Comparison of Recommender Systems Using Various ModelsIshan100% (1)

- Electricity Bill Payment PDF FreeDokument16 SeitenElectricity Bill Payment PDF Freekrishna mouliNoch keine Bewertungen

- 444560the Urban Dictionary of Final Cut Pro X TransitionsDokument2 Seiten444560the Urban Dictionary of Final Cut Pro X Transitionsbrough37lkNoch keine Bewertungen

- Getting Started With CalculiXDokument26 SeitenGetting Started With CalculiXjeffbaylorNoch keine Bewertungen

- Topsnake'S Guide To Retain Root Xt1080/M 4.4 KitkatDokument3 SeitenTopsnake'S Guide To Retain Root Xt1080/M 4.4 KitkatMatthew CannonNoch keine Bewertungen

- 90%-UGRD-IT6203 Database Management System 2 (Oracle 10g Admin 2)Dokument16 Seiten90%-UGRD-IT6203 Database Management System 2 (Oracle 10g Admin 2)michael sevillaNoch keine Bewertungen

- Checklist CMDBDokument3 SeitenChecklist CMDBkatz3011Noch keine Bewertungen

- Learning OpenStack High Availability - Sample ChapterDokument15 SeitenLearning OpenStack High Availability - Sample ChapterPackt PublishingNoch keine Bewertungen

- Car Rental System AbstractDokument3 SeitenCar Rental System AbstractVengatNoch keine Bewertungen

- Form UtamaDokument6 SeitenForm Utamauzix bogangNoch keine Bewertungen

- Triton Pro TKL ManualDokument6 SeitenTriton Pro TKL ManualGuy FalexNoch keine Bewertungen

- Django by DurgaDokument199 SeitenDjango by DurgaParshuramPatil100% (2)

- Amazon Elastic Container ServiceDokument683 SeitenAmazon Elastic Container ServiceJusticeshrs Portal100% (1)

- AUTODESK AUTOCAD PLANT 3D 2010 User GuideDokument4 SeitenAUTODESK AUTOCAD PLANT 3D 2010 User GuidePiyawat Pimol50% (2)

- OpenShift Online 2.0 REST API Guide en USDokument160 SeitenOpenShift Online 2.0 REST API Guide en USrch978Noch keine Bewertungen