Beruflich Dokumente

Kultur Dokumente

Gate Valve Maintenance Manual

Hochgeladen von

Faizan AbbasiCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Gate Valve Maintenance Manual

Hochgeladen von

Faizan AbbasiCopyright:

Verfügbare Formate

GATE VALVE MAINTENANCE AND ADJUSTMENT PROCEDURE

GATE VALVE MAINTENANCE

AND ADJUSTMENT PROCEDURES

Valve Maintenance Manual

May 15, 2001

GATE VALVE MAINTENANCE AND ADJUSTMENT PROCEDURE

Table of Contents

TABLE OF CONTENTS .................................................................................................................. 2

I. GATE AND BONNET O-RING 0.625" - 21" GATE VALVES ..................................................... 3

II. BELLOWS, PNEUMATIC STD 0.625" - 21" GATE VALVES .................................................... 5

III. ACTUATOR O-RING 0.625" - 21" GATE VALVES .................................................................. 8

IV. SEAL PLATE ASSEMBLY/ PINS BEARING 0.625" - 21" GATE VALVES .......................... 10

VI. VALVE ADJUSTMENT 0.625" - 21" GATE VALVES ............................................................ 14

VII. VALVE ADJUSTMENT CHART 1.5" - 21" GATE VALVES .................................................. 15

Table of Figures, Tables and Drawings

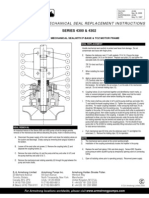

FIGURE 1 BONNET ACTUATOR CARRIGE ASSY. SEPARATED FROM VALVE BODY .................... 3

FIGURE 2 GATE O-RING AND BONNET PLATE O-RING ...................................................................... 4

FIGURE 3 BELLOWS AND PISTON SHOWN WITH ACTUATOR HOUSING REMOVED ..................... 5

FIGURE 4 PISTON CLOSE-UP FOR SPANNER WRENCH POSITIONING ........................................... 5

FIGURE 5 BELLOWS AND ACTUATOR ASSEMBLIES DRAWING ...................................................... 7

FIGURE 6 DRIVE SHAFT O-RING ........................................................................................................... 8

FIGURE 7 ACTUATOR O-RING ............................................................................................................... 9

FIGURE 8 LINKAGE REMOVAL ............................................................................................................ 10

FIGURE 9 PIN AND LINKAGE CLOSE-UP............................................................................................ 11

FIGURE 10 GATE AND STRONGBACK ASSEMBLIES OPENED ....................................................... 11

FIGURE 11 PIN, WASHERS AND R-RING REMOVAL DRAWING ....................................................... 12

FIGURE 12 GATE AND STRONGBACK ASSYS AFTER REASSEMBLY ........................................... 13

FIGURE 13 STRONGBACK AND GATE ASSYS DRAWING ................................................................ 13

FIGURE 14 VALVE ADJUSTMENT TABLE .......................................................................................... 15

FIGURE 15 DIMENSIONS "A","B","C" ................................................................................................. 15

FIGURE 16 PNEUMATIC ACTUATOR ASSY........................................................................................ 16

Valve Maintenance Manual

GATE VALVE MAINTENANCE AND ADJUSTMENT PROCEDURE

I. VITON GATE AND BONNET O-RING

STD AND MSB 0.625 21 GATE VALVES

A. Tools and Materials Required:

1. Allen Wrench for 1 14 Gate Valves

2. Box Wrench for 1621 Gate Valves

3. O-Ring Pick

4. Rubber Gloves

5. Grease Apezion L O-Ring Type

6. IPA

B. Procedure: Always wear Rubber Gloves when handling the Gate Valve

1. Vent station and pump corresponding to Gate Valve to atmosphere;

2. Actuate valve to Gate Open position;

3. For safety, remove air to actuator;

4. Remove bolts that hold Bonnet Actuator Assembly to body; or for Quick-Clamp

Bonnet, undo the clamp;

5. Pull out the Bonnet Actuator Carriage Assembly, taking care not to move

adjustment of linkage;

VALVE BODY

GATE ASSY. AND STRONGBACK

LOWER LINKAGE-UPPER LINKAGE

BONNET PLATE ASSY

ACTUATOR ASSY

ACTUATOR TOP WITH SENSORS

(OPEN/CLOSED)

Figure 1 BONNET ACTUATOR CARRIGE ASSY. SEPARATED FROM VALVE BODY

Valve Maintenance Manual

GATE VALVE MAINTENANCE AND ADJUSTMENT PROCEDURE

6. Remove O-Ring or Gasket from Bonnet Assembly and discard;

7. Remove Gate O-Ring with the plastic pick, taking care not to scratch the O-Ring

groove; Discard the O-Ring;

8. Clean O-Ring groove with IPA and dry out with Nitrogen or CDA;

9. Apply a light coat of Apezion L Grease to the new Gate O-Ring;( It is very

important that gloves are worn for this step)

10. Install new O-Ring on gate, taking care to avoid twisting or deforming the

O-Ring;

11. Apply a light coat of Apezion L Grease to the new Bonnet assembly Viton ORing; Copper Gasket install dry

12. Install new O-Ring/Gasket on Bonnet assembly, taking care to avoid twisting or

deforming the O-Ring

13. Replace Bonnet Actuator Assembly into valve body;

14. Install bolts and tighten. (For MSB, Copper gasket type, tighten side to side 2025ft-lb)

BONNET PLATE O-RING

GATE ASSY. O-RING

NOTE:

1. BE CAREFUL NOT TO

SCRATCH O-RING GROOVE;

2. APPLY ONLY THIN LAYER OF

GREASE;

3. AVOID TWISTING,

STRETCHING OR DEFORMING

THE O-RING

4.

Figure 2 GATE O-RING AND BONNET PLATE O-RING

Valve Maintenance Manual

GATE VALVE MAINTENANCE AND ADJUSTMENT PROCEDURE

II. BELLOWS, PNEUMATIC STD CYCLE ONLY

0.625 21 GATE VALVES

A. Tools and Materials Required:

1. Spanner Wrench

2. Allen Wrench Set

3. O-Ring Pick

4. Pick (for R-Ring removal)

5. Needle-Nose Pliers

6. Small Standard Screw Driver

7. Actuator O-Rings

8. Grease for Bellows O-Ring: Apezion L

9. Vacuum Grease

10. IPA

11. Heat Gun

12. Lock-Tite

B. Procedure:

1. Vent station and pump corresponding to Gate Valve to atmosphere;

2. Actuate valve to Gate Open position;

3. For safety, remove air to actuator;

4. Remove Actuator Cover ( 2 screws);

5. Remove Actuator Top ( 6 screws);

6. Measure the distance between the top of the Piston and the top of the Drive

Shaft. (This will be helpful later during reassembly and adjustment)

7. Remove the Jam Nut from the Drive Shaft. (Heat gun may be needed to melt the

Lock-Tite on the thread)

BELLOWS

PISTON

DIMENSION A

Figure 3 BELLOWS AND PISTON SHOWN WITH ACTUATOR HOUSING REMOVED

Valve Maintenance Manual

GATE VALVE MAINTENANCE AND ADJUSTMENT PROCEDURE

INDENTATIONS ON THE

PISTON FOR SPANNER

WRENCH

NOTE: GATE MUST BE IN

OPEN POSITION TO ACCESS

THESE EASILY

JAM NUT

NOTE: MAY REQUIRE USE

OF HEAT GUN TO MELT

ANY LOCK-TITE

Figure 4 PISTON CLOSE-UP FOR SPANNER WRENCH POSITIONING

8. Using a spanner wrench, turn Piston counterclockwise to remove from Actuator

Housing;

9. Remove O-Ring from top of Drive Shaft;

10. Remove remaining screws holding the Actuator Housing to the Bonnet Plate (2

screws)

11. Remove the Actuator Housing;

12. Remove R-Ring from Drive Shaft, using a pick. If a replacement is NOT

available, use care to preserve the R-Ring. Otherwise, pull out using the needle

nose pliers and discard;

13. Remove bellows by pulling and twisting slightly. Discard;

14. Remove O-Ring in the Bellows drive shaft area and discard;

15. Clean Drive Shaft groove and Bellows area with IPA;

16. Apply a thin coat of grease (Apezion L) on the O-Ring for the Drive Shaft in

Bellows area;

17. Install O-Ring;

18. Apply a thin coat of grease (Apezion L) on the O-Ring for the Bellows base

Flange;

19. Install O-Ring;

20. Replace Bellows assembly on the Drive Shaft, pushing and twisting slightly to go

over the O-Ring;

21. Install R-Ring on the Drive Shaft, using a screw driver and a pick. Make sure it

clicks into the groove next to the top of the Bellows.

22. Apply a thin coat of Vacuum Grease to the Drive Shaft;

23. Install Actuator Housing on the Bonnet plate;

24. Apply a thin coating of Vacuum Grease to the O-Ring for the top of the Drive

Shaft;

25. Install O-Ring on the top of the Drive Shaft;

26. Apply a thin coating of vacuum Grease to the Piston area, if necessary;

27. Install Piston on Drive Shaft; using a spanner wrench, turn clockwise until the

measurement in step # 5 is achieved;

Valve Maintenance Manual

GATE VALVE MAINTENANCE AND ADJUSTMENT PROCEDURE

28.

29.

30.

31.

Install Jam Nut, using Lock-Tite and tighten;

Install Actuator Top and tighten screws;

Install Actuator Cover and tighten screws;

Install air line and test operation of Valve and Actuator.

SCREW (6X)

ACTUATOR

TOP

O-RING

JAM NUT

O-RING

PISTON

MAGNET

O-RING

ACTUATOR

HOUSING

O-RING

R-RING

O-RING

BELLOWS

BELLOWS END FLG

R-RING

REED SW DRIVE

SHAFT

WASHER (3X)

BEARING

R-RING

PINS (2X)

STEM

O-RING

Figure 5 BELLOWS AND ACTUATOR ASSEMBLIES DRAWING

Valve Maintenance Manual

GATE VALVE MAINTENANCE AND ADJUSTMENT PROCEDURE

III. ACTUATOR O-RING

0.625 21 GATE VALVES STD AND MSB

A. Tools and Materials Required:

1. Spanner Wrench

2. Allen Wrench Set

3. O-Ring Pick

4. Pick (for R-Ring removal)

5. Needle-Nose Pliers

6. Small Standard Screw Driver

7. Actuator O-Rings

8. Grease for Bellows O-Ring: Apezion L

9. Vacuum Grease

10. IPA

11. Heat Gun

12. Lock-Tite (Def Pro #51574 for high temp applications or Lock-Tite 242-31 for

standard applications recommended)

B. Procedure:

1. Actuate valve to Gate Open position;

2. For safety, remove air to actuator;

3. Remove Actuator Cover ( 2 screws);

4. Remove Actuator Top ( 6 screws);

5. Measure the distance between the top of the Piston and the top of the Drive

Shaft. (This will be helpful later during reassembly and adjustment)

6. Remove the Jam Nut from the Drive Shaft. (Heat gun may be needed to melt the

Lock-Tite on the thread)

7. Using a spanner wrench, turn Piston counterclockwise to remove from Actuator

Housing;

8. Remove O-Ring from top of Drive Shaft;

DRIVE SHAFT O-RING

NOTE: REMOVE THIS O-RING

FIRST BEFORE REMOVING

THE ACTUATOR HOUSING

Figure 6 DRIVE SHAFT O-RING

Valve Maintenance Manual

GATE VALVE MAINTENANCE AND ADJUSTMENT PROCEDURE

9. Remove remaining screws holding the Actuator Housing to the Bonnet Plate (2

screws)

10. Remove the Actuator Housing;

11. Remove O-Ring in Actuator Housing, using a pick and using care to not scratch

the groove surface;

ACTUATOR O-RING

NOTE:

1. REMOVE THIS O-RING BEFORE

REMOVING ACTUATOR HOUSING;

2. BE CAREFUL NOT TO

SCRATCH O-RING GROOVE

Figure 7 ACTUATOR O-RING

12.

13.

14.

15.

16.

17.

18.

19.

20.

21.

22.

23.

24.

25.

26.

27.

Apply a thin coat of vacuum grease on the new O-Ring;

Install O-Ring;

Inspect the drive shaft; clean and lubricate as necessary;

Install Actuator Housing on the Bonnet plate; Tighten screws;

Apply a thin coat of Vacuum grease on the O-Ring for the top of the Drive Shaft;

Install O-Ring;

Inspect actuator housing; clean and lubricate as necessary;

Apply a thin coat of vacuum grease on the O-Ring for the Piston;

Install O-Ring on the Piston;

Install Piston on Drive Shaft, using a spanner wrench and turning clockwise until

the measurement in step # 5 is achieved;

Install Jam Nut, using Lock-Tite (Def Pro #51574 for high temp applications or

Lock-Tite 242-31 for standard applications recommended) and tighten;

Apply a thin coat of vacuum grease to the O-Ring for the Actuator Top;

Install O-Ring on the Actuator Top;

Install Actuator Top and tighten screws;

Install Actuator Cover and tighten screws;

Install air line and test operation of Valve and Actuator.

Valve Maintenance Manual

GATE VALVE MAINTENANCE AND ADJUSTMENT PROCEDURE

IV. SEAL PLATE ASSEMBLY/ PINS BEARING

0.62521

A. Tools and Materials Required:

1. Allen Wrench Set

2. Arbor Press

3. Punch

4. Hammer

5. Wrenches (Box or Open)

6. R-R Pliers

7. Vacuum Grease

8. IPA

9. Latex Gloves

B. Procedure 4 21

1. Actuate valve to gate Open position;

2. For safety, remove air to actuator;

3. Remove bolts that hold Bonnet Actuator Assembly to body; For Quick-Clamp

Bonnet, undo the clamp;

4. Pull out the Bonnet Actuator Carriage Assembly;

5. Using a punch and hammer, remove the pin that holds the Upper Linkage to the

Lower Linkage-Upper Linkage of Strongback; (Three washers and an R-Ring

should be recovered) Note: If the pin does not move, flip the assembly over

and try from the other side. Caution: Be careful not to bend the Upper Linkage;

the use of a wooden block for support is recommended)

HAMMER

WOODEN BLOCK

PUNCH

LOWER LINKAGE-UPPER LINKAGE

LOWER LINKAGE-STRONGBACK

Figure 8 LINKAGE REMOVAL

6. Separate the Bonnet Upper Linkage Assembly from the Carriage Assembly;

Valve Maintenance Manual

10

GATE VALVE MAINTENANCE AND ADJUSTMENT PROCEDURE

7. Measure the distance between the Strongback Lower Linkage and the Upper

Linkage-Lower Linkage; (This will be helpful later during reassembly and valve

adjustment)

Figure 9 PIN AND LINKAGE CLOSE-UP

PIN

(HOLDS UPPER AND

LOWER LINKAGES)

DIMENSION C

NOTE: IF PIN DOESNT COME OUT

EASILY, FLIP OVER AND HIT WITH

PUNCH ON THE OTHER SIDE

8. Move Carriage assembly to a suitable work place for disassembly and the

replacement of Pins, Bearings and R-Rings;

9. Remove Gate Spring by removing one set screw (Allen Wrench);

10. Remove four set screws( Allen-3/32) that hold Gate and Strongback together;

11. Separate Gate from Strongback.

WHEEL

LINK

LOWER LINKAGESTRONGBACK

CARRIAGE BAR

GATE SPRING

Figure 10 GATE AND STRONGBACK ASSEMBLIES OPENED

12. Remove Set Screws, Links, Washers, Pins, and Carriage Bars; Discard

Washers;

Valve Maintenance Manual

11

GATE VALVE MAINTENANCE AND ADJUSTMENT PROCEDURE

13. Using a punch and hammer, remove wheels from their pin. Note: If the pin does

not move, try from the other side.

14. Using an arbor press, remove the bearings from the links and wheels; Discard

expendable parts;

15. Clean all reusable parts such as the gate, Strongback, Links, Carriage Bars, and

Gate Spring with IPA;

16. Press new Bearings in using an arbor press; For Viton Bonnet sealing valves,

ensure that the Bearings are properly lubricated with the appropriate vacuum

grease( Micro Coat 601 recommended); For Copper sealing bonnet valves run

bearings dry

17. Verify that all bearings spin freely;

18. Install Washers, Pins and R-Rings into Strongback;

19. The recommended technique is as follows:

a) Slide long side of pin through hole first (the side without the groove);

b) Install R-Ring close to the end of the pin, not in the groove;

c) Add on the pin one Washer, then the Wheel, then the other two Washers;

d) Push Pin in until the R-Ring snaps into its groove;

UPPER LINKAGE

WASHERS (3X)

R-RING

PIN

R-RING GROOVE

LOWER LINKAGE

NOTE; THE SAME TECHNIQUE IS USED TO REMOVE AND

REINSTALL THE WHEELS IN THE STRONGBACK ASSY.

Figure 11 PIN, WASHERS AND R-RING REMOVAL DRAWING

20.

21.

22.

23.

24.

25.

26.

27.

28.

29.

30.

Verify that all wheels spin freely;

Set Strongback aside for later assembly;

Install Links, Washers, and Pins into Gate Slots;

Adjust Pins to correspond to Strongback Pin Pockets;

Install Gate to Strongback; Verify that all Pins fit into Strongback pockets;

Tighten the set screws loosened in step # 10;

Verify that Gate moves freely up and down and is flush with the Strongback in

the down position;

Install Gate Spring;

Install and tighten set screw removed in step # 9;

Reattach Upper Linkage to Strongback Lower Linkage-Upper Linkage, using the

technique detailed in step # 19;

Replace complete assembly into valve body;

Valve Maintenance Manual

12

GATE VALVE MAINTENANCE AND ADJUSTMENT PROCEDURE

AFTER REASSEMBLY,

CHECK THAT THE GATE

ASSY SITS FLUSH ON THE

STRONGBACK AND MOVES

FREELY UP AND DOWN. DO

THIS BEFORE INSTALLING

THE GATE SPRING.

Figure 12 GATE AND STRONGBACK ASSYS AFTER REASSEMBLY

31.

32.

33.

34.

Verify the measurement in step # 7, and adjust as necessary;

Tighten bolts or install Quick-Clamp as appropriate;

Test Valve operation;

If necessary, refer to Valve Adjustment Procedure.

LOWER LINKAGEUPPER LINKAGE

LOWER LINKAGE

STRONGBACK

Figure 13 STRONGBACK AND GATE ASSYS DRAWING

Valve Maintenance Manual

13

GATE VALVE MAINTENANCE AND ADJUSTMENT PROCEDURE

V. VALVE ADJUSTMENT

COMPRESSION AND OVER-CENTER 0.625 21

A. Tools and Materials required:

1. Allen Wrench Set

2. Wrench Set (Box and Open)

3. Air Regulator

4. Heat Gun

5. Latex Gloves

B. Procedure:

Steps 1 8 apply to 0.625 3 Gate Valves Only

1. Actuate Valve to Open Gate position;

2. For safety, remove air from Actuator;

3. Remove Actuator Cover (2 screws);

4. Remove Actuator Top (6 screws);

5. Loose Jam Nut on Drive Shaft ( This may require the use of the heat gun to melt

the Lock-Tite ((Def Pro #51574 for high temp applications or Lock-Tite 242-31 for

standard applications recommended) on the thread);

6. Check Dimension A on Chart for specific valve size;(This is only the starting

adjustment)

7. Adjust and tighten Jam Nut; (Do not use Lock-Tite at this point, as adjustment

may be needed later);

8. Install Actuator Top, using only 2-4 screws;

9. Remove bolts holding the Bonnet Actuator Assembly to valve body; For QuickClamp Bonnet, undo the clamp;

10. Pull out Actuator Bonnet Carriage Assembly from valve body;

11. Check Dimension C on Chart for specific valve size;

12. To adjust, loosen Jam Nut, then turn Lower Linkage-Upper Linkage counter

clockwise to increase dimension for more compression; or turn clockwise to

decrease the dimension for less compression.(More Compression means more

air pressure to lock valve; Less Compression means less air pressure to lock

valve);

13. After adjusting, tighten Jam Nut;

14. Reassemble Bonnet Carriage Assembly on valve body;

15. Using an in-line air regulator, check the air pressure required to lock valve. Refer

to Chart for Recommended Locking Air Pressure per size of gate valve.

16. Adjust Dimension C until the correct Locking Air Pressure is achieved;

Steps 17 20 apply to 4 12Gate Valves Only

Steps 17 20 apply to 4 12Gate Valves Only

17. Check Dimension B on Chart for specific valve size, depending on Over center or

Steps 17 20 apply to 4 12Gate Valves Only

No Over center requirement. (Note: Proper Over center means that the Gate

does not drop when air pressure is removed from the Actuator)

18. If necessary, loosen nut and adjust Dimension B by turning screw counter

clockwise to increase dimension for less Over center or turn clockwise to

decrease dimension for more Over center. Less Over center means less travel

for the Linkage; more Over center means more travel;

19. Check for Over center adjustment: If gate drops after removal of air pressure for

valves that require over center, go back to Step # 18.

20. Tighten nut;

21. Install all bolts and tighten;

22. Test valve operation.

Valve Maintenance Manual

14

GATE VALVE MAINTENANCE AND ADJUSTMENT PROCEDURE

VI. VALVE ADJUSTMENT CHART

INSTRUCTION FOR VALVE ADJUSTMENT

VALVE

SIZE

DIMENSION A

PISTON ADJUST *

DIMENSION B

OVERCENTER

ADJUST

DIMENSION B

NO

OVERCENTER

ADJUST

N/A

N/A

N/A

N/A

.360

.160

.465

.800

.900

.950

-.730

.730

.850

1.10

DIMENSION C

COMPRESSION

ADJUST

1.50

.110 **

N/A

2.00

.120 **

N/A

2.50

.125 **

N/A

3.00

.125 **

N/A

4.00

N/A

.278

6.00

N/A

.085

8.00

N/A

.365

10.00

N/A

.770

10.75

N/A

.770

12.00

N/A

.690

14.00

N/A

-16.00

N/A

.550

18.00

N/A

.400

21.00

N/A

.550

32.00

N/A

.950

ALL DIMENSIONS IN INCHES

* = STARTING ADJUSTMENT

** = PISTON ADJUSTMENT CONTROLS OVER-CENTER ADJUSTMENT

Figure 14 VALVE ADJUSTMENT TABLE

DIM A

PISTON ASSEMBLY

ADJUSTMENT

LOWER LINK

ASSEMBLY

LOWER LINK

ASSEMBLY

ADJUSTMENT

Figure 15 DIMENSIONS "A","B","C"

Valve Maintenance Manual

15

.210

.360

.190

.390

.420

.350

.260

.500

.650

.520

-.730

.730

.550

.975

RECOMMENDED

LOCKING AIR

PRESSURE

20-30 PSI

35-50 PSI

35-55 PSI

60-65 PSI

20-35 PSI

35-45 PSI

55-70 PSI

25-35 PSI

30-40 PSI

30-40 PSI

45-55 PSI

65-80 PSI

----

as of 12/13/2012

GATE VALVE MAINTENANCE AND ADJUSTMENT PROCEDURE

Figure 16 PNEUMATIC ACTUATOR ASSY.

Valve Maintenance Manual

16

GATE VALVE MAINTENANCE AND ADJUSTMENT PROCEDURE

Notes:

Valve Maintenance Manual

17

GATE VALVE MAINTENANCE AND ADJUSTMENT PROCEDURE

Valve Maintenance Manual

18

Das könnte Ihnen auch gefallen

- Centrifugal Pump Commissioning ReportDokument3 SeitenCentrifugal Pump Commissioning ReportOctavio PerezNoch keine Bewertungen

- Flowserve Seal InstructionDokument4 SeitenFlowserve Seal InstructionhafizudinNoch keine Bewertungen

- T20 Retractable SootblowerDokument4 SeitenT20 Retractable SootblowerBadukwangNoch keine Bewertungen

- Globe ValvesDokument7 SeitenGlobe ValvesAngela IlaganNoch keine Bewertungen

- Sree TB 0002Dokument12 SeitenSree TB 0002Tanmoy DuttaNoch keine Bewertungen

- Ball Valve Overhaul ProcedureDokument7 SeitenBall Valve Overhaul Procedurerocket789Noch keine Bewertungen

- Pressure Relief ValvesDokument12 SeitenPressure Relief ValvesyvhtejaswaroopNoch keine Bewertungen

- Globe Valve General Installation Operation & Maintenance ManualDokument5 SeitenGlobe Valve General Installation Operation & Maintenance ManualViba Fluid ControlNoch keine Bewertungen

- Furmanite Leak and Safety Valve Onsite Services PDFDokument11 SeitenFurmanite Leak and Safety Valve Onsite Services PDFJessica ButlerNoch keine Bewertungen

- Technical Bulletin: AudcoDokument12 SeitenTechnical Bulletin: AudcoHrushikesh ReddyNoch keine Bewertungen

- Use of Pressure Control Valve: Presented byDokument12 SeitenUse of Pressure Control Valve: Presented byPremangshu SahaNoch keine Bewertungen

- Pressure RegulatorDokument4 SeitenPressure RegulatorRICHIHOTS2Noch keine Bewertungen

- Lesson Valve Maintenance and Valve Packing: Sub-ObjectiveDokument30 SeitenLesson Valve Maintenance and Valve Packing: Sub-Objectivemister pogi100% (1)

- Installation, Operation & Maintenance Manual: Virgo Engineers LimitedDokument47 SeitenInstallation, Operation & Maintenance Manual: Virgo Engineers LimitedSreenivasNoch keine Bewertungen

- Sump - Self Priming PumpDokument10 SeitenSump - Self Priming PumpErlanggaNoch keine Bewertungen

- Valve StudentDokument68 SeitenValve StudentToniNoch keine Bewertungen

- Api StandartDokument2 SeitenApi Standartyg89Noch keine Bewertungen

- Safety Valve O&MDokument39 SeitenSafety Valve O&MaravindharajanNoch keine Bewertungen

- EPRV Installation ManualDokument21 SeitenEPRV Installation ManualdrlijothomasNoch keine Bewertungen

- Metering Pumps TroubleshootDokument13 SeitenMetering Pumps TroubleshootFawad Yousaf100% (1)

- Damper Technology BrochureDokument8 SeitenDamper Technology Brochurejoy100% (1)

- Safety Valve LaserDokument15 SeitenSafety Valve Lasersajjad_naghdi241Noch keine Bewertungen

- Breather Valve - PV Valve - CNC380Dokument2 SeitenBreather Valve - PV Valve - CNC380mhidayat108Noch keine Bewertungen

- UCM Ball ValvesDokument22 SeitenUCM Ball ValvesBalakrishna BisoyiNoch keine Bewertungen

- TD42 Thermodynamic Steam Trap-Installation Maintenance Manual PDFDokument12 SeitenTD42 Thermodynamic Steam Trap-Installation Maintenance Manual PDFAnonymous FZs3yBHh7Noch keine Bewertungen

- Pneumatic Control ValvesDokument59 SeitenPneumatic Control Valvespatil_raaj7234Noch keine Bewertungen

- CatalogueDokument429 SeitenCatalogueHarkamal SinghNoch keine Bewertungen

- Regulator's Swegelok (High PressuDokument64 SeitenRegulator's Swegelok (High PressuhoangcokhiNoch keine Bewertungen

- Pipe StrainDokument5 SeitenPipe StrainJack WeaverNoch keine Bewertungen

- Nord Lock Washers InfoDokument8 SeitenNord Lock Washers InfoMaclean ArthurNoch keine Bewertungen

- Bab 09 Expansion JointsDokument29 SeitenBab 09 Expansion JointsWendi JunaediNoch keine Bewertungen

- Gate Valve Wedge PDFDokument5 SeitenGate Valve Wedge PDFpvsreddy2002Noch keine Bewertungen

- Spiral Wound GasketsDokument3 SeitenSpiral Wound GasketsHarish GundaNoch keine Bewertungen

- EZR RegulatorDokument40 SeitenEZR RegulatorBranko BabicNoch keine Bewertungen

- Butterfly ValveDokument25 SeitenButterfly ValveRahul JadhavNoch keine Bewertungen

- JC Ball Valves Fig 6000fb 7000rb Iom Rev 4 1Dokument39 SeitenJC Ball Valves Fig 6000fb 7000rb Iom Rev 4 1Inspection Engineer100% (1)

- Turbine ErectionDokument49 SeitenTurbine Erectionazeemmet9924Noch keine Bewertungen

- Pumps ChecklistDokument3 SeitenPumps ChecklistRaouf AbdelmonemNoch keine Bewertungen

- Butterfly Valve Cycle TestDokument4 SeitenButterfly Valve Cycle TestParthiban MechanicalNoch keine Bewertungen

- Hopkinson Valves IOM ManualDokument7 SeitenHopkinson Valves IOM ManualGiorgiana RosuNoch keine Bewertungen

- Safety ValveDokument56 SeitenSafety ValveAbhishek KumarNoch keine Bewertungen

- In-Place Pipe Support Load Testing & Hanger SurveysDokument5 SeitenIn-Place Pipe Support Load Testing & Hanger SurveysArzu AkarNoch keine Bewertungen

- Unique Online Leak Repair TechniquesDokument8 SeitenUnique Online Leak Repair TechniquesMario Alfredo MunafóNoch keine Bewertungen

- Deluge Sprinkler SystemsDokument3 SeitenDeluge Sprinkler Systemsfalconcrest320% (1)

- Failure of Mechanical SealDokument30 SeitenFailure of Mechanical SealTg TarroNoch keine Bewertungen

- Sizing of Check ValvesDokument4 SeitenSizing of Check ValvesjeffconnorNoch keine Bewertungen

- Safety ValvesDokument8 SeitenSafety ValvesvenkeekuNoch keine Bewertungen

- BOLTRIGHT Tightening Procedure 6 - 2500Dokument2 SeitenBOLTRIGHT Tightening Procedure 6 - 2500Saad Abou-ZeidNoch keine Bewertungen

- Thermal ExpansionDokument15 SeitenThermal ExpansionReynard SorianoNoch keine Bewertungen

- Mechanical Seal Replacement InstructionsDokument1 SeiteMechanical Seal Replacement InstructionsGiorgio FerNoch keine Bewertungen

- Pressure Safety ValveDokument6 SeitenPressure Safety ValveRaju JadavNoch keine Bewertungen

- Piping and Vessels Preparation For Commissioning - Part 2Dokument12 SeitenPiping and Vessels Preparation For Commissioning - Part 2MohamedNoch keine Bewertungen

- Pressure - Vacuum Relief Valve - Part 1Dokument10 SeitenPressure - Vacuum Relief Valve - Part 1winarnobNoch keine Bewertungen

- Chapter 2 - Air Generation and DistributionDokument10 SeitenChapter 2 - Air Generation and DistributionUdin AnuarNoch keine Bewertungen

- Forbes Marshall Turbine Bypass ValvesDokument28 SeitenForbes Marshall Turbine Bypass Valveser_sanjaypatelNoch keine Bewertungen

- MS For DIVERTER DAMPER INSTALLATIONDokument12 SeitenMS For DIVERTER DAMPER INSTALLATIONJuantoro Puspo WiryolukitoNoch keine Bewertungen

- Isolation Valves - Linear MovementDokument9 SeitenIsolation Valves - Linear MovementEmad A.AhmadNoch keine Bewertungen

- Sistema de FrenosDokument290 SeitenSistema de FrenosCez Lopez BañezNoch keine Bewertungen

- Farris Valve ManualDokument11 SeitenFarris Valve ManualsumsolcaggNoch keine Bewertungen

- A - 1400 (2) MidlandDokument15 SeitenA - 1400 (2) MidlandLucas MonteNoch keine Bewertungen

- Protective Coatings For Turbine BladesDokument231 SeitenProtective Coatings For Turbine BladesFaizan Abbasi100% (1)

- Operating and Maintenance ManualDokument156 SeitenOperating and Maintenance ManualFaizan AbbasiNoch keine Bewertungen

- Screws Nuts BoltsDokument28 SeitenScrews Nuts BoltsFaizan AbbasiNoch keine Bewertungen

- Energy ManagementDokument254 SeitenEnergy ManagementNguyễn Thanh HòaNoch keine Bewertungen

- Steam TracingDokument18 SeitenSteam TracingSyed Mujtaba Ali Bukhari100% (2)

- Structural Detailing in SteelDokument253 SeitenStructural Detailing in Steelandrugrasu100% (27)

- The Basic Design of Two Stroke EnginesDokument347 SeitenThe Basic Design of Two Stroke EnginesNumata รักในหลวง88% (8)

- Offshore Book 2010Dokument117 SeitenOffshore Book 2010Mos Woraphon100% (1)

- AlignmentDokument31 SeitenAlignmentFaizan AbbasiNoch keine Bewertungen

- Waste Management PDFDokument240 SeitenWaste Management PDFskilmagNoch keine Bewertungen

- Solenoid Valves BasicsDokument47 SeitenSolenoid Valves BasicsGary8100% (6)

- BrakesDokument289 SeitenBrakesFaizan AbbasiNoch keine Bewertungen

- Friction Loss-Fitting PDFDokument3 SeitenFriction Loss-Fitting PDFdcf67myNoch keine Bewertungen

- Solar EnergyDokument440 SeitenSolar EnergyFernando Vanetti AnsaniNoch keine Bewertungen

- Wind Electrical SystemDokument338 SeitenWind Electrical SystemFaizan Abbasi67% (3)

- Cooking 101Dokument8 SeitenCooking 101Faizan AbbasiNoch keine Bewertungen

- REC 036 Stern Tube LO ContaminationDokument2 SeitenREC 036 Stern Tube LO Contamination003086Noch keine Bewertungen

- Centrifugal Pumps TipsDokument34 SeitenCentrifugal Pumps TipsFaizan AbbasiNoch keine Bewertungen

- ASHRAE Journal - Primary-Only Vs Primary-Secondary Variable Flow SystemsDokument5 SeitenASHRAE Journal - Primary-Only Vs Primary-Secondary Variable Flow SystemsQaz Zaq100% (1)

- Building Your Own Wind Turbine PDFDokument157 SeitenBuilding Your Own Wind Turbine PDFAlfredoPoloniNoch keine Bewertungen

- Stainless OverviewDokument6 SeitenStainless OverviewClaudia MmsNoch keine Bewertungen

- Hugh Piggott PMG May-October 2002Dokument33 SeitenHugh Piggott PMG May-October 2002markleaver1Noch keine Bewertungen

- 1857 Oil Gas Fuel Fired Furnaces Steam Boilers Water TreatmentDokument9 Seiten1857 Oil Gas Fuel Fired Furnaces Steam Boilers Water TreatmentFaizan AbbasiNoch keine Bewertungen

- LDD 08 RDS BPDDokument6 SeitenLDD 08 RDS BPDFaizan AbbasiNoch keine Bewertungen

- Cooling Tower Thermal DesignDokument106 SeitenCooling Tower Thermal Designxuense100% (4)

- SRI Trunnion Ball ValvesDokument40 SeitenSRI Trunnion Ball ValvesFaizan AbbasiNoch keine Bewertungen

- BOPV Section 6 - Assembly InstructionsDokument4 SeitenBOPV Section 6 - Assembly InstructionsusamakhattakNoch keine Bewertungen

- Armstrong Steam FiltersDokument20 SeitenArmstrong Steam FiltersLord KrsnikNoch keine Bewertungen

- Catalogo Chumaceras SKFDokument95 SeitenCatalogo Chumaceras SKFmanuelzavala2012100% (1)

- Phot SKF PDFDokument379 SeitenPhot SKF PDFLê Duy PhongNoch keine Bewertungen

- Sakagami Empaques HidraulicosDokument183 SeitenSakagami Empaques HidraulicosMIGUELNoch keine Bewertungen

- FluorezDokument27 SeitenFluorezRick RgNoch keine Bewertungen

- Repuestos Caja EquivalenteDokument2 SeitenRepuestos Caja EquivalenteCesar Cauper CardenasNoch keine Bewertungen

- HR2470Dokument4 SeitenHR2470Imro'atus SolikahNoch keine Bewertungen

- Parker O-Ring Material Guide-2008Dokument72 SeitenParker O-Ring Material Guide-2008Ian Pillay50% (2)

- Blowout Preventer WirelineDokument16 SeitenBlowout Preventer WirelineAdi M. MutawaliNoch keine Bewertungen

- Catalog F7000 8000 Oct2020Dokument32 SeitenCatalog F7000 8000 Oct2020Tomás MercadoNoch keine Bewertungen

- Trelleborg o Ring GB enDokument226 SeitenTrelleborg o Ring GB enGabor CsomóNoch keine Bewertungen

- Hl250M Parts Breakdown: Build Code CI-ACW-1Dokument13 SeitenHl250M Parts Breakdown: Build Code CI-ACW-1Amanda FitzgeraldNoch keine Bewertungen

- Apeks O Rings IDDokument2 SeitenApeks O Rings IDdenisNoch keine Bewertungen

- FSAE Powertrain Packaging - MITDokument42 SeitenFSAE Powertrain Packaging - MITPreetam RayNoch keine Bewertungen

- Machinery Coupling Guard Oil Leakage Design Solutions 1595104444Dokument13 SeitenMachinery Coupling Guard Oil Leakage Design Solutions 1595104444Alexander Rodriguez SarmientoNoch keine Bewertungen

- FLY GZ Face Seals Reference July 19 Web - Compressed PDFDokument32 SeitenFLY GZ Face Seals Reference July 19 Web - Compressed PDFCaroline RosaNoch keine Bewertungen

- Graver Catalog 2012 PDFDokument76 SeitenGraver Catalog 2012 PDFAskar HarisNoch keine Bewertungen

- Air-Driven, High Flow, High Pressure Liquid Pump: Series AHL33-2DDokument4 SeitenAir-Driven, High Flow, High Pressure Liquid Pump: Series AHL33-2DBurhan AyubNoch keine Bewertungen

- Piston Pump Service Manual: Installation and Start-Up InformationDokument8 SeitenPiston Pump Service Manual: Installation and Start-Up InformationErik RodriguezNoch keine Bewertungen

- Ready-Mixed Paint For Road Marking - Specification: Indian StandardDokument22 SeitenReady-Mixed Paint For Road Marking - Specification: Indian StandardDevesh Kumar PandeyNoch keine Bewertungen

- Imtt Bayonne Cogen Inventory 08012018 by TopsDokument32 SeitenImtt Bayonne Cogen Inventory 08012018 by TopsThanapaet RittirutNoch keine Bewertungen

- 2420 Pressure Reducing PilotDokument14 Seiten2420 Pressure Reducing PilotRyan VelezNoch keine Bewertungen

- 4357-SGR055 Diesel Engine Driven & Parts Alkota PDFDokument1 Seite4357-SGR055 Diesel Engine Driven & Parts Alkota PDFmichNoch keine Bewertungen

- 1LX100 SchematicDokument4 Seiten1LX100 Schematicab5951Noch keine Bewertungen

- Gas Springs1Dokument32 SeitenGas Springs1GLADWIN PAUL SIM 16-18Noch keine Bewertungen

- Production Chokes Flow Line Accessories and Manifold Skid Packages PDFDokument16 SeitenProduction Chokes Flow Line Accessories and Manifold Skid Packages PDFRicardo Paz SoldanNoch keine Bewertungen

- Peco CatalogDokument152 SeitenPeco CatalogClaudio Israel Godinez SomeraNoch keine Bewertungen

- D31PX-21 S/N 50001-50499 (For North America)Dokument1 SeiteD31PX-21 S/N 50001-50499 (For North America)Mbahdiro KolenxNoch keine Bewertungen

- Motor M14 ControlDokument6 SeitenMotor M14 ControlROBERSON ROMERÒNoch keine Bewertungen

- Arizona, Utah & New Mexico: A Guide to the State & National ParksVon EverandArizona, Utah & New Mexico: A Guide to the State & National ParksBewertung: 4 von 5 Sternen4/5 (1)

- Japanese Gardens Revealed and Explained: Things To Know About The Worlds Most Beautiful GardensVon EverandJapanese Gardens Revealed and Explained: Things To Know About The Worlds Most Beautiful GardensNoch keine Bewertungen

- The Bahamas a Taste of the Islands ExcerptVon EverandThe Bahamas a Taste of the Islands ExcerptBewertung: 4 von 5 Sternen4/5 (1)

- New York & New Jersey: A Guide to the State & National ParksVon EverandNew York & New Jersey: A Guide to the State & National ParksNoch keine Bewertungen

- Naples, Sorrento & the Amalfi Coast Adventure Guide: Capri, Ischia, Pompeii & PositanoVon EverandNaples, Sorrento & the Amalfi Coast Adventure Guide: Capri, Ischia, Pompeii & PositanoBewertung: 5 von 5 Sternen5/5 (1)

- South Central Alaska a Guide to the Hiking & Canoeing Trails ExcerptVon EverandSouth Central Alaska a Guide to the Hiking & Canoeing Trails ExcerptBewertung: 5 von 5 Sternen5/5 (1)