Beruflich Dokumente

Kultur Dokumente

Coil Winder

Hochgeladen von

Sindhu ManchukondaCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Coil Winder

Hochgeladen von

Sindhu ManchukondaCopyright:

Verfügbare Formate

MORRIS COIL WINDER

Coil Winder is a mechanical device used to wind the wire or coil in a particular

fashion. This is used for winding Single layer coils, multi layer coils and also

Solenoid windings. Morris Coil Winder mainly consists of six parts mainly

categorized as the metal base made up of zinc substrate with posts on it which

holds all the parts of the Coil Winder like rotating handle, two parallel shafts, a

circular scale, wire guide and wooden Coil Winder. A rotating handle is mechanically

rotated which helps in driving the gear wheels and shaft, in which gear helps in the

movement of another shaft which is connected to the circular scale with a pointer

attached to it so that it counts the number of rotations made by the gear. The shaft

attached to the rotating handle helps in handling the wire in the wire guide which in

turn helps in winding the wire across the wooden Coil Winder which is in the shape

of a pulley. So by the motion of the rotating handle the whole winding process is

initiated. Morris coil winder is a part of a ham radio used in early 1940s.

Mainly a coil winder is used in many field of modern engineering which involves

winding of wire that may be in winding coil around a generator, motor etc. Precision

forms the important factor to be considered while making a coil winding because if

there is a problem in winding the machine or device may not work properly. So, coil

winder helps in attaining high precision and accuracy to an extent of 0.01mm in the

present world there by reducing the chance of failure of device due to winding.

In present paper there is a brief explanation on the mechanical shaft attached to the

rotating handle. A shaft is a mechanical part which is helpful in driving the torque or

rotatory motion to other parts of the system. A mechanical shaft is also commonly

known as drive shaft. A shaft is used between two parts of the body due to several

interconnection problems like distance between the connected parts or due to the

need for the relative motion between the parts. Usually to allow for the driving point

variations in the mechanical shaft, they are incorporated with one or more universal

joints, jaw couplings and also rag joints. Shaft is a commonly used part where a

mechanical motion is involved so as to transfer power, differential rotatory motion

to other parts connected of the body.

In the Morris coil winding machine the shaft used is mounted on two posts which

rest on the zinc substrate. The shaft is attached to the rotating handle through the

internal threading present in the rod of the rotating handle. So, when the handle is

rotated there is a rotatory motion incorporated in the shaft which drives the shaft

forward or backward. The shaft consists of threading or spring on it so when there is

a motion in the handle there will be a motion in the shaft too which involves the

motion of spring through the groove present in the post and this result in the

forward or backward motion of the shaft which is again dependent on the direction

of the rotation of the rotating handle. The other side of the mechanical shaft guides

the wire guide. The wire guide consists of two parallel metal strips with three holes

on it. According to the requirement the shaft is driven through any of these three

holes present in the wire guide. The top edge of the wire guide consists of a bent

metal structure with an opening (pointer) which holds and points the coil according

to the diameter of the coil and the wire guide is used to wind the coil on to the

wooden Coil Winder. So, in this way a shaft is used to guide the winding in a Morris

Coil Winder.

MORRIS COIL WINDER

Das könnte Ihnen auch gefallen

- Downloaded From Manuals Search EngineDokument19 SeitenDownloaded From Manuals Search EngineOmarBle100% (2)

- No Load and Block Rotor Test: Premier Trading CorporationDokument11 SeitenNo Load and Block Rotor Test: Premier Trading CorporationKsr Akhil100% (1)

- Sinkron Motor - AtmiDokument87 SeitenSinkron Motor - AtmiHaryo Probo100% (1)

- Generator Testing Project ReportDokument95 SeitenGenerator Testing Project ReportSindhu ManchukondaNoch keine Bewertungen

- 308CCR Series Spec SheetDokument24 Seiten308CCR Series Spec SheetBang Kojek100% (4)

- A Linear Motor or Linear Induction Motor Is An Alternating CurrentDokument6 SeitenA Linear Motor or Linear Induction Motor Is An Alternating CurrentAnand KanaujiyaNoch keine Bewertungen

- Power Supply Unit For An Electric Discharge MachineDokument6 SeitenPower Supply Unit For An Electric Discharge MachineAhmed ShadeedNoch keine Bewertungen

- Induction Motors For Farm ApplicationsDokument9 SeitenInduction Motors For Farm ApplicationsramfalNoch keine Bewertungen

- Lab 3 Squirrel Cage Induction Machine-1Dokument8 SeitenLab 3 Squirrel Cage Induction Machine-1max100% (1)

- A Presentation On Shaded Pole Induction Motor: Prepared By: Salunkhe KalpeshDokument20 SeitenA Presentation On Shaded Pole Induction Motor: Prepared By: Salunkhe KalpeshKalpesh SalunkheNoch keine Bewertungen

- DCpower SuplyDokument12 SeitenDCpower Suplymm30973097Noch keine Bewertungen

- 1998 AEMT Repair of Induction Motors Best Practices To Maintain Energy EfficiencyDokument50 Seiten1998 AEMT Repair of Induction Motors Best Practices To Maintain Energy EfficiencySing Yew LamNoch keine Bewertungen

- uSDX88s Handheld Shortwave Radio Assembly Instructions V2.3Dokument46 SeitenuSDX88s Handheld Shortwave Radio Assembly Instructions V2.3Costin100% (1)

- Introduction To Vacuum TubesDokument22 SeitenIntroduction To Vacuum TubesChrisTNoch keine Bewertungen

- Kearney and Trecker Installation ManualDokument12 SeitenKearney and Trecker Installation Manualaa987100% (1)

- Linear Induc MotorDokument4 SeitenLinear Induc MotorDivya Bharathi RNoch keine Bewertungen

- Driver Lamparas Fluorescentes 12 VoltsDokument7 SeitenDriver Lamparas Fluorescentes 12 VoltsDiego García MedinaNoch keine Bewertungen

- Stepper MotorDokument59 SeitenStepper Motorya zool / يا زولNoch keine Bewertungen

- DC Motor PrimerDokument26 SeitenDC Motor PrimerastroltravlerNoch keine Bewertungen

- GEARS FUNdaMENTALS of Design Topic 6 PDFDokument62 SeitenGEARS FUNdaMENTALS of Design Topic 6 PDFCristina Andreea CrissyNoch keine Bewertungen

- Metal Discriminator: Girish O Pranav AgarwalDokument8 SeitenMetal Discriminator: Girish O Pranav AgarwallotarrNoch keine Bewertungen

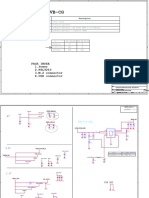

- RTL9210-VB-CG Demo V203 PDFDokument5 SeitenRTL9210-VB-CG Demo V203 PDFCenusa MihaiNoch keine Bewertungen

- Synchronous Machines and SCDokument6 SeitenSynchronous Machines and SCivancho04mNoch keine Bewertungen

- Electrical TransformersDokument10 SeitenElectrical TransformersSindhu ManchukondaNoch keine Bewertungen

- PATENT - Axial Flux Motor AssemblyDokument13 SeitenPATENT - Axial Flux Motor Assemblyrakeshee2007Noch keine Bewertungen

- Continuation of Machne DesignDokument38 SeitenContinuation of Machne DesignHalley Mayer TorresNoch keine Bewertungen

- Repulsion CoilDokument6 SeitenRepulsion CoilJim100% (1)

- Challenge 20 Manual PDFDokument65 SeitenChallenge 20 Manual PDFAlfonso Sanchez VerduzcoNoch keine Bewertungen

- Service Manual Vox Tb18C1: Schematic Diagram:2 Hookup:5 Test Mode:6 Parts List:7Dokument7 SeitenService Manual Vox Tb18C1: Schematic Diagram:2 Hookup:5 Test Mode:6 Parts List:7Jan KubalaNoch keine Bewertungen

- SCIENCE 9 Quarter 4 Assessment TestDokument5 SeitenSCIENCE 9 Quarter 4 Assessment TestAngelita MenesesNoch keine Bewertungen

- FEM Analysis of A Synchronous Generator With Inset Permanent Magnet RotorDokument6 SeitenFEM Analysis of A Synchronous Generator With Inset Permanent Magnet RotorConstantin Gabriel Dobrean100% (1)

- Induction Motor: Navigation SearchDokument8 SeitenInduction Motor: Navigation SearchSoni Mishra TiwariNoch keine Bewertungen

- An Experimenters ElectrometerDokument5 SeitenAn Experimenters Electrometerdennis6171Noch keine Bewertungen

- Improving Dehumidification in HVAC SystemsDokument48 SeitenImproving Dehumidification in HVAC Systems2360459Noch keine Bewertungen

- Chiller ConfigurationDokument8 SeitenChiller Configurationavid_ankurNoch keine Bewertungen

- Nontraditional Machining Processes: Mr. D. N. PatelDokument53 SeitenNontraditional Machining Processes: Mr. D. N. PatelrrameshsmitNoch keine Bewertungen

- Blocking Oscillator: Resistor Transformer Transistor Duty-Cycle Leds Red-Eye EffectDokument5 SeitenBlocking Oscillator: Resistor Transformer Transistor Duty-Cycle Leds Red-Eye EffectArul RajNoch keine Bewertungen

- Armature WindingDokument20 SeitenArmature Windingk rajendra100% (1)

- Operating: Maintenance ManualDokument18 SeitenOperating: Maintenance ManualAnonymous reYe6iCCNoch keine Bewertungen

- Magnum Metal LocatorDokument11 SeitenMagnum Metal Locatorercan dizdar100% (1)

- EdmDokument16 SeitenEdmaj87_goswamiNoch keine Bewertungen

- Home Made Metal DetectorDokument9 SeitenHome Made Metal DetectorDeep PatelNoch keine Bewertungen

- Complete EDM Handbook - 12Dokument10 SeitenComplete EDM Handbook - 12ks2000n1Noch keine Bewertungen

- Standalone Motion Controller DDCS V3.1 User's Guide: Shenzhen Digital Dream Numerical Technology Co., LTDDokument44 SeitenStandalone Motion Controller DDCS V3.1 User's Guide: Shenzhen Digital Dream Numerical Technology Co., LTDFarhan Ashraf AliNoch keine Bewertungen

- Project 1 Synchronous MachineDokument34 SeitenProject 1 Synchronous MachineDivya Kumar SharmaNoch keine Bewertungen

- Magnetic AmplifierDokument2 SeitenMagnetic Amplifierrintarejoy100% (1)

- LaserDokument29 SeitenLaserGaurav YadavNoch keine Bewertungen

- Pioneer Avh-P3100dvd p3150dvd SMDokument190 SeitenPioneer Avh-P3100dvd p3150dvd SMRogerio E. SantoNoch keine Bewertungen

- Metal Detector BrochureDokument7 SeitenMetal Detector Brochurenedim986Noch keine Bewertungen

- TR139 Transistor TesterDokument5 SeitenTR139 Transistor TesterstefanNoch keine Bewertungen

- Constructional Features of DC MotorDokument34 SeitenConstructional Features of DC MotorBala SankarNoch keine Bewertungen

- Maintenance of Brushes and Commutators 2 enDokument14 SeitenMaintenance of Brushes and Commutators 2 enSavitha VinayNoch keine Bewertungen

- Atwater Kent 40-42-52-56-57 SchematicsDokument1 SeiteAtwater Kent 40-42-52-56-57 SchematicsEdd WhatleyNoch keine Bewertungen

- Cold Setting The Valves On A 1953 Dodge M37 Power WagonDokument2 SeitenCold Setting The Valves On A 1953 Dodge M37 Power Wagoncriag100% (1)

- Winding Machines CatalogDokument20 SeitenWinding Machines CatalogToroid Do BrasilNoch keine Bewertungen

- Detector Es de MetalDokument4 SeitenDetector Es de Metalfredy8704100% (1)

- Brushless DC MotorDokument6 SeitenBrushless DC Motorpsksiva13Noch keine Bewertungen

- Dual Acting ShaperDokument30 SeitenDual Acting ShaperAbhijeet NaikNoch keine Bewertungen

- d882p PDFDokument3 Seitend882p PDFdiego rotpeNoch keine Bewertungen

- Hysteresis MotorDokument27 SeitenHysteresis MotorSubham GhoshNoch keine Bewertungen

- Practical Properties of Rogowski Coil Construction - Presentation SlideDokument25 SeitenPractical Properties of Rogowski Coil Construction - Presentation SlideDavid Halomoan MalauNoch keine Bewertungen

- Data Pulley CVTDokument2 SeitenData Pulley CVTMuflihMuhammadNoch keine Bewertungen

- Raytheon Radio and Television Recieving Tube Data 1957Dokument54 SeitenRaytheon Radio and Television Recieving Tube Data 1957kgrhoadsNoch keine Bewertungen

- Governing, Ignition System, Fire OrderDokument33 SeitenGoverning, Ignition System, Fire OrderProf. Jignesh Sohaliya100% (1)

- Electric Machinery FundamentalsDokument6 SeitenElectric Machinery FundamentalsKashyap Dubey0% (1)

- Directions for Using Bottum's Patent Improved Universal Lathe Chucks and Improved Lathes for Turning and Finishing Every Description of Watch Pivots, Pinions, Staffs, EtcVon EverandDirections for Using Bottum's Patent Improved Universal Lathe Chucks and Improved Lathes for Turning and Finishing Every Description of Watch Pivots, Pinions, Staffs, EtcNoch keine Bewertungen

- Digital SystemsDokument45 SeitenDigital SystemsSindhu ManchukondaNoch keine Bewertungen

- Ee221 HWS01Dokument4 SeitenEe221 HWS01Sindhu ManchukondaNoch keine Bewertungen

- Strain Type InsulatorDokument3 SeitenStrain Type InsulatorSindhu ManchukondaNoch keine Bewertungen

- MeasurementsDokument21 SeitenMeasurementsSindhu ManchukondaNoch keine Bewertungen

- Engineering Manual Compact CWDokument28 SeitenEngineering Manual Compact CWlaufseNoch keine Bewertungen

- VT-evo Kubota-Spare Parts - SP007-01-00-00Dokument25 SeitenVT-evo Kubota-Spare Parts - SP007-01-00-00Justice Machiwana100% (1)

- Kel Univ ECatDokument8 SeitenKel Univ ECatShAi_MyStERiOuSNoch keine Bewertungen

- Types of Scavenging: Loop or Cross Scavenge UniflowDokument22 SeitenTypes of Scavenging: Loop or Cross Scavenge UniflowBharatiyulamNoch keine Bewertungen

- DC GeneratorDokument16 SeitenDC GeneratorSiddique MuhammadNoch keine Bewertungen

- QAS 14 KD APP S/N APP207576 - APP225648: Spare Parts List: Portable GeneratorsDokument171 SeitenQAS 14 KD APP S/N APP207576 - APP225648: Spare Parts List: Portable Generatorsdmm tgctpNoch keine Bewertungen

- Chapter 6 Energy ConDokument6 SeitenChapter 6 Energy ConLuelsonCordovaDeclarador0% (1)

- Stepper MotorsDokument26 SeitenStepper MotorsRam Kumar GogadaNoch keine Bewertungen

- CL408-412e Parts ListDokument24 SeitenCL408-412e Parts ListrubenNoch keine Bewertungen

- Full AssemblyDokument1 SeiteFull AssemblybenNoch keine Bewertungen

- 4 Chimi WangmoDokument3 Seiten4 Chimi WangmoChimi Wangmo0% (1)

- Features:: 1250kVA, Open Type, 4012-46TWG2A, PI734A, 3phase, AMFDokument7 SeitenFeatures:: 1250kVA, Open Type, 4012-46TWG2A, PI734A, 3phase, AMFhelmy muktiNoch keine Bewertungen

- 6ALBR5233JQODokument23 Seiten6ALBR5233JQOTom CatNoch keine Bewertungen

- Pittman GM9236S027Dokument0 SeitenPittman GM9236S027Nicola's SacNoch keine Bewertungen

- Musso A1 F2Dokument50 SeitenMusso A1 F2Paulo De CastroNoch keine Bewertungen

- Why Switched Reluctance Motors?Dokument9 SeitenWhy Switched Reluctance Motors?Raja VivekNoch keine Bewertungen

- Motor StartersDokument14 SeitenMotor StartersairamNoch keine Bewertungen

- The 1.8 Turbo Gasoline: Drive Your IdeasDokument4 SeitenThe 1.8 Turbo Gasoline: Drive Your Ideasmechatronics overviewNoch keine Bewertungen

- Cobra Proi: Spare Parts ListDokument52 SeitenCobra Proi: Spare Parts ListTasha KuskNoch keine Bewertungen

- Motor Selection NewerDokument2 SeitenMotor Selection Newerdan paluskaNoch keine Bewertungen

- 90kVA PDFDokument4 Seiten90kVA PDFXander DelinyaNoch keine Bewertungen

- Marine Auxiliary Engine: SpecificationsDokument2 SeitenMarine Auxiliary Engine: SpecificationsContessa JamesNoch keine Bewertungen

- Atb 935Dokument5 SeitenAtb 935Raul Rodriguez JuarezNoch keine Bewertungen

- Fire Pump Drive Engines: User Guide Radiator Cool EdDokument42 SeitenFire Pump Drive Engines: User Guide Radiator Cool EdReynaldo Mariano100% (1)