Beruflich Dokumente

Kultur Dokumente

Productivity Rates

Hochgeladen von

Sagar AliasjackeyCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Productivity Rates

Hochgeladen von

Sagar AliasjackeyCopyright:

Verfügbare Formate

1 of 10

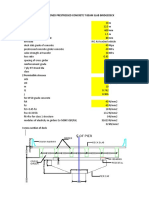

PRODUCTIVITY RATES

SL. NO.

01 GENERAL REQUIREMENT

TEMPORARY FACILITIES

DESCRIPTION

a.

Watchman & Curing

b.

Site Cleaning

c.

Fencing

d.

Fixing of Light Weight Scaffolding

02 SITE WORK

EARTH WORK

Excavation

a.

Soft Soil (Hand Tools)

b.

Hard Soil (Hand Tools)

c.

Soft Soil

d.

Hard Soil

e.

Soft Soil

f.

Hard Soil

Backfilling

a.

Filling in foundation, plinth

b.

Level, Compaction

c.

Spreading 200 mm layer (Subkha, Road Base)

d.

Compaction 200 mm layer (Subkha, Road Base)

PAVING & SURFACING

Interlock Paving

a.

Compaction/ Levelling

b.

Spreading Sand and Brushing

c.

Laying Tiles

d.

Filling, Compaction

Precast Kerb Stone

a.

Excavation & Blinding for kerbstone

b.

Laying Kerbs

Issued

MANPOWER

(Duration x 2H)

----------1H

--1H

2H

2H

1M + 2H

1H

1H

1M + 2H

OUTPUT

--1

50

70

Hand Tools

Hand Tools

Shovel

Shovel

JCB

JCB

m/Day

m/Day

m/Hr

m/Hr

m/Hr

m/Hr

3

1

40

25

20

10

Shovel

Roller Compr.

Shovel

Roller Compr.

m/Hr

m/Day

m/Hr

m/Day

30

100

100

200

Roller Compr.

m/Day

m/Day

m/Day

m/Day

200

200

60

150

R.M/Day

R.M/Day

10

35

1C + 2H + 1P

1C + 1H

1H

1H

UNIT

Day

Day

Rm/Day

m/Day

(Dhs.Contract Value/

50,000) Helper-Day

- C = Carpenter, M = Mason, P = Painter, SF = Steel Fitter, E = Erector, H = Helper, Po = Polisher, El = Electrician, Pl = Plumber

- One Day is considered as 8 working hours.

EQUIPMENT

1-Sep-11

Plate Compr.

2 of 10

PRODUCTIVITY RATES

SL. NO.

DESCRIPTION

c.

Kerb stone on curved lines

d.

Hunching

Issued

MANPOWER

1M + 1H

1M + 1H

- C = Carpenter, M = Mason, P = Painter, SF = Steel Fitter, E = Erector, H = Helper, Po = Polisher, El = Electrician, Pl = Plumber

- One Day is considered as 8 working hours.

EQUIPMENT

UNIT

R.M/Day

R.M/Hr

1-Sep-11

OUTPUT

15

20

3 of 10

PRODUCTIVITY RATES

SL. NO.

DESCRIPTION

03 CONCRETE

CONCRETE FORMWORK

Shuttering (with supports)

a.

Shuttering Of Blinding

b.

Shuttering Of Footing (Plywood)

c.

Shuttering Of Footing (Plates)

d.

Shuttering Of Stub Column

e.

Shuttering Of Strap/ Tie Beam (Plywood)

f.

Shuttering Of Strap/ Tie Beam (Plates)

g.

Shuttering Of Wall

h.

Shuttering Of Column 20 x 20

I.

Shuttering Of Column 20 x 40

j.

Shuttering Of Beam with support

k.

Shuttering Of Roof Slab

l.

Shuttering Of Lintel

m.

Shuttering Of Copying beam 20 x 20 cm

n.

Shuttering Of Parapet

o.

Shuttering Of Arch Lintel

p.

Expansion Joints/ Ground Slab

q.

Shuttering of beam& column for 8m to 12m high

r.

Shuttering of staircase

s.

De-shuttering works

CONCRETE REINFORCEMENT

Reinforcement (Tightening for Cut & Bend Steel)

a.

Reinforcement of Footing

b.

Reinforcement of Stub Column

c.

Reinforcement of Strap Beam

d.

Reinforcement of Tie Beam

e.

Reinforcement of Wall

f.

Reinforcement of Column

Issued

MANPOWER

1C + 1H

1C + 1H

1C + 1H

1C + 1H

1C + 1H

1C + 1H

1C + 1H

1C + 1H

1C + 1H

1C + 1H

1C + 2H

1C + 1H

1C + 1H

1C + 1H

1C + 1H

1C + 1H

1C + 1H

1C + 1H

1SF + 1H

1SF + 1H

1SF + 1H

1SF + 1H

1SF + 1H

1SF + 1H

- C = Carpenter, M = Mason, P = Painter, SF = Steel Fitter, E = Erector, H = Helper, Po = Polisher, El = Electrician, Pl = Plumber

- One Day is considered as 8 working hours.

EQUIPMENT

UNIT

m/Day

m/Day

m/Day

m/Day

m/Day

m/Day

m/Day

m/Day

m/Day

m/Day

m/Day

m/Day

m/Day

m/Day

m/Day

L.M/Day

m/Day

m/Day

20% of shuttering works

Kg/Day

Kg/Day

Kg/Day

Kg/Day

Kg/Day

Kg/Day

1-Sep-11

OUTPUT

35

15

20

5

12

20

14

10

10

12

10

6

6

12

6

70

8

12

400

250

300

350

400

300

4 of 10

PRODUCTIVITY RATES

SL. NO.

DESCRIPTION

g.

Reinforcement of Beam

h.

Reinforcement of Solid Slab

I.

Reinforcement of Lintel

j.

Reinforcement of Copying beam 20 x 20 cm

k.

Reinforcement of Parapet

l.

Reinforcement of Arch Lintel

m.

Reinforcement of Staircase

Mesh Reinforcement

a.

Mesh Reinforcement

CAST IN PLACE CONCRETE

Casting Concreting (Readymix)

a.

Cast. Blinding 5cm

b.

Cast. Blinding 10cm

c.

Cast. Blinding 5cm, 10cm

d.

Cast. Of Footing

e.

Cast. Of Footing (Pump)

f.

Cast. Of Strap/ Tie Beam

g.

Cast. Of Tie Beam (Pump)

h.

Cast. Of Ground Floor Slab 10cm

I.

Cast. Of Ground Floor Slab 15cm

j.

Cast. Of Ground Floor Slab 20cm

k.

Cast. Of Wall

l.

Cast. Of Column

m.

Cast. Of Beam of Slab

n.

Cast. Of Roof Slab

o.

Cast. Of Lintel

p.

Cast. Of Copying beam 20x20cm (upto 2.5m)

q.

Cast. Of Copying beam 20x20cm (above 2.5m)

r.

Cast. Of Parapet

Issued

MANPOWER

1SF + 1H

1SF + 1H

1SF + 1H

1SF + 1H

1SF + 1H

1SF + 1H

1SF + 1H

UNIT

Kg/Day

Kg/Day

Kg/Day

Kg/Day

Kg/Day

Kg/Day

Kg/Day

OUTPUT

300

300

150

200

300

150

250

1SF + 2H

m/Day

300

1M + 2H

1M + 2H

2M + 4H

2M + 4H

3M + 8H

1M + 6H

2M + 6H

3M + 5H

3M + 5H

3M + 5H

1M + 1C + 3H

1M + 4H

1M + 4H

2M + 2C + 5H

1M + 2H

1C + 5H

1C + 5H

1M + 1C + 4H

m/Day

m/Day

m/Day

m/Day

m/Day

m/Day

m/Day

m/Day

m/Day

m/Day

m/Day

m/Day

m/Day

m/Day

Nos./Hour

RM/Day

RM/Day

m/Day

30

40

250

40

120

20

50

30

45

60

40

4

12

50

4

150

60

10

- C = Carpenter, M = Mason, P = Painter, SF = Steel Fitter, E = Erector, H = Helper, Po = Polisher, El = Electrician, Pl = Plumber

- One Day is considered as 8 working hours.

EQUIPMENT

1-Sep-11

Pump

Pump

Pump

Pump

Pump

Pump

5 of 10

PRODUCTIVITY RATES

SL. NO.

s.

t.

u.

04 MASONRY

BLOCK WORK

Solid Block

a.

DESCRIPTION

Issued

Cast. Of Arch Lintel

Cast. Of Neck Column

Cast. Of Staircase

MANPOWER

1M + 3H

1M + 3H

1C + 1H

200mm Solid Block upto 2.5m Height

1M + 2H

Nos./Day

140

1M + 1H

1m + 2H

1M + 1H

1M + 1H

1M + 2H

1M + 2H

1M + 1H

Nos./Day

Nos./Day

Nos./Day

Nos./Day

Nos./Day

Nos./Day

Nos./Day

150

140

150

180

140

100

120

1M + 1H

1M + 1H

m/Day

m/Day

10

8

1P + 1H

1P + 1H

m/Day/Coat

m/Day/Coat

50

40

3E + 3H

m/Day

250

3E + 3H

m/Day

175

3E + 3H

3E + 3H

3E + 3H

m/Day

m/Day

m/Day

350

150

250

Hollow Block

a.

100mm Hollow Block upto 2.5m Height

b.

100mm Hollow Block -2.5m to 6m Height

c.

150mm Hollow Block - upto 2.5m Height

d.

200mm Hollow Block - upto 2.5m Height

e.

200mm Hollow Block - 2.5m to 6m Height

f.

200mm Block Work above 6m Height

g.

200mm Block Work including pointing

Claustra Block

a.

Claustra Block 200 x 200

b.

Claustra Block 150 x 150

05 METALS

STRUCTURAL METAL FRAMING

Steel Structure

a.

Painting of steel structure columns

b.

Painting of steel structure rafters

Erection of steel structure main frame (Eave Height upto

c.

6m span upto 25m)

Erection of steel structure main frame (Eave Height more

d.

than 6m span upto 36m)

e.

Fixing of Single Skin Sheet (Roof)

f.

Fixing of single skin sheet (Walls)

g.

Single skin with fibre glass insulation (Roof)

- C = Carpenter, M = Mason, P = Painter, SF = Steel Fitter, E = Erector, H = Helper, Po = Polisher, El = Electrician, Pl = Plumber

- One Day is considered as 8 working hours.

EQUIPMENT

UNIT

m/Day

m/Day

m/Day

1-Sep-11

OUTPUT

5

4

12

6 of 10

PRODUCTIVITY RATES

SL. NO.

DESCRIPTION

h.

Single skin with fibre glass insulation (Wall)

I.

Sandwich panels (Roof)

j.

Sandwich panels (Wall)

k.

Corner Flashing & Trims, etc

l.

4m x 4m Double Sliding Door

m.

Wall or roof opening + frames (1.0m x 1.0m)

n.

Ridge Ventilator

o.

Gutter/ Down Spout

07 MOISTURE THERMAL CONTROL

WATER PROOFING & DAMP PROOFING

Polythene Sheets

a.

Polythene under footings

b.

Polythene under slab

c.

Polythene under tie beam

Bitumin Paint

a.

Cold Bituminuous Painting

b.

Hot Bituminous Painting

Bituminous Membrane

a.

Bituminous Membrane + Protection Board

SEALERS

Construction Joint

a.

Flexel Board

b.

Sealant

09 FINISHES

PLASTER

Internal Plaster

a.

Ceiling Plaster

b.

Wall plaster upto 3m Height

Issued

MANPOWER

3E + 3H

3E + 3H

3E + 3H

1E + 3H

1E + 3H

1E + 3H

1E + 3H

1E + 3H

UNIT

m/Day

m/Day

m/Day

Rm/Day

Nos.

Nos.

Nos./Day

Rm/Day

OUTPUT

100

250

150

80

1

8

6

70

1C + 1H

1C + 1H

1H

m/Day

m/Day

Rm/Day

200

1000

200

1H

2H

m/Day/Coat

m/Day/Coat

100

60

1C + 1H

m/Day

30

1C + 1H

1H

Rm/Hr

Rm/Hr

18

7

1M + 1H

1M + 1H

m/Day

m/Day

10

20

- C = Carpenter, M = Mason, P = Painter, SF = Steel Fitter, E = Erector, H = Helper, Po = Polisher, El = Electrician, Pl = Plumber

- One Day is considered as 8 working hours.

EQUIPMENT

1-Sep-11

7 of 10

PRODUCTIVITY RATES

SL. NO.

DESCRIPTION

c.

Wall plaster 3m to 6m Height

d.

Wall plaster above 6m Height

e.

Fixing of Plaster Mesh

f.

Fixing of Corner beed

External Plaster

a.

Wall plaster upto 3m Height

b.

Wall plaster 3m to 6m Height

c.

Wall plaster above 6m Height

TILES

Mosaic

a.

Floor Mosaic Tiles

b.

Mosaic Skirting

c.

Mosaic Steps (Riser & Tread)

d.

Mosaic Polishing

Ceramic

a.

Fixing of Ceramic Wall Tiles (Glue Type)

b.

Grouting of Ceramic Wall Tiles

c.

Fixing of Ceramic Wall Tiles (Cement Mortar Type)

d.

Fixing of Ceramic Floor Tiles 20 x 20cm

e.

Fixing of Ceramic Floor Tiles 30 x 30cm

f.

Fixing of Ceramic Floor Tiles 50 x 50cm

g.

Grouting of Ceramic Floor Tiles

h.

Ceramic Skirting

PVC Tiles

a.

PVC Tiles

b.

PVC Skirting

Marble

a.

Marble Wall

b.

Marble Floor

c.

Marble Skirting

Issued

MANPOWER

1M + 2H

1M + 2H

1C + 1H

1M + 1H

UNIT

m/Day

m/Day

Rm/Day

Rm

OUTPUT

17

15

90

30

1M + 1H

1M + 2H

1M + 2H

m/Day

m/Day

m/Day

20

18

15

1M + 1H

1M + 1H

1M + 1H

1Po + 1H

m/Day

Rm/Day

Rm/Day

m/Day

15

40

14

100

1M + 1H

1M + 1H

1M + 1H

1M + 1H

1M + 1H

1M + 1H

1M + 1H

1M + 1H

m/Day

m/Day

m/Day

m/Day

m/Day

m/Day

m/Day

Rm/Day

10

30

8

12

15

20

40

30

1M + 1H

1M + 1H

m/Day

Lm/Day

35

40

1M + 1H

1M + 1H

1M + 1H

m/Day

m/Day

Rm/Day

6

15

30

- C = Carpenter, M = Mason, P = Painter, SF = Steel Fitter, E = Erector, H = Helper, Po = Polisher, El = Electrician, Pl = Plumber

- One Day is considered as 8 working hours.

EQUIPMENT

1-Sep-11

8 of 10

PRODUCTIVITY RATES

SL. NO.

DESCRIPTION

d.

Marble Steps (Riser & Treads)

Floor Screed (50mm)

a.

Floor Screed (50mm)

b.

Cement Skirting

Wooden Skirting

a.

Timber

Issued

MANPOWER

1M + 1H

EQUIPMENT

UNIT

Rm/Day

1-Sep-11

OUTPUT

10

1M + 1H

1M + 1H

m/Day

Rm/Day

50

25

1C + 1H

Rm/Day

100

1M

Rm/Day

10

False Ceiling

a.

False Ceiling - Suspended Type

1C + 1H

m/Day

30

Dry Wall Partition

a.

Dry wall Partition

1C + 1H

m/Day

20

1M + 1H

1M + 1H

m/Day/Coat

m/Day/Coat

100

100

1P

1P

1P

1P

m/Day/Coat

m/Day/Coat

m/Day/Coat

m/Day/Coat

200

80

100

60

1P + 1H

m/Day/Coat

50

Threshold

a.

Threshold

PAINTING & WALL COVERINGS

Tyrolene (Cullamix)

a.

Tyrolene over plastered surface

b.

Tyrolene over block wall

Normal Paint (Emulsion/Oil)

a.

Primer

b.

Stucco (Putty)

c.

Emulsion Paint

d.

Oil Paint

Epoxy Painting

a.

Epoxy Painting

10 MECHANICAL

PIPE & FITTINGS

- C = Carpenter, M = Mason, P = Painter, SF = Steel Fitter, E = Erector, H = Helper, Po = Polisher, El = Electrician, Pl = Plumber

- One Day is considered as 8 working hours.

9 of 10

PRODUCTIVITY RATES

SL. NO.

DESCRIPTION

Copper & PVC Pipes

a.

" to 1" Copper Pipe (Hot Water)

b.

" to 1" PVC Pipe

c.

2" to 3" PVC Pipe

d.

4" to 6" PVC Pipe

PLUMBING FIXTURES

Plumbing Fixtures

a.

Shower Tray

b.

Kitchen Sink

c.

Urinals + Partition

d.

Wash Basin

e.

W/C Asian

f.

W/C Western

g.

Bidet

h.

Booster Pump

I.

Manhole 60cm to 90cm

PLUMBING APPLIANCES

Plumbing Appliances

a.

Water Heater

11 ELECTRICAL

RACE WAYS

Race Ways

a.

Conduits

b.

Trunking

CONDUCTORS & GROUNDING

Conductors & Grounding

a.

Laying Cables

Issued

MANPOWER

UNIT

OUTPUT

1Pl + 1H

1Pl + 1H

1Pl + 1H

1Pl + 1H

Rm/Day

Rm/Day

Rm/Day

Rm/Day

12

20

75

60

1Pl + 1H

1Pl + 1H

1Pl + 1H

1Pl + 1H

1Pl + 1H

1Pl + 1H

1Pl + 1H

1Pl

1M + 1H

Nos/Day

Nos/Day

Nos/Day

Nos/Day

Nos/Day

Nos/Day

Nos/Day

Nos/Day

Nos/Day

2

2

3

2

2

2

2

1

2

1Pl + 1H

Nos/Day

1El + 1H

1El + 1H

Rm/Day

Rm/Day

50

50

1El + 2H

Rm/Day

150

WIRING

- C = Carpenter, M = Mason, P = Painter, SF = Steel Fitter, E = Erector, H = Helper, Po = Polisher, El = Electrician, Pl = Plumber

- One Day is considered as 8 working hours.

EQUIPMENT

1-Sep-11

10 of 10

PRODUCTIVITY RATES

SL. NO.

Wiring

a.

Wiring

BOARDS

Boards

a.

b.

D.B's

M.D.B's

DESCRIPTION

Issued

MANPOWER

UNIT

OUTPUT

1El + 1H

Rm/Day

300

1El + 1H

1El + 1H

Nos/Day

Nos/Day

2

1

- C = Carpenter, M = Mason, P = Painter, SF = Steel Fitter, E = Erector, H = Helper, Po = Polisher, El = Electrician, Pl = Plumber

- One Day is considered as 8 working hours.

EQUIPMENT

1-Sep-11

Das könnte Ihnen auch gefallen

- Equipment ProductivityDokument13 SeitenEquipment ProductivityGerry Triaz84% (19)

- Work Item ProductivityDokument85 SeitenWork Item ProductivityShiham Sherifdeen89% (18)

- AWS Services OverviewDokument5 SeitenAWS Services OverviewSrikanth Pentakota100% (2)

- Labour Productivity Chart in UaeDokument11 SeitenLabour Productivity Chart in Uaegeorge israel50% (4)

- Productivity RateDokument2 SeitenProductivity RateSyed Viqar Ahmed88% (49)

- Productivity RateDokument3 SeitenProductivity RateJalaludeen Mohammed Ayub100% (4)

- Gulf Productivity RateDokument108 SeitenGulf Productivity Ratekarthik100% (1)

- Manpower Productivity Rates: ElectricalDokument1 SeiteManpower Productivity Rates: ElectricalMing Ella100% (4)

- Labor Cost Productivity RateDokument29 SeitenLabor Cost Productivity RateMary John Paul BetontaNoch keine Bewertungen

- Production RatesDokument84 SeitenProduction Ratessui198190% (10)

- Productivity Constraints: S. No. DescriptionDokument32 SeitenProductivity Constraints: S. No. Descriptionrehan84075% (4)

- BOQ For Plumbing, Sanitary Works: SR - No Item Description Quantity Unit Rate Amount (RS.)Dokument6 SeitenBOQ For Plumbing, Sanitary Works: SR - No Item Description Quantity Unit Rate Amount (RS.)Paran GogoiNoch keine Bewertungen

- 786 Productive Rate PDFDokument12 Seiten786 Productive Rate PDFSIVACHANDRAN100% (2)

- Method Statement For RCC WorksDokument10 SeitenMethod Statement For RCC WorksSagar AliasjackeyNoch keine Bewertungen

- Productivity RateDokument6 SeitenProductivity Ratefarhanyazdani100% (1)

- Method StatementDokument102 SeitenMethod StatementSagar AliasjackeyNoch keine Bewertungen

- Productivity Rate - Interior PaintingDokument5 SeitenProductivity Rate - Interior Paintinglouie_mapuan100% (4)

- Productivity Rate TablesDokument69 SeitenProductivity Rate TablesAhmed Kassem75% (4)

- Construction ProductivityDokument1 SeiteConstruction ProductivityShubham K100% (1)

- Productivity RatesDokument27 SeitenProductivity Ratesmido medo100% (2)

- Labour Productivity RatesDokument17 SeitenLabour Productivity Ratesmohammednatiq86% (7)

- Productivity Rate PDFDokument2 SeitenProductivity Rate PDFmangjitNoch keine Bewertungen

- Labour Productivity ChartDokument9 SeitenLabour Productivity Chartahmed100% (1)

- Productivity RateDokument4 SeitenProductivity RateJo An Valdez100% (6)

- Productivity RateDokument12 SeitenProductivity RateZubair Mohammed98% (41)

- BOQ Approach RoadDokument4 SeitenBOQ Approach RoadApollo RajkumarNoch keine Bewertungen

- Almohileb Productivity RatesDokument6 SeitenAlmohileb Productivity Ratestharazain100% (1)

- Construction ProductivityDokument1 SeiteConstruction Productivitywatany72100% (1)

- Productivity Rate Labor Eqpt 4Dokument31 SeitenProductivity Rate Labor Eqpt 4Gerald Yason100% (1)

- Anicut Tender Sample ExcelDokument342 SeitenAnicut Tender Sample ExcelcrajkumarsinghNoch keine Bewertungen

- Output Rate DceDokument5 SeitenOutput Rate DcerichuroseNoch keine Bewertungen

- معدلات الانتاج للعمالDokument10 Seitenمعدلات الانتاج للعمالhih2Noch keine Bewertungen

- Standard Construction Productivity Norms-ManpowerDokument1 SeiteStandard Construction Productivity Norms-ManpowerGold Agharese90% (84)

- Animal Feed EFFORTDokument16 SeitenAnimal Feed EFFORTHaftamu Tekle100% (1)

- Production RateDokument50 SeitenProduction Rateakinlade100% (3)

- Usb3 1 PDFDokument631 SeitenUsb3 1 PDFutpalwxyz100% (2)

- BOQDokument108 SeitenBOQG. M. BayazidNoch keine Bewertungen

- Labour Productivity Chart in UaeDokument9 SeitenLabour Productivity Chart in UaeAbraham Alex91% (32)

- International Productivity ListDokument39 SeitenInternational Productivity ListDeveloping86% (44)

- Method Statement For Excavation WorksDokument8 SeitenMethod Statement For Excavation WorksSagar AliasjackeyNoch keine Bewertungen

- Method Statement For Excavation WorksDokument8 SeitenMethod Statement For Excavation WorksSagar AliasjackeyNoch keine Bewertungen

- BOCW ActDokument41 SeitenBOCW ActSai KiranNoch keine Bewertungen

- BOQ For Productivity RateDokument7 SeitenBOQ For Productivity RateDick Anthony Mabao100% (1)

- Productivity Rates-Downloaded From Planning PlanetDokument100 SeitenProductivity Rates-Downloaded From Planning PlanetManoj Ek93% (15)

- BOQ OLYMPIC InitialDokument322 SeitenBOQ OLYMPIC InitialKEYSTONE INFRA PVT LTD0% (1)

- New BSR 16-02-2010Dokument818 SeitenNew BSR 16-02-2010Charith SachindraNoch keine Bewertungen

- Design A Cantilever Retaining Wall To Retain An Earth Embankment of 4 - 1Dokument12 SeitenDesign A Cantilever Retaining Wall To Retain An Earth Embankment of 4 - 1yudhishkarthickNoch keine Bewertungen

- Method Statement For Anti Termite TreatmentDokument6 SeitenMethod Statement For Anti Termite TreatmentSagar Aliasjackey0% (1)

- Date-070209 SR - No. Description Unit Rate A Rcc. WorkDokument6 SeitenDate-070209 SR - No. Description Unit Rate A Rcc. WorkAjay SinghNoch keine Bewertungen

- MEP Productivity NormsDokument2 SeitenMEP Productivity Normstnazirov100% (5)

- Hawar HighwayDokument31 SeitenHawar HighwayantogsNoch keine Bewertungen

- Interior Installation ProductivityDokument10 SeitenInterior Installation Productivityrehan8400% (1)

- ET - CONCRTE GENERIC ITP - 001 - Rev0 (Prelim) 1Dokument2 SeitenET - CONCRTE GENERIC ITP - 001 - Rev0 (Prelim) 1Sagar Aliasjackey100% (1)

- ET - CONCRTE GENERIC ITP - 001 - Rev0 (Prelim) 1Dokument2 SeitenET - CONCRTE GENERIC ITP - 001 - Rev0 (Prelim) 1Sagar Aliasjackey100% (1)

- Almohileb Productivity Rates PDFDokument6 SeitenAlmohileb Productivity Rates PDFAnonymous 94TBTBRksNoch keine Bewertungen

- LABOUR RATEs For Rajesh Bhai (Smit)Dokument6 SeitenLABOUR RATEs For Rajesh Bhai (Smit)Eshan ParekhNoch keine Bewertungen

- ASHRAE Journal - A New Approach To Museum HVAC DesignDokument8 SeitenASHRAE Journal - A New Approach To Museum HVAC DesignSandy :pNoch keine Bewertungen

- PT I Girder Design 20mDokument18 SeitenPT I Girder Design 20msamirbendre1Noch keine Bewertungen

- Productivity RatesDokument16 SeitenProductivity Rateszawadimran33% (3)

- B-Net-Nma Estate 5% 4bdroom NmaDokument160 SeitenB-Net-Nma Estate 5% 4bdroom Nmamystyfyme79Noch keine Bewertungen

- Daftar Harga Bahan Bangunan & Upah Kerja: Pemerintah Kabupaten Pasuruan Dinas Cipta KaryaDokument274 SeitenDaftar Harga Bahan Bangunan & Upah Kerja: Pemerintah Kabupaten Pasuruan Dinas Cipta KaryaHilda Isfanovi100% (6)

- Method Statement For Anti Termite TreatmentDokument7 SeitenMethod Statement For Anti Termite TreatmentSagar Aliasjackey100% (2)

- Method Statement For Anti Termite TreatmentDokument7 SeitenMethod Statement For Anti Termite TreatmentSagar Aliasjackey100% (2)

- BOQ of Proposed Bungalow For Providing Approximate CostDokument13 SeitenBOQ of Proposed Bungalow For Providing Approximate CostA.k. Mishra100% (1)

- VLSI TimingDokument23 SeitenVLSI TimingAhmed ZЗzЗNoch keine Bewertungen

- Industrial BuildingDokument23 SeitenIndustrial BuildingNaveen SinghNoch keine Bewertungen

- Quotation For AggrementDokument12 SeitenQuotation For AggrementA.JANE GLYNNISNoch keine Bewertungen

- Sylvania Engineering Bulletin - Lumalux & Unalux Lamps 1977Dokument16 SeitenSylvania Engineering Bulletin - Lumalux & Unalux Lamps 1977Alan Masters100% (1)

- BoQ For Water TankDokument10 SeitenBoQ For Water TankMenaka GurusingheNoch keine Bewertungen

- Cico Office: Qatar Decoration Offices & ShowroomsDokument13 SeitenCico Office: Qatar Decoration Offices & ShowroomsJhay ManeclangNoch keine Bewertungen

- 457Dokument117 Seiten457Rajesh ChowhanNoch keine Bewertungen

- G+4 QuantityDokument19 SeitenG+4 QuantityEyob DejeneNoch keine Bewertungen

- CSR Final - 13-14 (Bridge)Dokument32 SeitenCSR Final - 13-14 (Bridge)rampw14581Noch keine Bewertungen

- Bedele HallDokument57 SeitenBedele Hallfayisamamo126Noch keine Bewertungen

- BoqDokument252 SeitenBoqkhajaimadNoch keine Bewertungen

- DC Satpute BOQ 05-07-23 Revised 15% HikeDokument24 SeitenDC Satpute BOQ 05-07-23 Revised 15% HikechetanjtNoch keine Bewertungen

- GSR Building 2019Dokument95 SeitenGSR Building 2019Ayusha ParsekarNoch keine Bewertungen

- MASONRY - Property of MaterialsDokument82 SeitenMASONRY - Property of MaterialsMaulana Ichsan GituriNoch keine Bewertungen

- RD ScheduledDokument30 SeitenRD ScheduledArup DebnathNoch keine Bewertungen

- Emirates Aluminium Smelter Complex QA PlanDokument32 SeitenEmirates Aluminium Smelter Complex QA PlanSagar AliasjackeyNoch keine Bewertungen

- Mg4012 Naf c00486 Civ Mts 0002 - 02 - Method Statement For Anti Termite WorksDokument13 SeitenMg4012 Naf c00486 Civ Mts 0002 - 02 - Method Statement For Anti Termite WorksSagar AliasjackeyNoch keine Bewertungen

- Etihad Towers Project: Inspection & Test Plan - Sub Structure Waterproofing SystemDokument3 SeitenEtihad Towers Project: Inspection & Test Plan - Sub Structure Waterproofing SystemSagar AliasjackeyNoch keine Bewertungen

- SAP MM Book 2Dokument11 SeitenSAP MM Book 2Sahil JadhavNoch keine Bewertungen

- Si-Kulo-Sentani 3D PreviewDokument15 SeitenSi-Kulo-Sentani 3D Previewkadir allotokdangNoch keine Bewertungen

- HVAC AcroymnsDokument6 SeitenHVAC AcroymnsglenlcyNoch keine Bewertungen

- Software EngineeringDokument27 SeitenSoftware EngineeringAnurag KumarNoch keine Bewertungen

- Building A SQL Server Test LabDokument18 SeitenBuilding A SQL Server Test LabFazal Ur Rehman ShahNoch keine Bewertungen

- TP-Link Wireless Extender Bridge N 150Mbps TL-WA730RE ManualDokument2 SeitenTP-Link Wireless Extender Bridge N 150Mbps TL-WA730RE Manuals0d0m1z3dNoch keine Bewertungen

- Mini PLC ReportDokument14 SeitenMini PLC ReportabdulnasirroghaniNoch keine Bewertungen

- Metalcraft Structural Technical Manual Feb 2011Dokument51 SeitenMetalcraft Structural Technical Manual Feb 2011John TaylorNoch keine Bewertungen

- Catch Up Schedule For 23F, 39F, 42F, 43FDokument10 SeitenCatch Up Schedule For 23F, 39F, 42F, 43FRica Angela LapitanNoch keine Bewertungen

- ESIC IP InterfaceDokument1 SeiteESIC IP InterfaceAbdullah AbdulNoch keine Bewertungen

- A. The Beginning of The PACO PNR Station, Rizal-The Paco Railroad Station Was BuiltDokument8 SeitenA. The Beginning of The PACO PNR Station, Rizal-The Paco Railroad Station Was BuiltchristianNoch keine Bewertungen

- Solar Energy Optimization Using Arduino Based Maximum Power Point Tracking SystemDokument62 SeitenSolar Energy Optimization Using Arduino Based Maximum Power Point Tracking SystemAnkit Kumar BurnwalNoch keine Bewertungen

- 13.design A Cantilever Retaining Wall To Retain An Earthwork Embankment With A Horizontal Top 4m Above GroundDokument1 Seite13.design A Cantilever Retaining Wall To Retain An Earthwork Embankment With A Horizontal Top 4m Above Grounddawn.devNoch keine Bewertungen

- CTW R Three: Moisture Content of Soil Water ContentDokument9 SeitenCTW R Three: Moisture Content of Soil Water ContentVOJNoch keine Bewertungen

- A 6602 - IS - 2204Dokument27 SeitenA 6602 - IS - 2204Hemant VinayakNoch keine Bewertungen

- Call For Applications: Young Urban Designers and Architects ProgrammeDokument2 SeitenCall For Applications: Young Urban Designers and Architects ProgrammeesamridhNoch keine Bewertungen

- Al Hamra Firdous Tower, Kuwait BMC 6Dokument23 SeitenAl Hamra Firdous Tower, Kuwait BMC 6marmik dholakia100% (1)

- Structural Design and Construction Lecture 1Dokument26 SeitenStructural Design and Construction Lecture 1Chong Ting ShengNoch keine Bewertungen

- ThesisDokument95 SeitenThesisAper ZavaNoch keine Bewertungen