Beruflich Dokumente

Kultur Dokumente

Us 20010047736

Hochgeladen von

wewewewOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Us 20010047736

Hochgeladen von

wewewewCopyright:

Verfügbare Formate

US 20010047736A1

(19) United States

(12) Patent Application Publication (10) Pub. No.: US 2001/0047736 A1

Thiesen

(43) Pub. Date:

(54) CARTRIDGE AMMUNITION

(75)

Inventor:

Stefan Thiesen, Willich (DE)

(30)

PO. Box 34385

Foreign Application Priority Data

Sep. 23, 1997

Correspondence Address:

VENABLE, BAETJ ER, HOWARD AND

CIVILETTI, LLP

Dec. 6, 2001

(DE) ................................... .. 197 41 841.4

Publication Classi?cation

(51)

Int. Cl? .................................................... ..F42B 14/06

(52)

Us. 01. ............................................................ ..102/523

Washington, DC 20043-9998 (US)

(73) Assignee: Rheinmetall W & M GmbH, Heinrich

Ehrhardt-Strasse, Unterluss (DE)

(21) Appl. No.:

09/903,519

(22) Filed:

Jul. 13, 2001

Related US. Application Data

(62) Division of application No. 09/157,951, ?led on Sep.

22, 1998, noW Pat. No. 6,279,448.

(57)

ABSTRACT

A cartridge ammunition includes a cartridge case having a

front and a rear; a projectile inserted into the cartridge case

at its front and extending into the cartridge case; an igniter

provided in the rear of the cartridge case; and a propellant

charge accommodated in the cartridge case. The propellant

charge is formed of a compacted bulk propellant poWder

having a density of betWeen 0.9 and 1.2 g/cm3.

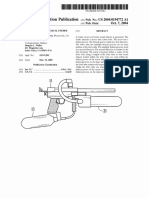

Patent Application Publication

Dec. 6, 2001 Sheet 1 0f 2

US 2001/0047736 A1

FIGJ

Patent Application Publication

Dec. 6, 2001 Sheet 2 0f 2

US 2001/0047736 A1

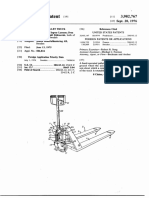

FIG.2

Dec. 6, 2001

US 2001/0047736 A1

CARTRIDGE AMMUNITION

axis of the cartridge case, Whereby a relatively high charge

density (packing density) of the propellant charge and thus

CROSS REFERENCE TO RELATED

APPLICATION

a substantial performance increase of the cartridge are

achieved.

[0001] This application is a division of application Ser.

No. 09/157,951 ?led Sep. 22, 1998.

[0009] Tests have shoWn that the frequency With Which the

rotary vibrator is oscillated is preferably betWeen 0.2 and 10

HZ and the amplitude of the pivotal motion is betWeen 10

and 270 in order to achieve the predetermined compactness

of the bulk poWder propellant charge in a relatively short

[0002] This application claims the priority of German

Application No. 197 41 841.4 ?led Sep. 23, 1997, Which is

incorporated herein by reference.

[0003]

time.

BACKGROUND OF THE INVENTION

[0010] In accordance With an advantageous embodiment

of the invention, a ?rst partial charge is provided not by

This invention relates to cartridge ammunition.

compression in the cartridge case, but as a stacked charge

[0004] German Offenlegungsschrift (application pub

lished Without examination) 41 39 269, to Which corre

sponds US. Pat. No. 5,335,599, discloses a cartridge having

a combustible cartridge case Which, for increasing perfor

mance, has three partial charges: a high charge-density ?rst

partial charge Which is a compressed propellant poWder and

Which is disposed betWeen the rear of the projectile and the

cartridge base, a second partial charge Which is a bulk

propellant poWder and Which is situated at that side of the

cartridge case Which is oriented toWards the projectile tip,

and a third partial charge situated betWeen the ?rst and

second partial charges. The third partial charge is a rod

shaped propellant Which may also contain bulk propellant

poWder shaken into the space accommodating the rod pro

having a compactness Which corresponds to that of a com

pressed partial charge. Since stacked charges may be very

accurately made, the cartridges accordingly have a repro

ducible inner ballistic behavior even When ?red at loW

temperatures. Further, by using such charges as separately

deliverable components, an introduction of such charges

into the cartridge may be performed in a short period of time.

[0011] According to another advantageous embodiment of

the invention, the ?rst partial charge too, is introduced into

the cartridge case as a bulk propellant poWder compacted by

the rotary vibrator until the desired packing density is

reached.

BRIEF DESCRIPTION OF THE DRAWING

pellant.

[0012]

FIG. 1 is an axial sectional vieW of a tWo-part

[0005] It is one of the disadvantages of the above-outlined

knoWn cartridge that the second partial charge, because of its

cartridge made according to the invention.

loW charge density, contributes only slightlyif at allto

the desired performance increase of the cartridge. Further,

the compression of the ?rst partial charge in the cartridge

[0013]

case leads to problems of reproducibility Which is particu

DESCRIPTION OF THE PREFERRED

EMBODIMENTS

larly disadvantageous When ?ring cartridges at loW tempera

tures. Also, introducing the propellant into the knoWn car

tridge is a relatively time-consuming process.

SUMMARY OF THE INVENTION

[0006]

It is an object of the invention to provide an

improved cartridge of the above-outlined type in Which the

second partial charge too, signi?cantly contributes to the

performance increase of the cartridge.

FIG. 2 is an enlarged sectional vieW taken along

line II-II of FIG. 1.

[0014] FIG. 1 shoWs a cartridge 1 having a frontal car

tridge case part 2 and a rearWard cartridge case part 3,

separated from one another by a combustible disk 4 made,

for example, of cardboard or textile fabric.

[0015]

The rearWard cartridge case part 3 is formed of a

combustible component 5 secured to a metal case bottom 6,

centrally supporting a bottom igniter part 7 by a threaded

connection. The cartridge case part 3 accommodates a ?rst

This object and others to become apparent as the

partial charge 8 Which is a stacked charge having a packing

speci?cation progresses, are accomplished by the invention,

according to Which, brie?y stated, the cartridge ammunition

density corresponding to the compressed material(1.2

[0007]

includes a cartridge case having a front and a rear; a

projectile inserted into the cartridge case at its front and

extending into the cartridge case; an igniter provided in the

rear of the cartridge case; and a propellant charge accom

modated in the cartridge case. The propellant charge is

formed of a compacted bulk propellant poWder having a

density of betWeen 0.9 and 1.2 g/cm3.

[0008] Essentially, the invention is based on the principle

to use a bulk propellant poWder Which is densely packed

(compacted) by means of a rotary vibrator. The rotary

vibrator is arranged in such a manner that its axis of rotation

coincides With the longitudinal axis of the cartridge case. As

a result of such a positional relationship, the vibrating

process results in a paralleliZation of the longitudinal axes of

the individual propellant poWder grains With the longitudinal

g/cm3) used in comparable cartridges (such as disclosed in

the earlier-noted German Offenlegungsschrift 41 38 269).

The ?rst partial charge 8 de?nes an axial bore for receiving

a metal ignition tube 9 Which passes through the ?rst partial

charge 8 and Which is supported on the bottom igniter part

7 to prevent it from lateral displacements.

[0016]

The frontal cartridge case part 2 accommodates a

?n-stabiliZed, subcaliber kinetic energy projectile 12 having

a sabot 11 and extending to the bottom 10 of the frontal

cartridge case part 2. The latter is formed of a combustible

component 13 Which has a cylindrical portion 14 and a

frontal circumferential shoulder 15 Whose forWard end is

inWardly crimped for providing an engagement face for the

sabot 11. The frontal cartridge case part 2 accommodates, in

the space surrounded by the shoulder 15, a second partial

charge 16 Which is a bulk propellant poWder, compacted

Dec. 6, 2001

US 2001/0047736 A1

according to the invention by means of a rotary vibrator (not

illustrated) to a packing density of betWeen approximately

0.9 and 1.2 g/cm3.

[0017]

In the frontal cartridge case part 2, betWeen the

second partial charge 16 and the bottom plate 10, propellant

rods are provided Which constitute a third partial charge 17.

The rods are packed closely to one another and extend over

the length of the cylindrical portion 14. For ?lling dead

spaces betWeen the rods or betWeen the rods on the one hand

and the rearWard part 18 of the projectile 12 on the other

hand, and thus for increasing the packing density of the third

partial charge, additionally bulk propellant may be shaken

feasible to again oscillate the assembly 2, 12 in the above

described manner for compacting the bulk poWder propel

lant occupying the cylindrical part 14.

[0024] Thereafter the combustible disk 4 is inserted to

form the bottom of the frontal cartridge case part 2.

[0025]

As a last step, the rearWard cartridge case part 3 is

secured to the frontal cartridge part 2, for example, by

gluing. The rearWard cartridge case part 3 Was previously

?lled With the stacked charge forming the ?rst partial charge

8.

[0026] According to an alternative, the pouring and vibrat

into those locations. Further, betWeen the second and the

third partial charges 16 and 17 a combustible apertured disk

ing step continues until the bulk poWder substantially

19 is provided.

tridge case part 2 as Well. In such a case then the rod-shaped

[0018] In FIG. 2 the individual poWder grains are desig

nated at 20; arroW 21 indicates the direction of the oscillat

ing motion of the cartridge during compacting of the pro

pellant. Such an oscillating motion is performed about the

longitudinal axis 22 of the cartridge With an amplitude of

about approximately 150 at a frequency of preferably

betWeen 0.2 and 10 HZ.

[0019]

In the description Which folloWs a preferred

embodiment of the invention Will be set forth.

[0020]

The kinetic energy projectile 12 is inserted into the

frontal cartridge case part 2 to assume a position as shoWn

in FIG. 1. At this stage, the frontal cartridge case part 2 has

no propellant charges nor are the bottom plates 4 and 19

present. Also, the frontal cartridge case part 2 and the

rearWard cartridge case part 3 are not yet joined to one

another.

entirely ?lls the cylindrical portion 14 of the frontal car

propellant poWder and the apertured disk 19 are omitted. Or,

after the bulk poWder has been compacted in the space

surrounded by the shoulder 15, the apertured disk 19 is

inserted and then the pouring and the vibrating step contin

ues to ?ll the cylindrical space 14 instead of providing the

poWder rods.

[0027]

As a further alternative Which may be combined

With either method concerning the ?lling of the frontal

cartridge case part 2, instead of a stacked propellant charge,

the ?rst propellant charge 8 contained in the rearWard

cartridge case part 5 may also be a bulk poWder, compacted

by a rotary vibrator as described in connection With the

frontal cartridge case part 2. Both alternatives contribute to

an economic manufacture of the cartridge ammunition.

[0028]

It is to be understood that the invention is not

limited to the described example. Thus, the cartridge need

not be a tWo-part structure; the invention may ?nd equally

[0021] Thereafter, the assembly formed by the frontal

advantageous application in one-part cartridges as Well.

cartridge case part 2 and the kinetic energy projectile 12 is

[0029] The packing densities of the partial charges should

be preferably betWeen 0.9 and 1.2 g/cm3.

placed in a non-illustrated rotary vibrator so that the kinetic

energy projectile 12 is pointing doWnWard and the assembly

axis 22 coincides With the rotary axis of the vibrator.

[0022] Then the rotary vibrator is set in motion such that

the assembly 2, 12 is oscillated With an amplitude of

betWeen 10 and 270 and With a frequency of betWeen 0.2

and 10 HZ. Simultaneously, bulk propellant poWder is

poured into the frontal cartridge part 2 from the top (that is,

through the presently open bottom of the cylindrical part

14), Whereby the bulk poWder Will build up in the space

Which is surrounded by the shoulder portion 15 and, by

virtue of the forces imparted on the poWder grains by the

oscillation, the longitudinal axes of the grains Will be aligned

parallel to the assembly axis 22. Thus, the rotary vibrator

causes a compacting of the bulk poWder in the forWard

portion of the frontal cartridge case part 2, particularly in the

space Which is surrounded by the shoulder 15. Vibrating the

assembly 2, 12 and pouring the bulk poWder are discontin

ued When the predetermined amount of bulk poWder has

been placed into the frontal cartridge case portion 2 to thus

constitute the second propellant charge 16.

[0023] As a next step, the perforated disk 19 is inserted in

the frontal cartridge case part 2 and then the poWder rods

forming the third propellant charge 17 are positioned in the

cylindrical portion 14 of the frontal cartridge case part 2. To

?ll out dead spaces, bulk poWder may be shaken into the

cylindrical part 14 to ?ll the spaces betWeen the rods and

betWeen the rods and the cylindrical portion 14. It is also

[0030] It Will further be understood that the above descrip

tion of the present invention is susceptible to various modi

?cations, changes and adaptations, and the same are

intended to be comprehended Within the meaning and range

of equivalents of the appended claims.

What is claimed is:

1. Cartridge ammunition comprising

(a) a cartridge case having a front and a rear;

(b) a projectile inserted into said cartridge case at said

front thereof; said projectile extending into said car

tridge case;

(c) an igniter provided in said cartridge case at said rear

thereof; and

(d) a propellant charge accommodated in said cartridge

case; said propellant charge being formed of a com

pacted bulk propellant poWder having a density of

betWeen 0.9 and 1.2 g/cm3.

2. The cartridge ammunition as de?ned in claim 1,

Wherein said propellant charge is a second propellant charge

extending from the front of said cartridge case rearWardly;

further comprising a ?rst propellant charge extending from

the rear of said cartridge case forWardly; and further Wherein

said ?rst propellant charge is formed of stacked propellant

poWder.

Dec. 6, 2001

US 2001/0047736 A1

3. The cartridge ammunition as de?ned in claim 2,

further comprising a ?rst propellant charge extending from

wherein said stacked propellant powder has a packing

the rear of said cartridge case forwardly and a third propel

density of 21.2 g/cm3.

lant charge disposed in said cartridge case between said ?rst

4. The cartridge ammunition as de?ned in claim 1,

wherein said propellant charge is a second propellant charge

extending from the front of said cartridge case rearwardly;

further comprising a ?rst propellant charge extending from

the rear of said cartridge case forwardly; further wherein

said ?rst propellant charge is formed of a compacted bulk

propellant powder having a density of between 0.9 and 1.2

g/cm2.

5. The cartridge ammunition as de?ned in claim 1,

wherein said propellant charge is a second propellant charge

extending from the front of said cartridge case rearwardly;

and second propellant charges.

6. The cartridge ammunition as de?ned in claim 5,

wherein said third propellant charge is formed of propellant

powder rods.

7. The cartridge ammunition as de?ned in claim 5,

wherein said third propellant charge is formed at least in part

of a compacted bulk propellant powder having a density of

between 0.9 and 1.2 g/cm3.

Das könnte Ihnen auch gefallen

- Pressure Vessel and Stacks Field Repair ManualVon EverandPressure Vessel and Stacks Field Repair ManualBewertung: 4 von 5 Sternen4/5 (4)

- Scientific American Supplement, No. 388, June 9, 1883Von EverandScientific American Supplement, No. 388, June 9, 1883Noch keine Bewertungen

- Us 6131519Dokument4 SeitenUs 6131519dgfhjsdg hfsdhyjNoch keine Bewertungen

- Us 5149907Dokument7 SeitenUs 5149907wewewewNoch keine Bewertungen

- Us 3345945Dokument3 SeitenUs 3345945dgfhjsdg hfsdhyjNoch keine Bewertungen

- Us 6019217Dokument5 SeitenUs 6019217dgfhjsdg hfsdhyjNoch keine Bewertungen

- United States Patent: (12) (10) Patent N0.: US 7,377,754 B2Dokument23 SeitenUnited States Patent: (12) (10) Patent N0.: US 7,377,754 B2Selvaraji MuthuNoch keine Bewertungen

- European Patent Specification: VehicleDokument38 SeitenEuropean Patent Specification: VehicleMuhammad NabilNoch keine Bewertungen

- EP0883790B1Dokument7 SeitenEP0883790B1dgfsduuwioNoch keine Bewertungen

- Us 5610365Dokument5 SeitenUs 5610365dgfhjsdg hfsdhyjNoch keine Bewertungen

- Us 4023499Dokument4 SeitenUs 4023499ererNoch keine Bewertungen

- Us 3823668Dokument4 SeitenUs 3823668wewewewNoch keine Bewertungen

- Us 4711181Dokument5 SeitenUs 4711181dfdfsdNoch keine Bewertungen

- European Patent Specification F01D 11/00: Printed by Jouve, 75001 PARIS (FR)Dokument10 SeitenEuropean Patent Specification F01D 11/00: Printed by Jouve, 75001 PARIS (FR)shamsNoch keine Bewertungen

- EP0928948B1Dokument5 SeitenEP0928948B1dfdfsdNoch keine Bewertungen

- Patent Application Publication (10) Pub. No.: US 2003/0192191 A1Dokument15 SeitenPatent Application Publication (10) Pub. No.: US 2003/0192191 A1Luis JJNoch keine Bewertungen

- United States Patent (19) : Gazalel, 72 8Dokument7 SeitenUnited States Patent (19) : Gazalel, 72 8Mihai RobertNoch keine Bewertungen

- US3982767Dokument6 SeitenUS3982767takanobu ouraNoch keine Bewertungen

- United States Patent (19) : VicardDokument4 SeitenUnited States Patent (19) : Vicard155100% (1)

- United States Patent (19) 11 4,226,186: Peck 45 (Oct. 7, 1980Dokument4 SeitenUnited States Patent (19) 11 4,226,186: Peck 45 (Oct. 7, 1980KundanNoch keine Bewertungen

- US4707035Dokument5 SeitenUS4707035aungkyawzoreNoch keine Bewertungen

- X III 110111113////////////////////////////11ml: (12) Ulllted States Patent (10) Patent N0.: US 8,453,633 B2Dokument9 SeitenX III 110111113////////////////////////////11ml: (12) Ulllted States Patent (10) Patent N0.: US 8,453,633 B2djsfNoch keine Bewertungen

- Us 5655509Dokument6 SeitenUs 5655509djsfNoch keine Bewertungen

- United States Patent (191: (54) Vibrostimulative DeviceDokument5 SeitenUnited States Patent (191: (54) Vibrostimulative Devicejalepa_esNoch keine Bewertungen

- US Patent 7090236 Land SailingDokument8 SeitenUS Patent 7090236 Land SailingDimas MaulanaNoch keine Bewertungen

- Diseño de Impulsores para Mezcla de SuspensionesDokument9 SeitenDiseño de Impulsores para Mezcla de SuspensionesrwtoorresdNoch keine Bewertungen

- References Cited The Tip 8f The Blade 1ils Rotatabge, Abfotuht LgnglixtltdinlflDokument11 SeitenReferences Cited The Tip 8f The Blade 1ils Rotatabge, Abfotuht LgnglixtltdinlflRubén Gutiérrez AmoNoch keine Bewertungen

- US4483464Dokument6 SeitenUS4483464Joao LemesNoch keine Bewertungen

- Patent USPTO 4098523 Traction DeviceDokument5 SeitenPatent USPTO 4098523 Traction Devicexeron7126Noch keine Bewertungen

- United States Patent (191: Patent Number: Date of Patent: (11) 145) GrimesDokument3 SeitenUnited States Patent (191: Patent Number: Date of Patent: (11) 145) GrimesDanister GladwinNoch keine Bewertungen

- Us 5153374Dokument5 SeitenUs 5153374ererNoch keine Bewertungen

- US4219241Dokument7 SeitenUS4219241aungkyawzoreNoch keine Bewertungen

- United States Patent: (10) Patent N0.: (45) Date of PatentDokument8 SeitenUnited States Patent: (10) Patent N0.: (45) Date of PatentwererNoch keine Bewertungen

- TEPZZ - 4 885B - T: European Patent SpecificationDokument10 SeitenTEPZZ - 4 885B - T: European Patent SpecificationshamsNoch keine Bewertungen

- EP0773421A2Dokument9 SeitenEP0773421A2Jacob MillerNoch keine Bewertungen

- European Patent Application: Method of Manufacturing A Spar CapDokument11 SeitenEuropean Patent Application: Method of Manufacturing A Spar CapBrenoLucenaNoch keine Bewertungen

- H!!!!! - EEHHE) : Nonononononon Niinin 'Dokument4 SeitenH!!!!! - EEHHE) : Nonononononon Niinin 'Hadi KoraniNoch keine Bewertungen

- Ep 0679137B1Dokument11 SeitenEp 0679137B1daveNoch keine Bewertungen

- European Patent Application F04B 27/10: Rotor For Variable Displacement Swash Plate CompressorDokument16 SeitenEuropean Patent Application F04B 27/10: Rotor For Variable Displacement Swash Plate CompressorSelvaraji MuthuNoch keine Bewertungen

- United States Patent: Arness Et A) - (10) Patent N0.: (45) Date of PatentDokument12 SeitenUnited States Patent: Arness Et A) - (10) Patent N0.: (45) Date of PatentshamsNoch keine Bewertungen

- EP0229675B1Dokument10 SeitenEP0229675B112348Noch keine Bewertungen

- (A Oe Émgoueogmo: +2 (ll/l4fl2Dokument6 Seiten(A Oe Émgoueogmo: +2 (ll/l4fl2wewewewNoch keine Bewertungen

- United States Patent (10) Patent No.: US 8,251,371 B2Dokument4 SeitenUnited States Patent (10) Patent No.: US 8,251,371 B2shamsNoch keine Bewertungen

- TEPZZ 4979Z B - T: European Patent SpecificationDokument12 SeitenTEPZZ 4979Z B - T: European Patent SpecificationAna LisaNoch keine Bewertungen

- Nov. 21, 1961 C, H, Burnside 3,009,385: Method of Loading A Rocket Motor With Solid PropellantDokument7 SeitenNov. 21, 1961 C, H, Burnside 3,009,385: Method of Loading A Rocket Motor With Solid PropellantSeenu CnuNoch keine Bewertungen

- United States Patent (191: Kern Et' AlDokument4 SeitenUnited States Patent (191: Kern Et' Aldgfhdg ereNoch keine Bewertungen

- United States Patent: Perlo Et Al. (45) Date of Patent: Dec. 20, 2005Dokument10 SeitenUnited States Patent: Perlo Et Al. (45) Date of Patent: Dec. 20, 2005tristanNoch keine Bewertungen

- Us5361479 PDFDokument5 SeitenUs5361479 PDFmohammadreza91Noch keine Bewertungen

- Us 3717946Dokument4 SeitenUs 3717946ererNoch keine Bewertungen

- Chlorine CylinderDokument9 SeitenChlorine Cylinderjoseph_mscNoch keine Bewertungen

- (12 Ulllted States Patent (10) Patent No.: US 6,860,188 B2Dokument13 Seiten(12 Ulllted States Patent (10) Patent No.: US 6,860,188 B2Selvaraji MuthuNoch keine Bewertungen

- United States Patent (19) : GrainDokument5 SeitenUnited States Patent (19) : Grainاحمد عبدالكريمNoch keine Bewertungen

- European Patent Application: A Wing Tip DeviceDokument16 SeitenEuropean Patent Application: A Wing Tip DevicegorgiNoch keine Bewertungen

- Err-Easels - / ' Ma. Ma @&?7hii?%: March 3, 1936. G, Gimera Et Al 2,032,695Dokument3 SeitenErr-Easels - / ' Ma. Ma @&?7hii?%: March 3, 1936. G, Gimera Et Al 2,032,695RakeshNoch keine Bewertungen

- 11111111mumnlllgglotgggglgggggnn - : United States Patent (19) (11) Patent Number: 5,613,555Dokument5 Seiten11111111mumnlllgglotgggglgggggnn - : United States Patent (19) (11) Patent Number: 5,613,555mohammadreza91Noch keine Bewertungen

- Unlted States Patent (19) (11) Patent Number: 4,660,248: IllllllDokument15 SeitenUnlted States Patent (19) (11) Patent Number: 4,660,248: Illllll113314Noch keine Bewertungen

- United States Patent (10) Patent No.: US 6,341,790 B1: Chen (45) Date of Patent: Jan. 29, 2002Dokument10 SeitenUnited States Patent (10) Patent No.: US 6,341,790 B1: Chen (45) Date of Patent: Jan. 29, 2002Eric Manuel Mercedes AbreuNoch keine Bewertungen

- Q Loader PatentsDokument20 SeitenQ Loader Patentssjdarkman1930Noch keine Bewertungen

- United States Patent (19) : (21) Appl. No.: 927,123Dokument7 SeitenUnited States Patent (19) : (21) Appl. No.: 927,123155Noch keine Bewertungen

- Patent Application Publication (10) Pub. No.: US 2013/0157528A1Dokument7 SeitenPatent Application Publication (10) Pub. No.: US 2013/0157528A1Tâm DươngNoch keine Bewertungen

- United States Patent (191: WinerDokument5 SeitenUnited States Patent (191: WinerwewewewNoch keine Bewertungen

- Us 8809689Dokument7 SeitenUs 8809689wewewewNoch keine Bewertungen

- Us 5775636Dokument6 SeitenUs 5775636wewewewNoch keine Bewertungen

- United States Patent: Ronn Et Al. (10) Patent N0.: (45) Date of PatentDokument7 SeitenUnited States Patent: Ronn Et Al. (10) Patent N0.: (45) Date of PatentwewewewNoch keine Bewertungen

- Us 3690255Dokument5 SeitenUs 3690255wewewewNoch keine Bewertungen

- United States Patent (191: Hau (11) Patent Number: (45) Date of PatentDokument7 SeitenUnited States Patent (191: Hau (11) Patent Number: (45) Date of PatentwewewewNoch keine Bewertungen

- Us 3823668Dokument4 SeitenUs 3823668wewewewNoch keine Bewertungen

- United States Patent: Berej Noi Et AlDokument6 SeitenUnited States Patent: Berej Noi Et AlwewewewNoch keine Bewertungen

- (A Oe Émgoueogmo: +2 (ll/l4fl2Dokument6 Seiten(A Oe Émgoueogmo: +2 (ll/l4fl2wewewewNoch keine Bewertungen

- Sept. 13, 1966: J. Marsh EtalDokument4 SeitenSept. 13, 1966: J. Marsh EtalwewewewNoch keine Bewertungen

- United States Patent (191: Ahlstriim Et A1. (11) Patent Number: (45) Date of PatentDokument5 SeitenUnited States Patent (191: Ahlstriim Et A1. (11) Patent Number: (45) Date of PatentwewewewNoch keine Bewertungen

- United States Patent (191Dokument7 SeitenUnited States Patent (191wewewewNoch keine Bewertungen

- LL L'L///"/"Z//: (12) United States PatentDokument4 SeitenLL L'L///"/"Z//: (12) United States PatentwewewewNoch keine Bewertungen

- Ester: United States PatentDokument5 SeitenEster: United States PatentwewewewNoch keine Bewertungen

- Us 5299499Dokument5 SeitenUs 5299499wewewewNoch keine Bewertungen

- Us 5237927Dokument4 SeitenUs 5237927wewewewNoch keine Bewertungen

- United States Patent (10) Patent N0.: US 7,540,240 B2Dokument4 SeitenUnited States Patent (10) Patent N0.: US 7,540,240 B2wewewewNoch keine Bewertungen

- United States Patent: CarverDokument4 SeitenUnited States Patent: CarverwewewewNoch keine Bewertungen

- Conversion Tables by Cafe Fernando Food BlogDokument5 SeitenConversion Tables by Cafe Fernando Food BlogElston FooNoch keine Bewertungen

- Free Non Veg Nutrition Plan YSF PDFDokument8 SeitenFree Non Veg Nutrition Plan YSF PDFAbhilash Wasekar100% (1)

- Ryan's DilemmaDokument11 SeitenRyan's DilemmaAkhi RajNoch keine Bewertungen

- Edrolo ch3Dokument42 SeitenEdrolo ch3YvonneNoch keine Bewertungen

- Rightship Ship Inspection Questionnaire RISQDokument177 SeitenRightship Ship Inspection Questionnaire RISQИгорь100% (3)

- 1984 Population Report EthiopiaDokument255 Seiten1984 Population Report EthiopiaOsvaldas ZagurskasNoch keine Bewertungen

- Stratigraphy MCQs With AnswerDokument10 SeitenStratigraphy MCQs With Answerkumar Harsh67% (3)

- (Rect-15) Experimental Study On Partial Replacement of Cement With Coconut Shell Ash in ConcreteDokument3 Seiten(Rect-15) Experimental Study On Partial Replacement of Cement With Coconut Shell Ash in Concretefrancis dimakilingNoch keine Bewertungen

- Long Quiz 1 Eim Tools, MaterialsDokument1 SeiteLong Quiz 1 Eim Tools, MaterialsLea Ann PalaciosNoch keine Bewertungen

- Module 1 Hvac Basics Chapter-1Dokument5 SeitenModule 1 Hvac Basics Chapter-1KHUSHBOONoch keine Bewertungen

- Fermat Contest: Canadian Mathematics CompetitionDokument4 SeitenFermat Contest: Canadian Mathematics Competitionสฮาบูดีน สาและNoch keine Bewertungen

- Astrophysics & CosmologyDokument2 SeitenAstrophysics & CosmologyMarkus von BergenNoch keine Bewertungen

- ARTS 9 Q2 M2 Wk2Dokument21 SeitenARTS 9 Q2 M2 Wk2Matt LimNoch keine Bewertungen

- NTDCDokument8 SeitenNTDCjaved_hanifNoch keine Bewertungen

- Fractal Audio Footswitch Functions Guide PDFDokument22 SeitenFractal Audio Footswitch Functions Guide PDFerikNoch keine Bewertungen

- Eoq PDFDokument10 SeitenEoq PDFविनय कुमार शर्माNoch keine Bewertungen

- BÀI TẬP TA 9 THEO CHUYÊN ĐỀ NGỮ PHÁPDokument213 SeitenBÀI TẬP TA 9 THEO CHUYÊN ĐỀ NGỮ PHÁPhoangmaiNoch keine Bewertungen

- Unit Test 7 (PDF)Dokument1 SeiteUnit Test 7 (PDF)emirelliucNoch keine Bewertungen

- Course For Loco Inspector Initial (Diesel)Dokument239 SeitenCourse For Loco Inspector Initial (Diesel)Hanuma Reddy93% (14)

- Electrical BOQ 07.12.2021 New Boq R4 05-01-2022 Final 16.02.2022Dokument92 SeitenElectrical BOQ 07.12.2021 New Boq R4 05-01-2022 Final 16.02.2022Upendra ChariNoch keine Bewertungen

- IPC-S-816 SMT Process Guideline ChecklistDokument4 SeitenIPC-S-816 SMT Process Guideline Checklistmigant23uNoch keine Bewertungen

- Pnbcontr0223en (Web)Dokument308 SeitenPnbcontr0223en (Web)James GeorgeNoch keine Bewertungen

- Aoc f22sDokument43 SeitenAoc f22sJoao Jose Santos NetoNoch keine Bewertungen

- (Q2) Electrochemistry 29th JulyDokument21 Seiten(Q2) Electrochemistry 29th JulySupritam KunduNoch keine Bewertungen

- Genesis of KupferschieferDokument15 SeitenGenesis of KupferschieferMaricela GarciaNoch keine Bewertungen

- Baldor Motor TestDokument14 SeitenBaldor Motor TestChecho BuenaventuraNoch keine Bewertungen

- The 50 Most Inspiring Travel Quotes of All TimeDokument4 SeitenThe 50 Most Inspiring Travel Quotes of All Timeungku1Noch keine Bewertungen

- Barilla SpaDokument11 SeitenBarilla Spavariapratik100% (1)

- Medgroup Packet Tracer Skills Integration Challenge: - Design and Prototype The New Medgroup TopologyDokument4 SeitenMedgroup Packet Tracer Skills Integration Challenge: - Design and Prototype The New Medgroup TopologyvilanchNoch keine Bewertungen

- Agricultural Machinery in PakistanDokument19 SeitenAgricultural Machinery in PakistanBadar NiaziNoch keine Bewertungen