Beruflich Dokumente

Kultur Dokumente

Zenith Offshore Vent Tip Replacement: V Stage S Caffold'

Hochgeladen von

Ton PhichitOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Zenith Offshore Vent Tip Replacement: V Stage S Caffold'

Hochgeladen von

Ton PhichitCopyright:

Verfügbare Formate

ZENITH OFFSHORE VENT TIP REPLACEMENT

This paper is intended to provide an overview of the removal and replacement of a

cold vent tip, completed on an offshore oil rig located off the coast of Malaysia.

Background

Zenith SAS were approached by a multinational oil and gas provider to propose an

innovative solution to remove and replace a defective cold vent tip at the head of a

30m steel stack on one of their production rigs off the Malaysian coast, without the

use of a costly barge crane.

The original design intent for tip replacement involved having to rotate the stack

through 90o at the base; this would have allowed access to the tip at platform level.

However, due to maintenance issues, and previous modifications to the rig, this

option was no longer deemed viable by the rigs operator.

Zenith SAS, in conjunction with Zenith Consultants were tasked with proposing an

alternative solution which would see the defective tip lowered to platform level and

the new replacement tip installed with minimum disruption to the rigs process.

The provision of a purpose designed lifting davit and temporary platform was the

preferred option from an early stage as it promised to tackle all the constraints and

could be used for future tip works.

Zenith SAS were subsequently appointed to design, fabricate and install the

innovative bespoke lifting davit, utilising traditional steeplejacking activities to access

the head of the stack and to carry out the essential maintenance works.

Proposed Solution

A practical, lightweight, easy to transport and easy to assemble solution was

required. In such remote locations reliability is crucial, so any lifting apparatus

needed to be robust enough to deal with the environmental conditions and simple

enough to minimise any risk of reliability issues often associated with mechanical

plant.

It was decided at an early stage in the project that the use of motorised equipment

would add unnecessary complications to the logistics of the operation.

A hand operated manual hoist would provide the ideal solution, with the required

lifting capacity to hoist the 750 kg vent tip up 30m to the head of the stack.

The davit support bands incorporated the brackets for the temporary access

platform, the structural form of such a temporary platform is akin to the traditional

steeplejack V Stage Scaffold. Due to proximity of the supports for the guy wires

and the redundant lifting bracket careful consideration had to be given to the

ZENITH OFFSHORE VENT TIP REPLACEMENT

geometry of the platform, this was achieved by creating a 3 dimensional model of the

stack based on historic drawing information.

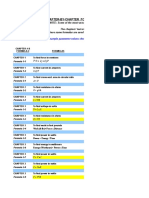

Figure 1 illustrates the proposed method of temporary platform and davit installation.

Figure 1

Design Methodology

On undertaking the detailed design of the lifting davit and temporary platform two

scenarios had to be considered.

The first being the actual design of the davit and platform itself, incorporating the

necessary details which would allow the materials to be hoisted into position.

The second being the structural appraisal of the existing 900mm diameter steel stack

and 4 no. guy wires to ensure the additional loading of the platform and the eccentric

load of the tip whilst it was being installed did not adversely overload the system.

The design of the lifting davit was developed to minimise the moment forces at the

base of the davit, consequently minimising the push/pull reactions on the stack

itself. In order to achieve this, the length of the upper boom was kept to a minimum

while the introduction of a back stay wire effectively balances out the overturning

forces. The majority of the forces are transferred through the davit structure in

compression.

ZENITH OFFSHORE VENT TIP REPLACEMENT

The base of the davit structure is held into position at the head of the stack (below

the tip), via two steel bands clamped to the shell. The two bands are physically

connected using 4no. steel rods, allowing both bands to act in a composite manner.

As a means of secondary support, the upper band is to be bolted through an existing

fin plate, whilst the lower band is secured to the guy wire fin plates by means of wire

strops.

Figure 2

On installation of the two steel support bands, the scaffolded working platform was

erected. Using hand operated mechanical lifting equipment the davit would then be

lifted, in sections into position and assembled.

ZENITH OFFSHORE VENT TIP REPLACEMENT

Figure 3

Figure 4

ZENITH OFFSHORE VENT TIP REPLACEMENT

Detailed Design Stage

The latest Building Information Modelling (BIM) software was used, enabling a

smoother workflow and interoperability between the drafting and the analysis

packages.

A loading assessment and detailed structural analysis of the davit and existing stack

was undertaken, with a number of loading permutations to establish the stress

increases in the stack and within the 4 no. guy wires. The stress increases were

interrogated within the model in order to establish if they were beyond the

permissible limits.

Figure 5

Figure6

Figure 7

Analysis demonstrated that there was sufficient structural capacity inherent within

the system to adequately resist the additional loads imposed onto the structure by

the proposed method of tip installation.

The effect on the pre-tension of the guy wires was found to be negligible.

ZENITH OFFSHORE VENT TIP REPLACEMENT

Execution of Works

At the heart of the success of this project was the ability to implement traditional

steeplejacking skills in a modern environment. Following the laddering of the stack,

the upper and lower support bands were installed.

Figure 8

ZENITH OFFSHORE VENT TIP REPLACEMENT

Figure 9

Progressively the temporary platform was constructed and secured to the vent stack,

with the lifting davit hoisted into position in sections and constructed at the work face.

Figure 10

ZENITH OFFSHORE VENT TIP REPLACEMENT

Conclusion

The key to achieving the successful delivery of the project was the ability to identify

and eliminate potential problems at the design stage, and to be able to transfer the

information to the highly skilled operatives undertaking the work on site.

Understanding the clients goals and brief.

Assembling a competent team with a proven track record.

Good communications throughout the team.

Technical competence and the ability to develop early stage designs through

to completion.

Safe Work Procedure and Risk assessment.

Execution of the Project.

Project review and Appraisal.

Das könnte Ihnen auch gefallen

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsVon Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsBewertung: 4 von 5 Sternen4/5 (1)

- 111 - The Design and Construction of Cliffsend UnderpassDokument4 Seiten111 - The Design and Construction of Cliffsend UnderpassYash SinghNoch keine Bewertungen

- Coiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Von EverandCoiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Bewertung: 5 von 5 Sternen5/5 (2)

- 0387 1301 FINAL CEPA Surface Loading Calculator User ManualDokument43 Seiten0387 1301 FINAL CEPA Surface Loading Calculator User ManualTon Phichit100% (2)

- Bs 302-Part2-1987 (Steel Wire Ropes-Specification For Ropes FDokument13 SeitenBs 302-Part2-1987 (Steel Wire Ropes-Specification For Ropes Fcelsocarvalh100% (1)

- 2015 15 OTC Subsea StructuresDokument7 Seiten2015 15 OTC Subsea StructuresAlberto darianNoch keine Bewertungen

- Headframe Conversion Project HandH Paper No.21Dokument11 SeitenHeadframe Conversion Project HandH Paper No.21Kandousi YassineNoch keine Bewertungen

- Sea Met - Self Installing Meteorological MastDokument11 SeitenSea Met - Self Installing Meteorological MastLewis LackNoch keine Bewertungen

- Tugnology PDFDokument41 SeitenTugnology PDFnavalzero910Noch keine Bewertungen

- Cost-Effective Hybrid Riser System for DeepwaterDokument6 SeitenCost-Effective Hybrid Riser System for DeepwaterHarmoni AndreasNoch keine Bewertungen

- Integration of The Rudder PropellerDokument41 SeitenIntegration of The Rudder PropellerVIVEK NAIRNoch keine Bewertungen

- Crane Boom ReplacementDokument13 SeitenCrane Boom ReplacementRavikumar mahadevNoch keine Bewertungen

- Offshore Oil Production Riser Desgn PDFDokument13 SeitenOffshore Oil Production Riser Desgn PDFdndudcNoch keine Bewertungen

- Technical Data: Truck-Mounted Concrete Pump Technical Data: Truck-Mounted Concrete PumpDokument4 SeitenTechnical Data: Truck-Mounted Concrete Pump Technical Data: Truck-Mounted Concrete PumpMihnea-Bogdan NicolaescuNoch keine Bewertungen

- Riser DesgnDokument13 SeitenRiser Desgnplatipus_8575% (4)

- Tower PipingDokument40 SeitenTower PipingenjoygurujiNoch keine Bewertungen

- Enlarged Cotter Dam Diversion Gate Design TestDokument6 SeitenEnlarged Cotter Dam Diversion Gate Design Testadelmo1175Noch keine Bewertungen

- 07 Strand Jack Sedition 92834Dokument7 Seiten07 Strand Jack Sedition 92834vigobboNoch keine Bewertungen

- Otc 20506Dokument12 SeitenOtc 20506Rasheed YusufNoch keine Bewertungen

- Stud Rail Reinforcement System DesignDokument3 SeitenStud Rail Reinforcement System DesignBruno PilieciNoch keine Bewertungen

- Hangar DesignDokument5 SeitenHangar DesignZoran100% (1)

- Wembley Stadium PDFDokument8 SeitenWembley Stadium PDFInayatur ANoch keine Bewertungen

- AA-V6-I1-Making-the-Connection WYE ILSDokument3 SeitenAA-V6-I1-Making-the-Connection WYE ILSAizat NajibNoch keine Bewertungen

- 6.04. Wüst MDokument8 Seiten6.04. Wüst MAnonymous NUn6MESxNoch keine Bewertungen

- Design and Fabrication of the New Wembley Stadium RoofDokument8 SeitenDesign and Fabrication of the New Wembley Stadium RoofSiv VejayNoch keine Bewertungen

- VSL Heavy LiftingDokument16 SeitenVSL Heavy LiftingDrPadipat ChaemmangkangNoch keine Bewertungen

- A Simple Method For Simultaneously Tensi PDFDokument8 SeitenA Simple Method For Simultaneously Tensi PDFAmit R. GhuleNoch keine Bewertungen

- Dynamic CSDDokument8 SeitenDynamic CSDDawie KhanNoch keine Bewertungen

- Tesco Casing Drive System™Dokument5 SeitenTesco Casing Drive System™Citra FerdyanNoch keine Bewertungen

- Design and Installation of A Production Jack-Up With StorageDokument16 SeitenDesign and Installation of A Production Jack-Up With StorageMoe LattNoch keine Bewertungen

- j2yq8kGt9Dn8NBu1Oceaneering Gantry Crane and Mud Mat Crane NetworkDokument37 Seitenj2yq8kGt9Dn8NBu1Oceaneering Gantry Crane and Mud Mat Crane NetworkniybiroNoch keine Bewertungen

- Motorized Screw Jack: Mohammed Yousuf, Shaik Ashraf, Yaaseen Shahid IqbalDokument5 SeitenMotorized Screw Jack: Mohammed Yousuf, Shaik Ashraf, Yaaseen Shahid IqbalRockNoch keine Bewertungen

- Cargo HandlingDokument5 SeitenCargo HandlingJoao AlmeidaNoch keine Bewertungen

- Crane Master Project References - Passive Heave Compensation - Shock AbsorberDokument3 SeitenCrane Master Project References - Passive Heave Compensation - Shock AbsorberDaniel LiuNoch keine Bewertungen

- Catalogo Fenner DrivesDokument20 SeitenCatalogo Fenner DrivesRamírez Vilca JulioNoch keine Bewertungen

- Páginas DesdeOilfieldTechnology January 15 7Dokument1 SeitePáginas DesdeOilfieldTechnology January 15 7Robert MontoyaNoch keine Bewertungen

- Design Guidelines For V Retainer Couplings Rev 0414Dokument12 SeitenDesign Guidelines For V Retainer Couplings Rev 0414Santosh Komire100% (1)

- Pipe Riser Support Systems: Mason Industries, IncDokument4 SeitenPipe Riser Support Systems: Mason Industries, IncAbdul RaheemNoch keine Bewertungen

- Plexus Ocean Systems LTD: "TRT-S" Mudline Suspension SystemDokument21 SeitenPlexus Ocean Systems LTD: "TRT-S" Mudline Suspension SystemCesar Augusto ValenciaNoch keine Bewertungen

- Articulated Self-Launching Gantries For Precast Segmental Bridges - BridgeTechDokument5 SeitenArticulated Self-Launching Gantries For Precast Segmental Bridges - BridgeTechSilvio CarrilloNoch keine Bewertungen

- Shaft-Hoisting System for BHP Billiton's Olympic Dam MineDokument7 SeitenShaft-Hoisting System for BHP Billiton's Olympic Dam MineAlfaro RoblesNoch keine Bewertungen

- Construction of Overhead Water Tank - A Cost Effective ApproachDokument4 SeitenConstruction of Overhead Water Tank - A Cost Effective ApproachBVJ TECH MOTO RIDERSNoch keine Bewertungen

- Drilling With Casing Promises Major BenefitsDokument12 SeitenDrilling With Casing Promises Major BenefitsRaul Alberto Miranda LoayzaNoch keine Bewertungen

- Design and Optimization of Top Tension Risers For Ultra Deep WaterDokument19 SeitenDesign and Optimization of Top Tension Risers For Ultra Deep WaterleelawrenceNoch keine Bewertungen

- Agitator DesignDokument8 SeitenAgitator DesignCMEngineersNoch keine Bewertungen

- SAFETY in Form Work ProgramDokument73 SeitenSAFETY in Form Work ProgramBharath CjNoch keine Bewertungen

- Desig of Deepwater Tower RiserDokument14 SeitenDesig of Deepwater Tower RiserJuan LopezNoch keine Bewertungen

- Whippet Single 10 CC Mod Eng 1963 XDokument20 SeitenWhippet Single 10 CC Mod Eng 1963 XmontyviaderoNoch keine Bewertungen

- Guidelines For The Construction and Maintenance of Transmission LinesDokument8 SeitenGuidelines For The Construction and Maintenance of Transmission LinesPierre Enrique Carrasco FuentesNoch keine Bewertungen

- Design and Fabrication of All-Welded Bridge CranesDokument4 SeitenDesign and Fabrication of All-Welded Bridge Cranesaiyubi2Noch keine Bewertungen

- IPC2014 33552 Structural Reliability Free SpansDokument11 SeitenIPC2014 33552 Structural Reliability Free SpansfrvdabeeNoch keine Bewertungen

- Efficiency in Pipe Handling PDFDokument8 SeitenEfficiency in Pipe Handling PDFemilyduflengNoch keine Bewertungen

- PT Incremental Launching MethodDokument20 SeitenPT Incremental Launching MethodDIky HendriNoch keine Bewertungen

- V Belts Catalog PDFDokument20 SeitenV Belts Catalog PDFLazwar Irhami PutraNoch keine Bewertungen

- ASME Code CalculationDokument12 SeitenASME Code Calculationmasoud_968370957Noch keine Bewertungen

- Sewage Disposal Works: Their Design and ConstructionVon EverandSewage Disposal Works: Their Design and ConstructionNoch keine Bewertungen

- How to Run a Lathe - Volume I (Edition 43) The Care and Operation of a Screw-Cutting LatheVon EverandHow to Run a Lathe - Volume I (Edition 43) The Care and Operation of a Screw-Cutting LatheBewertung: 4.5 von 5 Sternen4.5/5 (2)

- Pneumatic and Hydrautic Conveying of Both Fly Ash and Bottom AshVon EverandPneumatic and Hydrautic Conveying of Both Fly Ash and Bottom AshNoch keine Bewertungen

- The Modern Chassis: A Practical Manual of Automotive Chassis and Suspension DesignVon EverandThe Modern Chassis: A Practical Manual of Automotive Chassis and Suspension DesignBewertung: 3.5 von 5 Sternen3.5/5 (3)

- Abb Review 2000Dokument9 SeitenAbb Review 2000Ton PhichitNoch keine Bewertungen

- Control TechnologyDokument104 SeitenControl TechnologyTon PhichitNoch keine Bewertungen

- Calculate Heat Loss from Insulated PipeDokument8 SeitenCalculate Heat Loss from Insulated PipeTon PhichitNoch keine Bewertungen

- Insert Flanges For Jacketed PipingDokument4 SeitenInsert Flanges For Jacketed PipingTon PhichitNoch keine Bewertungen

- Finite Element Analysis of Stress Factors in Pipe BendsDokument7 SeitenFinite Element Analysis of Stress Factors in Pipe BendsSteve IpNoch keine Bewertungen

- LP Bypass SystemDokument25 SeitenLP Bypass SystemTon Phichit100% (1)

- Pump Clinic - Centrifugal Troubleshooting Chapters 1 - 43Dokument295 SeitenPump Clinic - Centrifugal Troubleshooting Chapters 1 - 43Noel Dunn75% (4)

- PSV Back PressureDokument2 SeitenPSV Back PressureTon PhichitNoch keine Bewertungen

- Pipe Wall Thickness Calculation Methods ASME B31.1 vs B31.3Dokument8 SeitenPipe Wall Thickness Calculation Methods ASME B31.1 vs B31.3Ton PhichitNoch keine Bewertungen

- 66 Lateral PDFDokument7 Seiten66 Lateral PDFGerman ToledoNoch keine Bewertungen

- Steam TurbinesDokument24 SeitenSteam Turbinesrt_sendhilNoch keine Bewertungen

- Pipe NoiseDokument10 SeitenPipe NoiseRoshin99Noch keine Bewertungen

- Aquarium PumpsDokument1 SeiteAquarium PumpsTon PhichitNoch keine Bewertungen

- Tracking Down Vibrations: Modal and Operating Deflection Shape Analysis As Damage-Analysis ToolsDokument4 SeitenTracking Down Vibrations: Modal and Operating Deflection Shape Analysis As Damage-Analysis ToolsTon PhichitNoch keine Bewertungen

- VibrationDokument10 SeitenVibrationAHMEDSAEED013Noch keine Bewertungen

- 390Dokument9 Seiten390Ton PhichitNoch keine Bewertungen

- Engineering Standard for Piping Material Selection (On Plot PipingDokument431 SeitenEngineering Standard for Piping Material Selection (On Plot PipingpradeepNoch keine Bewertungen

- 21 5 1710Dokument31 Seiten21 5 1710Ton PhichitNoch keine Bewertungen

- ML 070260376Dokument25 SeitenML 070260376Ton PhichitNoch keine Bewertungen

- Tracking Down Vibrations: Modal and Operating Deflection Shape Analysis As Damage-Analysis ToolsDokument4 SeitenTracking Down Vibrations: Modal and Operating Deflection Shape Analysis As Damage-Analysis ToolsTon PhichitNoch keine Bewertungen

- 12 Ernie Sturtz Pumping Facility Design StandardsDokument41 Seiten12 Ernie Sturtz Pumping Facility Design StandardsTon PhichitNoch keine Bewertungen

- KU-11-6 FinalDokument208 SeitenKU-11-6 FinalTon PhichitNoch keine Bewertungen

- Viibratiion DiiagnostiicsDokument113 SeitenViibratiion DiiagnostiicsDanielAvellanedaNoch keine Bewertungen

- Load SequencingDokument7 SeitenLoad SequencingTon PhichitNoch keine Bewertungen

- System DesignDokument16 SeitenSystem DesignTon PhichitNoch keine Bewertungen

- Thermal Considerations in Pipe FlowsDokument11 SeitenThermal Considerations in Pipe FlowsWaqas AhmadNoch keine Bewertungen

- Hurricane-2006 12 46-53Dokument8 SeitenHurricane-2006 12 46-53Ton PhichitNoch keine Bewertungen

- Tension and Sag 07-25-06Dokument7 SeitenTension and Sag 07-25-06Ton PhichitNoch keine Bewertungen

- Design Rules CMOS Transistor LayoutDokument7 SeitenDesign Rules CMOS Transistor LayoututpalwxyzNoch keine Bewertungen

- DIMENSIONAL TOLERANCES FOR COLD CLOSE RADIUS PIPE BENDINGDokument11 SeitenDIMENSIONAL TOLERANCES FOR COLD CLOSE RADIUS PIPE BENDINGpuwarin najaNoch keine Bewertungen

- Letter To Local Residents From Sutton Council Re. Lidl Development To Replace Matalan Ref DM2019-02113 10 January 2020Dokument5 SeitenLetter To Local Residents From Sutton Council Re. Lidl Development To Replace Matalan Ref DM2019-02113 10 January 2020etajohnNoch keine Bewertungen

- Product Data Sheet: Linear Switch - iSSW - 2 C/O - 20A - 250 V AC - 3 PositionsDokument2 SeitenProduct Data Sheet: Linear Switch - iSSW - 2 C/O - 20A - 250 V AC - 3 PositionsMR. TNoch keine Bewertungen

- Strength of A440 Steel Joints Connected With A325 Bolts PublicatDokument52 SeitenStrength of A440 Steel Joints Connected With A325 Bolts Publicathal9000_mark1Noch keine Bewertungen

- Model Railroad Plans and DrawingsDokument7 SeitenModel Railroad Plans and DrawingsBán ZoltánNoch keine Bewertungen

- Carbon Trading: Delaying Transition Away from Fossil FuelsDokument36 SeitenCarbon Trading: Delaying Transition Away from Fossil FuelsFitria AyuNoch keine Bewertungen

- PMO ProceduresDokument21 SeitenPMO ProceduresTariq JamalNoch keine Bewertungen

- حل جميع المعادلات الكهربائيةDokument60 Seitenحل جميع المعادلات الكهربائيةGandhi HammoudNoch keine Bewertungen

- Programmability in SPSS 16 & 17, Jon PeckDokument36 SeitenProgrammability in SPSS 16 & 17, Jon PeckJasmin MaricNoch keine Bewertungen

- Suparco+ KRL Test Ques For Electrical EngrzDokument5 SeitenSuparco+ KRL Test Ques For Electrical Engrzمحمد فصیح آفتابNoch keine Bewertungen

- Prepositions-Of-place Worksheet Azucena SalasDokument3 SeitenPrepositions-Of-place Worksheet Azucena SalasAndreia SimõesNoch keine Bewertungen

- August 2017Dokument72 SeitenAugust 2017Treatment Plant Operator MagazineNoch keine Bewertungen

- TN 46Dokument23 SeitenTN 46Khalil AhmadNoch keine Bewertungen

- Gillette and The Men's Wet Shaving Market: Group 8 Section BDokument12 SeitenGillette and The Men's Wet Shaving Market: Group 8 Section BAmit Hemant JainNoch keine Bewertungen

- How The Draganflyer Flies: So How Does It Work?Dokument5 SeitenHow The Draganflyer Flies: So How Does It Work?sav33Noch keine Bewertungen

- Mid Exam Odd Semester Academic Year 2021/2022 Study Program Management Faculty of Business Universitas Multimedia NusantaraDokument9 SeitenMid Exam Odd Semester Academic Year 2021/2022 Study Program Management Faculty of Business Universitas Multimedia NusantaraaekimNoch keine Bewertungen

- Nec 2006Dokument59 SeitenNec 2006loots69Noch keine Bewertungen

- MGS3750 28FDokument4 SeitenMGS3750 28FAndi Z Pasuloi PatongaiNoch keine Bewertungen

- How To Choose Food StarchesDokument20 SeitenHow To Choose Food StarchesBoat Tanin100% (3)

- UntitledDokument47 SeitenUntitledAndy SánchezNoch keine Bewertungen

- Write Like An Academic: Designing An Online Advanced Writing Course For Postgraduate Students and ResearchersDokument9 SeitenWrite Like An Academic: Designing An Online Advanced Writing Course For Postgraduate Students and ResearchersLexi TronicsNoch keine Bewertungen

- Plumbing Practical Problems QuizDokument5 SeitenPlumbing Practical Problems QuizLoren ViejayNoch keine Bewertungen

- PLCDokument16 SeitenPLCMohit Kinger100% (1)

- Tda 1526Dokument15 SeitenTda 1526Adilcio Melo0% (1)

- ESG Service Information: BackgroundDokument6 SeitenESG Service Information: BackgroundAbdulSattarNoch keine Bewertungen

- Daily DAWN News Vocabulary With Urdu Meaning (05 April 2020) PDFDokument6 SeitenDaily DAWN News Vocabulary With Urdu Meaning (05 April 2020) PDFAEO Begowala100% (2)

- Questionnaire For Future BLICZerDokument1 SeiteQuestionnaire For Future BLICZerAlejandra GheorghiuNoch keine Bewertungen

- PERFAPPRAISAL Research proposal on performance appraisal practices at National Bank of Pakistan and United Bank LimitedDokument4 SeitenPERFAPPRAISAL Research proposal on performance appraisal practices at National Bank of Pakistan and United Bank LimitedNadia KhanNoch keine Bewertungen

- Product Portfolio ManagementDokument10 SeitenProduct Portfolio ManagementSandeep Singh RajawatNoch keine Bewertungen