Beruflich Dokumente

Kultur Dokumente

Saudi Aramco CP Accessories Inspection

Hochgeladen von

aamirapiOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Saudi Aramco CP Accessories Inspection

Hochgeladen von

aamirapiCopyright:

Verfügbare Formate

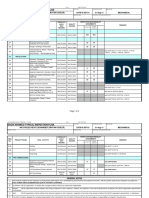

SAUDI ARAMCO ID/PID - 18-MAY-05 - REV 0 (Standards Cutoff - August 2010)

Rev 5

SAIC NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

CP Accessories - Material Receiving

SAIC-X-3002

PROJECT TITLE

WBS / BI / JO NUMBER

EQUIPMENT ID NUMBER(S)

EQUIPMENT DESCRIPTION

LAYOUT DRAWING NUMBER

REV. NO.

SCHEDULED INSPECTION DATE & TIME

ACTUAL INSPECTION DATE & TIME

31-Mar-10

DATE APPROVED

QR NUMBER

31-Aug-11

CP-

CONTRACTOR / SUBCONTRACTOR

EQPT CODE

SYSTEM ID.

PURCHASE ORDER NUMBER

PLANT NO.

EC / PMCC / MCC NO.

QUANTITY INSP.

MH's SPENT

TRAVEL TIME

SAUDI ARAMCO USE ONLY

SAUDI ARAMCO TIP NUMBER

SAUDI ARAMCO ACTIVITY NUMBER

SAUDI ARAMCO INSPECTION LEVEL

CONTRACTOR INSPECTION LEVEL

ITEM

No.

A.

ACCEPTANCE CRITERIA

REFERENCE

Document Review

Schedule Q

Att. IV

Sec. 3.3

Schedule Q

Att. IV

Sec. 4.2

A1

Review documents of Material Receiving for the CP Accessories.

A2

Identification procedure reviewed and implemented for the CP

Accessories.

A3

Material identification shall be implemented for all materials, parts and

components, including partially fabricated assemblies. CP Accessories

shall be identified by using tags, stamps, color coding, stencils or labels.

The location and method of identification shall not affect the function or

quality of the material.

Schedule Q

Att. lV

Sec. 4.2

A4

The Supervisor of CSD/ME&CCD/Cathodic Protection and Coatings Unit

and the Supervisor of the proponent cathodic protection organization

shall indicate their review and approval of each Cathodic Protection

drawing by signature. The signatures shall be placed in the "Review of

Key Drawings" block of each Index X Drawing.

SAES-X-400

Sec. 5.1.2

B.

General Requirements

B1

Documentation for traceability reviewed and implemented. CP

Accessories shall be traceable from the manufacturer and supplier

through delivery, storage, fabrication, erection, installation, repair,

modification and use.

Schedule Q

Att. IV

Sec. 4.3

B2

Documented Control System shall be implemented for all Saudi Aramco

supplied material and equipment.

Schedule Q

Att. lV

Sec. 4

C.

Material Inspection

C1

QC Before Installation - CP Accessories shall conform to all applicable

requirements, standards, and specifications prior to release to be used

as part of work.

Schedule Q

Att. IV

Sec. 3.3

C2

Incoming CP Accessories shall be visually inspected for damage /

defects occurred during transportation.

Schedule Q

Att. IV

Sec. 3.3

C3

CP Accessories shall be new and unused.

Schedule G

Sec. 2.1

C4

CP Accessories shall be in accordance with the Saudi Aramco-approved

project-specific design drawings, diagrams, schedules, lists, databases,

and associated design documents.

Schedule G

Sec. 4.1

C5

Check that the Contractor or it's Saudi Aramco approved third party

inspector performed the quality activities at the supplier and sub-supplier

locations as required by the inspection level assigned for the materials

and equipment identified in SAER-1972 Inspection Requirements.

Schedule Q

Att. llI

Sec. 1.2

C6

Check that the details of CP accessories are according to the galvanic

anodes.

Standard Drawing # 990-X-AA-036389 Sheet 001 Rev. 02.

Page 1 of 3

17-SAMSS-006

Sec. 3.1

WORK PERMIT REQUIRED?

PASS

FAIL

N/A

RE-INSP DATE

SAUDI ARAMCO ID/PID - 18-MAY-05 - REV 0 (Standards Cutoff - August 2010)

Rev 5

SAUDI ARAMCO INSPECTION CHECKLIST

CP Accessories - Material Receiving

SAIC-X-3002

PROJECT TITLE

ITEM

No.

SAIC NUMBER

WBS / BI / JO NUMBER

ACCEPTANCE CRITERIA

REFERENCE

C7

Check that the details of CP accessories are according to the galvanic

anodes used for Vessels.

Standard Drawing # 990-X-AA-036388 Sheet 001 Rev. 02.

17-SAMSS-006

Sec. 3.1

C8

Check that the details of CP accessories are according to the galvanic

anodes used for Tanks.

Standard Drawing # 990-X-AA-036762 Sheet 001 Rev. 06.

17-SAMSS-006

Sec. 3.1

C9

Lead Wires

Lead wires on packaged anodes shall be 10 mm (No. 8 AWG) stranded

copper insulated wire suitable by NEC Table 310.13 for burial in wet

locations. Lead wires on packaged magnesium and zinc anodes shall be

brazed or silver soldered to the steel core and the connection shall be

sealed with potting compound. The brazing rod or silver solder shall be

SILVABRITE or an equivalent approved by the SME.

17-SAMSS-006

Sec. 7.2

C10

Vendor Document Submittals:

The Vendor shall submit the following documents to the Buyer and

Vendor inspection. Any proposed alternative designs in addition to the

required design shall be clearly described in these submittals. The

English language shall be used on all documents, drawings, labels, etc.

a) Manufacturer's name

b) Minimum anode energy capacity

c) Anode material composition

d) Test data and certificate of compliance with Section 6 of this

specification

e) Certified drawings, fully dimensioned and scaled, showing details of

anode assembly

17-SAMSS-006

Sec. 4.3

31-Mar-10

DATE APPROVED

QR NUMBER

31-Aug-11

CP-

CONTRACTOR / SUBCONTRACTOR

PASS

FAIL

N/A

RE-INSP DATE

REMARKS:

REFERENCE DOCUMENTS:

1. Schedule G -- Material, Tools and Equipment (Pro Forma MP-IK-LS Contract), Contract Specific

2. Schedule Q -- Quality Requirements (Pro Forma Contract), Contract Specific

3. Standard Drawing # 990-X-AA-036389 Sheet 001 Rev. 02

4. Standard Drawing # 990-X-AA-036388 Sheet 001 Rev. 02

5. Standard Drawing # 990-X-AA-036762 Sheet 001 Rev. 06

6. 17-SAMSS-006 -- Galvanic Anodes for Cathodic Protection, 28 February 2010

7. SAES-X-400 -- Cathodic Protection of Buried Pipelines, 02 September 2009

NOTES:

1. Approved - Acceptable to the authority having jurisdiction (i.e., Saudi Aramco ID).

2. Identified - Recognizable as suitable for the specific application by a qualified testing laboratory (i.e., listing and/or labeling).

3. Listed - Equipment and materials included in a list published by an approved qualified organization concerned with evaluation of products

or services, that maintains periodic inspection of production of listed equipment or materials or periodic evaluation of services, and whose listing

states

that the equipment, material, or services either meets appropriate designated standards or has been tested and found suitable for a specified

purpose.

4. Labeled - Equipment or materials to which has been attached a label, symbol, or other identifying mark of an approved qualified organization

concerned

with product evaluation, that maintains periodic inspection of production of labeled equipment or materials, and by whose labeling the

manufacturer

indicates compliance with appropriate standards or performance in a specified manner.

Contractor / Third-Party

Saudi Aramco

Page 2 of 3

SAUDI ARAMCO ID/PID - 18-MAY-05 - REV 0 (Standards Cutoff - August 2010)

Rev 5

SAIC NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

CP Accessories - Material Receiving

SAIC-X-3002

PROJECT TITLE

ITEM

No.

WBS / BI / JO NUMBER

ACCEPTANCE CRITERIA

REFERENCE

Construction Representative*

31-Mar-10

DATE APPROVED

QR NUMBER

31-Aug-11

CP-

CONTRACTOR / SUBCONTRACTOR

PASS

FAIL

N/A

RE-INSP DATE

PMT Representative

Work is Complete and Ready for Inspection:

Name, Initials and Date:

T&I Witnessed

QC Record Reviewed

Work Verified

T&I Witnessed

QC Record Reviewed

Work Verified

T&I Witnessed

QC Record Reviewed

Work Verified

Name, Initials and Date:

QC Inspector

PID Representative

Performed Inspection

Work / Rework May Proceed

Name, Initials and Date:

Name, Initials and Date:

QC Supervisor

Proponent and Others

Quality Record Approved:

Name, Sign and Date:

Name, Organization,

Initials and Date:

*Person Responsible for Completion of Quality Work / Test

Y = YES

Page 3 of 3

N = NO F = FAILED

Das könnte Ihnen auch gefallen

- Saudi Aramco Inspection Checklist: Post-Application Inspection of Fireclay Brick Installation SAIC-N-2041 15-Dec-09 MechDokument5 SeitenSaudi Aramco Inspection Checklist: Post-Application Inspection of Fireclay Brick Installation SAIC-N-2041 15-Dec-09 MechaamirapiNoch keine Bewertungen

- Saic N 2037Dokument5 SeitenSaic N 2037aamirapiNoch keine Bewertungen

- Work Permit System: Saudi Arabian Oil Company (Saudi Aramco)Dokument7 SeitenWork Permit System: Saudi Arabian Oil Company (Saudi Aramco)Danilo de JurasNoch keine Bewertungen

- Saep 50Dokument33 SeitenSaep 50Demac SaudNoch keine Bewertungen

- RFI (Blank)Dokument1 SeiteRFI (Blank)SajjadPervaizNoch keine Bewertungen

- Saes B 018Dokument15 SeitenSaes B 018Li PengNoch keine Bewertungen

- AE-036411-001 INDEX For Drawing and EquipmentDokument1 SeiteAE-036411-001 INDEX For Drawing and Equipmentnarutothunderjet216Noch keine Bewertungen

- Saudi Aramco Inspection Checklist: Storage & Preservation of Fireclay Bricks & Mortar SAIC-N-2038 15-Dec-09 MechDokument1 SeiteSaudi Aramco Inspection Checklist: Storage & Preservation of Fireclay Bricks & Mortar SAIC-N-2038 15-Dec-09 MechaamirapiNoch keine Bewertungen

- Uzair CVDokument3 SeitenUzair CVJilani ShaikNoch keine Bewertungen

- Initial Screening FOR Tank Cleaning, Repair & Painting Services General Bid SlateDokument5 SeitenInitial Screening FOR Tank Cleaning, Repair & Painting Services General Bid SlateJamal Mohamed RahamathullahNoch keine Bewertungen

- SAIC-L-2136 Rev 0Dokument3 SeitenSAIC-L-2136 Rev 0philipyapNoch keine Bewertungen

- GI-0002.600 (Unit Accpetance After T&I Shut DownDokument4 SeitenGI-0002.600 (Unit Accpetance After T&I Shut DownSanthoshNoch keine Bewertungen

- Saic N 2031Dokument4 SeitenSaic N 2031aamirapi100% (1)

- Saudi Aramco piping inspection checklistDokument3 SeitenSaudi Aramco piping inspection checklistEswari AnandNoch keine Bewertungen

- Ae 036881 002Dokument1 SeiteAe 036881 002narutothunderjet216Noch keine Bewertungen

- Inspectable MaterialsDokument2 SeitenInspectable MaterialsMohamed RedaNoch keine Bewertungen

- MST Gravity Test OwsDokument5 SeitenMST Gravity Test OwsJenson T VNoch keine Bewertungen

- Yanbu Refinery Materials Inspection GuideDokument20 SeitenYanbu Refinery Materials Inspection GuideCrisanto CenaNoch keine Bewertungen

- 0002 100Dokument7 Seiten0002 100Ahmed FityanNoch keine Bewertungen

- Saudi Aramco Leak Test ChecklistDokument1 SeiteSaudi Aramco Leak Test ChecklistLegend AnbuNoch keine Bewertungen

- Sen 1399 CSD Pur MR 052 01Dokument16 SeitenSen 1399 CSD Pur MR 052 01Kamran JamilNoch keine Bewertungen

- Saudi Aramco Inspection Checklist: Re-Instatement/Punchlisting of Under Ground Pipeline SAIC-L-2133 25-May-05 PipeDokument7 SeitenSaudi Aramco Inspection Checklist: Re-Instatement/Punchlisting of Under Ground Pipeline SAIC-L-2133 25-May-05 PipeAnonymous S9qBDVkyNoch keine Bewertungen

- Saudi Aramco Inspection Checklist: Manhole Receiving, Handling, Storage and Preservation SAIC-S-4001 30-Apr-13 PlumbDokument1 SeiteSaudi Aramco Inspection Checklist: Manhole Receiving, Handling, Storage and Preservation SAIC-S-4001 30-Apr-13 Plumbbiplabpal2009Noch keine Bewertungen

- Zamil TrainingDokument2 SeitenZamil TrainingSmdharwnNoch keine Bewertungen

- SAEP-321 Performance Qualification Testing and Certification of Saudi Aramco WeldersDokument28 SeitenSAEP-321 Performance Qualification Testing and Certification of Saudi Aramco WeldersSergey KichenkoNoch keine Bewertungen

- Saudi Aramco Test Report Pre-Pressure Test Checklist (Form) : SATR-A-2007 30-Oct-17 MechDokument2 SeitenSaudi Aramco Test Report Pre-Pressure Test Checklist (Form) : SATR-A-2007 30-Oct-17 MechJagdishNoch keine Bewertungen

- General Instruction Manual: ScopeDokument14 SeitenGeneral Instruction Manual: ScopeJithuRajNoch keine Bewertungen

- Saes B 064Dokument14 SeitenSaes B 064Engr HafeezullahNoch keine Bewertungen

- Saudi Aramco Refractory Receiving ChecklistDokument4 SeitenSaudi Aramco Refractory Receiving ChecklistphilipyapNoch keine Bewertungen

- Cleaning Gauging Hydrautesting and Chemical CleaningDokument2 SeitenCleaning Gauging Hydrautesting and Chemical CleaningJosephKaren LorzanoIlaganNoch keine Bewertungen

- Satip e 007 01Dokument2 SeitenSatip e 007 01Anonymous 4e7GNjzGWNoch keine Bewertungen

- HGP Insulation ProcedureDokument22 SeitenHGP Insulation ProcedureShamas TabraizNoch keine Bewertungen

- SATIP-N-001-02 Rev. 4Dokument2 SeitenSATIP-N-001-02 Rev. 4Anonymous 4e7GNjzGW100% (1)

- Content:: Saudi Arabian Oil Company (Saudi Aramco) General Instruction ManualDokument5 SeitenContent:: Saudi Arabian Oil Company (Saudi Aramco) General Instruction ManualMd Azizul MawlaNoch keine Bewertungen

- Boiler Refractory Dry Out PDFDokument2 SeitenBoiler Refractory Dry Out PDFBoiler Scrubber100% (1)

- Msds 0864 Aquafill Wallfiller Fine en 1Dokument10 SeitenMsds 0864 Aquafill Wallfiller Fine en 1baseet gazaliNoch keine Bewertungen

- APPENDIX A3 - Concrete Batching PlantDokument6 SeitenAPPENDIX A3 - Concrete Batching PlantAymanEssamNoch keine Bewertungen

- Saudi Aramco Pre-Commissioning Form: Testing Guide LinesDokument4 SeitenSaudi Aramco Pre-Commissioning Form: Testing Guide LinesSathiya SeelanNoch keine Bewertungen

- Qc Manager, Oil and Gas ExperienceDokument25 SeitenQc Manager, Oil and Gas ExperienceniranjanvengadNoch keine Bewertungen

- Saudi Aramco Inspection ChecklistDokument11 SeitenSaudi Aramco Inspection ChecklistleonysNoch keine Bewertungen

- SAUDI ARAMCO BOILER INSPECTION PLANDokument4 SeitenSAUDI ARAMCO BOILER INSPECTION PLANAnonymous 4e7GNjzGWNoch keine Bewertungen

- Saic W 2003Dokument14 SeitenSaic W 2003Mohammed IlliasuddinNoch keine Bewertungen

- Erection Contractor's ScopeDokument4 SeitenErection Contractor's ScopeasifaliabidNoch keine Bewertungen

- Evolutionary Developments of Thermal Desalination PlantDokument15 SeitenEvolutionary Developments of Thermal Desalination PlantIsrar SyahrirNoch keine Bewertungen

- Plumbing Rfi Front SheetDokument14 SeitenPlumbing Rfi Front SheetMD SHARIQUENoch keine Bewertungen

- MNT-INTG-2007OP - Maintenance Welding InspectionDokument43 SeitenMNT-INTG-2007OP - Maintenance Welding InspectionNatarajan MurugesanNoch keine Bewertungen

- QM-Q23-PL-1746 Rev 00 Perssonel QualificationDokument27 SeitenQM-Q23-PL-1746 Rev 00 Perssonel QualificationRampal Rahul Rampal Rahul100% (1)

- CRMS ItpDokument2 SeitenCRMS Itparockiyathass100% (1)

- Saes B 005Dokument13 SeitenSaes B 005Karu 2100% (1)

- QCP 040 QCP CrmsDokument7 SeitenQCP 040 QCP Crmsarockiyathass100% (1)

- Saudi Aramco Inspection Checklist: In-Process Welding Inspection (API Tanks) SAIC-W-2086 31-Aug-11 WeldDokument3 SeitenSaudi Aramco Inspection Checklist: In-Process Welding Inspection (API Tanks) SAIC-W-2086 31-Aug-11 WeldAnonymous 4e7GNjzGWNoch keine Bewertungen

- SCH.Q - Contract No.6600044663 (IK)Dokument81 SeitenSCH.Q - Contract No.6600044663 (IK)kamilNoch keine Bewertungen

- AramcoDokument9 SeitenAramcoTamsila AmjadNoch keine Bewertungen

- QRG-VI-004 Procedure and Regulation Governing Requirements For CPW in MIC - RLC Rev06 - April2018Dokument54 SeitenQRG-VI-004 Procedure and Regulation Governing Requirements For CPW in MIC - RLC Rev06 - April2018Irshad AlamNoch keine Bewertungen

- Schedule B - Attachment IVDokument29 SeitenSchedule B - Attachment IVAbdul Ahad LoneNoch keine Bewertungen

- On - Plot HydrotestingDokument14 SeitenOn - Plot HydrotestingarunmirandaNoch keine Bewertungen

- Refractory Inspection: Prepared by Integrity EngineeringDokument17 SeitenRefractory Inspection: Prepared by Integrity EngineeringAhmedNoch keine Bewertungen

- QMIS RFI RaisedDokument2 SeitenQMIS RFI RaisedSulman YounasNoch keine Bewertungen

- Saudi Aramco Inspection Checklist: Flow - Integral Orifice - Material Receiving. SAIC-J-6106 1-Oct-05 InstDokument2 SeitenSaudi Aramco Inspection Checklist: Flow - Integral Orifice - Material Receiving. SAIC-J-6106 1-Oct-05 InstAdel KlkNoch keine Bewertungen

- SAIC-X-3001 Rev 2Dokument2 SeitenSAIC-X-3001 Rev 2josephjohn2Noch keine Bewertungen

- SAIC-X-3001 Rev 5Dokument3 SeitenSAIC-X-3001 Rev 5aamirapiNoch keine Bewertungen

- SATIP-X-400-01 Rev 5Dokument3 SeitenSATIP-X-400-01 Rev 5aamirapiNoch keine Bewertungen

- Saes N 140Dokument10 SeitenSaes N 140aamirapiNoch keine Bewertungen

- Saic N 2040Dokument4 SeitenSaic N 2040aamirapiNoch keine Bewertungen

- Saic A 1001rev 5Dokument2 SeitenSaic A 1001rev 5aamirapiNoch keine Bewertungen

- Saic N 2039Dokument1 SeiteSaic N 2039aamirapiNoch keine Bewertungen

- Refractory Dry-Out Procedure For SRU Train 5 (MC-P06) Rev-ADokument107 SeitenRefractory Dry-Out Procedure For SRU Train 5 (MC-P06) Rev-Aaamirapi100% (2)

- Saudi Aramco Inspection ChecklistDokument2 SeitenSaudi Aramco Inspection ChecklistaamirapiNoch keine Bewertungen

- Architectural SymbolsDokument34 SeitenArchitectural SymbolsNiallburke100% (4)

- Saes N 130Dokument5 SeitenSaes N 130aamirapiNoch keine Bewertungen

- Saudi Aramco Inspection Checklist: Storage & Preservation of Fireclay Bricks & Mortar SAIC-N-2038 15-Dec-09 MechDokument1 SeiteSaudi Aramco Inspection Checklist: Storage & Preservation of Fireclay Bricks & Mortar SAIC-N-2038 15-Dec-09 MechaamirapiNoch keine Bewertungen

- Saudi Aramco Refractory Repair InspectionDokument4 SeitenSaudi Aramco Refractory Repair InspectionaamirapiNoch keine Bewertungen

- Saic N 2035Dokument9 SeitenSaic N 2035aamirapiNoch keine Bewertungen

- Saudi Aramco Refractory Repair InspectionDokument4 SeitenSaudi Aramco Refractory Repair InspectionaamirapiNoch keine Bewertungen

- Saic N 2036Dokument6 SeitenSaic N 2036aamirapiNoch keine Bewertungen

- Saic N 2033Dokument5 SeitenSaic N 2033aamirapiNoch keine Bewertungen

- Saudi Aramco Inspection ChecklistDokument6 SeitenSaudi Aramco Inspection Checklistaamirapi100% (1)

- Saic N 2028Dokument4 SeitenSaic N 2028aamirapi100% (1)

- Saic N 2031Dokument4 SeitenSaic N 2031aamirapi100% (1)

- Saudi Aramco Inspection ChecklistDokument5 SeitenSaudi Aramco Inspection Checklistaamirapi100% (1)

- Saic N 2030Dokument6 SeitenSaic N 2030aamirapi100% (1)

- Saudi Aramco Inspection ChecklistDokument5 SeitenSaudi Aramco Inspection Checklistaamirapi100% (1)

- Saudi Aramco Inspection ChecklistDokument1 SeiteSaudi Aramco Inspection Checklistaamirapi100% (1)

- Saic N 2029Dokument6 SeitenSaic N 2029aamirapi100% (1)

- Saudi Aramco Inspection ChecklistDokument5 SeitenSaudi Aramco Inspection Checklistaamirapi100% (1)

- Saudi Aramco Inspection Checklist: Pre-Application Inspection of Castable & Brick Refractory SAIC-N-2024 15-Dec-09 MechDokument12 SeitenSaudi Aramco Inspection Checklist: Pre-Application Inspection of Castable & Brick Refractory SAIC-N-2024 15-Dec-09 Mechaamirapi100% (1)

- Logistic Regression to Predict Airline Customer Satisfaction (LRCSDokument20 SeitenLogistic Regression to Predict Airline Customer Satisfaction (LRCSJenishNoch keine Bewertungen

- COVID-19's Impact on Business PresentationsDokument2 SeitenCOVID-19's Impact on Business PresentationsRetmo NandoNoch keine Bewertungen

- Top Brand Story Bar Supervisor Jobs Chennai Apply Now Latest Fresher Experienced Bar Supervisor Jobs in Various Location July 18 2021Dokument1 SeiteTop Brand Story Bar Supervisor Jobs Chennai Apply Now Latest Fresher Experienced Bar Supervisor Jobs in Various Location July 18 2021Surya JamesNoch keine Bewertungen

- Course Syllabus: Aurora Pioneers Memorial CollegeDokument9 SeitenCourse Syllabus: Aurora Pioneers Memorial CollegeLorisa CenizaNoch keine Bewertungen

- Ralf Behrens: About The ArtistDokument3 SeitenRalf Behrens: About The ArtistStavros DemosthenousNoch keine Bewertungen

- 1.1 Introduction To Networks - Networks Affect Our LivesDokument2 Seiten1.1 Introduction To Networks - Networks Affect Our LivesCristian MoralesNoch keine Bewertungen

- AE383LectureNotes PDFDokument105 SeitenAE383LectureNotes PDFPoyraz BulutNoch keine Bewertungen

- 9IMJan 4477 1Dokument9 Seiten9IMJan 4477 1Upasana PadhiNoch keine Bewertungen

- 01 Automatic English To Braille TranslatorDokument8 Seiten01 Automatic English To Braille TranslatorShreejith NairNoch keine Bewertungen

- Insulators and Circuit BreakersDokument29 SeitenInsulators and Circuit Breakersdilja aravindanNoch keine Bewertungen

- Gary Mole and Glacial Energy FraudDokument18 SeitenGary Mole and Glacial Energy Fraudskyy22990% (1)

- 158 Oesmer Vs Paraisa DevDokument1 Seite158 Oesmer Vs Paraisa DevRobelle Rizon100% (1)

- NAC Case Study AnalysisDokument25 SeitenNAC Case Study AnalysisSushma chhetriNoch keine Bewertungen

- SE Myth of SoftwareDokument3 SeitenSE Myth of SoftwarePrakash PaudelNoch keine Bewertungen

- Death Without A SuccessorDokument2 SeitenDeath Without A Successorilmanman16Noch keine Bewertungen

- B3 Zoning Diagram, Atlantic Yards/Pacific ParkDokument4 SeitenB3 Zoning Diagram, Atlantic Yards/Pacific ParkNorman OderNoch keine Bewertungen

- Gattu Madhuri's Resume for ECE GraduateDokument4 SeitenGattu Madhuri's Resume for ECE Graduatedeepakk_alpineNoch keine Bewertungen

- Marketing ManagementDokument14 SeitenMarketing ManagementShaurya RathourNoch keine Bewertungen

- Safety QualificationDokument2 SeitenSafety QualificationB&R HSE BALCO SEP SiteNoch keine Bewertungen

- Chapter 7 - Cash BudgetDokument23 SeitenChapter 7 - Cash BudgetMostafa KaghaNoch keine Bewertungen

- Internship Report Recruitment & Performance Appraisal of Rancon Motorbikes LTD, Suzuki Bangladesh BUS 400Dokument59 SeitenInternship Report Recruitment & Performance Appraisal of Rancon Motorbikes LTD, Suzuki Bangladesh BUS 400Mohammad Shafaet JamilNoch keine Bewertungen

- ANDRITZ Company Presentation eDokument6 SeitenANDRITZ Company Presentation eAnonymous OuY6oAMggxNoch keine Bewertungen

- Instrumentos de Medición y Herramientas de Precisión Starrett DIAl TEST INDICATOR 196 A1ZDokument24 SeitenInstrumentos de Medición y Herramientas de Precisión Starrett DIAl TEST INDICATOR 196 A1Zmicmarley2012Noch keine Bewertungen

- Elaspeed Cold Shrink Splices 2010Dokument3 SeitenElaspeed Cold Shrink Splices 2010moisesramosNoch keine Bewertungen

- QSK45 60 oil change intervalDokument35 SeitenQSK45 60 oil change intervalHingga Setiawan Bin SuhadiNoch keine Bewertungen

- Material Properties L2 Slides and NotesDokument41 SeitenMaterial Properties L2 Slides and NotesjohnNoch keine Bewertungen

- ADSLADSLADSLDokument83 SeitenADSLADSLADSLKrishnan Unni GNoch keine Bewertungen

- 1990-1994 Electrical Wiring - DiagramsDokument13 Seiten1990-1994 Electrical Wiring - Diagramsal exNoch keine Bewertungen

- Chapter 2a Non Structured DataRozianiwatiDokument43 SeitenChapter 2a Non Structured DataRozianiwatiNur AnisaNoch keine Bewertungen

- Advance Bio-Photon Analyzer ABPA A2 Home PageDokument5 SeitenAdvance Bio-Photon Analyzer ABPA A2 Home PageStellaEstel100% (1)