Beruflich Dokumente

Kultur Dokumente

Makita BJR182 18V

Hochgeladen von

Jose SanchezOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Makita BJR182 18V

Hochgeladen von

Jose SanchezCopyright:

Verfügbare Formate

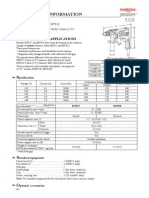

T

ECHNICAL INFORMATION

Models No.

BJR182

Description

Cordless Recipro Saw

PRODUCT

P 1/11

L

CONCEPT AND MAIN APPLICATIONS

Model BJR182 has been developed as a sister tool of BJR181.

featuring higher cost-competitiveness than the current model.

H

W

Dimensions: mm (")

449 (17-3/4)

Length (L)

Width (W)

91 (3-5/8)

Height (H)

241 (9-1/2)

This product is available in the following variations.

Battery

Battery

type

quantity cover

Model No.

BJR182

BJR182RFE

BJR182RF

BJR182Z

BL1830

(Li-ion 3.0Ah)

No

No

No

Plastic

carrying case

Charger

Offered to

North America

DC18RA

Yes

No

No

All countries except North America

All models also include the accessories listed below in "Standard equipment".

Specification

Battery

Voltage: V

18

Capacity: Ah

3.0

Cell

Li-ion

22

with DC18RA

Charging time: min.

Max output (W)

320

Length of stroke: mm (")

28 (1-1/8)

No load speed: min-1=spm

0 - 2,900

Max cutting capacities: mm (")

[when cutting with a 300mm blade]

wood

255 (10)

pipe

dia. 130 (5-1/8)

Variable speed control by trigger

Electric brake

Net weight*: kg (lbs)

Yes

Yes

3.5 (7.7)

*with battery BL1830

Standard equipment

Recipro saw blade for composite materials ............. 1

Recipro saw blade for metal .................................... 1

Note: The standard equipment for the tool shown above may differ by country.

Optional

accessories

Fast charger DC18RA

Charger DC24SA (for North America only)

Charger DC24SC (for all countries except North America)

Li-ion battery BL1830

Recipro saw blades

All countries

P 2/11

Repair

CAUTION: Remove the recipro saw blade and battery cartridge from the machine

for safety before repair/ maintenance !

[1] NECESSARY REPAIRING TOOLS

Code No.

Description

1R146

1R232

1R242

1R250

1R267

1R269

1R291

L type Torx wrench M6

Pipe 30

Round bar foe arbor 13-100

Round bar foe arbor 26-100

Spring pin extractor 2.5

Bearing extractor

Retaining ring S and R pliers

Removing Shoe guide

Removing/ installing Needle bearing 1012

Removing/ installing Needle bearing 1012

Press-fitting Oil seal 14

Removing Shift button

Removing Ball bearing 6001DDW

Removing/ installing Retaining rings S-18 and S-12

Use for

1R296

1R314

---

Spring pin extractor 1.5

Torx bit VT-25

Recipro saw blade

Removing Pin 3 from the Blade clamp section

Removing/ installing Torx socket head screw

Assembling Pin 3 to the Blade clamp section

[2] LUBRICATION and ADHESIVE

Lubrication: Apply Makita grease FA No.2 to the following portions designated with the black triangle to protect

parts and product from unusual abrasion. (Fig. 1)

Adhesive: When reusing threadlocker coated screws, be sure to apply adhesive before tightening.

Recommended adhesives are ThreeBond 1321B or 1342, or Loctite 242.

Item No.

Description

Portion to lubricate

Shoulder pin 5

Pin head that contacts Driving sleeve

17

X ring 14

Inside surface that contacts

29

Slider complete

38

Gear assembly

Surface of crank pin that contacts Needle bearing 708

40

Flat washer 14

Surface that contacts

46

Gear housing complete

Slider complete

Surface that contacts Plane bearing 14A

Surface that contacts Needle bearing 708 (Put approx. 7g.)

Gear assembly

Pin 10 (the gear shaft for Gear assembly)

Gear room (Put approx. 10g.)

Fig. 1

Gear housing cover complete

Plane bearing 14A

Plane bearing 14A

Blade clamp section

Needle bearing 708

Driving sleeve

P 3/11

Repair

[3] DISASSEMBLY/ASSEMBLY

[3] -1. Blade Clamp Section

Fig. 2

DISASSEMBLING

1) Remove Shoe. If the Blade clamp section is positioned inside

Gear housing, pull it out of Gear housing. (Fig. 2)

2) After removing Protector, remove Retaining ring S-18 using 1R291.

Then remove the following parts:

Driving sleeve, Shoulder pin 5, Compression spring 6,

Pin 3 (of 6mm length), Guide sleeve, Driving sleeve guide

Now Sleeve can now be seen. (Fig. 3)

Blade clamp section

Shoe

Fig. 3

Protector

Shoulder pin 5

Compression spring 6

Driving sleeve guide

Retaining ring S-18

Driving sleeve

Pin 3

(of 6mm length)

Guide sleeve

Sleeve

3) Sleeve is still locked at this Fig. 4

stage. Therefore, release it

using a recipro saw blade

[Sleeve Locked]

as illustrated in Fig. 4.

Recipro saw blade

[Sleeve Released]

Push the recipro saw blade.

Now sleeve can rotate.

Pin 3, 19.8mm long

Sleeve

Pin 3 is positioned at

the lower end of the

groove on Sleeve

when Sleeve is released.

groove

4) While putting your finger on the top of Slider to close the slit of Slider, remove Pin 3 (of 19.8mm length) by pushing

with a thin bar. (Fig. 5)

Note: Be sure to put your finger on the top of Slider or Push plate will pop out from the slit of Slider.

5) Remove Sleeve and Torsion spring 17 from Slider, then take Push plate and Compression spring 2 out of the slit of

Slider. (Fig. 6)

Fig. 5

Fig. 6

Slider

Sleeve

Push plate

Torsion

spring 17

Compression

spring 2

thin bar

Sleeve

Pin 3, 19.8mm long

Slider

P 4/11

Repair

[3] -1. Blade Clamp Section (cont.)

ASSEMBLING

1) Assemble Torsion spring 17 to Slider as illustrated in Fig. 7.

Important: Be sure that Torsion spring 17 is not reversible when assemble to Slider.

Follow the instruction described in Fig. 7.

2) Insert Compression spring 2 into the slit of Slider.

3) Install Sleeve on Slider, and lock Pin 3 provisionally by turning Sleeve clockwise. (Fig. 8)

Fig. 7

Fig. 8

Torsion spring 17

Insert this end

into the slit of

Slider.

This end has to

be positioned

on the Cap side.

Slider

Pin 3, 19.8mm long

Sleeve

Cap

Shift button

Slider

[Side view of cap]

Cap has an insert hole

for Shift button.

4) Mount Guide sleeve provisionally, then put Push plate into the slit of Slider as illustrated to left in Fig. 9.

Important: Be sure that Push plate is not reversible when installed.

While pushing Push plate straight into Slider with recipro saw blade, insert Pin 3 (of 19.8mm length) through the hole

of Push plate as illustrated to right in Fig. 11. Then remove Guide sleeve.

Note: Guide sleeve is used as a jig, not assembled to Slider yet in this step.

Fig. 9

While pushing recipro saw blade,

This projection must

face the blade side.

Push plate

Recipro saw blade

Pin 3, 19.8mm long

Guide sleeve

insert pin 3 through

the hole of push plate.

P 5/11

Repair

[3] -1. Blade Clamp Section (cont.)

5) While fitting the two projections of Driving sleeve in the concavities of Sleeve, push Driving sleeve into Gear housing.

At this time, turn Driving sleeve clockwise so that the protruding portion of Driving sleeve cannot be interfered by

Gear housing. After Driving sleeve is pushed into Gear housing to the full, turn Driving sleeve clockwise to lock Pin 3

in place. (Fig. 10)

Note: Driving sleeve is used as a jig to lock Pin 3 in place, not assembled to Slider in this step.

6) Remove Driving sleeve.

Fig. 10

Driving sleeve

Concavities

Driving sleeve

Sleeve

Projections

Sleeve

7) Assemble the following parts to Slider (Refer to Fig. 3.):

Driving sleeve guide, Guide sleeve, Pin 3 (of 6mm length), Shoulder pin 5, Compression spring 6

8) Put Driving sleeve over Guide sleeve and secure with Retaining ring S-18 using 1R291.

Then cover Driving sleeve with Protector. (When installing Driving sleeve, fit its projections in the concavities of

Sleeve and Driving sleeve guide.)

[3] -2. Shift Button and Cap

DISASSEMBLING

Fig. 11

Shift button can be removed from Gear housing cover by

inserting a thin bar into the hole of Cap and push the bar.

(Fig. 11)

Shift button

Cap

thin bar

ASSEMBLING

1) Replace Cap by new one because removal of Shift button

damages the inside surface of Cap.

2) From Shift button, remove all the plastic dust scraped off

the removed Cap. Insert Shift button through the holes in

the both sides of Gear housing cover.

Then press-fit Shift button in the new Cap by hand.

Important:

Be sure to assemble Shift button to Gear housing cover

so that the two notches of Shift button face the side

opposite to slider as illustrated in Fig. 12.

Fig. 12

Slider

Shift button

Cap

These notches of Shift button must

face the side opposite to Slider.

P 6/11

Repair

[3] -3. Slider Section

DISASSEMBLING

1) After removing Shoe, then Insulation cover. (Fig. 13)

2) Remove the Blade clamp section. (See "[3] -1. Blade Clamp Section.)

Fig. 13

For smooth removal of Insulation cover,

apply soapy water into the space between

Insulation cover and Gear housing cover

complete.

Gear housing

cover complete

Insulation cover

Slider

(after removal of

Blade clamp section)

Gear housing

cover complete

Insulation cover

3) Remove Gear housing cover complete from Gear housing complete by unscrewing four M5x25 Pan head screws.

(Fig. 14)

4) Remove two Plates from Gear housing cover complete by unscrewing four M5x16 Pan head screws. (Fig. 15)

Note: It is recommended to use impact driver to remove the screws because they are coated with threadlocker.

5) Disassemble Slider as illustrated in Fig. 16.

Fig. 14

Fig. 15

Pan head screw

M5x25 (4pcs)

Pan head screw M5x16,

threadlocker coated

Plate

Plate

Plane bearing 14A

Gear housing

cover complete

Plane bearing 14A

Slider

Gear housing complete

Gear housing

cover complete

Fig. 16

Remove Plane bearing 14A

on the Motor housing side.

Plane bearing 14A

Slider

Push Slider toward

the Motor housing side.

While raising this

end, pull off Slider.

Plane bearing 14A

P 7/11

Repair

[3] -3. Slider Section (cont.)

ASSEMBLING

Do the reverse of the disassembling steps.

Note: a) Do not forget to apply Makita grease FA No.2 to slider before assembling. (Fig. 17)

b) Both of the two Plane bearing 14A's are not reversible when assembled to Slider.

Be sure to assemble as illustrated in Fig. 18.

Fig. 17

Fig. 18

Stepped portion

Stepped portion

Plane bearing 14A

Slider

Plane bearing 14A

Motor housing side

Gear housing cover side

Blade clamp side

Surface that contacts

Needle bearing 708: approx. 7g

Surface that contacts

Plane bearing 14A: a little amount

Gear housing side

[3] -4. Oil Seal 14, X Ring 14

Fig. 19

DISASSEMBLING

1) Referring to "[3]- 3. Slider Section", separate Gear housing cover

complete from the tool.

2) Oil seal 14 can be removed by pushing X ring 14 toward the Blade

clamp side using a slotted screwdriver as illustrated to left in Fig. 19.

3) X ring 14 can now be removed by pushing toward the Blade clamp

side by hand as illustrated to right in Fig. 21.

Motor housing side

ASSEMBLING

1) As illustrated to left in Fig. 20, assemble X ring 14 to Gear housing

cover complete from the Blade clamp side, then put Oil seal 14 onto

X ring 14.

Note: Oil seal 14 is not reversible when assembled to Gear housing

complete. Be sure to assemble so that the lip portion of Oil

seal 14 faces toward the Blade clamp side.

2) As illustrated to right in Fig. 20, set 1R250 on Oil seal 14,

then press down with arbor press until the end of the lip portion of

Oil seal 14 gets is flush with the top surface of the ring installation

hole of Gear housing cover complete.

Oil seal 14

X ring 14

Blade clamp side

Fig. 20

Blade clamp side

lip portion

No.1R250

Oil seal 14

X Ring 14

Motor housing side

P 8/11

Repair

[3] -5. Gear Assembly

DISASSEMBLING

1) Referring to "[3]- 3. Slider Section", remove Gear housing cover complete from Gear housing complete.

2) Remove two Plate C's by unscrewing four M5x14 Torx socket head screws with 1R314. (Fig. 21)

Note: It is recommended to use impact driver to remove the screws because they are coated with threadlocker.

3) The following parts can now be removed from Gear housing complete (Fig. 22);

Gear assembly, Needle bearing 708, Needle bearing 1012, Flat washer 14

Fig. 21

Fig. 22

Needle bearing 708

Plate C

Gear assembly

1R314

Needle bearing 1012

Flat washer 14

Torx socket

head screw M5x14

Pin 10

Gear housing

complete

ASSEMBLING

Do the reverse of the disassembling steps.

Note: a) Apply Makita grease FA No.2 to the following parts, before assembling:

*Flat washer 14: the surface that contacts Gear assembly

*Pin 10 (of Gear housing complete): surface that contacts Gear assembly

b) Torx socket head screw M5x14 is threadlocker coated. Therefore, if reusing the screw, be sure to apply adhesive

before tightening.

P 9/11

Repair

[3] -6. Armature

DISASSEMBLING

1) Separate Gear housing cover complete from Gear housing complete. (Figs. 13, 14)

2) Remove Carbon brushes, then separate the assembly of Armature and Gear housing complete from Motor housing

complete by unscrewing four 5x25 tapping screws. (Fig. 23)

Fig. 23

Gear housing complete

Tapping screw 5x25 (4 pcs)

Motor housing complete

Armature

Carbon brush

Brush holder cap

3) Remove two M5x16 Pan head screws that fasten Bearing retainer 63 to Gear housing complete.

The assembly of Armature and Bearing retainer 63 can now be removed from Gear housing complete by tapping the end

surface of Gear housing complete. (Fig. 24)

4) Remove Retaining ring S-12 using 1R291, then Ball bearing 6001DDW using 1R269.

Bearing retainer 63 can now be removed. (Fig. 25)

Fig. 24

Fig. 25

Pan head screw M5x16

Retaining ring

S-12

Ball bearing

6001DDW

Bearing

retainer 63

Armature

Bearing

retainer 63

ASSEMBLING

Do the reverse of the disassembling steps.

Note: Make sure that Stop ring E-10 is assembled in place on Armature shaft

to secure Ball bearing 6001DDW. (Fig. 26)

Fig. 26

Stop ring E-10

P 10/11

Circuit

diagram

Fig. D-1

Color index of lead wires' sheath

Black

Red

Right side

Brush holder, Right

Left side

Switch

Brush holder, Left

Right side

Brush holder, Right

FET

Switch

Heatsink

Brush holder, Left

Left side

Terminal

P 11/11

Wiring

diagram

1) Rear of Motor Housing

Fig. D-2

Fix Lead wire of each Brush holder with Lead wire holders as illustrated below.

Lead wire

Motor housing

Lead wire holder

on Motor housing

Lead wire holder

on Motor housing

Lead wire holder

on Brush holder

Lead wire holder

on Brush holder

Brush holder, Left

Brush holder, Right

2) Handle L

Fig. D-3

Route all Lead wires between

the boss and the rib.

boss

Put slack portion of all Lead wires

in this space.

rib

Handle L

FET

Heatsink

Switch

Connecting Flag Connector to Terminal

The flag connector has to be so connected that

the wire connecting portion is positioned on

the side of pole marks of Terminal.

Wire connecting portion

Pole mark

Flag connector

Terminal

Terminal

Das könnte Ihnen auch gefallen

- T 176Dokument9 SeitenT 176ashkansoheylNoch keine Bewertungen

- Laptop Motherboard Fault FinderDokument127 SeitenLaptop Motherboard Fault Finderchipmaster8650% (2)

- Assembly ProcedureDokument115 SeitenAssembly ProcedureAlex Castillo100% (1)

- 500 Watt Inverter Circuit With Battery Charger - Homemade Circuit ProjectsDokument38 Seiten500 Watt Inverter Circuit With Battery Charger - Homemade Circuit ProjectskaleemullaNoch keine Bewertungen

- Cylinder Head 3sfeDokument27 SeitenCylinder Head 3sfePham Huy83% (18)

- Model Master Testors Conversion Color ChartDokument2 SeitenModel Master Testors Conversion Color ChartJose Sanchez100% (6)

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceVon EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNoch keine Bewertungen

- HTX 202 Owners ManualDokument44 SeitenHTX 202 Owners Manualbellscb100% (2)

- 07-124 Motor CharlynDokument12 Seiten07-124 Motor CharlynMiguel Angel Santos Pintado100% (2)

- Dropbox ReconditioningDokument47 SeitenDropbox ReconditioningRezha50% (2)

- Revell Conversion Color ChartDokument2 SeitenRevell Conversion Color ChartJose Sanchez42% (12)

- Toyota Matrix L4 2008Dokument16 SeitenToyota Matrix L4 2008Gesco EscobarNoch keine Bewertungen

- Gun Digest American Arms ATI GSG-5 Assembly/Disassembly InstructionsVon EverandGun Digest American Arms ATI GSG-5 Assembly/Disassembly InstructionsNoch keine Bewertungen

- Bumper Car ManualDokument52 SeitenBumper Car ManualHaris Kolasinac100% (1)

- 310 CircuitsDokument546 Seiten310 CircuitsSlobodan Mitrovic100% (1)

- Electric Vehicle Ddesign & Development ProcessDokument6 SeitenElectric Vehicle Ddesign & Development Processparth sarthyNoch keine Bewertungen

- Engine DismantlingDokument9 SeitenEngine DismantlingRezha100% (1)

- Service Manual: EH025/EH035 EngineDokument66 SeitenService Manual: EH025/EH035 EngineJose SanchezNoch keine Bewertungen

- Ac Compressor ServicingDokument25 SeitenAc Compressor Servicingsonny1234100% (1)

- CanonT 90 AddDokument47 SeitenCanonT 90 AddJose Sanchez100% (1)

- Full ManualDokument13 SeitenFull ManualSteve Dowell80% (5)

- Aircraft Manual - Lockheed SR-71A-1 - Flight Manual PDFDokument1.012 SeitenAircraft Manual - Lockheed SR-71A-1 - Flight Manual PDFJose Sanchez100% (7)

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementVon EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNoch keine Bewertungen

- Testors MM AcrylicDokument1 SeiteTestors MM AcrylicJose SanchezNoch keine Bewertungen

- EC210 - Track Motor, DisassemblyDokument14 SeitenEC210 - Track Motor, DisassemblyPreett Rajin MenabungNoch keine Bewertungen

- Cambio Arbol de LevasDokument12 SeitenCambio Arbol de LevasgenaroNoch keine Bewertungen

- SM - Volvo Ec210b LC Ec210blc ExcavatorDokument18 SeitenSM - Volvo Ec210b LC Ec210blc ExcavatorNikitko Dmitry33% (3)

- ROTALIGN Ultra Is Shaft Handbook Edition 1 DOC 40 200-06-12 Web enDokument156 SeitenROTALIGN Ultra Is Shaft Handbook Edition 1 DOC 40 200-06-12 Web enxX1crist1Xx100% (1)

- Eaton: Model 74318 and 74348 Piston Motors Fixed Displacement, Valve Plate DesignDokument9 SeitenEaton: Model 74318 and 74348 Piston Motors Fixed Displacement, Valve Plate Designluisbravo1264Noch keine Bewertungen

- Service Bulletin: SUBJECT: 19XR Split Ring Diffuser Assembly and SetupDokument18 SeitenService Bulletin: SUBJECT: 19XR Split Ring Diffuser Assembly and SetupANGEL MURILLO100% (1)

- HM1203C PBDokument3 SeitenHM1203C PBJose SanchezNoch keine Bewertungen

- Remove and Install Torque Divider 3113-010Dokument19 SeitenRemove and Install Torque Divider 3113-010Milton Hernandez PérezNoch keine Bewertungen

- Flow Doc 2 PDFDokument18 SeitenFlow Doc 2 PDFJozefNoch keine Bewertungen

- WheelHorse 36 Inch Tiller Manual Models 79271, 99271, 9861915Dokument20 SeitenWheelHorse 36 Inch Tiller Manual Models 79271, 99271, 9861915Kevins Small Engine and Tractor Service100% (3)

- 6.0L Turbo Rebuild Instructions PDFDokument5 Seiten6.0L Turbo Rebuild Instructions PDFW MoralesNoch keine Bewertungen

- Remo TBDokument5 SeitenRemo TBTyler MacNoch keine Bewertungen

- Orbit RolDokument12 SeitenOrbit RolFabio MartinsNoch keine Bewertungen

- 2012 Dorado Pro Service ManualDokument29 Seiten2012 Dorado Pro Service ManualSea RidersNoch keine Bewertungen

- 05 Embrage Suzuki IntruderDokument26 Seiten05 Embrage Suzuki Intruderbenjapana75% (4)

- Install PistonDokument6 SeitenInstall PistonSteven Y.MNoch keine Bewertungen

- 07K Manifold IEIMVB1 IEIMVB2 Install GuideDokument18 Seiten07K Manifold IEIMVB1 IEIMVB2 Install GuideEmmanuel HernandezNoch keine Bewertungen

- 2012 Fork Service ManualDokument36 Seiten2012 Fork Service ManualFer SabidongNoch keine Bewertungen

- Https 127.0.0.1 Sisweb Sisweb Techdoc Techdoc Print PageDokument9 SeitenHttps 127.0.0.1 Sisweb Sisweb Techdoc Techdoc Print Pagep.motortechNoch keine Bewertungen

- 011 - FlywheelDokument12 Seiten011 - Flywheelmax_simonsNoch keine Bewertungen

- Assembly and Disassembly of Screw Type CompressorDokument16 SeitenAssembly and Disassembly of Screw Type Compressorhitesh bhoiNoch keine Bewertungen

- Ac Compressor ServicingDokument5 SeitenAc Compressor Servicinghcalima.quitoNoch keine Bewertungen

- 1988 Tomos A3 Workshop ManualDokument30 Seiten1988 Tomos A3 Workshop ManualcerubdzijaNoch keine Bewertungen

- Manual Da Furadeira MakitaDokument10 SeitenManual Da Furadeira Makitaani_matrixx4733Noch keine Bewertungen

- Service Procedure-Front and Rear Drive Shafts - MSA5T9506A29533Dokument6 SeitenService Procedure-Front and Rear Drive Shafts - MSA5T9506A29533Ramel Aguilar CarlosNoch keine Bewertungen

- Starter CluchDokument8 SeitenStarter CluchJerry BeckettNoch keine Bewertungen

- Caterpillar Cat 245B EXCAVATOR (Prefix 1SJ) Service Repair Manual (1SJ00001-00712)Dokument24 SeitenCaterpillar Cat 245B EXCAVATOR (Prefix 1SJ) Service Repair Manual (1SJ00001-00712)rpoy9396615Noch keine Bewertungen

- 950F CaterpillarDokument15 Seiten950F CaterpillarMartinez Mauricio Martinez GomezNoch keine Bewertungen

- Steering Axle: Safety Precautions Maintenance and RepairDokument9 SeitenSteering Axle: Safety Precautions Maintenance and RepairPhilip Peter HanssenNoch keine Bewertungen

- REVE Dorado Service ManualDokument32 SeitenREVE Dorado Service ManualHéctor Alberto LaioloNoch keine Bewertungen

- S-91 Triple Drill Installation and Maintenance ManualDokument34 SeitenS-91 Triple Drill Installation and Maintenance Manualjuliocesar.caNoch keine Bewertungen

- Adjustment For The Final Drive BearingsDokument8 SeitenAdjustment For The Final Drive Bearingsrapha raphaNoch keine Bewertungen

- Timing Chain Components & Instalation Toyota Hilux 22R-E: Preparation of RemovalDokument7 SeitenTiming Chain Components & Instalation Toyota Hilux 22R-E: Preparation of RemovalPablo FernandezNoch keine Bewertungen

- Unpacking and Installation Procedure For The Main Body and OptionsDokument11 SeitenUnpacking and Installation Procedure For The Main Body and OptionsNistor SilviuNoch keine Bewertungen

- AC Compressor ServicingDokument28 SeitenAC Compressor Servicinggentiles mdqNoch keine Bewertungen

- 740 Timing Appendix ADokument2 Seiten740 Timing Appendix AturbobrikNoch keine Bewertungen

- Manitou Tower ServiceDokument35 SeitenManitou Tower ServiceKélio Wolfrane Santos MachadoNoch keine Bewertungen

- 11susp. Tras y Parte Trasera Suzuki IntruderDokument22 Seiten11susp. Tras y Parte Trasera Suzuki Intruderbenjapana100% (2)

- 2005-2010 Tacoma Bed Extender PT329-35050 Rev. A - PT329-35050Dokument8 Seiten2005-2010 Tacoma Bed Extender PT329-35050 Rev. A - PT329-35050kylemac123Noch keine Bewertungen

- Orbitrol Repairing1Dokument30 SeitenOrbitrol Repairing1Islam ShoukryNoch keine Bewertungen

- Blurlt BearingDokument12 SeitenBlurlt BearingJavi BaalNoch keine Bewertungen

- 7 CP 06Dokument12 Seiten7 CP 06JackNoch keine Bewertungen

- 3304-3306 Medidas de Bielas y BancadasDokument3 Seiten3304-3306 Medidas de Bielas y BancadasJuan Carlos RivasNoch keine Bewertungen

- Sti Timing Belt InstructionsDokument19 SeitenSti Timing Belt InstructionsPablo DpNoch keine Bewertungen

- 2013-2015 FIT CTD Cartridge Rebuild - Bike Help Center - FOXDokument36 Seiten2013-2015 FIT CTD Cartridge Rebuild - Bike Help Center - FOXYadi RomaNoch keine Bewertungen

- Piston: Zoom Sized For PrintDokument8 SeitenPiston: Zoom Sized For PrintHillary WoodwardNoch keine Bewertungen

- XL Series Actuators 1: Installation, Operating and Maintenance InstructionsDokument8 SeitenXL Series Actuators 1: Installation, Operating and Maintenance InstructionsFranco M. CaverzanNoch keine Bewertungen

- Sanden SD6V12 Service Manual. Date of Issue May Prepared by Sanden International (Europe) Ltd. For Opel.Dokument25 SeitenSanden SD6V12 Service Manual. Date of Issue May Prepared by Sanden International (Europe) Ltd. For Opel.Luigi TencoNoch keine Bewertungen

- Hm1317cb PBDokument4 SeitenHm1317cb PBJose SanchezNoch keine Bewertungen

- Zvezda Su-47 Berkut Russian Fifth Generation Fighter Zvezda No7215Dokument7 SeitenZvezda Su-47 Berkut Russian Fifth Generation Fighter Zvezda No7215Jose Sanchez100% (1)

- BOSCH 2012 Parts List Price (Only)Dokument427 SeitenBOSCH 2012 Parts List Price (Only)Jose Sanchez100% (1)

- CatalogoDokument17 SeitenCatalogoJose SanchezNoch keine Bewertungen

- Special 17 M18 Gun Motor Carriage HellcatDokument24 SeitenSpecial 17 M18 Gun Motor Carriage HellcatJose SanchezNoch keine Bewertungen

- Academy m18 Hellcat No1375Dokument16 SeitenAcademy m18 Hellcat No1375Jose Sanchez100% (1)

- Makita HR4013C, HR4013CV - Dec2014Dokument5 SeitenMakita HR4013C, HR4013CV - Dec2014Jose SanchezNoch keine Bewertungen

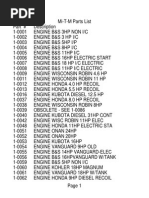

- Mitm PartsDokument977 SeitenMitm PartsJose SanchezNoch keine Bewertungen

- Makita hr4000c Parts ManualDokument44 SeitenMakita hr4000c Parts ManualJose SanchezNoch keine Bewertungen

- Ramsett3 Schematic EngDokument10 SeitenRamsett3 Schematic EngJose SanchezNoch keine Bewertungen

- Subaru Eh025 Engine Parts ManualDokument78 SeitenSubaru Eh025 Engine Parts ManualJose SanchezNoch keine Bewertungen

- Makita HR2621 Parts Manual - DEC2014Dokument5 SeitenMakita HR2621 Parts Manual - DEC2014Jose SanchezNoch keine Bewertungen

- Wiring Instructions: Band SawDokument1 SeiteWiring Instructions: Band SawJose SanchezNoch keine Bewertungen

- Manual Cargador Ferro Five CDDokument76 SeitenManual Cargador Ferro Five CDIván RegaladoNoch keine Bewertungen

- Rail Power FNC Manual enDokument102 SeitenRail Power FNC Manual enMariano Salomon PaniaguaNoch keine Bewertungen

- Qcs 2014 - Sec21 p18 - Uninterruptible Power SupplyDokument6 SeitenQcs 2014 - Sec21 p18 - Uninterruptible Power Supplychandra100% (1)

- Manual Blue Power Battery ChargerDokument79 SeitenManual Blue Power Battery ChargerEstebanNoch keine Bewertungen

- SPECIFICATION SHEET - Li2800QC TWIN PACDokument2 SeitenSPECIFICATION SHEET - Li2800QC TWIN PACElias ZabanehNoch keine Bewertungen

- New Vari Comp Ar SionDokument6 SeitenNew Vari Comp Ar SionravitejaNoch keine Bewertungen

- Wireless Battery ChargerDokument22 SeitenWireless Battery ChargerAvinashreddy 9490665077100% (1)

- Bms Battery ChargingDokument12 SeitenBms Battery ChargingMEGALA DEVINoch keine Bewertungen

- AlfaBat Pro Manual v2.0Dokument43 SeitenAlfaBat Pro Manual v2.0supljinaNoch keine Bewertungen

- Technical Specification of PLCC: Wbsetcl Page - 1/26 Battery ChargerDokument26 SeitenTechnical Specification of PLCC: Wbsetcl Page - 1/26 Battery ChargerpvenkyNoch keine Bewertungen

- Stonex R2 Plus User Manual (L Style) Ver 1 enDokument117 SeitenStonex R2 Plus User Manual (L Style) Ver 1 enGiuseppe Borgese50% (2)

- Refurbishing A Plastic BatteryDokument2 SeitenRefurbishing A Plastic Batterypaul .a larnerNoch keine Bewertungen

- WIP LimitDokument15 SeitenWIP LimitMohammad KamruzzamanNoch keine Bewertungen

- User Manual of TEM912 Digital Test Hammer-2023Dokument26 SeitenUser Manual of TEM912 Digital Test Hammer-2023medhat sherifNoch keine Bewertungen

- Samsung Galaxy S21 5G User ManualDokument187 SeitenSamsung Galaxy S21 5G User ManualSvinčnikNoch keine Bewertungen

- Legacy Titanium HF Charger BrochureDokument2 SeitenLegacy Titanium HF Charger BrochureLuis Alberto Rivas GarciaNoch keine Bewertungen

- Manual Sun (5 12) K sg04lp3 Au Deye 1Dokument53 SeitenManual Sun (5 12) K sg04lp3 Au Deye 1Irfan RisaldiNoch keine Bewertungen

- Reaper Mechanical and Electrical Operations 129Dokument16 SeitenReaper Mechanical and Electrical Operations 129Yurii ChinovNoch keine Bewertungen

- Native Falco Ip ControllerDokument6 SeitenNative Falco Ip ControllerSanja BoganoskaNoch keine Bewertungen

- Procedure Text GILANGDokument3 SeitenProcedure Text GILANGMar KudidNoch keine Bewertungen

- USN60 Operating ManualDokument278 SeitenUSN60 Operating ManualagciocanNoch keine Bewertungen

- 013-007 Batteries: InspectDokument3 Seiten013-007 Batteries: InspectWahyuni WayuniNoch keine Bewertungen

- Zebra Et51-56Dokument31 SeitenZebra Et51-56Freddy AlvarezNoch keine Bewertungen