Beruflich Dokumente

Kultur Dokumente

8 Recipes For Sponge Biscuits

Hochgeladen von

jamaljamal20Originalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

8 Recipes For Sponge Biscuits

Hochgeladen von

jamaljamal20Copyright:

Verfügbare Formate

8

Recipes for sponge biscuits

8.1

Introduction

Sponge confections usually make one think of cakes and certainly we are on

the borders of biscuits and cakes with these products. However, as they are

manufactured by biscuit producers it seems appropriate to include a few

examples here.

Sponge products derive their aeration from air contained in a batter which

is a foam. The stability of the foam is from egg and the quantity of egg in

the recipe is much higher than in any other biscuit product.

If the product is baked to a low moisture content it is hard and has a long

shelf-life as for other biscuits. If the sponge is softer, as for example in Jaffa

cakes, the composition of the total product should have a water content sufficiently low to preclude mould growth. The moisture-proof wrapping of high

moisture sponge products must stop them from drying rather than from

picking up moisture from the atmosphere as with other biscuits.

105

Biscuit, cracker and cookie recipes

8.2

Recipes for sponge drop biscuits

Recipe no.

Type product

flour, weak

cornflour

granulated sugar

icing sugar

caster sugar

cane syrup 80 %

glucose syrup 80 %

dough fat

butter

oil

SMP

fresh egg

amm. bic.

soda

ACP

SAPP

salt

glycerine

colour*

Added water

121

Langues

de Chat

122

sponge

drops

123

Jaffa

cake

124

Jaffa

cake

125

boudoir

100.00

100.00

100.00

100.00

90.32

9.68

56.50

150.00

100.00

86.59

43.50

6.95

6.50

100.00

0.77

70.00

100.00

2.57

80.00

5.00

70.00

69.52

0.64

0.50

0.50

1.25

0

25

3.09

0.10

3

97.80

90.30

1.09

3.23

0.54

0.06

2.17

0.10

5

3.23

* This ingredient is not represented by an accurate quantity.

Critical ingredients The quality of the egg is important and it is usual to

use either freshly shelled whole eggs or carefully thawed frozen fresh eggs.

The egg entrains the air and the batter is then pumped to a depositor. In

the more luxurious products such as Langues de Chat the fat contributes

greatly to the taste and eating texture so butter is used. The syrups and

glycerine are used as humectants to prevent the baked product from drying

too much and to maintain a softer eating texture.

Mixing This is usually done in two stages. Firstly, all the ingredients are

blended together as a batch operation. This is followed by vigorous beating

when air is incorporated to give a lower density. This latter stage is usually

achieved as a continuous operation by passing the blended batter through

a very high shear mixer inside a water cooled barrel under pressure (for

example, an Oakes mixer). Air is injected into the mixer at a given rate and

pressure to give a batter density of about 0.88 g/cc at around 19 C. A back

pressure valve at the exit of the mixer barrel gives better control of the

pressure during mixing.

Recipes for sponge biscuits

106

Dough handling The aerated batter is pumped without delay to the depositing head.

Batter drop forming By intermittent opening of nozzles in the depositing

head measured volumes of batter are placed either on a steel oven band or

into cavities in steel trays for baking. The pressure drops across the depositing head so nozzle aperture adjustment is necessary to maintain even

weights delivered from all the nozzles.

As most sponge batters are low in fat and high in sugar there is a great

tendency for the drops to stick firmly to the baking surface during baking.

It is therefore necessary to oil or grease the band before depositing the batter.

However, as the batter also tends to spread as it gets warm in the oven, before

the heat sets the egg proteins, it is necessary to use a band greasing material

that not only prevents sticking but also controls the amount of spread. If this

critical part of the process is neglected the size and shape of the baked drops

are very irregular. The band greasing is therefore usually of a special oil (with

or without emulsifier) spread evenly and in a very thin film or a mixture of

fat or oil and a cereal like wheat flour or starch which is also spread very

evenly. In other cases the film of oil is evenly dusted with a trace of flour

before the batter is deposited.

The shape of the drop is determined by the relative speed of the depositor head and the band during the time when the nozzles are open. Thus Jaffa

drops are round because the head moves at the same speed as the band and

deposits for boudoir consist of long fingers in trays because the head is stationary and the tray moves beneath the head as the nozzles deliver the batter.

A dressing of granulated sugar or nut pieces may be dusted over the drops

before baking.

Baking Most sponge drops are baked on a normal flat steel oven band.

Boudoir and sponge boats are baked in formed trays which are fed onto

chains to be passed through the oven. After baking these trays of product

are cooled and then inverted and knocked to release the baked biscuits.

Thorough cleaning and regreasing are necessary before reuse.

Bake times are about 78 minutes with a temperature profile of 200, 200,

150 C. After leaving the oven the products are soft or delicate. It is necessary to allow them to cool and set before removal from the band. A roller

may be used to depress, a little, the tops of the biscuits while they are still

hot and thereby control the thickness.

Removal from the band is a critical operation. The biscuits must not be

damaged and if a stripping knife is used it may collect messy band dressing

materials which will be transferred to the edges of the biscuits and soil them.

The use of wire fingers in place of a knife is recommended.

The oven band must be well cleaned before returning to be regreased and

receiving new drops of batter.

Boudoir biscuits are also known as lady fingers, savoiardi and champagne

biscuits.

Das könnte Ihnen auch gefallen

- Basic Steps in Yeast Dough ProductionDokument26 SeitenBasic Steps in Yeast Dough Productionraymond marcos100% (1)

- Cakes and IcingDokument53 SeitenCakes and IcingRian RoferosNoch keine Bewertungen

- The Perfect Croissant: Step-by-Step Instructions Plus Fabulous FillingsVon EverandThe Perfect Croissant: Step-by-Step Instructions Plus Fabulous FillingsNoch keine Bewertungen

- The Essential Guide To BakingDokument57 SeitenThe Essential Guide To BakinghymerchmidtNoch keine Bewertungen

- Cheese Making Made Easy: Make your own favorite cheesesVon EverandCheese Making Made Easy: Make your own favorite cheesesNoch keine Bewertungen

- Unit 6 PastryDokument29 SeitenUnit 6 PastryRicardo HarveyNoch keine Bewertungen

- Baking TechniquesDokument7 SeitenBaking TechniquesRovie Valdez100% (1)

- Egg Tart Recipe With Chinese Puff PastryDokument30 SeitenEgg Tart Recipe With Chinese Puff PastryAngie LinNoch keine Bewertungen

- 2ssc Abb PubDokument3 Seiten2ssc Abb PubO.L.D.E.Noch keine Bewertungen

- Donuts: Recipes for Glazed, Sprinkled, and Jelly-Filled TreatsVon EverandDonuts: Recipes for Glazed, Sprinkled, and Jelly-Filled TreatsBewertung: 5 von 5 Sternen5/5 (2)

- Baking Book by CTDokument10 SeitenBaking Book by CTRutendo ShamuyariraNoch keine Bewertungen

- 12 Steps To Bread Production, DOUGH MAKINGDokument7 Seiten12 Steps To Bread Production, DOUGH MAKINGrobert babidaNoch keine Bewertungen

- Baking Fundamentals - Notes & RecipesDokument14 SeitenBaking Fundamentals - Notes & RecipesRutendo ShamuyariraNoch keine Bewertungen

- Foam Cake: Sponge CakeDokument21 SeitenFoam Cake: Sponge CakeJuliecel Arimado0% (1)

- Advance Baking ResearchDokument26 SeitenAdvance Baking ResearchEllysa Mae Pablo ManlupigNoch keine Bewertungen

- Taste of Home Ultimate Baking Cookbook: 575+ Recipes, Tips, Secrets and Hints for Baking SuccessVon EverandTaste of Home Ultimate Baking Cookbook: 575+ Recipes, Tips, Secrets and Hints for Baking SuccessNoch keine Bewertungen

- (All Purpose Flour Can Be Used. Experiment With Different Types of Flour) (Should You Use Pastrex Super, Then Freezing The Fat Is Not Required)Dokument3 Seiten(All Purpose Flour Can Be Used. Experiment With Different Types of Flour) (Should You Use Pastrex Super, Then Freezing The Fat Is Not Required)Linaden FernanNoch keine Bewertungen

- Yeast BreadsDokument43 SeitenYeast BreadsRENATO NATORNoch keine Bewertungen

- Learning PastryDokument18 SeitenLearning PastryTemmyNoch keine Bewertungen

- Sliced Bread: The Science ofDokument4 SeitenSliced Bread: The Science ofGayatri PrameswariNoch keine Bewertungen

- CRIMP Definition of CrimpingDokument11 SeitenCRIMP Definition of CrimpingJim FloresNoch keine Bewertungen

- BakeryWorld Vol8, Iss1-2Dokument24 SeitenBakeryWorld Vol8, Iss1-2Manish Gaur100% (1)

- Pies Background InfoDokument4 SeitenPies Background InfojammNoch keine Bewertungen

- BakeInfo Info CakesDokument3 SeitenBakeInfo Info CakesSQF PractitionerNoch keine Bewertungen

- The Donut Cookbook: 100 Easy, Sweetened Homemade Donut Recipes To RelishVon EverandThe Donut Cookbook: 100 Easy, Sweetened Homemade Donut Recipes To RelishNoch keine Bewertungen

- Japanese CakeDokument6 SeitenJapanese CakeRijah WeiweiNoch keine Bewertungen

- Pies & Pastry 1: Information SheetDokument3 SeitenPies & Pastry 1: Information SheetCwt ChanNoch keine Bewertungen

- Pastry Basics Chapter 14: Presented By: Patricia Cassandra DijanDokument29 SeitenPastry Basics Chapter 14: Presented By: Patricia Cassandra DijanReggie Ann PerezNoch keine Bewertungen

- Bake+Info Info Yeast+Raised+DoughnutsDokument3 SeitenBake+Info Info Yeast+Raised+DoughnutsTomNoch keine Bewertungen

- Pate Brisee and PuffDokument14 SeitenPate Brisee and Puffleonevill cadanoNoch keine Bewertungen

- Tools and EquipmentsDokument6 SeitenTools and EquipmentsRoselle Gunsay LozanoNoch keine Bewertungen

- Anne Cazor Master French Pastry PDFDokument458 SeitenAnne Cazor Master French Pastry PDFTarak Zayani100% (6)

- Short Crust PastryDokument12 SeitenShort Crust PastrysarathNoch keine Bewertungen

- Bakery: Laminated DoughsDokument15 SeitenBakery: Laminated DoughsTemet Nosche100% (1)

- Baking UpdateDokument2 SeitenBaking UpdateAchyut TripathiNoch keine Bewertungen

- Types of CakesDokument11 SeitenTypes of CakesJeff JamisolaNoch keine Bewertungen

- The Essential Guide To BakingDokument57 SeitenThe Essential Guide To BakingMohd Zulhakimi100% (1)

- Cereal Tech From CakesDokument48 SeitenCereal Tech From Cakesgrace mwenjeNoch keine Bewertungen

- Taste of Home Breads: 100 Oven-Fresh Loaves, Rolls, Biscuits and MoreVon EverandTaste of Home Breads: 100 Oven-Fresh Loaves, Rolls, Biscuits and MoreNoch keine Bewertungen

- Recipe Collection 77 PDFDokument5 SeitenRecipe Collection 77 PDFSal LieNoch keine Bewertungen

- Bakery Products and Rice MillingDokument19 SeitenBakery Products and Rice Millingabhishek.ajmaniNoch keine Bewertungen

- Springerle RecipesDokument45 SeitenSpringerle RecipesNicoleta RaducanuNoch keine Bewertungen

- Cakes Pies Pastries - LecDokument48 SeitenCakes Pies Pastries - LecGloria Le Thi Esquivel100% (1)

- E Portfolio Food4022Dokument19 SeitenE Portfolio Food4022FranNoch keine Bewertungen

- Second Quarter Handout Bread and Pastry ProductionDokument8 SeitenSecond Quarter Handout Bread and Pastry ProductionJeb PampliegaNoch keine Bewertungen

- Manufacturing Process of Food Grade PastriesDokument20 SeitenManufacturing Process of Food Grade PastriesMuneeb0% (1)

- Baking and PastriesDokument15 SeitenBaking and Pastriesapi-311077275Noch keine Bewertungen

- Pastry Puff MakingDokument80 SeitenPastry Puff MakingYip AlexNoch keine Bewertungen

- Baking Equipments and Their UsesDokument38 SeitenBaking Equipments and Their UsesWilkendrick CallanganNoch keine Bewertungen

- Ingredients: Classification of CakesDokument32 SeitenIngredients: Classification of CakesRheen Clarin100% (1)

- Factors That Contribute To Successful BakingDokument8 SeitenFactors That Contribute To Successful BakingErrol San Juan100% (1)

- Steps Involved in Cheese MakingDokument2 SeitenSteps Involved in Cheese MakingArunkumar KPNoch keine Bewertungen

- Types of Yeast DoughDokument7 SeitenTypes of Yeast DoughJoel MangallayNoch keine Bewertungen

- Basic Foods 2-YEAST BREADSDokument7 SeitenBasic Foods 2-YEAST BREADSBernadette YurongNoch keine Bewertungen

- Little Treats Donuts: Recipes for Glazed, Sprinkled & Jelly-Filled DelightsVon EverandLittle Treats Donuts: Recipes for Glazed, Sprinkled & Jelly-Filled DelightsNoch keine Bewertungen

- Creative Éclairs: Over 30 Fabulous Flavours & Easy Cake-Decorating Ideas for Choux Pastry CreationsVon EverandCreative Éclairs: Over 30 Fabulous Flavours & Easy Cake-Decorating Ideas for Choux Pastry CreationsNoch keine Bewertungen

- D 858 - 02 - Rdg1oaDokument8 SeitenD 858 - 02 - Rdg1oajamaljamal20Noch keine Bewertungen

- F 148 - 95 - Rje0oc05nqDokument2 SeitenF 148 - 95 - Rje0oc05nqjamaljamal20Noch keine Bewertungen

- Elements in Water by Direct-Current Plasma Atomic Emission SpectrosDokument7 SeitenElements in Water by Direct-Current Plasma Atomic Emission Spectrosjamaljamal20Noch keine Bewertungen

- D 2527 - 83 R01 - Rdi1mjcDokument2 SeitenD 2527 - 83 R01 - Rdi1mjcjamaljamal20Noch keine Bewertungen

- D 1331 - 89 R01 - RdezmzeDokument3 SeitenD 1331 - 89 R01 - Rdezmzejamaljamal20Noch keine Bewertungen

- D 726 - 94 R99 - Rdcyni05nfi5oqDokument3 SeitenD 726 - 94 R99 - Rdcyni05nfi5oqjamaljamal20Noch keine Bewertungen

- D 928 - 03 - Rdkyoc1sruqDokument3 SeitenD 928 - 03 - Rdkyoc1sruqjamaljamal20Noch keine Bewertungen

- D 3236 - 88 r99 - RdmymzytodhsotkDokument8 SeitenD 3236 - 88 r99 - Rdmymzytodhsotkjamaljamal20Noch keine Bewertungen

- D 2116 - 02 - RdixmtyDokument6 SeitenD 2116 - 02 - Rdixmtyjamaljamal20Noch keine Bewertungen

- D 1921 - 01 - Rde5mjeDokument5 SeitenD 1921 - 01 - Rde5mjejamaljamal20100% (1)

- Reviewer MathDokument6 SeitenReviewer MathLuna Ronquillo100% (1)

- Process Control Plan Excel TemplateDokument13 SeitenProcess Control Plan Excel TemplateTalal NajeebNoch keine Bewertungen

- Pedestrian Volume Studies: A Case Study in The City of GothenburgDokument80 SeitenPedestrian Volume Studies: A Case Study in The City of GothenburgPaula A. FigueroaNoch keine Bewertungen

- Failure Modes For Flooded & VRLA BatteriesDokument46 SeitenFailure Modes For Flooded & VRLA Batteriesazhagaan100% (1)

- Function Modules Available in MM & EWMDokument3 SeitenFunction Modules Available in MM & EWMgopalaaraoNoch keine Bewertungen

- Clinical Practice Guideline On Diagnosis and Treatment of Hyponatremia PDFDokument12 SeitenClinical Practice Guideline On Diagnosis and Treatment of Hyponatremia PDFLuis Mochas HClNoch keine Bewertungen

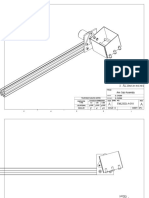

- Arm SubassemblyDokument4 SeitenArm Subassemblyapi-541897663Noch keine Bewertungen

- Guidelines On Water ProofingDokument88 SeitenGuidelines On Water ProofingViệt Đặng XuânNoch keine Bewertungen

- Viscosity MeasurementDokument8 SeitenViscosity MeasurementRian SteveNoch keine Bewertungen

- Datasheet en 20170526Dokument9 SeitenDatasheet en 20170526LODELBARRIO RDNoch keine Bewertungen

- Ap Computer Science A Course OverviewDokument2 SeitenAp Computer Science A Course Overviewbaojia chenNoch keine Bewertungen

- A Quick Route To Sums of PowersDokument6 SeitenA Quick Route To Sums of PowersJason WongNoch keine Bewertungen

- Training On Optical Fiber NetworkDokument96 SeitenTraining On Optical Fiber Networkpriyasingh1682100% (1)

- Mobile Communications: Chapter 4: Wireless Telecommunication SystemsDokument108 SeitenMobile Communications: Chapter 4: Wireless Telecommunication Systemsradislamy-1Noch keine Bewertungen

- Mark Scheme (Results) October 2020: Pearson Edexcel International Advanced Level in Core Mathematics C34 (WMA02) Paper 01Dokument29 SeitenMark Scheme (Results) October 2020: Pearson Edexcel International Advanced Level in Core Mathematics C34 (WMA02) Paper 01nonNoch keine Bewertungen

- 9011 VW Rebar Strainmeter (E)Dokument2 Seiten9011 VW Rebar Strainmeter (E)JasonNoch keine Bewertungen

- Operation & Maintenance: A160-Om-C-May15Dokument66 SeitenOperation & Maintenance: A160-Om-C-May15Thomas AliNoch keine Bewertungen

- Knitting GSM Calculations PDFDokument11 SeitenKnitting GSM Calculations PDFHifza khalidNoch keine Bewertungen

- Calflo Heat Transfer Fluids Tech DataDokument4 SeitenCalflo Heat Transfer Fluids Tech DataKhaled ElsayedNoch keine Bewertungen

- Boiler Efficiency R K JainDokument28 SeitenBoiler Efficiency R K JainPriyesh KumarNoch keine Bewertungen

- Strike RiskDokument4 SeitenStrike RiskAdilson Leite ProençaNoch keine Bewertungen

- Solids Induced Pack-Off Packing Off - First ActionsDokument4 SeitenSolids Induced Pack-Off Packing Off - First ActionsBhagwal TravelsNoch keine Bewertungen

- 1 Seam 2 LM FinalDokument84 Seiten1 Seam 2 LM FinalTrestan TenegraNoch keine Bewertungen

- Unit 9: Areas and PerimetersDokument22 SeitenUnit 9: Areas and PerimetersSanchit GargNoch keine Bewertungen

- QP NTSE Stage 1 2016 17 AndhraPradeshDokument27 SeitenQP NTSE Stage 1 2016 17 AndhraPradeshsudhir_narang_3Noch keine Bewertungen

- Detergents (Anionic Surfactants, MBAS)Dokument1 SeiteDetergents (Anionic Surfactants, MBAS)Anggun SaputriNoch keine Bewertungen

- Warrick 26m Control de Nivel AuxiliarDokument3 SeitenWarrick 26m Control de Nivel AuxiliarCarlos WayNoch keine Bewertungen

- Modeling of Reinforced Concrete BeamDokument28 SeitenModeling of Reinforced Concrete BeamNGUYEN89% (27)

- Flight Inspection of GAST D Approach and Taxi Guidance Systems - v1Dokument10 SeitenFlight Inspection of GAST D Approach and Taxi Guidance Systems - v1Olivier LaylyNoch keine Bewertungen

- Conic SectionDokument9 SeitenConic SectionJomana MacalnasNoch keine Bewertungen