Beruflich Dokumente

Kultur Dokumente

Stringing 30kV Line

Hochgeladen von

SamuelTrinandoCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Stringing 30kV Line

Hochgeladen von

SamuelTrinandoCopyright:

Verfügbare Formate

Date:Feb.

29,2012

Ref.No.:PPEP001Rev.00

METHODSTATEMENT

STRINGINGOF30KVOVERHEADLINE

FOR

2X30MWCFPPINPOMALAA

PT.ANTAM(PERSERO)Tbk,INDONESIA

FEBRUARY2012

PT.WASAMITRAENGINEERING

TABLE OF CONTENT

Page

1. Work Procedure and Job Safety Analysis .......................................................... 2

1.1

Preparation ................................................................................................ 2

1.2 Personal Protective Equipment ................................................................. 2

1.3

Others. ....................................................................................................... 2

2. Method Statement .............................................................................................. 2

2.1

General Condition...................................................................................... 2

2.2

Preparation Work ............................................................................................ 2

2.3

Procedure .................................................................................................. 3

2.4

Others ........................................................................................................ 4

3. Location of Work. ............................................................................................... 4

4. Attachment

a. Power Plan Layout

PT. WASA MITRA ENGINEERING

POMALAA CFPP 2 X 30MW

Method Statement for Installation of 30kV Conductor

(Crossing with existing 20kV PLNs Overhead Line)

1. Work Procedure and Job Safety Analysis.

1.1

Preparation

1) Man Power.

Safety Induction for workers by Safety Officer.

Tool Box meeting before start of work.

2) Necessary tools.

All necessary electrical tools shall be passed inspection.

3) Work Permit.

Permit shall be obtained from PLN & local government.

4) Installation of scaffolding.

Install of scaffolding for work access and inspection before use.

1.2

Personal Protective Equipment

Appropriate equipment, e.g. helmet, safety shoes, goggle, masker, safety

harness and other equipment, shall be given to related persons before

commencing work.

1.3

Others.

1) Barricade, sign board and temporary protection.

To be kept in container or job side and to be placed as required, refer to

each activity.

2) First aid box must be available on job site.

2. Method Statement

2.1

General Condition

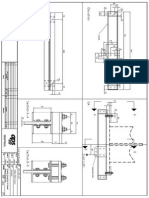

Height of existing 20kV tower or pole is 13 meters, for new 30kV pole is 10

meters. Therefore, installation of 30kV overhead line will be under 20kV

existing PLNs transmission line.

2.2

Preparation Work.

1) Ensure all the necessary electrical and hand tools complete already.

2) Ensure that storage of materials not obstruct to road traffic and public

facilities.

STRINGING OF 30KV OVERHEAD LINE

PT. WASA MITRA ENGINEERING

POMALAA CFPP 2 X 30MW

3) Puller preparation

-

Placement of engine puller in place has been determined previously

Dig a hole for anchor engine

4) Preparation tensioner

-

Placement of a tensioner in place has been determined previously

Transporting and Placing Conductor on location tensioner

Preparing Conductor on Drum Stand (drum jack)

5) Installation of roller

-

Installation of roller for conductors at pole to be done

6) Hold the rope

-

Connecting the rope puller and tensioned with polypropylene 12 mm

7) Stringing Wire Rope 12 mm

-

Stringing wire rope 12 mm with polypropylene 12 mm which had

been held earlier.

2.3

Procedure.

1) Before start the work, existing 20kV line must be shut down for a while.

2) Install scaffolding at the existing 20kV pole span, which crossing with

new 30kV line.

3) After the existing 20kV transmission line shut down, ensure that no

electrical power at existing conductor cable using grounding device or

Jin Pole.

4) Install the permanent safety nets under the 20kV transmission line

which crossing with new 30kV line and install warning sign under 20kV

line for safety guidance.

5) After point 3 and 4 finish, 20kV line can be operated.

6) During stringing work, the contractor shall take all necessary steps to

insure proper temporary grounding of the cables and equipment.

7) Ensure new pole at crossings with existing 20kV line shall be finish

before stringing work.

8) Install scaffolding at new pole.

9) First Conductor phase Stringing

-

Held the rope polypropylene 12 mm

Pulling the wire rope 12 mm with polypropylene 12 mm which had

been held earlier

Pull the conductor and polypropylene 12 mm with wire rope 12 mm

STRINGING OF 30KV OVERHEAD LINE

PT. WASA MITRA ENGINEERING

POMALAA CFPP 2 X 30MW

Pulling the wire rope 12 mm with polypropylene 12 mm

Repeat the procedure until it is fixed three conductors

10) Second Conductor phase Stringing

-

Repeat the first phase Stringing

11) Third Conductor phase Stringing

- Repeat the second phase Stringing

12) Place the tension insulator sets

-

Place the tension insulator sets in tower

Conductor pieces one by one and "press" in the tension clamp

conductor to be connected to the insulator sets.

2.4

Repeat the procedure to all the conductors

Others

1) Cleaning area after work finished.

2) At the work area of cabling works shall be provide of security and safety

person for control activity.

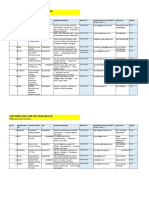

3. Location of Work

As per attached drawing

STRINGING OF 30KV OVERHEAD LINE

ATTACHMENT

PT Antam (Persero) Tbk, 2 x 30 MW CFPP In Pomalaa, Indonesia

Inquiry Documents of M&E Erection Work

Page 93 of 109

20kV PLN

overhead line

New 30kV

transmission line

Crossing with

existing 20kV PLN

overhead line

Das könnte Ihnen auch gefallen

- Under Ground Cable Laying HVDokument2 SeitenUnder Ground Cable Laying HVHansika RajapakshaNoch keine Bewertungen

- Method of Transportation GIS Ternate Transformers PDFDokument10 SeitenMethod of Transportation GIS Ternate Transformers PDFAditya FirgiantoNoch keine Bewertungen

- Distribution Conductor StringingDokument21 SeitenDistribution Conductor Stringingmadhava_srinivasan174Noch keine Bewertungen

- Temporary BarrierDokument1 SeiteTemporary BarrierAbohana MmNoch keine Bewertungen

- KPS HSE UST 001 - Use of Special ToolsDokument1 SeiteKPS HSE UST 001 - Use of Special Toolsgangadharan000Noch keine Bewertungen

- EXHIBIT O.site Safety and Health Plan - SHP 098 00. 20150615Dokument31 SeitenEXHIBIT O.site Safety and Health Plan - SHP 098 00. 20150615safetydmrcNoch keine Bewertungen

- Tps OHLDokument88 SeitenTps OHLNaseem AhmedNoch keine Bewertungen

- Test and Commissioning Manual 2877081Dokument26 SeitenTest and Commissioning Manual 2877081StephenNoch keine Bewertungen

- SFPSG-Reducing Unintended Movement of PlantDokument60 SeitenSFPSG-Reducing Unintended Movement of PlantLyle KorytarNoch keine Bewertungen

- Lock Out Tag OutDokument7 SeitenLock Out Tag Outharry mulyafitNoch keine Bewertungen

- Specification, Boat Ambulance PDFDokument1 SeiteSpecification, Boat Ambulance PDFErick Galarza100% (1)

- 7.16: Electrical Safety OEMS Element: Safe Work PracticesDokument10 Seiten7.16: Electrical Safety OEMS Element: Safe Work Practicesum erNoch keine Bewertungen

- NSC-400-CE-3110-MOS-02-A-Method Statement For 69kV Transmission Pole ErectionDokument18 SeitenNSC-400-CE-3110-MOS-02-A-Method Statement For 69kV Transmission Pole ErectionElisco Pher SalmasanNoch keine Bewertungen

- Transformer 1 MosDokument5 SeitenTransformer 1 MosMohamedAhmedFawzyNoch keine Bewertungen

- Dibia Ifeanyichukwu Peter Updated CV (Resume)Dokument7 SeitenDibia Ifeanyichukwu Peter Updated CV (Resume)wizzy basseyNoch keine Bewertungen

- Pre Installationfor Opgw 48 FDokument5 SeitenPre Installationfor Opgw 48 FMayank PorwalNoch keine Bewertungen

- PPE PolicyDokument3 SeitenPPE PolicyTolbert OkiringNoch keine Bewertungen

- Ehs 019 Houston Contactor Safety ProcedureDokument17 SeitenEhs 019 Houston Contactor Safety ProcedureSayed AbbasNoch keine Bewertungen

- Silica Gel Blue MSDSDokument5 SeitenSilica Gel Blue MSDSRajesh GalgalikarNoch keine Bewertungen

- Method Statement For Installation of Emt Conduit-OldDokument13 SeitenMethod Statement For Installation of Emt Conduit-OldSalman SaifuddinNoch keine Bewertungen

- LineDokument4 SeitenLineShaharyar WaliullahNoch keine Bewertungen

- HEMP-005 Excavation Manual & Mechanical Rev.2Dokument9 SeitenHEMP-005 Excavation Manual & Mechanical Rev.2saravana.bNoch keine Bewertungen

- Press On Permit To Work SystemDokument7 SeitenPress On Permit To Work SystemashwaniNoch keine Bewertungen

- OHLDokument106 SeitenOHLvaithy1990Noch keine Bewertungen

- Electrical Safe Work Practices PlanDokument5 SeitenElectrical Safe Work Practices PlanAjay KrishnanNoch keine Bewertungen

- SSR Competency Assurance Guidance Booklet No.2 (SSR Summary For Contractors' CP)Dokument8 SeitenSSR Competency Assurance Guidance Booklet No.2 (SSR Summary For Contractors' CP)wavehayiathNoch keine Bewertungen

- MoS LiLo Sinaw2Dokument26 SeitenMoS LiLo Sinaw2Antaryami Singh GoondiNoch keine Bewertungen

- A Copy of Sample Traffic Management PlanDokument20 SeitenA Copy of Sample Traffic Management PlanIsr W. MekonnenNoch keine Bewertungen

- Pe12 3067 Doc q900 Project Hse Plan r0Dokument16 SeitenPe12 3067 Doc q900 Project Hse Plan r0morgojoyoNoch keine Bewertungen

- Energization - Substation # 2Dokument2 SeitenEnergization - Substation # 2Hussain KhanNoch keine Bewertungen

- Procedure Installation of Lighting - LABUAN BAJO PDFDokument6 SeitenProcedure Installation of Lighting - LABUAN BAJO PDFWika Djoko ONoch keine Bewertungen

- MV Cable Jointing TerminationDokument27 SeitenMV Cable Jointing Terminationwahyu hutamaNoch keine Bewertungen

- Cable Repair Procedure (OVER 1.75)Dokument7 SeitenCable Repair Procedure (OVER 1.75)Mahmoud Tobala100% (1)

- Alchohol and Drug Testing ProcedureDokument14 SeitenAlchohol and Drug Testing ProcedureisaacbombayNoch keine Bewertungen

- 5 Smfe HDD Mos HDDDokument20 Seiten5 Smfe HDD Mos HDDshamiraNoch keine Bewertungen

- Electrical Safe Work PracticeDokument138 SeitenElectrical Safe Work PracticeIjaz HussainNoch keine Bewertungen

- Method Statement IPBsDokument7 SeitenMethod Statement IPBskamil100% (1)

- Jsa Nitrogen Purging PDFDokument2 SeitenJsa Nitrogen Purging PDFBISWA RANJAN SAHOONoch keine Bewertungen

- Procedure For Trenching: Laying & Construction of 12", 6" & 4" NB U/G Steel P/L Network & Associated Works at HyderabadDokument7 SeitenProcedure For Trenching: Laying & Construction of 12", 6" & 4" NB U/G Steel P/L Network & Associated Works at HyderabadMecon HyderabadNoch keine Bewertungen

- DC Cable LayingDokument8 SeitenDC Cable LayingAhamed UmarNoch keine Bewertungen

- Procedures For Safe Working and Testing of Energized Electrical EquipmentDokument25 SeitenProcedures For Safe Working and Testing of Energized Electrical EquipmentSelvn SubramanianNoch keine Bewertungen

- International Transmission Line Contractors - Teems IndiaDokument13 SeitenInternational Transmission Line Contractors - Teems IndiaTransmission Line Construction Company - Teems IndiaNoch keine Bewertungen

- Raychem Screened, Separable Connection System RSTI-68 800 A Up To 42 KVDokument4 SeitenRaychem Screened, Separable Connection System RSTI-68 800 A Up To 42 KVgiovany_vq91Noch keine Bewertungen

- Under Ground CablesDokument29 SeitenUnder Ground Cablesfawad nawaz ghuman100% (1)

- Tbl-Retel-Aa-Sf-Ta-003 - Environment Management PlanDokument31 SeitenTbl-Retel-Aa-Sf-Ta-003 - Environment Management PlanMoaatazz Nouisri100% (1)

- PTW - Electrical PermitDokument2 SeitenPTW - Electrical PermitJahanzaib KhanNoch keine Bewertungen

- Installation Method StatementDokument6 SeitenInstallation Method StatementgururajNoch keine Bewertungen

- LIFTING PLAN Crane 7tonDokument1 SeiteLIFTING PLAN Crane 7tonSeftian Muhardy100% (1)

- NO HLD 10 TPSH 810008 - Rev00 Electrical Isolation Procedure TotalDokument16 SeitenNO HLD 10 TPSH 810008 - Rev00 Electrical Isolation Procedure TotalAUGUSTA WIBI ARDIKTANoch keine Bewertungen

- Final Handover Certificate ElecricalDokument1 SeiteFinal Handover Certificate ElecricalDeonNoch keine Bewertungen

- Mansoon Sop & ChecklistDokument3 SeitenMansoon Sop & ChecklistRoselyn SharronNoch keine Bewertungen

- Crane Safety Tool Box TalkDokument2 SeitenCrane Safety Tool Box Talksathees4329Noch keine Bewertungen

- Fire Prevention and Protection Plan-2Dokument22 SeitenFire Prevention and Protection Plan-2Ashok sNoch keine Bewertungen

- CP For Safe Lifting OperationDokument26 SeitenCP For Safe Lifting OperationLaughlikesiao HeheNoch keine Bewertungen

- Hazard And Risk Analysis A Complete Guide - 2020 EditionVon EverandHazard And Risk Analysis A Complete Guide - 2020 EditionNoch keine Bewertungen

- EAP BUILDING SCOPE OF WORK UpdatedDokument7 SeitenEAP BUILDING SCOPE OF WORK UpdatedMasesi RadebeNoch keine Bewertungen

- Verificat Installation of Power and Control Cables - CELIN - Black Sea - IrakDokument8 SeitenVerificat Installation of Power and Control Cables - CELIN - Black Sea - IrakAlinaIordacheNoch keine Bewertungen

- Study, Supply and Installation of Xlpe 150 KV Underground and Submarine Cables For Transmission Line Skiathos - MantoudiDokument30 SeitenStudy, Supply and Installation of Xlpe 150 KV Underground and Submarine Cables For Transmission Line Skiathos - MantoudiMohamed HadadNoch keine Bewertungen

- G101 25 1804.00 Om171 - P0 2Dokument8 SeitenG101 25 1804.00 Om171 - P0 2SamuelTrinandoNoch keine Bewertungen

- G101 25 1804.00 Om171 - P0 3Dokument24 SeitenG101 25 1804.00 Om171 - P0 3SamuelTrinandoNoch keine Bewertungen

- G101 25 1804.00 Om171 - P0 1Dokument58 SeitenG101 25 1804.00 Om171 - P0 1SamuelTrinando100% (1)

- MM M05 3Dokument94 SeitenMM M05 3SamuelTrinandoNoch keine Bewertungen

- MM M05 2Dokument162 SeitenMM M05 2SamuelTrinandoNoch keine Bewertungen

- MM M05 4Dokument221 SeitenMM M05 4SamuelTrinandoNoch keine Bewertungen

- 3of5mm 1Dokument120 Seiten3of5mm 1SamuelTrinandoNoch keine Bewertungen

- APS-GA-001 Plan View Setup in BoilerDokument1 SeiteAPS-GA-001 Plan View Setup in BoilerSamuelTrinandoNoch keine Bewertungen

- MM M02 2Dokument347 SeitenMM M02 2SamuelTrinandoNoch keine Bewertungen

- Mm9a0e 1Dokument177 SeitenMm9a0e 1SamuelTrinandoNoch keine Bewertungen

- MM M02 1Dokument312 SeitenMM M02 1SamuelTrinandoNoch keine Bewertungen

- MM M05 1Dokument353 SeitenMM M05 1SamuelTrinandoNoch keine Bewertungen

- 5of5mm 1Dokument119 Seiten5of5mm 1SamuelTrinandoNoch keine Bewertungen

- Annual Outage Maintenence Check List - BFPTDokument8 SeitenAnnual Outage Maintenence Check List - BFPTSamuelTrinandoNoch keine Bewertungen

- 1OF5WME - Project/%Temp%/From CD Paiton3Maint2015/APS PlatformMM 1Dokument120 Seiten1OF5WME - Project/%Temp%/From CD Paiton3Maint2015/APS PlatformMM 1SamuelTrinandoNoch keine Bewertungen

- Chapter 4 Preventive Maintenance: B o I L e R M I T S U B I S H IDokument120 SeitenChapter 4 Preventive Maintenance: B o I L e R M I T S U B I S H ISamuelTrinandoNoch keine Bewertungen

- APS-GA-007 Front Wall Elevation Dead Hang SetupDokument1 SeiteAPS-GA-007 Front Wall Elevation Dead Hang SetupSamuelTrinandoNoch keine Bewertungen

- APS-GA-009 Section - Technitruss Dead Hang and Gondola SetupDokument1 SeiteAPS-GA-009 Section - Technitruss Dead Hang and Gondola SetupSamuelTrinandoNoch keine Bewertungen

- APS-DeTL-007 Gondola Suspension Bracket Front WalllDokument1 SeiteAPS-DeTL-007 Gondola Suspension Bracket Front WalllSamuelTrinandoNoch keine Bewertungen

- APS-GA-006 Plan View of Roof PenetrationsDokument1 SeiteAPS-GA-006 Plan View of Roof PenetrationsSamuelTrinandoNoch keine Bewertungen

- APS-GA-008 Section - Technitruss Hoist SetupDokument1 SeiteAPS-GA-008 Section - Technitruss Hoist SetupSamuelTrinandoNoch keine Bewertungen

- APS-DeTL-008 Roof Hole Penetration DetailDokument1 SeiteAPS-DeTL-008 Roof Hole Penetration DetailSamuelTrinandoNoch keine Bewertungen

- APS-DeTL-002 Dead Hang SetupsDokument1 SeiteAPS-DeTL-002 Dead Hang SetupsSamuelTrinandoNoch keine Bewertungen

- APS DETL 001 Hoisting SetupDokument1 SeiteAPS DETL 001 Hoisting SetupSamuelTrinandoNoch keine Bewertungen

- APS-DeTL-005 T-Truss Suspension Bracket Front WallDokument1 SeiteAPS-DeTL-005 T-Truss Suspension Bracket Front WallSamuelTrinandoNoch keine Bewertungen

- APS-DeTL-006 Gondola Suspension Bracket NoseDokument1 SeiteAPS-DeTL-006 Gondola Suspension Bracket NoseSamuelTrinandoNoch keine Bewertungen

- APS-DeTL-004 T-Truss Suspension Bracket NoseDokument1 SeiteAPS-DeTL-004 T-Truss Suspension Bracket NoseSamuelTrinandoNoch keine Bewertungen

- APS DETL 003 T Truss Hoist BracketDokument1 SeiteAPS DETL 003 T Truss Hoist BracketSamuelTrinandoNoch keine Bewertungen

- APS Drawing TransmittalDokument1 SeiteAPS Drawing TransmittalSamuelTrinandoNoch keine Bewertungen

- Electoral Roll For Auto Tyres Tubes Panel of CAPEXIL For The Year 2021 22Dokument2 SeitenElectoral Roll For Auto Tyres Tubes Panel of CAPEXIL For The Year 2021 22asif.ayyub7624Noch keine Bewertungen

- CMB Metropolitan Region Transport 2015-08-11 Final v7Dokument120 SeitenCMB Metropolitan Region Transport 2015-08-11 Final v7hima_bindu_89Noch keine Bewertungen

- January 2017Dokument15 SeitenJanuary 2017Pumper TraderNoch keine Bewertungen

- Chapter 1: Transportation and The Laws On Traffic Unit 1-History of TransportationDokument73 SeitenChapter 1: Transportation and The Laws On Traffic Unit 1-History of TransportationVin SabNoch keine Bewertungen

- History of Civil EngineeringDokument3 SeitenHistory of Civil EngineeringkhajaimadNoch keine Bewertungen

- Sdre14-6 Vig 1-8-May 2019Dokument9 SeitenSdre14-6 Vig 1-8-May 2019danielsu87Noch keine Bewertungen

- Tata AceDokument26 SeitenTata AceNitin Kr banka100% (2)

- Pipeline Construction Stages With PDFDokument11 SeitenPipeline Construction Stages With PDFBrijesh Katariya VCSNoch keine Bewertungen

- Notice Inviting Expression of Interest (Eoi) For Empanelment of Consultants in Various FieldsDokument28 SeitenNotice Inviting Expression of Interest (Eoi) For Empanelment of Consultants in Various FieldsakbondadaNoch keine Bewertungen

- Sample Safe System of WorkDokument13 SeitenSample Safe System of WorkHossamKandil50% (4)

- CDI 4 Traffic MNGTDokument19 SeitenCDI 4 Traffic MNGTRoui FacunNoch keine Bewertungen

- Welcome To Industrial Training Institute: Controller Area NetworkDokument47 SeitenWelcome To Industrial Training Institute: Controller Area NetworkNiza Jamil100% (1)

- Site Analysis Site Visit ChecklistDokument2 SeitenSite Analysis Site Visit ChecklistFizaNoch keine Bewertungen

- AClass AW168 FusesMainBoardDokument2 SeitenAClass AW168 FusesMainBoardsotannaNoch keine Bewertungen

- Rule: Flood Elevation Determinations: South DakotaDokument3 SeitenRule: Flood Elevation Determinations: South DakotaJustia.comNoch keine Bewertungen

- Film Production Risk Assessment FormDokument1 SeiteFilm Production Risk Assessment FormDemimasonNoch keine Bewertungen

- Sieve Analysis and Finess ModulusDokument20 SeitenSieve Analysis and Finess ModulusGeomanjeriNoch keine Bewertungen

- Design of Rigid Pavement For TunnelsDokument19 SeitenDesign of Rigid Pavement For TunnelsHemant YesajiNoch keine Bewertungen

- Keele Campus Guide ColourDokument5 SeitenKeele Campus Guide ColourCarlos ColeNoch keine Bewertungen

- Print Ticket: Onward Journey Ticket DetailsDokument2 SeitenPrint Ticket: Onward Journey Ticket DetailsImran SharieffNoch keine Bewertungen

- Airbags and Collisions EssayDokument2 SeitenAirbags and Collisions EssayDianaNoch keine Bewertungen

- College DetailsDokument4 SeitenCollege DetailsVinay KumarNoch keine Bewertungen

- Task 5 - Local Agenda 21Dokument16 SeitenTask 5 - Local Agenda 21liyanarusman100% (1)

- Pinout Tablero Haval m4Dokument1 SeitePinout Tablero Haval m4Erasmo Israel Garcia OchoaNoch keine Bewertungen

- Types of Movement JointsDokument7 SeitenTypes of Movement Jointsvinmanishs0% (1)

- Automatic Parking Space Detection System PaperDokument6 SeitenAutomatic Parking Space Detection System PaperRed MiNoch keine Bewertungen

- Jeep Security ManualDokument14 SeitenJeep Security ManualThyrza LawrenceNoch keine Bewertungen

- 3 Design Considerations StandardsDokument117 Seiten3 Design Considerations StandardsAldwin Joseph Abainza100% (2)

- IDLVChecklist 230713Dokument2 SeitenIDLVChecklist 230713Malkeet SinghNoch keine Bewertungen