Beruflich Dokumente

Kultur Dokumente

Wear Resistant

Hochgeladen von

Durjoy Chakraborty0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

126 Ansichten2 SeitenWear

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenWear

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

126 Ansichten2 SeitenWear Resistant

Hochgeladen von

Durjoy ChakrabortyWear

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 2

special focus : wear protection

47

Grinding elements take the wear

and tear of coal pulverisation

Nathalie Charlier looks

at a new technology for

use in coal pulverisation

which is claimed to be is

the next frontier of material

advancement in severe

duty applications.

or more than 10 years Xwin

technology from Magotteaux has

been applied to numerous vertical

roller mills (VRM) applications

throughout the world in aggregate, cement,

mining and power. For power generation, Xwin

VRM grinding elements have been implemented

on all types of coal pulverisation from brown

coals (lignite) to anthracite and Petcoke.

Xwin is a technology in which granularised

ceramic, with a hardness of 2100

Vickers, is combined with a high

chrome alloy in a unique casting

process. This combination of metal

and ceramic, in a granular form,

creates a metal matrix composite

(MMC) called Xwin. Within the

MMC layer the granularised

ceramic is encapsulated by the

high chrome metal. The result is

an Xwin casting that provides the

extreme hardness of ceramic with the durable

reliability and ductility of a high chrome alloy.

Xwin castings are no more susceptible to

breakage than a solid high chrome casting

whether it be from the subjection of rock or

tramp metal entering the mill or from operational

excursions of the pulverizer. No special handling,

operating or maintenance is required with Xwin

castings. Xwin is a direct replacement to the

existing grinding elements whether it is tires,

rolls, tables or segments. Xwin is applicable for

the grinding elements on all types and styles of

vertical mills such as Alstom/CE, BHEL, B&W

MPS (Pfeiffer), EVT, FWEC MBF, IHI, MHI,

SHMP, Stein or any pendulum style roller mill

such as Williams or Raymond.

The hardness of Xwin grinding elements,

at 2100 Vickers, can be compared with that

of high chrome or hard-faced high chrome

grinding elements at 800950 Vickers. The

resulting product being an Xwin casting that

is much harder and longer

lasting. Additionally, Xwin is not

susceptible to potential cracking

or spalling that is sometimes

encountered with hard-surfaced

grinding elements particularly

those castings that are hardsurfaced more than once.

The aggressiveness of coal is

primarily determined by the silica

content of the ash within the coal.

Silica (Quartz) having a general hardness range

of 17001800 Vickers is much harder than the

high chromium and high chromium hard-faced

materials (800-950 Vickers). However, the Xwin

MMC layer at 2100 Vickers is harder than the

quartz and will not be adversely affected by the

quartz content of the ash as compared with those

grinding elements composed of materials softer

than quartz.

Vertical Roller Mills are commonly referred to

as attrition mills because the material, being fed

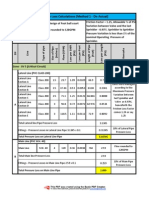

Xwin Rolls / Lignite 14 months

Hardsurfaced Roll

Superiority (3x)

Lignite 14 months

(End of Life)

www.engineerlive.com

Fig. 1. Rolls:

Xwin vs high

chrome

hard-surfaced

lignite coal.

48

special focus : wear protection

Xwin - Segments - 24 months

superiority (4x)

High Chrome

Rroll

Hi-Cr Segments 24 months

End of Life

Xwin Superiority (3x)

Xwin Roll

1 year Opera

tion

Fig. 2. Segments: Xwin versus High Chrome Bituminous Coal.

(under pressure) between the grinding elements by means

of centrifugal force imparted by the rotating table or by a

rotating pendular shaft, is being crushed against itself. As

such the primary wear component in the crushing zone is

compression which is a direct force that acts normal to

the grinding face. The VRM also utilises air to dry, classify

and convey the pulverized coal from the pulveriser. The

portions of the grinding elements that are exposed to

Following Two (2) Years of Operation

16 mm tyre wear

Following Three (3) Years of Operation

26 mm tyre wear

Fig. 3. Pendulum style roller mill sub bituminous coal.

the pulverised coal/air mixture from the pulverised coal

being pulled off the bowl are also subjected to abrasion

or erosion. Erosion is a velocity related wear component

in which the force of erosion acts at an acute angle to the

grinding face. The erosion component can be quite severe

to the grinding elements particularly if high amounts of

silica are present. Xwin, being much harder than the

materials being crushed, can resist the components of

wear whether it is in the form of compression or erosion.

Numerous operating experiences have demonstrated

that Xwin grinding elements can extend the lifetime of the

grinding elements by at least 2x for MPS and MBF type

mills, 23x+ for Alstom/CE type pulverisers and 3x for

Pendulum style roller mills. This increase in running life,

extends the maintenance cycles (Time Between Outages),

reduces the frequency for routine maintenance (ie, roll/

ring adjustments) and improves pulveriser availability.

Xwin eliminates the grinding elements as being the weak

link to the maintenance cycle and reduces the operating

and maintenance cost of the pulveriser.

Xwin reduces the wear velocity of the grinding

elements. This reduction of wear velocity directly

correlates to the ability to maintain a consistent grinding

profile. Because the Xwin wear velocity is greatly

reduced, the grinding profile and the grinding efficiency of

the pulveriser is maintained for a much longer duration

allowing optimum pulveriser efficiency and achievement

of acceptable fineness, capacity and assistance in

maintaining furnace performance (ie, maximised

performance coupled with optimum maintenance

cycles). The ability to maintain pulveriser efficiency at

rated capacity correlates to the ability to better maintain

downstream furnace and back-end performance. m

Enter 48 or at www.engineerlive.com/ipe

Xwin superiority (2x)

Fig. 4. Xwin tyre and Xwin Table: Lignite (brown coal).

Nathalie Charlier is with Magotteaux International S A,

Vaux-sous-Chvremont, Belgium. www.magotteaux.com

www.engineerlive.com

Das könnte Ihnen auch gefallen

- PaM Compact Blow-Bars enDokument48 SeitenPaM Compact Blow-Bars enDaniel Alejandro Navarro Jara100% (1)

- Friction Loss Calculations of Irrigation Design A Foot Ball CourtDokument13 SeitenFriction Loss Calculations of Irrigation Design A Foot Ball Courtmathewmanjooran100% (2)

- AISI SteelsDokument5 SeitenAISI Steelsanirudh_indana100% (1)

- Wireman, Terry - Training Programs For Maintenance Organizations - Maintenance Strategy Series (2013, Reliabilityweb Com)Dokument221 SeitenWireman, Terry - Training Programs For Maintenance Organizations - Maintenance Strategy Series (2013, Reliabilityweb Com)Faiza TariqNoch keine Bewertungen

- Modern PetrochemicalsDokument179 SeitenModern PetrochemicalsHani Kirmani100% (9)

- 500 Technical Questions Safety&Fire-1Dokument26 Seiten500 Technical Questions Safety&Fire-1Saad GhouriNoch keine Bewertungen

- Motors For Rotax Kiln DriveDokument17 SeitenMotors For Rotax Kiln DrivesreeganeshrNoch keine Bewertungen

- Waste To Energy Plant in SuratDokument18 SeitenWaste To Energy Plant in SuratDurjoy ChakrabortyNoch keine Bewertungen

- Ihs Kingdom Hot Keys ReferenceDokument1 SeiteIhs Kingdom Hot Keys ReferenceMuhammad Jahangir100% (1)

- Brochure Wind Industry Solutions For More Wind Force PDFDokument28 SeitenBrochure Wind Industry Solutions For More Wind Force PDFphucdc095041Noch keine Bewertungen

- Wear Mechanism of Abrasion Resistant Wear Parts in Raw Material Vertical Roller Mill Jensen2011Dokument13 SeitenWear Mechanism of Abrasion Resistant Wear Parts in Raw Material Vertical Roller Mill Jensen2011Rendotian Anugrah100% (1)

- Epanet Vs Watergems (083011)Dokument9 SeitenEpanet Vs Watergems (083011)MABA02100% (1)

- Coal Characteristics محفلا صئاصخDokument28 SeitenCoal Characteristics محفلا صئاصخMohammed Al-OdatNoch keine Bewertungen

- Planning For Procurement of Construction ContractsDokument41 SeitenPlanning For Procurement of Construction ContractsJoel AlcantaraNoch keine Bewertungen

- Mat 3422 For Suppliers PDFDokument3 SeitenMat 3422 For Suppliers PDFbaskaran ayyapparajNoch keine Bewertungen

- MAT 3420 MCGB - Data Sheet For Suppliers Old MAT No.: 361Dokument3 SeitenMAT 3420 MCGB - Data Sheet For Suppliers Old MAT No.: 361Diógenes da Silva PereiraNoch keine Bewertungen

- Manual Hornos KHDDokument309 SeitenManual Hornos KHDjkanclaNoch keine Bewertungen

- Abrasion Resistant, White Cast Iron Materials PDFDokument1 SeiteAbrasion Resistant, White Cast Iron Materials PDFjlplazaolaNoch keine Bewertungen

- Heat Resitant Steel Castings MaterialsDokument2 SeitenHeat Resitant Steel Castings MaterialssusisaravananNoch keine Bewertungen

- Mat 3810 For Suppliers PDFDokument3 SeitenMat 3810 For Suppliers PDFbaskaran ayyapparajNoch keine Bewertungen

- Polytrack Clinker Cooler.: PolysiusDokument3 SeitenPolytrack Clinker Cooler.: PolysiushathamphanNoch keine Bewertungen

- Waste Heat Recovery in Cement Plant IJERTV3IS051014 PDFDokument5 SeitenWaste Heat Recovery in Cement Plant IJERTV3IS051014 PDFDurjoy ChakrabortyNoch keine Bewertungen

- Area Report Raw Mill: Submitted By: Zohaib Ahmed Memon (96658) SMT (Production)Dokument7 SeitenArea Report Raw Mill: Submitted By: Zohaib Ahmed Memon (96658) SMT (Production)Zohaib AhmedNoch keine Bewertungen

- 1811 Reclaiming SystemsDokument4 Seiten1811 Reclaiming SystemsDurjoy ChakrabortyNoch keine Bewertungen

- Electrostatic Precipitators With Igbt Inverter PDFDokument8 SeitenElectrostatic Precipitators With Igbt Inverter PDFmohammad.zNoch keine Bewertungen

- Mat 3831 For Suppliers PDFDokument3 SeitenMat 3831 For Suppliers PDFbaskaran ayyapparaj100% (1)

- V6 EngineeringDokument252 SeitenV6 Engineeringcrengifo1726Noch keine Bewertungen

- Internal Bearing CleardssanceDokument3 SeitenInternal Bearing Cleardssancejicki09Noch keine Bewertungen

- Sinter CastDokument6 SeitenSinter Castsiva100% (1)

- Tech Spec. of EOT CraneDokument7 SeitenTech Spec. of EOT CraneSuresh MuttaNoch keine Bewertungen

- Ione-Aa00-Pe-Cm-0005 Hse Procedure For Pre Start-Up Safety Review - Rev. ADokument21 SeitenIone-Aa00-Pe-Cm-0005 Hse Procedure For Pre Start-Up Safety Review - Rev. AYusuf100% (2)

- CBG8144 en Solution Cement IndustryDokument12 SeitenCBG8144 en Solution Cement IndustryJavier TorresNoch keine Bewertungen

- Materials Used For Construction: 1. Reciprocating CompressorDokument6 SeitenMaterials Used For Construction: 1. Reciprocating CompressorEdemNoch keine Bewertungen

- Fabricating Inconel Alloy 625LCFDokument8 SeitenFabricating Inconel Alloy 625LCFDet100% (2)

- 8 - XCC Hammers UKDokument2 Seiten8 - XCC Hammers UKSampreeth TekkadNoch keine Bewertungen

- Beumer Belt Bucket Elevator enDokument8 SeitenBeumer Belt Bucket Elevator enLev Maravi MandujanoNoch keine Bewertungen

- KHD Rotary KilnsDokument4 SeitenKHD Rotary KilnsRajib DuttaNoch keine Bewertungen

- Ovality MeasurmentDokument11 SeitenOvality MeasurmentAbul Qasim Qasim0% (1)

- WDF ClassificationDokument37 SeitenWDF ClassificationBerkan FidanNoch keine Bewertungen

- Ball Mill Inspection Procedure PDFDokument4 SeitenBall Mill Inspection Procedure PDFYoya AhmedNoch keine Bewertungen

- Wear Rate LoescheDokument8 SeitenWear Rate LoescheEdson Ricardo Lima100% (2)

- Modification HPGR 18Dokument28 SeitenModification HPGR 18Anonymous gcMAj2IXlNoch keine Bewertungen

- FLSMIdth-Matcode DeatilDokument1 SeiteFLSMIdth-Matcode DeatilEswar Enterprises Qc100% (1)

- Backstop For ConveyorDokument28 SeitenBackstop For ConveyorabdulscribdNoch keine Bewertungen

- FAD Calculation For CompressorDokument2 SeitenFAD Calculation For CompressorDurjoy ChakrabortyNoch keine Bewertungen

- VEGA - Indonesia PresentationDokument62 SeitenVEGA - Indonesia PresentationSteve WanNoch keine Bewertungen

- HoromillDokument17 SeitenHoromillVijay BhanNoch keine Bewertungen

- WCA Time Critical: (Formerly Known As VCK Air BV)Dokument43 SeitenWCA Time Critical: (Formerly Known As VCK Air BV)zeta100% (1)

- High-Pressure Grinding Roller Presses For Minerals ProcessingDokument24 SeitenHigh-Pressure Grinding Roller Presses For Minerals ProcessingYaser Asmani100% (1)

- Sintercast Vs Hardfacing PDFDokument21 SeitenSintercast Vs Hardfacing PDFanruloNoch keine Bewertungen

- CB Continental CatalogueDokument69 SeitenCB Continental CatalogueAina LikuntatiNoch keine Bewertungen

- MAT 2520 MCGB - Data Sheet For Suppliers Old MAT No.: 321: PropertiesDokument3 SeitenMAT 2520 MCGB - Data Sheet For Suppliers Old MAT No.: 321: PropertiesDiógenes da Silva PereiraNoch keine Bewertungen

- Failure Analysis of Sheared Shaft of A Brine Recycle Pump...Dokument12 SeitenFailure Analysis of Sheared Shaft of A Brine Recycle Pump...Pd RarNoch keine Bewertungen

- Molding Training PresentationDokument30 SeitenMolding Training PresentationVinesh RJNoch keine Bewertungen

- Comments - MSEL 25072017 Rod Mill RequirementDokument14 SeitenComments - MSEL 25072017 Rod Mill RequirementHarshGuptaNoch keine Bewertungen

- Loesche - For SIG - Slip Ring SealingDokument37 SeitenLoesche - For SIG - Slip Ring SealingRizki MWNoch keine Bewertungen

- STOCk - Gravimetric FeederDokument6 SeitenSTOCk - Gravimetric FeederVijay Kumar100% (1)

- Sinter Plant Single Toothed Roll Crusher PDFDokument14 SeitenSinter Plant Single Toothed Roll Crusher PDFrmsh301Noch keine Bewertungen

- Cast IronDokument29 SeitenCast Ironavutu_kunduruNoch keine Bewertungen

- KünneDokument28 SeitenKünneMohd AliNoch keine Bewertungen

- Polycom High-Pressure Grinding Roll: Our New Name IsDokument7 SeitenPolycom High-Pressure Grinding Roll: Our New Name Isrmano22Noch keine Bewertungen

- 2011 Flsmidth Terms and ConditionsDokument2 Seiten2011 Flsmidth Terms and ConditionsIrving Dirzo CarrilloNoch keine Bewertungen

- Disclosure To Promote The Right To InformationDokument13 SeitenDisclosure To Promote The Right To InformationTennis Mathew100% (1)

- S3 Product Range - EnglishDokument35 SeitenS3 Product Range - EnglishJuan Esteban Luque ZegarraNoch keine Bewertungen

- Boiler Recommended Lubrication ChartDokument10 SeitenBoiler Recommended Lubrication ChartsuryakanthareddyNoch keine Bewertungen

- Refractory Installation in The Cement Rotary Kiln 3.1 Installation of Refractory Bricks in The Cement Rotary KilnDokument51 SeitenRefractory Installation in The Cement Rotary Kiln 3.1 Installation of Refractory Bricks in The Cement Rotary KilnkINGNoch keine Bewertungen

- Pro Wearflex2000ht UkDokument1 SeitePro Wearflex2000ht UkJagadeesh GuttiNoch keine Bewertungen

- Clause - 1 FansDokument441 SeitenClause - 1 Fansvel mech100% (1)

- MCGB - Data Sheet For Suppliers Old MAT Nos.: 344, - , - : Heat-Resistant Cast Steel, Cr-Ni-AlloyedDokument3 SeitenMCGB - Data Sheet For Suppliers Old MAT Nos.: 344, - , - : Heat-Resistant Cast Steel, Cr-Ni-AlloyedgraduateNoch keine Bewertungen

- 2.2 - ICR DEC 05 - Fractured Kiln WeldingDokument3 Seiten2.2 - ICR DEC 05 - Fractured Kiln WeldingKreshnik StratiNoch keine Bewertungen

- Durehete 1055Dokument5 SeitenDurehete 1055alextentwenty100% (1)

- HX900 Brochure LowresDokument8 SeitenHX900 Brochure LowresMathew VargheseNoch keine Bewertungen

- CM400 Hammar Mills Low Res PDFDokument8 SeitenCM400 Hammar Mills Low Res PDFKrishna prasadNoch keine Bewertungen

- H2 KoreanDokument3 SeitenH2 KoreanDurjoy ChakrabortyNoch keine Bewertungen

- TG SynchronizationDokument7 SeitenTG SynchronizationDurjoy ChakrabortyNoch keine Bewertungen

- Glass Fibre Reinforced Products PDFDokument16 SeitenGlass Fibre Reinforced Products PDFDurjoy ChakrabortyNoch keine Bewertungen

- Coal FLowDokument28 SeitenCoal FLowDurjoy ChakrabortyNoch keine Bewertungen

- Comparison of Counter Flow and Cross Flow CoolingDokument2 SeitenComparison of Counter Flow and Cross Flow CoolingDurjoy ChakrabortyNoch keine Bewertungen

- Restriction Orifice Diamater CalculationDokument1 SeiteRestriction Orifice Diamater CalculationDurjoy ChakrabortyNoch keine Bewertungen

- Gas TurbineInlet Air CoolingDokument41 SeitenGas TurbineInlet Air CoolingDurjoy ChakrabortyNoch keine Bewertungen

- Wind Loads - IS 875 - Where Does Our Code of Practice StandDokument11 SeitenWind Loads - IS 875 - Where Does Our Code of Practice StandRavi Kiran NandyalaNoch keine Bewertungen

- db12 HornDokument3 Seitendb12 HornGerman Andres GarciaNoch keine Bewertungen

- Wrights Offshore Hydrate Remediation Skid ArticleDokument4 SeitenWrights Offshore Hydrate Remediation Skid ArticleAnonymous ItzBhUGoiNoch keine Bewertungen

- CS193a Android ProgrammingDokument4 SeitenCS193a Android Programmingrosy01710Noch keine Bewertungen

- TCP IP CompleteDokument167 SeitenTCP IP Completereddyhell99Noch keine Bewertungen

- Code Eac NaceDokument2 SeitenCode Eac NaceEvan BuwanaNoch keine Bewertungen

- SWOT Analysis of Viyellatex Spinning LimitedDokument81 SeitenSWOT Analysis of Viyellatex Spinning LimitedHossain RanaNoch keine Bewertungen

- OTN Training-Lv1-Fonst 3000 Equipment IntroductionDokument28 SeitenOTN Training-Lv1-Fonst 3000 Equipment IntroductionJenny Rodriguez Aguirre100% (1)

- Overview of Ultrasound Detection Technologies For Photoacoustic ImagingDokument24 SeitenOverview of Ultrasound Detection Technologies For Photoacoustic ImagingShuvam5 GuptaNoch keine Bewertungen

- Kioti Daedong NX4520, NX5020, NX5520, NX6020 Tractors Service Manual 10-2019Dokument19 SeitenKioti Daedong NX4520, NX5020, NX5520, NX6020 Tractors Service Manual 10-2019LisakolyNoch keine Bewertungen

- Pompa WarmanDokument2 SeitenPompa WarmanRahmad Saleh SiregarNoch keine Bewertungen

- Fischer Technical Services Safety ManualDokument15 SeitenFischer Technical Services Safety ManualHenry FlorendoNoch keine Bewertungen

- Empaque Espirometalicos PDFDokument50 SeitenEmpaque Espirometalicos PDFgregorioNoch keine Bewertungen

- Guide To The Systems Engineering Body of Knowledge (Sebok), Version 1.1Dokument51 SeitenGuide To The Systems Engineering Body of Knowledge (Sebok), Version 1.1António FerreiraNoch keine Bewertungen

- A Review of Power Electronics Based Microgrids: Josep M. Guerrero, Xiongfei Wang, Zhe Chen, and Frede BlaabjergDokument5 SeitenA Review of Power Electronics Based Microgrids: Josep M. Guerrero, Xiongfei Wang, Zhe Chen, and Frede BlaabjergSaksham GuptaNoch keine Bewertungen

- Ball ValvesDokument4 SeitenBall ValvesIgde Agung ChandraNoch keine Bewertungen

- OurLocalExpert Exeter 2013-14Dokument15 SeitenOurLocalExpert Exeter 2013-14Nick HallNoch keine Bewertungen

- Gear Selector CableDokument3 SeitenGear Selector CableojopodoabeNoch keine Bewertungen

- T Turboexpander Alternative FuelingDokument24 SeitenT Turboexpander Alternative FuelingJose Luis Rodriguez LópezNoch keine Bewertungen

- Verilog Implementation of Reed - Solomon CodeDokument16 SeitenVerilog Implementation of Reed - Solomon CodeManik Prabhu ChillalNoch keine Bewertungen

- Metrolla Steels Industrial Visit ReportDokument39 SeitenMetrolla Steels Industrial Visit ReportSanjay R Nair100% (1)