Beruflich Dokumente

Kultur Dokumente

Winco Inc. Generators - Troubleshooting Guide - Dyna Technology Inc PDF

Hochgeladen von

pevareOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Winco Inc. Generators - Troubleshooting Guide - Dyna Technology Inc PDF

Hochgeladen von

pevareCopyright:

Verfügbare Formate

TROUBLESHOOTING

GUIDE

NOTE: The following conditions are necessary for all tests that follow. Your life, your safety

and the life of your test equipment depend on paying attention to these details.

1) All resistance checks are with the unit STOPPED!

2) All voltage checks are with the engine running.

3) Always start with the highest voltage scale. (600 Volt scale minimun)

4) Check for residual voltage before any disassembly.

5) Dont disassemble any more than necessary.

6) Mark leads for reassembly.

7) Disconnect loads before residual voltage checks.

8) Write down all your readings.

9) Record Model #, Serial #, and P/N before calling.

NO OUTPUT (ALL GENERATORS)

1.

2.

3.

4.

5.

6.

(All AC voltage readings are with engine running)

Check for Residual output at receptacles WITH THE ENGINE RUNNING. Expect

Minimum of 3 - 5 VAC at the 120V receptacles, double at the 240V recept.

Always start on the HIGHEST ACV Scale. Dont blow the ohms scale on the first

test!

With the engine running, flash the field with 9 VDC dry battery if output is below

5 VAC. Refer to diagram #1

Re-Check for output at ALL receptacles.

STOP the engine. On WINCO units remove end-cover and disconnect only the

generator output leads G1, G3 and N from the control box leads. Restart engine

and check for output at stator power leads. The DYNA generators cannot be

checked this way , for DYNA units move to step #9.

a.

All units with 120 volt capabilities:

G-1 to N = 120 volts AC

Q-1 to Q-2 =170-300 Volts AC (Capacitor Winding)

b.

For units with 240 volt capabilities:

G-1 to N = 120 volts AC

G-3 to N = 120 volts AC

G-1 to G-3 = 240 volts AC

Q-1 to Q-2 = 170-300 Volts AC (Capacitor Winding)

If you get proper AC voltage from stator leads the generator end is good.Check

receptacle panel for loose wires, shorted receptacles or defective parts.

If you get no output from stator leads:

a.

For RFB - Rotating Field Brush type excitation - move to #17.

b.

For RFL - Rotating Field BrushLess Capacitor excitation - move to #7.

RFL - Rotating field with brushless Capacitor type excitation.

7.

Check capacitors.

a.

Visually check capacitors for loose or burned wires and leaking caps.

225 South Cordova Ave

Le Center MN 56057

507-357-6831

b.

Discharge capacitors by momentarily grounding capacitor terminals to

the capacitor case. (Failure to ground capacitors may cause a shock)

c.

Disconnect capacitor leads.

d.

Using an VOM (ohm meter) set at 200K ohms. Connect meter leads to

the two sets of terminals on one capacitor. Ohm meter should read 0

and slowly move to an open circuit. (5 to 10 seconds) (the battery in ohm

meter is charging capacitor) Reversing the meter leads will cause the

Ohm meter to count down to zero. Then charge up and move to open

circuit.

e.

Repeat step (d) for any remaining capacitors. (there may be up to three

capacitors depending on the model of generator)

8.

Check stator capacitor leads for continuity and grounding.

a.

There should be continuity between leads.

b.

The resistance values are shown in table #1.

c.

There should not be any reading to ground.

9.

Check stator output power leads for continuity, resistance and grounding.

a.

There should be continuity between leads.

b.

The resistance values are shown in table #1.

c.

There should not be any reading to ground.

10. Check for continuity between the capacitor leads and power leads in the stator.

a.

There should not be continuity between these two sets of leads.

11. Remove stator/shell assembly.

12. Unbolt the diode(s) from mounting bracket or the fan on rotor.

13. Check diode(s) with an ohm meter. Most meters use a special setting for testing

a diode. If your meter does not have special setting use the RX1 ohms scale.

a.

Meter leads should be placed on either end of one diode, check meter for

current flow. (Diode must be unbolted to test)

b.

Reverse meter leads, check meter for current flow.

c.

Current flow (reading) should be detected in only one direction. If diode

reads current flow in both or neither direction it should be replaced.

d.

Depending on model. Repeat step a thru c for the other diode if installed.

NOTE: All of the two diode systems use one forward polarity and one

reverse polarity diode.

14. Check rotor leads for continuity and grounding. Place meter leads on solder end

of diode(s). At least one of the diodes must be disconnected from the rotor to

check continuity and resistance. There should be continuity between leads but no

reading to ground See table #1 for resistance values.

15. Replace any defective parts and reassemble generator.

16. Flash field according to diagram #1.

RFB - Rotating Field with Brush type excitation.

17.

18.

Disconnect wires from rectifier and check rectifier.

Check rectifier leads from the stator for continuity and grounding.

a.

There should be continuity between leads.

Page 2

19.

20.

19.

20.

21.

22.

23.

b.

The resistance values are shown in table #1.

c.

There should not be any reading to ground.

Check Stator Output power leads for continuity, resistance and grounding.

a.

There should be continuity between leads.

b.

The resistance values are shown in table #1.

c.

There should not be any reading to ground.

Check for continuity between the rectifier leads and power leads from the stator.

a.

There should not be continuity between these two sets of leads.

Remove brush rack and check brushes for spring tension, binding, burning, and

a minimum of 3/8 in. length.

Check rotor slip rings for wear and corrosion.

Check rotor slip rings for continuity and grounding.

a.

There should be continuity between slip rings.

b.

The resistance values are shown in table #1.

c.

There should not be any reading to ground.

Replace any defective parts and reassemble generator.

Flash field according to diagram #1.

TESTING RECTIFIERS

The field excitation is supplied through a full wave bridge rectifier. This type of rectifier has four

terminals - two AC, one DC positive and one DC negative. There are 4 diodes within each

rectifier, one between each of the terminals as you go around the outside of the rectifier.

6.

7.

8.

9.

The rectifier is tested in the following manner:

1.

Disconnect all leads from rectifier.

2.

Connect the red ohmmeter lead to the positive DC (+)

terminal.

3.

Connect the black lead to each of the AC terminals in turn.

Either a high or low resistance reading will be obtained.

4.

Reverse the meter leads, black lead to the DC POS (+)

and red lead to the AC terminals, each in turn. An opposite

reading should be observed.

5.

Connect the red ohmmeter lead to the negative DC (-)

terminal.

Connect the black lead to each of the AC terminals in turn. Either a high or low

resistance reading will be obtained.

Reverse the meter leads, black lead to the DC NEG (-) and red lead to the AC

terminals, each in turn. An opposite reading should be observed.

Check each terminal to the case. An open circuit (very high resistance) reading

should be observed.

If the rectifier fails any of the above tests, it should be considered defective and

replaced.

If a battery powered test light is used. Follow the same procedures described below. A good

diode element will allow current to pass to the light in the test lamp in only one direction.

Page 3

FIELD FLASHING PROCEDURES

Material Required

Diagram #1

1. 9 Volt DC Transistor Battery

2. Jumper wires 20 to 22 gauge

Each wire should have a clip on one end

and be stripped about 3/8 of an inch on the other.

Procedure

Neutral

Hot Side

Caution: Insure there is no open or spilled fuel in the

area of the unit when flashing the fields. Insure the

Positive

wires used to flash the field have no bare spots on them.

Terminal

Negative

1. Clip the jumper wires to the terminals on the battery.

Terminal

9 Volt Transistor

2. Start the engine generator set.

Battery

3. Locate the 120 volt receptacle with the two flat blade slots.

4. Making sure not to touch the bare wire, momentarily insert the bare ends of the wires into

the appropriate slots.

5. BRIEFLY POKE THE WIRES INTO THE RECEPTACLES, BUT DO NOT HOLD THE

WIRES IN THE RECEPTACLE. THIS RECEPTACLE WILL ENERGIZE TO 120 VOLTS

IMMEDIATELY.

GENERATOR RESISTANCE TABLE #1

MODELS

ROTOR

G1TO N

HD3200, HD3200H HP3300,

HP3300H, WT3000, WC3000H

0.83-0.92

0.52-0.57

1.68-1.87

SS 1530

TF4500, DX4500, HP4500, HP4500H

HP5000H, HD4500, HD4500, EC4500

WC4500, WC5000H, W4500, W5000H

0.95-1.05

0.17-0.19

0.34-0.375 0.53-0.58

SS 1531

TF6000, DX6000, HP6000, HP6000H

1.87-2.08

0.12-0.14

0.25-0.28

0.34-0.39

SS 1533

TFM6000,DXM6000, HDM6000, HDM6000H

HPM6000, HPM6000H, WC6000, WC6000H

W6000, W6000H

10.9-12.1

0.10-0.11

0.17-0.19

0.76-0.84

SS 1544

DX9000, HP9000, HP9500H

TF9000, PSS8000, WC9000, W9500

0.69-0.77

0.12-0.13

0.12-0.13

0.22-0.24

SS 1538

LC1500, LC1750

0.73-0.82

0.72-0.86

2.40-2.67

SS 1545

LC3000, LC3000H, LC3000I, D3000

0.83-0.92

0.52-0.57

2.40-2.67

SS 1540

LC4500, LC5000H, LLC4500, LLC5000H

DLC4500, D4500, D5000, DL4500, DL5000

0.79-0.87

0.61-0.67

0.61-0.67

2.10-2.33

SS 1541

LC6000, LLC6000, DLC6000,

TFLC6000, DL6000, DL6000H

1.95-1.05

0.21-0.23

0.22-0.25

0.53-0.58

SS1543

LLC9000, TFLC9000, DL9000

0.69-0.77

0.12-0.13

0.12-0.13

0.22-0.24

SS1538

7325-00

Page 4

G2 TO N

Q1 TO Q2 SS SPEC

60711-018

Das könnte Ihnen auch gefallen

- Boat Maintenance Companions: Electrics & Diesel Companions at SeaVon EverandBoat Maintenance Companions: Electrics & Diesel Companions at SeaNoch keine Bewertungen

- Troubleshooting and Service Information For Voltmaster GeneratorsDokument15 SeitenTroubleshooting and Service Information For Voltmaster GeneratorsMd Rodi Bidin100% (1)

- Alternator Delco With Integral RegulatorDokument10 SeitenAlternator Delco With Integral Regulatormad659100% (1)

- Mecc Alte Portable Ts GuideDokument9 SeitenMecc Alte Portable Ts GuidesfeNoch keine Bewertungen

- Lucas Generator and Control Box Tests 1963Dokument28 SeitenLucas Generator and Control Box Tests 19632humbersNoch keine Bewertungen

- Lucas Generator and Control Box TestsDokument28 SeitenLucas Generator and Control Box Testsruben_balea100% (1)

- 20EE504-PE Lab ManualDokument59 Seiten20EE504-PE Lab Manual20EUEE018 - DEEPAK. MNoch keine Bewertungen

- Trouble Shooting Capacitor Regulated Pancake Light Tower GeneratorsDokument7 SeitenTrouble Shooting Capacitor Regulated Pancake Light Tower GeneratorsBilly MecanizadoNoch keine Bewertungen

- Alternator and RegulatorDokument6 SeitenAlternator and Regulatorsonny1234Noch keine Bewertungen

- Lucas Generator and Control Box Tests PDFDokument28 SeitenLucas Generator and Control Box Tests PDFdkjohnbarjoNoch keine Bewertungen

- Astron TroubleshootingDokument7 SeitenAstron TroubleshootingLuis CarlosNoch keine Bewertungen

- ReguladorRectificador Troubleshoting PDFDokument1 SeiteReguladorRectificador Troubleshoting PDFNicoNoch keine Bewertungen

- Trouble Shooting - Magnaplus / Mariner / Harsh DutyDokument10 SeitenTrouble Shooting - Magnaplus / Mariner / Harsh Dutyrizky ListyawanNoch keine Bewertungen

- Trouble Shooting Pancake GeneratorsDokument7 SeitenTrouble Shooting Pancake GeneratorsRomel José Londoño CamachoNoch keine Bewertungen

- Servicing The KL400Dokument20 SeitenServicing The KL400Pisu Miau Pisu MiauNoch keine Bewertungen

- IRMC Transistor CheckDokument7 SeitenIRMC Transistor ChecksebifuenteNoch keine Bewertungen

- Physics ActivitiesDokument16 SeitenPhysics ActivitiesSoumik MahapatroNoch keine Bewertungen

- Anti-Lock Brake SystemDokument21 SeitenAnti-Lock Brake SystemWoong-Sub LeeNoch keine Bewertungen

- Deek ShaDokument13 SeitenDeek ShaShivani SharmaNoch keine Bewertungen

- Alternator No Volt StartupDokument1 SeiteAlternator No Volt StartupManish Alexander MohanNoch keine Bewertungen

- Experiment 5 Introduction To Diodes, Rectifiers, and Construction of A DC Power SupplyDokument15 SeitenExperiment 5 Introduction To Diodes, Rectifiers, and Construction of A DC Power SupplyJessica Laine TumbagaNoch keine Bewertungen

- Stator - Bobina Carregadora BateriaDokument1 SeiteStator - Bobina Carregadora BateriaArtur ValNoch keine Bewertungen

- List of ExperimentsDokument6 SeitenList of ExperimentsNishika GuptaNoch keine Bewertungen

- MRTPDokument20 SeitenMRTPStephen Crawford100% (1)

- Sr. No. Name of Experiment: Load Test On 3 Phase Squirrel Cage Induction MotorDokument40 SeitenSr. No. Name of Experiment: Load Test On 3 Phase Squirrel Cage Induction MotorSagar G ReddyNoch keine Bewertungen

- Gs Generator TroubleshootingDokument38 SeitenGs Generator Troubleshootingகோவி கோபால் ஆர்ட்ஸ்Noch keine Bewertungen

- PS Lab ManualDokument25 SeitenPS Lab ManualPRAVEEN KUMAR SINGHNoch keine Bewertungen

- Troubleshooting Guide For Capacitor Excited GeneratorsDokument16 SeitenTroubleshooting Guide For Capacitor Excited GeneratorstracypearlNoch keine Bewertungen

- Hfe Classe Audio Cap-80 101 ServiceDokument19 SeitenHfe Classe Audio Cap-80 101 Servicehesso1Noch keine Bewertungen

- Test Methods and PracticesDokument30 SeitenTest Methods and PracticesBảo BìnhNoch keine Bewertungen

- Dentron MLA-2500 GI7B Modification Procedure 3Dokument27 SeitenDentron MLA-2500 GI7B Modification Procedure 3david bonilla pinoNoch keine Bewertungen

- Electronic Devices and Circuits (EME-306) Lab 1: ObjectiveDokument7 SeitenElectronic Devices and Circuits (EME-306) Lab 1: ObjectiveAhmed SayedNoch keine Bewertungen

- DC SystemDokument3 SeitenDC SystemlrpatraNoch keine Bewertungen

- AV1000 + Assembly + ManualDokument22 SeitenAV1000 + Assembly + ManualAnonymous V1NW1Cm3w4100% (3)

- Chassis ElectricalDokument111 SeitenChassis Electricaltruckman1000Noch keine Bewertungen

- ChassisElectrical PDFDokument111 SeitenChassisElectrical PDFdhanysiregarNoch keine Bewertungen

- NOTES (2023-2024) Subject: Physics Lab Manual Class: Xii Sec: Activity No.1Dokument5 SeitenNOTES (2023-2024) Subject: Physics Lab Manual Class: Xii Sec: Activity No.1Mohammed KashifNoch keine Bewertungen

- Service Nickel-Cadmium Batteries and Electrolytes Used: A. How To Measure VoltageDokument17 SeitenService Nickel-Cadmium Batteries and Electrolytes Used: A. How To Measure Voltagejames kuriaNoch keine Bewertungen

- Smart Charger Notes & Assembly Instructions: General InformationDokument4 SeitenSmart Charger Notes & Assembly Instructions: General Informationanirudh.r.s.Noch keine Bewertungen

- BE8161-Basic Electrical Electronics and Instrumentation Engineering Lab ManualDokument81 SeitenBE8161-Basic Electrical Electronics and Instrumentation Engineering Lab ManualAntonio LeonNoch keine Bewertungen

- Alternator Regulator TroubleshootingDokument2 SeitenAlternator Regulator Troubleshootingsheba1023Noch keine Bewertungen

- Inverter Troubleshooting ChecksDokument4 SeitenInverter Troubleshooting ChecksTarak BenslimaneNoch keine Bewertungen

- 4570 NDokument12 Seiten4570 NDaniboy1994Noch keine Bewertungen

- BE8161-Basic Electrical Electronics and Instrumentation Engineering Lab Manual FINAL PDFDokument82 SeitenBE8161-Basic Electrical Electronics and Instrumentation Engineering Lab Manual FINAL PDFBHUVANA ARUMUGAMNoch keine Bewertungen

- DS19730Dokument12 SeitenDS19730Joel Roberto MolinaNoch keine Bewertungen

- Wiring Diagram PDFDokument89 SeitenWiring Diagram PDFisabelism19100% (2)

- Six Activities Class 12Dokument16 SeitenSix Activities Class 12Priyanshu jhaNoch keine Bewertungen

- Danger Warning Caution: Safety InformationDokument7 SeitenDanger Warning Caution: Safety InformationcombaheeNoch keine Bewertungen

- Axis Drive Systems PDFDokument62 SeitenAxis Drive Systems PDFJoshNoch keine Bewertungen

- Testing and AdjustingDokument11 SeitenTesting and Adjustingahmad sulaimanNoch keine Bewertungen

- Ee0041l-Finals (Sa) KilakigaDokument85 SeitenEe0041l-Finals (Sa) KilakigaKYLE LEIGHZANDER VICENTENoch keine Bewertungen

- Testing A CapacitorDokument4 SeitenTesting A Capacitorroman reeseNoch keine Bewertungen

- Manual Chasis 25B800-7562Dokument16 SeitenManual Chasis 25B800-7562Bren RgzNoch keine Bewertungen

- Power Supply Projects: A Collection of Innovative and Practical Design ProjectsVon EverandPower Supply Projects: A Collection of Innovative and Practical Design ProjectsBewertung: 3 von 5 Sternen3/5 (2)

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2Von EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2Noch keine Bewertungen

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Von EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Bewertung: 2.5 von 5 Sternen2.5/5 (3)

- MOD MOD MOD MOD Modal AL AL AL AL: Modal Section 11.0 Issue 3.0 June 2002Dokument1 SeiteMOD MOD MOD MOD Modal AL AL AL AL: Modal Section 11.0 Issue 3.0 June 2002ZeckNoch keine Bewertungen

- Hvac PDFDokument473 SeitenHvac PDFtikha randy100% (1)

- Romondes RD510 Battery Charger Repair ManualDokument18 SeitenRomondes RD510 Battery Charger Repair ManualZeckNoch keine Bewertungen

- User Manual: Jump Start Your Vehicle - Charge Your DeviceDokument24 SeitenUser Manual: Jump Start Your Vehicle - Charge Your DeviceZeckNoch keine Bewertungen

- ZEP Zone Defense Parts Cleaner SolutionDokument1 SeiteZEP Zone Defense Parts Cleaner SolutionZeckNoch keine Bewertungen

- Air Line Filter: Operating Instructions & Parts ManualDokument18 SeitenAir Line Filter: Operating Instructions & Parts ManualZeckNoch keine Bewertungen

- Heli Forklift ModelsDokument8 SeitenHeli Forklift ModelsZeck100% (1)

- Midtronics EXP HD Instruction ManualDokument52 SeitenMidtronics EXP HD Instruction ManualZeckNoch keine Bewertungen

- EMAM Baldwin Filter Size ChartsDokument282 SeitenEMAM Baldwin Filter Size ChartsLiceth SornozaNoch keine Bewertungen

- 3a0293en GDokument12 Seiten3a0293en GEngTamerNoch keine Bewertungen

- Zep Dyna Clean Installation and Operator's Manual: A. General InformationDokument6 SeitenZep Dyna Clean Installation and Operator's Manual: A. General InformationZeckNoch keine Bewertungen

- The Ready To Go Range: The 8 Series. What Do You Tow?Dokument8 SeitenThe Ready To Go Range: The 8 Series. What Do You Tow?Mohamad NasserNoch keine Bewertungen

- International NSDokument84 SeitenInternational NSXavier MorenoNoch keine Bewertungen

- MSD-V104 Oily Water Separator FiltersDokument5 SeitenMSD-V104 Oily Water Separator FiltersZeckNoch keine Bewertungen

- Id Sheet Stegobium Paniceum Biscuit BeetleDokument2 SeitenId Sheet Stegobium Paniceum Biscuit BeetleZeckNoch keine Bewertungen

- Brochure Evx and VX Series RadiosDokument9 SeitenBrochure Evx and VX Series RadiosZeckNoch keine Bewertungen

- HAZARD - Honda - Generator - Recall EU2000iDokument1 SeiteHAZARD - Honda - Generator - Recall EU2000iZeckNoch keine Bewertungen

- P-PTB54942 RC58 PosterDokument1 SeiteP-PTB54942 RC58 PosterZeckNoch keine Bewertungen

- INSPECTION FORM: Self-Retracting Lifeline: Frequency of Inspection in The Following Categories: Look atDokument1 SeiteINSPECTION FORM: Self-Retracting Lifeline: Frequency of Inspection in The Following Categories: Look atZeckNoch keine Bewertungen

- Eu22i Safteyrecall Consumer 2020 v2Dokument1 SeiteEu22i Safteyrecall Consumer 2020 v2ZeckNoch keine Bewertungen

- Wiring Diagram 5026 5031Dokument1 SeiteWiring Diagram 5026 5031ZeckNoch keine Bewertungen

- ELD Lead Defender Spec SheetDokument2 SeitenELD Lead Defender Spec SheetZeckNoch keine Bewertungen

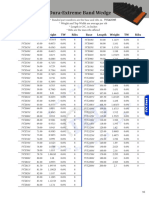

- Vbelt DC45 5VX1600 05Dokument1 SeiteVbelt DC45 5VX1600 05ZeckNoch keine Bewertungen

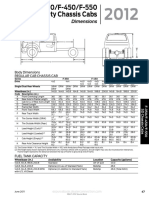

- Dimensions: Body Dimensions Regular Cab Chassis CabDokument32 SeitenDimensions: Body Dimensions Regular Cab Chassis CabZeckNoch keine Bewertungen

- Did You Know?: VOICE: 1-800-367-1492 - FAX: 1-800-206-3444Dokument2 SeitenDid You Know?: VOICE: 1-800-367-1492 - FAX: 1-800-206-3444ZeckNoch keine Bewertungen

- Hole Size Data: Self-Tapping ScrewsDokument2 SeitenHole Size Data: Self-Tapping Screwsahmed el sayedNoch keine Bewertungen

- Inspection Form: Lanyard: Frequency of Inspection in The Following Categories: Look atDokument1 SeiteInspection Form: Lanyard: Frequency of Inspection in The Following Categories: Look atZeckNoch keine Bewertungen

- INSPECTION FORM: Full Body Harness: Frequency of Inspection in The Following Categories: Look atDokument1 SeiteINSPECTION FORM: Full Body Harness: Frequency of Inspection in The Following Categories: Look atZeckNoch keine Bewertungen

- Fall Arrest Systems - Confined Space - Engineering - Rescue SystemsDokument36 SeitenFall Arrest Systems - Confined Space - Engineering - Rescue SystemsZeckNoch keine Bewertungen

- 2012 Hougen Pilot ChangeDokument1 Seite2012 Hougen Pilot ChangeZeckNoch keine Bewertungen