Beruflich Dokumente

Kultur Dokumente

Specification For Park City-clubhouse-Rev 0

Hochgeladen von

ThatnguyentonOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Specification For Park City-clubhouse-Rev 0

Hochgeladen von

ThatnguyentonCopyright:

Verfügbare Formate

PROPOSED PARKCITY HANOI CLUBHOUSE AT LE TRONG TAN

STREET, HANOI, VIETNAM

Mechanical & Electrical Installation

Specification and Drawings

March 2015

THAM & WONG M&E (VIETNAM) CO., LTD

No.6, 2nd alley, Pham Tuan Tai street, Cau Giay District, Hanoi

Tel: +84 43748 0327

Fax: +84 43755 8903

PARKCITY

Clubhouse Facilities ParkCity at Le Trong Tan Ha Noi, Viet Nam

Mechanical & Electrical Specification Rev 0

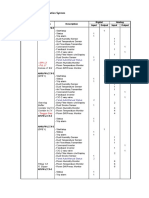

CONTENTS

Page

1.0

PROJECT TEAM ......................................................................................................................... 3

2.0

GENERAL REQUIREMENTS ..................................................................................................... 4

3.0

SCOPE OF WORK ....................................................................................................................22

4.0

RESPONSIBILITIES OF CONTRACTOR.................................................................................27

5.0

ELECTRICAL SERVICES .........................................................................................................29

6.0

AIR-CONDITIONING & MECHANICAL VENTILATION SERVICES .....................................142

7.0

PLUMBING & SANITARY.......................................................................................................191

8.0

FIRE PROTECTION SERVICES .............................................................................................212

9.0

SWIMMING POOL SERVICES ...............................................................................................242

10.0

SCHEDULE OF UNIT RATE ...................................................................................................258

11.0

SCHEDULES OF TECHNICAL DATA....................................................................................310

12.0

SCHEDULE OF SUB-CONTRACTOR ...................................................................................331

Tham & Wong M&E (Viet Nam)

Page 2

PARKCITY

1.0

Clubhouse Facilities ParkCity at Le Trong Tan Ha Noi, Viet Nam

Mechanical & Electrical Specification Rev 0

Project Team

Owner

Vietnam International Township Development

(Parkcity)

No.8, Quang Trung Road, Ha Dong - Hanoi, Vietnam

Tel

+84 4 3355 3366

Fax

+84 4 3355 3365

Architect

Archicentre (Vietnam) Co.,Ltd.

31 Phan Boi Chau Street, Ward 14, Binh Thanh District

Ho Chi Minh City, Viet Nam

Tel:

+603 5633 2455 / +84 83841 3883

Fax:

+603 5633 8213 / +84 83841 8516

Structural & Civil engineer

Tham & Wong VN Co.,Ltd.

th

4 Floor, Packsimex Building, No.52 Dong Du, District 1

Ho Chi Minh City, Viet Nam

Tel:

+84 8 3821 7737

Fax:

+84 8 3821 7736

M&E Consulting Engineer

Tham & Wong M&E (Vietnam) Co.,Ltd.

nd

No.06, 2 Alley, Pham Tuan Tai street, Cau Giay District

Ha Noi, Viet Nam

Tel:

+84 43748 0327

Fax:

+84 43755 8903

Landscape Designer

Site Concepts International (Vietnam) Company Limited

Landscape Architecture

9th Floor WMC Tower, 102 A-B-C Cong Quynh Street,

Pham Ngu Lao Ward, District 1, Ho Chi Minh City, Vietnam.

Tel:

(84) 8 3920 9895

Tham & Wong M&E (Viet Nam)

Jsc

Page 3

PARKCITY

2.0

Clubhouse Facilities ParkCity at Le Trong Tan Ha Noi, Viet Nam

Mechanical & Electrical Specification Rev 0

General Requirements

2.1 General

This Specification describes the standards, performance, materials, manufacture, supply,

installation, testing, commissioning, operation and maintenance of all systems described in

this document and shown on the Drawings.

The intent of the Contract is to provide for the completion in every detail of the Contract

Works, and unless otherwise stated, the Contractor shall furnish all labour, superintendence,

materials, tools, equipment, storage, permits, certificates, drawings, temporary work,

inspection, testing and all accessories, auxiliaries and incidentals necessary to complete the

Contract Works in a proper, safe, thorough and skilful manner to the satisfaction of the

Employer/Engineer.

2.2

Site of the Contract Works

The site is located as shown on the Tender Drawings.

2.3

Climatic Conditions

The Contractor is deemed to be familiar with climatic conditions prevailing in Vietnam and to

0

be aware of the high temperature (up to 40 C) and the high relative humidity.

The Contractor in submitting a tender will be assumed to warrant that all materials and items

of equipment are suitable for continued use and/or operation in the various climatic conditions

encountered.

2.4

Standards

The Contract Works shall fully comply with all statutory obligations and regulations together

with any amendments made thereto as required.

The Contractor shall arrange for all submissions, liaisons and pay the cost of all statutory

inspections and certificates. The payment to the Authorities shall be paid well in advance so

as to meet with the construction programme.

Where applicable, the Installation shall comply with the statutory obligations and regulations

and consistent with good practice in Singapore to satisfy the Engineers requirements.

Singapore Code of Practices;

British Standards Institution or other approved international standards;

Chartered Institution of Building Services Engineers;

Air Conditioning and Refrigeration Institute;

American Society of Heating, Refrigeration and Air Conditioning Engineers;

The Regulations for the Electrical Equipment of Buildings published by the Institution

of Electrical Engineers (London);

Environmental Protection Department;

Pollution Control and Drainage Act and Regulations;

Environmental Public Health Act and Regulations and Codes;

Building Control Act and Regulations;

Fire Safety Act and Regulations;

Factories Act and Regulations;

Public Utilities Act and Regulations;

Fire Precautions for Building;

Handbook on Energy Conservation in Building and Building Services;

Handbook on Application for Electricity Supply;

Code of Practice for Info-Communications Facilities in Buildings;

Tham & Wong M&E (Viet Nam)

Page 4

PARKCITY

Clubhouse Facilities ParkCity at Le Trong Tan Ha Noi, Viet Nam

Mechanical & Electrical Specification Rev 0

NPQS

Any other local authority having jurisdiction; and

All other requirements from Authorities having jurisdiction over the installation.

Viet Nam Standard

The work shall be carried out by a registered Licensed Worker approved by the relevant

authority for each particular category of work. The Contractor shall submit for approval the

following within one month of award of Contract for approval:

Licensed Water Service Plumber

Sanitary/Sewerage Registered Licensed Plumber

Licensed Electrical Worker

Where the materials or equipment offered comply with other standards, the

Contractor shall demonstrate they meet the requirements of the Specification and details shall

be provided to the Architect for approval.

The Contractor shall provide and perform all necessary inspections and maintain quality and

workmanship in his works to ensure compliance with the Specification.

2.5

Building Provisions

Certain provisions will be made in the existing Building for the accommodation of the Contract

Works. These provisions shall include space allocation, holes / openings through structural

slabs, walls and beams, plant bases, inserts etc. The modified building layout incorporating

basic M&E Installations are shown in the tender Documents.

The Contractor shall provide comprehensive builders work requirements for approval prior to

the execution of works. It shall be the Contractors responsibility to ensure that all the

required holes/openings and inserts and their setting out dimensions are incorporated in the

structure prior to the formation of openings. Where additional holes/openings are required

after concrete has been poured, such holes shall be provided at the Contractors expense,

unless they are covered on a duly authorized basis by the Employer on an instruction issued

by the Engineer. The Contractor shall also be responsible to ensure that these holes are

correctly reserved and protected during construction. The floor and wall openings shall be

provided by the Contractor. The Contractor shall take the responsibility to ensure the opening

is technically sound and approved by their employed structural engineers if necessary.

Infill and repairs around openings in the building structure for the passage of building services

shall be carried out by the Contractor. Where pipes and services pass through walls, floors,

etc.(including floors in ducts), the Contractor shall provide pipe sleeves and in fill between the

sleeves and pipe/services.

Concrete bases and/or foundations required for the support or anchoring of equipment shall

be provided by the Contractor except where otherwise specified. The Contractor shall provide

the dimensions and locations for all bases to be provided or set in the structure. The

Contractor shall furnish the bolts to the Builder for setting the bolts in position. Anchor bolts in

concrete bases shall be securely fixed in position before concrete is poured. Templates shall

be furnished by the Contractor.

All structural and supporting steelwork required for the installation of the Contract Works shall

be supplied and fixed by the Contractor, except otherwise specified.

Tham & Wong M&E (Viet Nam)

Page 5

PARKCITY

2.6

Clubhouse Facilities ParkCity at Le Trong Tan Ha Noi, Viet Nam

Mechanical & Electrical Specification Rev 0

Limited Access

The Contractor shall note the limited access available in ceilings, pipe and duct shafts.

All cables busbars, duct work and pipework should be installed in the correct sequence to

ensure that all services shall be accommodated. Where works by other trades are to occupy

the same pipe and duct space, care must be taken to leave clear access for sequential or

future provision of these services within builders work shafts, plant rooms and false ceilings,

etc.

2.7

Co-ordination Between Trades

The acquisition and checking of all documents and drawings from the Engineer to be provided

under the Contract and to ensure the compatible integration of all the work. Such coordination shall include recommending to the Engineer for approval design solutions to

eliminate any conflict between elements of the work, and to provide adequate space between

elements of the work for subsequent maintenance of the various installations in accordance

with good practice.

All checking, co-ordination and where necessary proposal to overcome conflicts in

accordance with the above shall be executed well in advance of the programme for carrying

out the works.

The provision of co-ordinated working drawings incorporating all design solutions approved by

the Engineer and showing the integration of all services to be executed by the Contractor.

The establishment of a detailed sequence of work to enable the expeditious completion of the

Works. The Contractor shall closely monitor the work progress and conflicts resolved in an

expeditious manner.

Liaison and co-ordination of works upon receipt of site instruction by the Engineer throughout

the duration of the Contract.

Co-ordination of government submission, testing and inspection of various building services

works in a timely manner to comply with building construction programme and building

occupation requirements.

Liaison and co-ordination regarding training requirements to be provided to the Employer and

handing over of the building services systems. Particular emphasis shall be given to the coordination of testing of various building services systems which require interface between

different Contracts. Testing and commissioning shall be carried out within the Contract

Period and only by agreement will the Engineer allow certain tests to be carried out within the

Defects Liability Period.

Receipt of lists of defects/outstanding work and liaise with the Builder for the rectification of

defects within the Defects Liability Period. Co-ordination is deemed to include liaison for

access and the ensure that rectification work is carried out in a expeditious manner.

2.8

Metric Units

The Contractor shall provide all information, drawings, manufacturers data and materials in

metric (S.I.) units and dimensions or include a conversion table which must be printed on or

within data sheets produced by the manufacturers.

Separate locally produced, e.g. duplicated typed conversions or conversion tables within the

written offer will not be acceptable.

2.9

Notations

Tham & Wong M&E (Viet Nam)

Page 6

PARKCITY

Clubhouse Facilities ParkCity at Le Trong Tan Ha Noi, Viet Nam

Mechanical & Electrical Specification Rev 0

Notations and symbols used throughout the tender documents area as listed on the

abbreviations and symbols sheet of the Drawings.

All other notations used shall have their normally accepted meaning and where any doubt or

ambiguity is found, then the Contractor must seek clarification in writing form the Engineer at

the time of tender

2.10

Submissions

Unless otherwise stated, all submissions to the Engineer for approval must be made at the

times stated in the various Sections of this Specification. For material/ equipment submission,

detail form of submission information and statement of compliance with this specification shall

be provided for checking.

All submissions must be made early enough in the Contract to enable the Engineer to fully

check each item prior to giving approval. The Contractor shall ensure that submissions are

made at least two months before any equipment is required to be ordered to meet the

Builders contracts construction programme.

The Contractor shall supply full drawings of all equipment to a scale suitable for the fullest

understanding by the Engineer of the design details but in any event not less than a scale of

1:50, within the time required by the Engineer that they may be incorporated into other

elements of works and as instructed by the Engineer, together with the fullest particulars and

details of positions where power for any elements is required.

The Contractor shall be responsible for ensuring that the works are carried out in strict

accordance with the distributed working drawings.

A schedule of submissions for individual, working drawings and equipment shall be submitted

for checking within one week after award of Contract.

Drawings showing locations of structural openings for services shall be submitted for

consideration at least one month prior to erection of formwork or reinforcement at the affected

area.

No claims for extensions of time or additional costs shall be entertained as a result of the

Contractors failure to make submissions in adequate time.

If, in the opinion of the Engineer, the Contractors failure to make his submissions in adequate

time may result in a delay in the completion of the project as a whole, then the Engineer shall

have the authority to instruct the Contractor to order materials and or equipment from a

source approved and nominated by the Engineer at no increase to the Contract Sum.

If the Contractor subsequently fails to place such orders within a period of two weeks from

receipt of the Engineers instruction, then the Employer shall have the right at his sole

discretion to order the materials and/or equipment directly from the manufacturer(s). The cost

of all such orders, including freight, shipping, insurance, handling and administrative charges

shall be deducted from the Contract Sum or recovered in any other method at the discretion

of the Employer.

The Contractor shall on request, or where specified elsewhere, submit to the Engineer

samples of materials and/or workmanship. Such samples shall be approved in writing before

the appropriate equipment or installation work is carried out.

Such samples shall be retained by the Engineer as the criteria of the workmanship or material

to be supplied and any items not so complying may forthwith be rejected by the Engineer and

shall be replaced by the Contractor without increase to the Contract Sum.

Tham & Wong M&E (Viet Nam)

Page 7

PARKCITY

2.11

Clubhouse Facilities ParkCity at Le Trong Tan Ha Noi, Viet Nam

Mechanical & Electrical Specification Rev 0

Sizes of Plant and Equipment

The Contractor shall be required to demonstrate that the duties required of the equipment by

the Specification are attainable by the Contractors proposed plant or equipment.

Physical sizes of all plant and equipment are to be suitable for the spaces allocated for the

accommodation of such plant and equipment, taking into account the requirement of access

for maintenance purposes.

Before ordering equipment, the Contractor shall provide the Engineer with full details of the

weights of the equipment for purposes of determining floor loadings, etc.

2.12

Makes and Types of Equipment

The Contract has been drawn up in such a manner as to allow firms tendering to submit

proposals incorporating their particular types of equipment and installation techniques while at

the same time ensuring that that building services comply fully with the basic requirements

and fit into the Building, having regard to the Engineering and planning requirements and to

the provisions which are being arranged in the structure for the accommodation of the

Contract Works.

The Employer reserves the right to reject any tender which disregards the basic requirements

or intentions of this Contract, or which seeks to vary the scope of the Contract Works, the

Contract Conditions or any other requirements of the Tender Documents.

In selecting makes and types of equipment, the Contractor shall ascertain that facilities for

proper maintenance, repair and replacement can be provided without such a delay as could

cause inconvenience or loss to the Employer.

2.13

Working Drawings

The Contractor is to note that the contract Drawings issued for the installation indicated the

general design intent. The Contractor shall be responsible for the preparation and coordinating his working drawings with the services installations of other trades and with the

fabric and the building structure, and for co-ordinating working drawings to facilitate coordination of the installation of all services in the correct sequence and position. All working

drawings must be submitted to the Engineer and his confirmation must be obtained that such

drawings comply with design intent prior to execution of the respective building services

installation works. Co-ordination working drawings shall be submitted at the same time as the

individual services working drawings to allow the Engineer to satisfy himself that co-ordination

of the Works has been implemented.

These drawings shall be based on the Contract Drawings and shall take into account any

modification either to the Building or to the installation which may have taken place during the

course of the works and shall be correctly related to the details of the actual items of plant

and equipment installed.

The Contractor shall prepare all equipment schedules and all necessary wiring diagrams,

including internal wiring diagrams for items of electrical equipment and diagrams showing the

interconnections and interface between different equipment and services.

Five copies of all such drawings, schedules, diagrams, shall be submitted to the Engineer for

approval before any work is commenced. After receiving written approval, six copies of all

stamped approved drawings, schedules, shall be supplied by the Contractor, free of charge,

for distribution.

The Contractor is to allow in his programme for amendment and/or resubmission of drawings

and schedules to the Engineer and this time shall include the periods necessary for coordinating with the Builder and other Contractors for the preparation of the aforesaid drawings

Tham & Wong M&E (Viet Nam)

Page 8

PARKCITY

Clubhouse Facilities ParkCity at Le Trong Tan Ha Noi, Viet Nam

Mechanical & Electrical Specification Rev 0

and schedules and periods required by the Engineer for checking same. The Engineer shall

endeavour to reply to the contractors Submissions within in a period of 2 weeks.

No claim will be entertained nor extension of time be granted arising out of any amendment or

resubmission required.

The Contractor shall be fully responsible for updating the installation drawings based on any

changes to the general plans which may from time to time be required.

Checking of working drawings by the Engineer shall not relieve the Contractor of his

responsibility for the technical, dimensional and co-ordination content of these working

drawings, in accordance with the Engineers design drawings and specification and in

observation of all relevant standards, codes and ordinances whether referred to in the

specification or of a statutory nature.

2.14

Builders Work Drawings

The Contractor shall submit to the Engineer for approval and subsequent distribution showing

details for all builders work required in connection with installation of all services.

In case where preliminary builders work information has already been given on the Drawings,

such information is to be checked and verified by the Contractor for incorporation in his own

drawings.

It is the intention that all holes, inserts and chases, shall be incorporated within the structural

work as it proceeds and not cut out subsequently, except in so far as may be necessary due

to subsequent authorized variations to the Contract Works.

The Contractor shall acquaint himself throughout the period of the Builder Works with the

Builders detailed construction programme and shall prepare the builders work drawings in

such order and at such times as to enable them to be checked and approved and

subsequently issued to the Builder not less than four weeks before the actual construction is

planned to take place.

No claims will be entertained in respect to additional holes, inserts and chases, that may be

required after the structure has been erected unless these are necessary due to authorized

variations to the Contract Works.

2.15

Maintenance and Operation Manual

Prior to the issuance of the Completion Certificate, the Contractor shall submit in triplicate full

operation and service and maintenance manuals for the complete installation.

These manuals shall be typed on good quality paper and neatly bound into a manual having

rigid covers with good lettering, giving the names of the Employer, Project and M&E Contract

and approximate date of completion. A sample shall be submitted to the Architect for

approval before final submission.

Tham & Wong M&E (Viet Nam)

Page 9

PARKCITY

Clubhouse Facilities ParkCity at Le Trong Tan Ha Noi, Viet Nam

Mechanical & Electrical Specification Rev 0

The manuals shall contain and be set out as follows :

Section 1

Maintenance Personnel

List to include name, address, fax and telephone number for normal and

emergency use separately.

Section 2

System Summary & General Description & Operating Instruction

Each system, separately, shall commence with the relevant Design Criteria,

comprehensive functional description of equipment.

Instructions for operating each items of plant, including adjustment of

controls, etc

Section 3

Emergency/Re-Start Instructions

Each items of plant to be listed in the same order as for Section 2.

Instructions to procedures after a fault, and for Plant production.

Section 4

Equipment List & Schedules & Manufacturers Literatures & Spare Parts

Include manufacturers' and suppliers' contact and serial numbers.

Literature clearly designating the relevant item(s) of equipment, including

detailed specification. Order as per Section 2, each with its own sub-file

divider. Catalogue listing, including source of supply.

Section 5

Maintenance Schedules & Maintenance Instructions

Proforma copy detailed schedules of periodic checks and maintenance and

replacement procedures.

Include description of each items of equipment or component in order as per

Section 2 listing, and with a complete phases and procedures preventative

maintenance.

Section 6

Commissioning Data

Include schedule of control and cut-out settings, copies of test certificates

and progressive test data obtained during construction and installation.

Section 7

Guarantee, Liabilities, Warranties

Section 8

Drawings

List all working drawings produced for the works.

Note:

2.16

In order that each set of volumes for each of the M&E installations are uniform, where

one of these sections is not relevant to a particular Service, the Contractor shall note

against that section in the main index: "Not Applicable".

As-Built Drawings

Upon completion of the M&E Contract Works and as a condition precedent to the certification

that the work is complete, the Contractor shall furnish to the Engineer one set of reproducible

Tham & Wong M&E (Viet Nam)

Page 10

PARKCITY

Clubhouse Facilities ParkCity at Le Trong Tan Ha Noi, Viet Nam

Mechanical & Electrical Specification Rev 0

transparencies and two sets of prints and one set of electronic files in CD Rom and in such

detail as to enable the employer to maintain, dismantle, reassemble and adjust all parts of the

M&E Contract Works. The As-built drawings must be drawn in a format that is suitable for

submission to all relevant Authorities and FSB in particular.

a)

As-built drawings may be folded and accommodated in the Operating and

Maintenance Manual if appropriate.

b)

As-built drawings should include a diagrammatic layout of the complete installation

with major items of plant suitably referenced to the schedules and combined services

drawing.

c)

A set of the as-built drawings should be provided for each copy of the Operating &

Maintenance Manual required to be provided. In addition, one set of AutoCAD soft

copy burned in CD-ROM/DVD should be provided.

The as-built drawings shall comprise the following:A)

Electrical Installation

1.

1.

2.

3.

4.

5.

6.

7.

B)

Air-Conditioning and Mechanical Ventilation Installation

1.

2.

3.

4.

5.

6.

7.

C)

Lighting layout plan and lighting control layout plan (including surface and

concealed cable, trunking/conduit routes on floor, wall and ceiling).

Power layout plan (same as above).

Telephone layout plan (same as above).

Data outlet layout plan (same as above).

Security layout plan (same as above).

Main single line diagram.

Switchboards, sub-switchboards, distribution boards, consumer units single

line diagram, general arrangement.

Schematic diagram for various systems like Telephone System, Cable TV

System, Security System, Audio / Video Colour Intercom System, etc.

Technical data/equipment schedule and brand of all A/C equipment and MV

fans.

A/C layout plan include any concealed pipings and conduits clearly

demarketed on plan and elevation. The cooling capacity of each system/

outlet to be indicated.

MV layout showing ductwork sizes, air quantity, guide-vane control and

accessories.

Control panels location, size and circuit diagrams.

Details of all equipment, model and capacity.

Schematic diagram.

Operational procedure of selected equipment clearly indicated.

Sanitary and Drainage Installation

1.

2.

3.

4.

5.

6.

7.

8.

Inspection chamber c/w pipework connection and gradient, all invert and top

levels indicated.

Sanitary pipework layout plan, including sump pump detail (if any)

All models of sanitary fittings: wc, basin, sink, shower, tap, etc.

Soil waste pipe and vent pipe riser duct details.

Schematic diagram of sanitary installation.

Catalogues of all sanitary wares (where applicable), pipes and pipe-fittings.

Operational procedure of selected equipment clearly indicating the model and

capacity.

Control panels location, size and circuit diagrams.

Tham & Wong M&E (Viet Nam)

Page 11

PARKCITY

9.

D)

connection and gradient, all invert & top levels

Water Supply Installation

1.

2.

3.

4.

5.

6.

7.

2.17

Manhole c/w pipework

indicated

Clubhouse Facilities ParkCity at Le Trong Tan Ha Noi, Viet Nam

Mechanical & Electrical Specification Rev 0

Water reticulation layout plans.

Detail for Water meter kiosk layout, pump and tank

Schematic diagram.of Cold and Hot water supply systems

Operation procedure of pump, electric water storage heaters.

Control panels location, size and circuit diagrams.

Valve chamber c/w pipe work connection, all invert & top levels

Detail of bulk water meter c/w valve chamber

As-new Condition

At the time of hand over of the Contract Works, the whole installation shall be in as-new

condition. The Contractor shall, during the course of the Contract, protect all plant and

equipment, and shall restore/repaint as necessary before completion of the Contract.

2.18

Guarantee

The Contractor in providing a specified piece of equipment or apparatus, whether specified

herein by name or whether of a make selected by the Contractor, shall be deemed to warrant

its satisfactory performance under all working conditions which may be encountered.

Unless otherwise stated in this Specification, the Contractors guarantee for the Contract

Works shall extend for a period of one year from the expiration of the Defects Liability Period

or the date of issue of the Certificate of Making Good Defects whichever is the later for the

Contract Works.

In the event that any manufacturers guarantees are still within their term of validity at the end

of the Guarantee Period, then all such manufacturers guarantees shall be assigned to the

Employer.

All subsequent rights under the manufacturers guarantees shall be the

Employers.

In the event of anything described in the Specification or shown in the Drawings being, in the

Contractors opinion, unsuitable or inconsistent with his guarantee or responsibilities, the

Contractor shall draw attention to such items at the time of tendering.

Neither the time limit imposed on the Contractors guarantee, nor the Certificate of Making

Good Defects issued by the Engineer, nor the acceptance of the installation by the Employer,

nor the approval by the Engineer of any material or method shall in any way absolve the

Contractor from his responsibility for any latent defects in the Contract Works which may

become apparent in the future and which are, in the opinion of the Engineer, due to the

Contractors failure to use materials and methods complying to this Specification and

Drawings.

2.19

Materials and Workmanship

All materials supplied and work carried out shall be the best of their respective kinds and to

the approval of the Engineer. All materials and work shall comply with British Standards

where available.

No substitution for approved materials will be permitted except by permission of the Engineer

in writing. Any cost savings which result from such substitution shall be credited in full to the

Employer. Any extra costs incurred shall be borne in full by the Contractor.

Tham & Wong M&E (Viet Nam)

Page 12

PARKCITY

Clubhouse Facilities ParkCity at Le Trong Tan Ha Noi, Viet Nam

Mechanical & Electrical Specification Rev 0

The phase or other Approved is deemed to be included whenever materials are specified by

proprietary name. Materials of different manufacture but of equal quality may be substituted if

prior Approval has been obtained but the rates and prices will not be changed from those

submitted at the time of tender.

The standard of equal quality, together with consideration of design suitability and

appearance, will be strictly applied and the Contractor will be required to pay for independent

testing to demonstrate equal quality prior to seeking Approval for any alternative to the

proprietary brand specified.

Where a choice of manufacturer is permitted for any material, advise the Engineer of that

choice early enough to allow deliveries to be arranged in compliance with the construction

programme. No change in the source of supply will be approved after deliveries have

commenced.

2.20

Rejection of Unsuitable Materials

The Engineer shall be at liberty to reject any plant, materials and workmanship not complying

with the requirements of this Specification or which are in any way unsuitable and to order

their removal and replacement, without increase to the Contract Sum.

The Engineers decision as to what constitutes compliance with requirements and suitability

shall be final and binding; the true intent and meaning of the Contract being that the whole of

the Contract Works shall be completed to the satisfaction of the Engineer.

No rejected item shall be considered as a reason for failure to meet the completion date of the

project.

2.21

Packing and Protection

All plant, equipment, apparatus, materials and parts shall be delivered to the Site in a new

condition, properly packed and protected against damage due to handling, adverse weather

or other circumstances, and as far as practicable, they shall be kept in the packing cases or

under protective coverings until required for use.

Any items suffering damage in transit or on the Site shall be rejected and replaced without

extra cost to the Employer.

No item so rejected will be considered as a reason for failure to meet the completion date of

the project.

2.22

Vesting of Plant and Equipment

The Contractor shall take reasonable measures to avoid damage, loss, etc., of material, plant

or equipment to be incorporated in the completed Building during the progress of the Works.

2.23

Samples

The Contractor shall on request or where specified elsewhere submit to the Engineer samples

of materials and/or workmanship and such samples shall be approved in writing before the

appropriate equipment or installation work is carried out.

Such samples are subsequently to be retained by the Engineer as the criteria of the standard

of the workmanship or material to be supplied and any items not so complying may forthwith

be rejected by the Engineer and shall be replaced by the Contractor without increase to the

Contract Sum.

Tham & Wong M&E (Viet Nam)

Page 13

PARKCITY

2.24

Clubhouse Facilities ParkCity at Le Trong Tan Ha Noi, Viet Nam

Mechanical & Electrical Specification Rev 0

Silence of Operation

The Contract Works as installed shall be reasonably silent in operation having regard to the

conditions under and locations in which they will be called upon to operate.

The Contractor shall take all necessary steps to ensure that the equipment supplied by him is

silent as specified and shall include for such sound absorbing, or anti-vibration, material or

devices as are necessary to ensure a satisfactory degree of silence and absence of vibration

in the structure of the Building.

The Engineers decision as to what constitutes satisfaction in this respect shall be final.

If on completion the system is not, in the Engineers opinion, sufficiently silent, the Contractor

shall, without additional charge, carry out such modifications or additions as may be required,

until the system is made silent to the Engineers satisfaction.

Octave band sound pressure levels in the various areas within the building and at certain

positions outside the building due to the operation of the equipment included in this Contract

shall not exceed the noise level ratings as set down from Government Authorities.

2.25

Storage and Delivery of Equipment

The Contractor shall, arrange storage and delivery of the equipment to suit the progress of

the Works.

Storage areas and siting together with routing to and from such storage areas of heavy

equipment on Site in relation to structural loading restriction shall be submitted to the

Engineer for approval.

2.26

Contractors Programme

The Contractor shall provide a bar chart programme giving realistic schedules or working

periods to conform to the construction Programme for the Contract Works.

The bar chart programme shall indicate how the various activities will be scheduled in order to

complete the Contract Works within the Contract Period.

Activities included in the Contractors programme shall take account of, without limitation, the

following :

Submission for approval of all equipment;

Ordering of equipment;

Manufacture of equipment;

Delivery of equipment;

Installation of equipment and plants;

Submission to and inspection by Authorities;

Testing, balancing and commissioning;

Submission of As Installed Drawings, operating, Maintenance Manuals and

maintenance programme.

The above list is indicative but not exhaustive of all factors required.

Tham & Wong M&E (Viet Nam)

Page 14

PARKCITY

2.27

Clubhouse Facilities ParkCity at Le Trong Tan Ha Noi, Viet Nam

Mechanical & Electrical Specification Rev 0

Origin of Materials

The Contractor shall produce documentary evidence to verify the place of origin for the

materials delivered to site or installed. Such documentary evidence shall be in the form of

purchase orders to, and shipment/delivery orders or produce certificates from the

manufacturers or the manufacturers agents in Singapore. The materials or the works

employing such materials will not be certified for payment until the required evidence has

been produced to the satisfaction of the Engineer. The Tenderer shall indicate in the

Schedule of Information Supplied by the Tenderers the place of origin of the materials being

offered at the time of tendering.

2.28

Electricity Supply

Unless otherwise specified, the complete electrical installation shall be suitable for operation

under the supply system with nominal frequency of 50Hz and nominal voltage of 400V, 3

phases and 230V, single phase within the variation limits as declared by Authority.

2.29

Radio and Television Interference

All electrically operated equipment used by the Contractor for the execution of the works shall

where applicable have suppressors fitted to prevent interference with radio, television in use

in the neighbourhood.

The above applies equally to all new items of equipment supplied and fixed by the Contractor.

Means of suppression shall comply with B.S. 800. Equipment and materials used in

determining the level of interference shall be in accordance with B.S. 727.

Reference shall also be made to B.S. CP1006 for further guidance in order to meet the

specified standards.

2.30

Calculations

The Contractor shall supply all calculations as may be required by the Engineer. Calculations

shall be submitted in triplicate, and shall be based on equipment selected and offered by the

Contractor.

The checking of calculations for compliance with Design Intent, shall not relieve the

Contractor from his responsibility or necessity of furnishing material or performing work as

required by this Specification and/or Drawings.

2.31

Safety Precautions

The Contractor shall arrange for the provision of industrial safety helmets to B.S. 2826 for the

use of all his personnel on site, including supervision staff.

The Contractor shall ensure that helmets are worn, when necessary by all his personnel on

site.

The Contractor shall be responsible for ensuring that all works are carried out in a safe

manner.

2.32

Testing and Commissioning

After having satisfied himself of the performance of the installation, the Contractor shall

demonstrate to the satisfaction of the Engineer that the installation or part thereof as the case

may be, complies with all the requirements of the Specification.

Tham & Wong M&E (Viet Nam)

Page 15

PARKCITY

Clubhouse Facilities ParkCity at Le Trong Tan Ha Noi, Viet Nam

Mechanical & Electrical Specification Rev 0

The Contractor shall provide all necessary facilities and instruments for the witnessing and

checking of such tests, but this shall not relieve the Contractor of his responsibility for testing

and satisfying himself of the adequacy of the installation before hand.

The Contractor shall make complete records of the tests as carried out and when the tests

have been successfully completed, he shall provide the Engineer with test records in triplicate

on a form to be agreed upon.

All tests shall be carried out at the direction of the Engineer.

Should the test results indicate that the plant or equipment is not functioning in a satisfactory

manner or complying with the requirements of the Specification, the Contractor shall carry out

at his own expense any alteration, replacement or adjustment as may be required to correct

the faulty work. The Engineers decision as to what constitutes a satisfactory test shall be

final.

All the equipment and systems shall be examined and tested after completion of the

installation work.

The Contractor shall furnish the Engineer with copies, in triplicate, of test certificates in

respect of all plant, equipment, materials and accessories showing compliance with tests to

British or any other comparable and acceptable standards, manufacturers instruction,

applicable insurance company or Governments requirements, and with any additional tests

specifically called for herein.

The Contractor shall be responsible for and bear all the costs in connection with any

inspection, tests and permits for the installation and shall make such tests as are called for by

any regulations or authorities. These tests shall be made in the presence of the authorized

representative of any such authority. The Employer may permit the Contractor to make use

of the permanent facilities from the utility companies to perform functional checks, and

commissioning tests on the plumbing & drainage equipment, provided that:

All plant & equipment are maintained, to as-new condition at the time of handing over of the

installation.

Should there be any damage to any part of the installation, the Contractor shall undertake to

repair and replace all damaged parts/components to the satisfaction of the Engineer.

In particular, the Contractor shall note that all equipment for the use of future tenants shall be

fully commissioned prior to hand over that is to say,

All equipment/fittings shall be made to work to demonstrate that they are fully functional after

installation.

All Protection Installation and distribution equipment shall be tested for full performance.

The Engineer shall be entitled at all reasonable times during manufacture to inspect,

examine, and test on the Contractors premises the materials and workmanship of all

equipment to be supplied under the Contract. Such inspection, examination, or testing, if

made, shall not release the Contractors from any obligation under the Contract. All costs

shall be borne by the Contractor.

At least two months prior to testing or commissioning any system, the Contractor shall furnish

the following information for each system or process to the Engineer for approval:

Type of instruments to be used;

Manufacturer of instruments;

Calibration methods for instruments;

Operating instruction for instruments;

Tham & Wong M&E (Viet Nam)

Page 16

PARKCITY

Clubhouse Facilities ParkCity at Le Trong Tan Ha Noi, Viet Nam

Mechanical & Electrical Specification Rev 0

Accuracy and tolerances of instruments;

Proposed formats for testing and commissioning reports; and

Complete schedule and programme of all testing and commissioning activities.

All plant, materials and systems shall be tested, balanced and commissioned as specified in

the Commissioning and Testing Section of this specification.

All testing, balancing and commissioning procedures and documentation shall be approved

by the Engineer prior to commencement. Four sets of all documents shall be provided for

record purposes.

All instruments shall have been recalibrated within six months of the start of commissioning or

testing.

Calibration of all instruments shall be certified by the instruments manufacturer or an

approved calibration agency.

2.33

Period of Notice

A minimum of seven days notice shall be given to the Engineer before all testing and

commissioning operations commence.

A minimum of four weeks notice shall be given in the case of factory tests on major plant.

2.34

Employers Instruction

The Contractor shall include in the Tender a minimum period of one month for giving

instructions training to the Employer regarding the operational details and maintenance

requirements of the plants and equipment to be installed in this Contract. During this period,

a full time engineer shall be assigned to co-ordinate training for the Employer. Training shall

consist of work sessions to explain in details the installation followed by site training on the

actual operation and maintenance of equipment.

The Contractor shall allow in the Tender for operating all plant and equipment on behalf of the

Employer for One (1) month following issue of the Certificate of Practical Completion.

2.35

Free Maintenance and Service

Apart from his contractual responsibilities for making good inherent defects, the Contractor

shall furnish maintenance service free of charge on the entire equipment supplied and

installed under this Contractor from the completion of the installation under this Contractor,

until twelve months after the Practical Completion of whole of the Works. Maintenance shall

include systematic and periodical examination, adjustment and lubrication of all equipment,

details of which shall be submitted to the Engineer for approval.

During this Free Maintenance and Service period, the Contractor shall also repair or replace

electrical and mechanical parts of the equipment wherever this is required and shall be only

genuine standard parts produced by the manufacturer of the equipment concerned. In the

case if standard parts being not readily available, a substitute may be accepted for

emergency use but must be replaced with the standard part as soon as possible all at the

Contractors expense. Renewals or repair necessitated by reason of negligence or misuse of

the equipment, or by reason of any other cause beyond the control of the Contractor, except

ordinary wear and tear, shall not be the responsibility of the Contractor.

All works under this maintenance provision shall be performed by competent personnel under

the supervision and in the direct employ of the Contractor. At the end of the free maintenance

period, a further test will carried out by the Contractor on the plant in the presence of the

Employers representatives, and any defects shall be rectified by the Contractor without

charge, to the satisfaction of the Engineer, as part of his normal contractual obligation.

Tham & Wong M&E (Viet Nam)

Page 17

PARKCITY

2.36

Clubhouse Facilities ParkCity at Le Trong Tan Ha Noi, Viet Nam

Mechanical & Electrical Specification Rev 0

Spare Items

The Contractor is required to guarantee that sufficient spare items of the specified materials

and goods are available to allow for the timely replacement of any defective ones during the

free maintenance period.

2.37

Maintenance Contract

The Contract shall submit with his tender the yearly cost and terms for the periodical

inspection, testing maintenance and repair of the whole installation and equipment to be

installed under this Contract for 3 years after the first twelve months of free maintenance.

2.38

Contractors Management and Site Organisation

The Contractor shall provide an experienced and fully qualified management team under the

overall direction and co-ordination of the Contractors Project Manager. The site organisation

shall include a competent Site Engineer, together with the necessary back-up technical staff

to supervise the work and to undertake co-ordination duties with the Engineer.

The Project Manager and site engineer shall be English and Mandarin speaking. The

management organisation and principle staff shall be provided to the satisfaction and

approval of the Employer and the Engineer.

The Project Manager shall be fully responsible for the timely completion of the entire Works to

the quality and the standards specified. He shall be a corporate member of a recognised

professional institute and must have a well demonstrated record in project management of

satisfactorily completed commercial rise projects. He shall be supported by an extensive

back up team to the satisfaction of the Engineer to ensure that the project is managed in a

comprehensive and orderly fashion.

The Contractor shall engage sufficient qualified and experienced site staff to execute the

Contractor Works. Registered and licensed trades person shall be employed and under the

direct employment of the Contractor and they shall be full time on site to supervise the works.

When requested by the Architect, sufficient draughtsmen shall be kept on site to facilitate

prompt preparation and issuance of shop drawings.

The Site Engineer shall be constantly on the Works responsible to the Project Manager for

the timely completion to the specified quality and standards. The Site Engineer is to be

exclusively employed for this Contract and is to be constantly upon the Works from

commencement of Works until the end of the Defect Liability Period.

2.39

Method Statements

Prepare and submit method statements for enabling works, installation,

commissioning, operation, demonstration, training and hand over procedures.

2.40

testing,

Certification and Approval

The Contractor shall be responsible for all technical submission, applications and liaison with

government departments and supply authorities, whether they are new submission or

following up of previous submission already made. The Contractor shall be responsible for

obtaining all the necessary approvals and certificates for his installation and payments

(excluding meter deposit, if any) for his applications.

2.41

Design Requirement and System Description

The contractor shall supply, deliver, install, test and set into perfect operating condition the

automatic fire protection and fire alarm system required for the above premises as shown in

Tham & Wong M&E (Viet Nam)

Page 18

PARKCITY

Clubhouse Facilities ParkCity at Le Trong Tan Ha Noi, Viet Nam

Mechanical & Electrical Specification Rev 0

the drawing. All equipment selected shall be of equivalent or higher standard to the existing

installation.

The Contractors particular attention is drawn to the items listed in this clause which will

involve in design, specification and/or selection of items based on such designs and

specification.

The selection of manufacturers or suppliers, equipment, plant, components or materials

against the requirement specified herein shall not be deemed to be the design or specification

by the Contractor under this clause.

The production of shop drawing by the Contractor for construction purpose shall not be

deemed to be the design or specification by the Contractor under this clause.

The items which will involve the Contractor in design or specification are as listed below:

a. Supporting systems including brackets, suspension rods, fixing methods including

builders work bases as necessary to support and secure the complete installation forming

the Works.

b. Modifications as necessary to designs indicated on the Contract Drawings to incorporate

the specific items of plant and equipment and components selected to meet the

requirements as specified herein.

c.

Adjustments to plant and equipment to allow for deviations between specified

requirements or data and details of items selected for incorporation into the Works.

d. Obtaining the Engineers prior approval on the equipment appearance, colour, finish and

method of installation for those equipment exposed in the lobbies/corridors/shop etc.

2.42

Performance Guarantee

The system schematic, layout and the equipment data in the technical schedules is meant as

guide. The Contractor shall be solely responsible for the complete design, supply, and

installation of a complete operable system and shall guarantee the performance to meet the

conditional criteria.

2.43

M&E Painting, Colour Coding and Labelling

General

Except where otherwise specified the external surfaces of all conduits, apparatus, equipment,

fittings and services including supports, hangers and brackets shall be painted.

All sheet metal control cabinets, switchboards and distribution board enclosures and similar

shall be painted internally and externally.

All surfaces are to be painted and shall be cleaned, prime coated, undercoated and then

finished with two finishing coats. Each coating (including priming, undercoating and the first

finishing coat) shall be allowed to dry and shall be rubbed down before the next coat is

applied.

Surfaces Not to be Painted

(i)

Fibreglass and plastic surfaces.

(ii)

Chrome plate and stainless steel surfaces.

Tham & Wong M&E (Viet Nam)

Page 19

PARKCITY

Clubhouse Facilities ParkCity at Le Trong Tan Ha Noi, Viet Nam

Mechanical & Electrical Specification Rev 0

(iii)

Bearing surfaces slides adjusting screws and any surface that is required to be

unpainted for the correct operation for adjustment of the equipment.

(iv)

Hot dipped galvanised lamp holes.

Paint Material

All paint and other preparations shall be non-poisonous, lead-free prepared synthetic

products of approved brand, conforming to the relevant British Standard, brought onto the site

ready mixed in manufacturers sealed containers and used to the manufacturers

Specification.

Preparation of Surfaces and Prime Coating

Metal surfaces shall be wire-brushed to remove loose rust and scale. Castings shall be either

ground smooth or alternatively filled with approved filling compound and then rubbed to a

smooth finish.

Steel plate and all rolled steel sections including brackets and supports not galvanised, shall

be given an application of cold phosphate compound before being prime coated with red zinc

chromate primer.

Steel pipes and conduits delivered to the site unpainted shall be prime coated as specified for

steel plate.

All galvanised or zinc sprayed steel surfaces and all non-ferrous surfaces shall be given an

application of PVB / Zinc chromate self-etching primer before being prime coated as specified

above.

Machinery, apparatus, equipment and fittings delivered to the site already prime or finish

painted shall be thoroughly cleaned down.

Finishes

Each finishing coat shall be of a different shade. The final coat shall be left smooth, even and

free from the visible brush marks and other defects.

For surfaces, which shall operate below 93C, the finishing coat shall be high-grade alkyd

enamel.

Piping, cable enclosures and conduits shall be painted to a gloss finish in colour or colours to

conform to Schedule of Colours.

The ground colour shall extend throughout the entire length of piping, cable enclosures and

conduits installed in the following locations:

(a) Plant rooms;

(b) Piping in trenches;

(c) Piping in basements underground floors and in vertical ducts; and

(d) Wherever exposed to weather or to view.

All piping, cable enclosures and conduits installed in ceilings and similar concealed spaces

shall have the ground colour applied in 400mm wide bands spaced at 6m centres except that

ground colour bands shall be provided adjacent to branches, junctions, valves, floors and

walls (both sides).

Tham & Wong M&E (Viet Nam)

Page 20

PARKCITY

Clubhouse Facilities ParkCity at Le Trong Tan Ha Noi, Viet Nam

Mechanical & Electrical Specification Rev 0

Labelling

All instruments, gauges, indicators, control equipment contactors, circuit breakers, switches,

starters, relays and cable terminals on switchboards, etc., shall be clearly labelled and

identified with their associated function.

Labels shall be of laminated plastic with engraved upper case black letters on a white

background. Plastic labels shall be attached by screw or rivet-fixing.

Punch machine type strip lettering and stick-on markings will not be approved.

Lettering shall not be less than 12mm high. Lettering for items installed in switchboards and

on control panels shall not be less than 9mm high.

Schedule of Colours

Equipment, conduit and trunking shall be identified in accordance with relevant standard and

in accordance with the following schedule:

Equipment / Services

Finish / Colour

Labelling / Identification

Electrical Panel Labels

Engraved

Electrical Conduit and Trunking

Exterior / Grey

Interior : Grey

Orange or Match surrounding

Speaker Conduit and Trunking

White or Match surrounding

Blue Band

Telephone Conduit and Trunking

Green or Match surrounding

Orange Band

Surface Light Fitting

White

Suspension Rod and Channels

White

Potable /drinking water pipe

Town Gas

2.44

Green

Yellow

Grey Band

Black/flow direction

Black/flow direction

Construction programme

The Contractor shall provide the equipment and carry out the works based on The Practical

Completion Date in this Document. The Contractor shall include the cost of the Contract to

meet the construction programme requirement and project completion date.

Detail programme shall be submitted by the Contractor for Engineers approval.

2.45

External Noise Criteria

The mechanical systems shall be such designed that noise generated will not be greater than

45 db(A) during daytime and 40 db(A) during night time when measured at 10 metres from

boundary. Under no circumstance the noise generated shall exceed the values as stipulated

in Environmental Protection Departments requirement. Acoustic treatment shall be provided

by the Contractor when noise generated exceeds the above stated values and when the

environment is affected.

Tham & Wong M&E (Viet Nam)

Page 21

PARKCITY

3.0

Clubhouse Facilities ParkCity at Le Trong Tan Ha Noi, Viet Nam

Mechanical & Electrical Specification Rev 0

Scope Of work

The scope shall include but not limited to:

3.1

Electrical Installation

3.1.1 Scope of work for external works

a.

Lead-in H.D. UPVC Pipes for Electrical, Telecom, Cable TV System from the

Authority intake point (1000mm beyond existing open drain) to the meter

compartment as shown.

b.

Lead-in H.D. UPVC Pipes for Electrical, Telecom, Cable TV & Security System c/w

MCTs at both ends

c.

Outdoor distribution boards, and submains as shown.

d.

External/Landscape, wiring.

e.

Take delivery and installation of all light fittings.

f.

Supply labour for installation of equipments, and lay Data control cabling including all

necessary termination works.

g.

Supply & install Cable TV System including cabling works & necessary equipments,

accessories and concealed/exposed conduit.

h.

External/Landscape Lighting layout as per drawing.

i.

Testing & commissioning for all system.

j.

Attendance to Power supply application and submission, inspection by all relevant

authorities including engagement of Licensed Electrical Worker (LEW).

3.1.2 Scope of work for typical units.

k.

Lead-in H.D. UPVC Pipes for Electrical, Telecom, Cable TV System from the

Authority intake point (1000mm beyond existing open drain) to the meter

compartment as shown.

l.

Supply & install Meter Panel (MP-1) located at Gate Pillar c/w Authority metering

facilities. Incoming supply sigle phase c/w necessary protection relay

m.

Lead-in H.D. UPVC Pipes for Electrical, Telecom, Cable TV c/w MCTs at both ends

n.

Distribution boards, and submains as shown.

o.

Small Power Distribution.

p.

Lighting points, Ceiling fan points and wiring.

q.

External/Landscape lighting and wiring.

r.

Take delivery and installation of all light fittings.

Tham & Wong M&E (Viet Nam)

Page 22

PARKCITY

3.2

s.

Supply labour for installation of equipments, and lay Data control cabling including all

necessary termination works.

t.

Supply & install Telephone System including Key phone system Panel, cabling works,

necessary accessories and UPVC concealed/exposed conduit/ metal trunking as

shown.

u.

Supply & install Cable TV System including TV splitter, cabling works & necessary

equipments, accessories and UPVC concealed/exposed conduit/ metal trunking.

v.

Lightning Protection System & Earthing System.

w.

Testing & commissioning for all system.

x.

Attendance to Power company application and submission, inspection by all relevant

authorities including engagement of Licensed Electrical Worker (LEW).

Air-conditioning & Ventilation Installation for typical units

a.

Take delivery and installation of the Air-cooled Split Air-Conditioning equipments.

b.

Supply and Installation of the Air Conditioning refrigerant pipes, drain pipes, electrical

wiring & control, etc. as shown in the tender drawings.

c.

Toilet exhaust systems c/w fans, ductworks, grilles, external weatherproof louvres,

etc. as shown in the tender drawings.

d.

Take delivery and installation of the Air-cooled Split Air-Conditioning equipments.

e.

Testing & Commissioning.

3.3

Plumbing and Sanitary Installation

3.3.1

Scope of work for external works

3.3.2

Clubhouse Facilities ParkCity at Le Trong Tan Ha Noi, Viet Nam

Mechanical & Electrical Specification Rev 0

a.

Supply and install of external underground sewer drainage system.

b.

Supply and install of external plumbing & fire protection system.

c.

Supply and install of external storm water drainage system.

d.

Take delivery and fixing of all sanitary and plumbing fittings

e.

Testing & Commissioning.

f.

Attendance to PUB/ENV application and submission of water and sanitary plans,

inspection by all relevant authorities including engagement of licensed plumber,

Licensed Water Service Plumber and Qualified Person/Professional Engineer.

Scope of work for typical units

g.

Supply and install of Internal underground sanitary drainage system.

h.

Supply and install of Internal plumbing system.

Tham & Wong M&E (Viet Nam)

Page 23

PARKCITY

3.4

Clubhouse Facilities ParkCity at Le Trong Tan Ha Noi, Viet Nam

Mechanical & Electrical Specification Rev 0

i.

Supply and install of Internal aboveground sanitary drainage system.

j.

Supply and install of Waste water pumping system

k.

Supply and install of Rain water pumping system (if any)

l.

Supply and install of Cold and Hot water supply system.

m.

Supply and install of Complete domestic water hydro-pneumatic Booster pump, &

storage tank system. The booster pump system inclusive pumps, pressure vessel,

pipe work, fittings, VSD Drive, control panel complete with wiring, pump starters,

water level sensors, controls, relays, trunking, conduit, pump automatic operation and

change-over to standby pump and accessories.

n.

Supply and install of Electric water storage Heater system.

o.

Take delivery and fixing of all sanitary and plumbing fittings

p.

Electrical equipment and installation work.

q.

Testing & Commissioning.

r.

Attendance to Authorities application and submission of water (including booster

pump system, pressure vessels and domestic water tank) and sanitary plans,

inspection by all relevant authorities including engagement of licensed plumber,

Licensed Water Service Plumber and Qualified Person/Professional Engineer.

General Scopes

a.

Acoustic treatment and vibration control.

b.

All interfacing work with other trades.

c.

Painting and labelling of pipework and equipment.

d.

Provision of all hold down bolts, spigots struts and the like required to be built in

during construction.

e.

Testing and commissioning.

f.

Provision of twelve (12) months operational maintenance and breakdown services for

external services. The period shall commence immediately upon issuance of the

Architects Completion Certification or handing-over date of the service to the

authorities, whichever is later.

g.

Provision of operating instructions and maintenance manuals; as-fitted drawings.

h.

Application, Submission and Liaison with authorities to obtain all necessary

certificates and approvals, including the completion of all submission drawings, forms

and payment of any fees and charges. All the costs for all the tests as required by all

relevant authorities shall be included.

i.

Take, delivery from site, installation, handling, commissioning and protection of all

sanitary wares and fittings including all valves, accessories, taps, brackets, plugs,

complete as specified.

j.

Provision of spare parts.

Tham & Wong M&E (Viet Nam)

Page 24

PARKCITY

3.5

Clubhouse Facilities ParkCity at Le Trong Tan Ha Noi, Viet Nam

Mechanical & Electrical Specification Rev 0

k.

Training of the employer for proper operation of the entire systems.

l.

Provision of the necessary installation which include pipework, connection of water

supply, conduit and control wiring, etc. to form a workable system as required.

m.

Attend to all authorities inspections regardless of whether this inspection is carried

out after the defect liability period.

n.

All other works and systems as specified in the Contract document and or shown on

the drawings.

o.

All M&E installation works shall be in accordance to the construction phasing

programme which include the various completion dates, target dates etc. for the

different areas in the development.

Servicing and Maintenance.

General

The works as described hereunder are for the servicing and maintenance of all the systems and

ancillary plant, machineries and equipment supplied and installed under the works during and

after the Maintenance Period and includes the supply of all materials, tools, apparatus,

equipment and appliances, labour and necessary incidentals.

During the Maintenance Period, the replacement and/or repairs of all defective plants,

machineries and equipment and installations or any parts thereof shall be entirely free of charge

to the Employer, if such repairs or replacements are necessitated by reason of defective design,

materials or workmanship.

Workmanship and Materials

The servicing, maintenance and repair (or replacement) shall be performed by skilled and

competent workmen and shall be executed in accordance with the best commercial, technical

and engineering practice.

All materials to be supplied shall be new and unused, and shall generally be of the best quality

as regards manufacture and performance.

Supervision

The servicing, maintenance and repair (or replacement) works shall be under the charge of a

Supervisor. For works required by local laws and regulations to be performed by licensed or

registered personnel, the Supervisor shall deem to have the appropriate licence or registration.

This Supervisor shall also be fully competent in supervising the servicing, maintenance and

repair (or replacement) work and be acceptable to the Employer.

Scope of Work

All plant, machineries and equipment comprising the complete systems and ancillary equipment

supplied and installed under these Works shall be serviced and maintained strictly in

accordance with the requirements/recommendations as stipulated by all the plant and

equipment manufacturers as well as in compliance with all by-laws, rules, regulations and

requirements of the Local Authorities and shall also satisfy all appropriate Singapore Standards

including all relevant Codes of Practice.

The Works includes the preparation of a comprehensive servicing and maintenance schedule

which shall be submitted to the Architect / Engineer for review after the award of the Work. The

reviewed schedule shall then be included and shall form an integral part of the Operating and

Maintenance Instructions and Parts List including monthly servicing.

Tham & Wong M&E (Viet Nam)

Page 25

PARKCITY

Clubhouse Facilities ParkCity at Le Trong Tan Ha Noi, Viet Nam

Mechanical & Electrical Specification Rev 0

The time and day for carrying out the servicing, maintenance and repair shall have agreement

with the Employer. It is to be expected that working outside normal working hours (i.e.

overtime) will be required. Also emergency repair services if so requested by the Employer

shall be carried out at any time of the day (overtime included).

It shall be contractually bound that the Employer be immediately advised of any defects or

deterioration in any part of the equipment/materials observed during the routine inspection and

servicing.

The Works shall include the services of a Licensed Electrical Worker to take charge of the entire

Electrical Installation of the entire Building including those related to all other building services,

i.e. Air Conditioning & Ventilation, Fire Fighting & Alarm, Lifts, Sanitary and Plumbing, etc. for

licensing purpose (if applicable). All costs connected therewith including fees payable to the

Authorities are deemed to have been included during the Maintenance Period.

The Works shall include routine inspections, servicing and maintenance of all the equipment,

machinery and plant to be carried out outside the peak hours of the building of at agreeable

time with the Employer.

The routine inspections, servicing and maintenance schedule shall be so arranged that

minimum inconvenience and interruption shall be caused to the occupants and Employer.

During every regular inspection, the Works to be performed shall include but not limited to the

following:

(a)

Check the performance of the complete Installation, including cleaning and adjusting all

control devices as and when technically necessary.

(b)

Advise the Employer's operators/maintenance in respect of the emergency rescue,

correct operation procedure etc.

(c)

Report in writing to the Employer any defects discovered, coming to light or observed in

any part or parts of the Installation. Such reports shall state fully the cause(s) of such

defect(s) and shall include, where applicable, an estimate of the cost of repairs or

replacement of the defective part or parts required.

(d)

Record, in the log book for each element of the Installation, kept by the Employer,

particulars of all maintenance or repair works carried out and initial all entries in the log

book.

(e)

Tests as and when necessary, any part of the Installation.

(f)

Report in writing to the Employer all servicing & maintenance works carried out.

Tham & Wong M&E (Viet Nam)

Page 26

PARKCITY

4.0

Clubhouse Facilities ParkCity at Le Trong Tan Ha Noi, Viet Nam

Mechanical & Electrical Specification Rev 0

Responsibilities of Contractor

The Contractor is to price for the followings:

Provision of hoisting facilities.

Provision of artificial lighting and temporary electricity supplies including power for

testing and commissioning of air-conditioning and ventilation, lifts and electrical

installation which will be from the permanent installations.

Removal of rubbish from locations on each floor.

Securing the building and building works in such a manner that it will not be subjected

to damage by construction activities such as falling debris or water seepage during

the progress of the Contract works.

Protecting, casing up and accepting full responsibility for loss or damage to which

have been fully, finally and properly incorporated into the Works.

Additional costs incurred due to the working hour different from and extended hours

to those worked by the Contractor.

Provision of all setting out and survey information including giving all necessary

dimensions and taking responsibility for their accuracy.

Programming, co-ordinating and organising the contractors work to ensure the

correct timing, sequencing and completion of all operations including preparing coordinated working drawings of all services.

Ascertaining all particulars relating to the contract works in regard to sizes and

positions of chases, holes and the like which are to be formed or left in the structure.

Cutting and forming holes, recesses, etc. for ductwork, pipes, conduits and fittings

through walls, floors, ceilings, roofs, etc. and making good after the contract works

are sufficiently advance. Cutting holes through false ceilings and special partitions

shall be by the respective specialist contractors. The contractor shall be responsible

for chasing of walls for pipes, conduits and fittings and making good.

Filling, grouting and making good under lift shaft entrance sills, around lift doorways

and casings for buttons and indicators, etc.