Beruflich Dokumente

Kultur Dokumente

Structure of Georgian Houses Explained

Hochgeladen von

João Ricardo Lopes0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

255 Ansichten2 Seitendescription of a georgian house built-up

Originaltitel

Structure of Georgian Houses

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldendescription of a georgian house built-up

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

255 Ansichten2 SeitenStructure of Georgian Houses Explained

Hochgeladen von

João Ricardo Lopesdescription of a georgian house built-up

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 2

SUPPORTING COLUMNS Structure of Georgian Houses

Page 1 of 3

SUPPORTING COLUMNS

Structure of Georgian Houses

Structural engineer Brian Morton describes the typical structural configuration of many

typical Georgian houses.

Recently I was asked to appraise a surveyors report on a

property in London. The client realised that the report

seemed to call for an extensive amount of unnecessary

work.

I wrote to her following my own survey, describing the

structure of Georgian houses associated with potential

problems. She was so enthusiastic that I felt readers of

Context might find the information useful.

Most

Georgian

buildings

are

constructed

of

comparatively soft, local stock bricks. Walls are built with

lime mortar, which again is soft and, like the bricks,

comparatively porous.

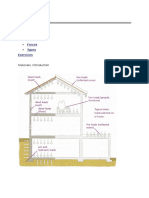

Floors are constructed of timber above basement level.

The structural support for these floors is provided by the

external walls, and generally a timber-stud partition clad

with lath and plaster as a central load-bearing wall

running up through the building. At ground floor level

this major cross partition is generally constructed of solid

brickwork. In many cases the cross partition at first floor

level is in a different line to the cross partition in the

ground floor level.

Timber-stud partitions clad with lath and plaster are

used throughout to support floors. It is unusual to

find any masonry internally above ground-floor level, except

in the case of large Georgian houses where the staircase is of

stone construction. In this case, brick walls are usually

carried up alongside the staircase to the underside of the

staircase to first-floor level, and occasionally to secondfloor level.

Roofs are constructed of timber, formed into principal

trusses with secondary rafters. Often there are open

internal, lead-lined gutters within the roof space to carry

water across the building and out through an external

(normally rear) wall. Roofs are generally clad with Welshtype slates set on to either boarding or battens, without any

underlying roofing felt.

The brick walls of the building start at basement level

as probably one-and-a-half brick thick walls, sometimes

two brick thick walls. As they go up the building, these

walls reduce until in the upper storeys they are simply one

brick thick.

The floor joists are built into the front and rear walls,

restraining them. In larger houses there are generally

main beams which divide up the floors, spanning the

width of the building. Sometimes they run from front to

back, restraining the front and rear

C O N T E X T 8 0 : J U LY 2 0 0 3

http://ihbc.org.uk/context_archive/80/first_Dir/first_Page1.htm

13

12/11/2014

SUPPORTING COLUMNS Structure of Georgian Houses

walls either by secondary joists bearing on to the walls or

the principal beams bearing on to those walls. The party

walls are a minimum of one brick thick, strengthened by

the chimneybreast to provide lateral restraint to the walls.

The face of the chimneybreast is generally only half a brick

thick.

Depending on the circumstances, and the sequence of

building, it is not unusual to find the front and back

walls butting on to an original gable end of a previously

built property, and not tied in. In other cases front and

rear walls simply fly past the party walls and are not

significantly connected.

These buildings were constructed quickly, with little or

no foundations. They were built of flexible materials. The

mortar took a significant time to set and the structures

tended to settle down as they were built, retaining a

degree of flexibility not found in later buildings of similar

size. This flexibility has undoubtedly led to the long life of

these buildings.

The structure of the buildings fails not because of

vertical load but because of lack of lateral restraint, and

sometimes lack of bonding within the thickness of the wall.

Such failures are found particularly in higher-quality

Georgian houses, where the outer skin of the face of the

external walls was built with very thin mortar joints, built

by the experienced bricklayer, while the inside face the

brickwork was built with thick joints by the apprentice.

Thus the walls were never bonded together because the

joints were at different levels. This form of construction

is described as snapped-header construction. Even when

high-quality facing bricks were not used, there was a

tendency for the outer face to be built by the experienced

bricklayer, backed up by the apprentice.

Basements or lower-ground floors are always potentially

a problem as far as damp-proof treatment is concerned.

The modern style of living does not normally suit the

form of construction.

Walls of soft bricks and lime mortar work because they

breathe. Rain makes the wall wet or damp, and the wind

dries the external face. The internal plaster also breathes

and allows a small proportion of the damp to dry out

within the atmosphere of the rooms. The basements or

lower ground floors were constructed with pammets (floor

bricks), covered by stone slabs. Both had open joints,

allowing moisture to dry up through the floors. Walls

were plastered with a hair-reinforced, lime-based plaster

which also allowed the walls to breathe. Even where these

conditions have prevailed for perhaps 150 years, I have

seen original plaster in perfect condition. Air circulated

within the rooms and a damp atmosphere seemed not to

worry the occupiers.

In the early days of conservation restoration, pammet

floors or stone floors were taken up, and floors were

concreted, generally with a damp-proof course. The result

was that the moisture was driven up the walls and the

plaster came off. The walls were then rendered with a

waterproof render, sometimes the full height of the room

but mostly about one

Page 2 of 3

metre high. Amazingly, the damp within the walls then

permeated the bricks up to ground-floor level. We have

found ends of floor joists rotten at that level due to the

damp-proof treatment in the basement.

In the early days of conservation, English Heritage and

local authorities would give grant aid for the form of

this form of damp treatment to the basement, until it was

realised the problems that this treatment caused. Generally

English Heritage will not now give consent to dealing with

basements or lower-ground floors in this way. If walls are

found to be damp, a properly specified lime-based plaster

is used even if there is a concrete floor, generally with

adequate ventilation to the room and no fixtures being

built against these walls.

English Heritage and conservation authorities do not

generally believe that injection damp-proof courses are

necessary or, in the slightly longer term, of any real

value. We have gone back to what is known to work.

Views on timber treatment have also changed. It is

generally not now acceptable to treat any timber element

within the construction of a house built prior to 1930. It

has even been suggested that to introduce timber

treatment into such structures may be negligent on the

part of the professional because it introduces a chemical

into the atmosphere unnecessarily.

If a method used in the past with particular materials

was found to work, we would certainly recommend its

reuse, but we have no objection to the use of modern

materials if they are going to prolong the life of a

building or an element of it. Stainless steel and resin

anchors, for example, can be used to tie skins of walls

together. The alternative would be to take down parts of

walls and rebuild them without a significantly better result.

http://ihbc.org.uk/context_archive/80/first_Dir/first_Page1.htm

12/11/2014

Das könnte Ihnen auch gefallen

- Masonry TutorialDokument45 SeitenMasonry TutorialGajendra Joshi100% (2)

- Framed structures guideDokument16 SeitenFramed structures guideRemya R. Kumar0% (1)

- Brick MasonaryDokument42 SeitenBrick MasonarySaddam HossainNoch keine Bewertungen

- Introduction To Masonry StructuresDokument33 SeitenIntroduction To Masonry StructuresEdralyn LuadNoch keine Bewertungen

- Bricklaying ManualDokument24 SeitenBricklaying Manualdonaldduck23100% (1)

- 5 Rammed EarthDokument138 Seiten5 Rammed EarthSilviu PaduraruNoch keine Bewertungen

- Construction Planning & ManagementDokument146 SeitenConstruction Planning & ManagementBrandon Warren100% (1)

- Building Materials Seminar ReportDokument63 SeitenBuilding Materials Seminar ReportTejas Joshi100% (1)

- Causes of decay and damage in old buildingsDokument13 SeitenCauses of decay and damage in old buildingstwinkle4545100% (2)

- Tech Drawing ProjectDokument30 SeitenTech Drawing ProjectchukyzillaNoch keine Bewertungen

- Basic Construction Training ManualDokument92 SeitenBasic Construction Training Manualshashanksaran100% (1)

- Architectural TermsDokument6 SeitenArchitectural TermsCamille MacatangayNoch keine Bewertungen

- Basements For DwellingsDokument86 SeitenBasements For DwellingsAFRI-N-HARI100% (1)

- Chimneys, Gables and Gargoyles: A Guide to Britain's RooftopsVon EverandChimneys, Gables and Gargoyles: A Guide to Britain's RooftopsBewertung: 5 von 5 Sternen5/5 (1)

- Substation Filter BankSpecsDokument7 SeitenSubstation Filter BankSpecsTudor BostanNoch keine Bewertungen

- Awarding EOTDokument40 SeitenAwarding EOTJoão Ricardo LopesNoch keine Bewertungen

- Walls Structure Walls StructureDokument32 SeitenWalls Structure Walls StructureNor Alia Shafia100% (1)

- Letters of Intent in ConstructionDokument4 SeitenLetters of Intent in ConstructionJoão Ricardo LopesNoch keine Bewertungen

- Types of WallsDokument12 SeitenTypes of Wallsdreamboy8792% (13)

- Waterproofing of BasementsDokument8 SeitenWaterproofing of BasementsJoão Ricardo Lopes100% (1)

- Types of Brick Bonds and ConnectionsDokument21 SeitenTypes of Brick Bonds and ConnectionsVanshika SpeedyNoch keine Bewertungen

- Construction Technology WallsDokument24 SeitenConstruction Technology WallsAsish Seeboo100% (1)

- Ip Qos Principles: Theory and PracticeDokument108 SeitenIp Qos Principles: Theory and Practicetest2012Noch keine Bewertungen

- Ship Rudder Types and Design FeaturesDokument10 SeitenShip Rudder Types and Design FeaturesAurvin SinghNoch keine Bewertungen

- Architectural Details FinalDokument29 SeitenArchitectural Details FinalNadia Martinelli100% (2)

- Construction Technology BrickworkDokument23 SeitenConstruction Technology BrickworkdahliagingerNoch keine Bewertungen

- Building Materials: From Peter Valdivia S WebsiteDokument8 SeitenBuilding Materials: From Peter Valdivia S Websitetechnologyaljanadic0910Noch keine Bewertungen

- TCH Seminar Cavity WallDokument30 SeitenTCH Seminar Cavity WallSachin AbhiramNoch keine Bewertungen

- Insulate Historic Timber FloorsDokument18 SeitenInsulate Historic Timber FloorsSamuel FuentesNoch keine Bewertungen

- Acoustic Technique-Cavity WallDokument33 SeitenAcoustic Technique-Cavity WallPriyadharshini MohanNoch keine Bewertungen

- Suspended Timber Floor ConstructionDokument3 SeitenSuspended Timber Floor ConstructionMarkDhanukaSiriwardaneNoch keine Bewertungen

- WallDokument8 SeitenWallMoshe RostenNoch keine Bewertungen

- Construction Technology 1Dokument4 SeitenConstruction Technology 1pbharris0% (1)

- Brickwork TextDokument4 SeitenBrickwork Textmoonna100% (1)

- Masonarywall 160825234415 PDFDokument36 SeitenMasonarywall 160825234415 PDFDrNallaShivamNoch keine Bewertungen

- Materials Building Structure Forces Types ExercicesDokument7 SeitenMaterials Building Structure Forces Types ExercicesnilminaNoch keine Bewertungen

- New Microsoft Office Word DocumentDokument19 SeitenNew Microsoft Office Word DocumentjamesandrewsonNoch keine Bewertungen

- Record 28 PDFDokument18 SeitenRecord 28 PDFSakisNoch keine Bewertungen

- Types of WallsDokument3 SeitenTypes of Wallsrowell naragNoch keine Bewertungen

- Retaining Walls and Road PavementDokument14 SeitenRetaining Walls and Road PavementPraise SamuelNoch keine Bewertungen

- Newari Dwelling ReportDokument16 SeitenNewari Dwelling ReportAnjali NetamNoch keine Bewertungen

- Concrete Wall in Tropical ClimateDokument11 SeitenConcrete Wall in Tropical ClimateSuryasis DasguptaNoch keine Bewertungen

- Unit-5: Partition and Cavity Wall Partition and Cavity WallDokument15 SeitenUnit-5: Partition and Cavity Wall Partition and Cavity Wallसमिर भण्डारीNoch keine Bewertungen

- VA 7 Building Technology and ProductionDokument41 SeitenVA 7 Building Technology and ProductionPrashna ShresthaNoch keine Bewertungen

- Type of WallDokument48 SeitenType of Wallkamardeen mustafa100% (3)

- Cavity wall technical seminarDokument22 SeitenCavity wall technical seminarSachin AbhiramNoch keine Bewertungen

- Advantages and Types of Masonry StructuresDokument45 SeitenAdvantages and Types of Masonry StructuresAl-Ain HomesNoch keine Bewertungen

- Walls calling: Understanding the principles of retaining wallsDokument11 SeitenWalls calling: Understanding the principles of retaining wallsPepe ChupinNoch keine Bewertungen

- Hollow Walls-1Dokument19 SeitenHollow Walls-1Princy sonejiNoch keine Bewertungen

- Types of Masonry WallsDokument30 SeitenTypes of Masonry Wallsbereket100% (1)

- Building Construction Lecture Note.Dokument31 SeitenBuilding Construction Lecture Note.Umar Bello NuhuNoch keine Bewertungen

- Simple Earth Buildings 3Dokument17 SeitenSimple Earth Buildings 3Anon BoletusNoch keine Bewertungen

- What Is Framing?Dokument6 SeitenWhat Is Framing?Mark Custodio AquinoNoch keine Bewertungen

- Brick masonry bonding patterns and effectsDokument11 SeitenBrick masonry bonding patterns and effectsmeetshah92Noch keine Bewertungen

- Cavity WallsDokument19 SeitenCavity Wallstideci1953Noch keine Bewertungen

- Unit3 BuildingMaterialsDokument27 SeitenUnit3 BuildingMaterialsffergallNoch keine Bewertungen

- AE 544 Building PhotosDokument43 SeitenAE 544 Building PhotosTotok SulistiyantoNoch keine Bewertungen

- Cavity Wall Guide: Everything You Need to KnowDokument19 SeitenCavity Wall Guide: Everything You Need to KnowRAHULNoch keine Bewertungen

- Reviewed - IJCE-Format-The Wall As Architecture SpaceDokument12 SeitenReviewed - IJCE-Format-The Wall As Architecture Spaceiaset123Noch keine Bewertungen

- Hybrid Final Paper PDFDokument13 SeitenHybrid Final Paper PDFSudan ShresthaNoch keine Bewertungen

- Partition WallDokument2 SeitenPartition WallMichael EspinosaNoch keine Bewertungen

- Cavity Wall Guide: Structure, Insulation & ConstructionDokument19 SeitenCavity Wall Guide: Structure, Insulation & ConstructionAditya MishraNoch keine Bewertungen

- 4-ATP-Building EnvelopeDokument39 Seiten4-ATP-Building EnvelopeShabbir AhmadNoch keine Bewertungen

- Introduction To Masonry StructuresDokument33 SeitenIntroduction To Masonry StructuresNiraj JhaNoch keine Bewertungen

- BDG NotesDokument18 SeitenBDG NotesTaiwo AyomideNoch keine Bewertungen

- Site Diary Document on 2 Storey Bungalow ConstructionDokument7 SeitenSite Diary Document on 2 Storey Bungalow ConstructionAlia KhalidNoch keine Bewertungen

- Structure in Design: Ali Abdulaziz Haya Ismail Sara Sardar Latifa FouadDokument17 SeitenStructure in Design: Ali Abdulaziz Haya Ismail Sara Sardar Latifa FouadAli AlawyNoch keine Bewertungen

- Principles of Traditional Building 051110Dokument6 SeitenPrinciples of Traditional Building 051110drmatthewhardyNoch keine Bewertungen

- Empowerment Technology Lesson 3Dokument3 SeitenEmpowerment Technology Lesson 3Yza Tepaurel ErmacNoch keine Bewertungen

- Wood Frame PDFDokument26 SeitenWood Frame PDFMaxNoch keine Bewertungen

- The Conversion of Traditional Farm Buildings - A Guide To Good Practice PDFDokument29 SeitenThe Conversion of Traditional Farm Buildings - A Guide To Good Practice PDFJoão Ricardo LopesNoch keine Bewertungen

- Cavity Trays Main Brochure PDFDokument192 SeitenCavity Trays Main Brochure PDFJoão Ricardo LopesNoch keine Bewertungen

- Domestic Ventilation Compliance GuideDokument63 SeitenDomestic Ventilation Compliance GuideDiana Alexandra ComaromiNoch keine Bewertungen

- Summary of Specific Heritage Crime Offences For Designated Heritage Assets PDFDokument14 SeitenSummary of Specific Heritage Crime Offences For Designated Heritage Assets PDFJoão Ricardo LopesNoch keine Bewertungen

- HEAG080 ChimneysDokument22 SeitenHEAG080 ChimneysJoão Ricardo LopesNoch keine Bewertungen

- Summary of Specific Heritage Crime Offences For Designated Heritage Assets PDFDokument14 SeitenSummary of Specific Heritage Crime Offences For Designated Heritage Assets PDFJoão Ricardo LopesNoch keine Bewertungen

- Code of Measuring PracticeDokument2 SeitenCode of Measuring PracticeJoão Ricardo LopesNoch keine Bewertungen

- Glass Architectural HardwareDokument24 SeitenGlass Architectural HardwareJoão Ricardo LopesNoch keine Bewertungen

- WallDokument19 SeitenWallJoão Ricardo LopesNoch keine Bewertungen

- Ancon - Wall Ties and Restraint FixingsDokument32 SeitenAncon - Wall Ties and Restraint FixingsJoão Ricardo LopesNoch keine Bewertungen

- Internal DoorsDokument24 SeitenInternal DoorsJoão Ricardo LopesNoch keine Bewertungen

- Brickshield Standard Colour Range SecDokument1 SeiteBrickshield Standard Colour Range SecJoão Ricardo LopesNoch keine Bewertungen

- Movement Joints1Dokument12 SeitenMovement Joints1João Ricardo LopesNoch keine Bewertungen

- Advice On Building Your Own HomeDokument20 SeitenAdvice On Building Your Own HomeJoão Ricardo LopesNoch keine Bewertungen

- The Great EstatesDokument56 SeitenThe Great Estatessapper2000Noch keine Bewertungen

- Householders Technical GuidanceDokument48 SeitenHouseholders Technical GuidanceJoão Ricardo LopesNoch keine Bewertungen

- 2015 DL Listed Buildings Supplementary Planning GuidanceDokument9 Seiten2015 DL Listed Buildings Supplementary Planning GuidanceJoão Ricardo LopesNoch keine Bewertungen

- An Illustrated Glossary For The Tick-Box Building Summary: WWW - Buildingarchaeology.co - UkDokument6 SeitenAn Illustrated Glossary For The Tick-Box Building Summary: WWW - Buildingarchaeology.co - UkJoão Ricardo LopesNoch keine Bewertungen

- CRM v17n5Dokument44 SeitenCRM v17n5João Ricardo LopesNoch keine Bewertungen

- Forum - The Salvage DilemmaDokument4 SeitenForum - The Salvage DilemmaJoão Ricardo LopesNoch keine Bewertungen

- Lecture - Force MethodDokument73 SeitenLecture - Force MethodF FNoch keine Bewertungen

- Slump and Compacting Factor Test Values and Uses in Concrete WorkabilityDokument2 SeitenSlump and Compacting Factor Test Values and Uses in Concrete WorkabilityNick GeneseNoch keine Bewertungen

- Last Name, First CHE426:: F C V C V C F + F F CDokument6 SeitenLast Name, First CHE426:: F C V C V C F + F F Clợi trầnNoch keine Bewertungen

- Projection Achievement ReportDokument8 SeitenProjection Achievement ReportPskaruppiah KarupsNoch keine Bewertungen

- Manaul de Partes Bws 1 YmDokument53 SeitenManaul de Partes Bws 1 YmRobinson GuanemeNoch keine Bewertungen

- Caterpillar Cat 336E L Excavator (Prefix YEP) Service Repair Manual (YEP00001 and Up)Dokument28 SeitenCaterpillar Cat 336E L Excavator (Prefix YEP) Service Repair Manual (YEP00001 and Up)kfsmmeNoch keine Bewertungen

- 30 Days Challenge For Electrical Engineeirng: Pantech SolutionsDokument11 Seiten30 Days Challenge For Electrical Engineeirng: Pantech SolutionsPerenpanathan Suganthan100% (1)

- Diamond Pin Locator and V Blocks 1Dokument8 SeitenDiamond Pin Locator and V Blocks 1pratik thakareNoch keine Bewertungen

- Romanian Power Grid Substation Refitting StrategyDokument16 SeitenRomanian Power Grid Substation Refitting StrategyParmeshwar MbNoch keine Bewertungen

- Weigelt Experience With Stator End-Winding Vibrations Causes, Solutions and Monitoring EPRI 2011, AlbanyDokument53 SeitenWeigelt Experience With Stator End-Winding Vibrations Causes, Solutions and Monitoring EPRI 2011, AlbanyKevin Luis Perez QuirozNoch keine Bewertungen

- White Paper c11 737101Dokument13 SeitenWhite Paper c11 737101Aleksandar PopovicNoch keine Bewertungen

- Topaz HTC English Manual PDFDokument232 SeitenTopaz HTC English Manual PDFRafael AdrianNoch keine Bewertungen

- Catalog DuctingDokument9 SeitenCatalog DuctingchristiadiargaNoch keine Bewertungen

- Machine Guarding LP PDFDokument4 SeitenMachine Guarding LP PDFrexivyNoch keine Bewertungen

- Carbon Compounds: Standard/ Class/ Grade - 10 SSC, CBSE - 8 ICSEDokument53 SeitenCarbon Compounds: Standard/ Class/ Grade - 10 SSC, CBSE - 8 ICSEsaintEmNoch keine Bewertungen

- Slope Stability Then and Now: Professor Emeritus, Virginia Tech, 1600 Carlson DR., Blacksburg, VA, 24060Dokument20 SeitenSlope Stability Then and Now: Professor Emeritus, Virginia Tech, 1600 Carlson DR., Blacksburg, VA, 24060anarNoch keine Bewertungen

- Portfolio Isaura SagredoDokument22 SeitenPortfolio Isaura SagredoIsauraNoch keine Bewertungen

- Scie 5 q1 Week 1 FinalDokument74 SeitenScie 5 q1 Week 1 FinalPrecilla HalagoNoch keine Bewertungen

- Ce R&D/Dli-22/CHANDI/2010-2011 Ce R&D/Dli - 24/CHANDI/2010-2011Dokument61 SeitenCe R&D/Dli-22/CHANDI/2010-2011 Ce R&D/Dli - 24/CHANDI/2010-2011rajjjjjiNoch keine Bewertungen

- N-Channel Low QG Mosfet 30V, 100A, 3.3m: MOS-TECH Semiconductor Co.,LTDDokument9 SeitenN-Channel Low QG Mosfet 30V, 100A, 3.3m: MOS-TECH Semiconductor Co.,LTDAnonymous p1ig0zX6p0Noch keine Bewertungen

- Technical Data Demag Hoist Units Volume 2: Double-Rail Crab EZDH 600 - EZDH 1000 Double-Rail Crab EZLDH 600 - EZLDH 2000Dokument88 SeitenTechnical Data Demag Hoist Units Volume 2: Double-Rail Crab EZDH 600 - EZDH 1000 Double-Rail Crab EZLDH 600 - EZLDH 2000mohammad khoraminiaNoch keine Bewertungen

- List of Organisations SAR147 Apr2012Dokument2 SeitenList of Organisations SAR147 Apr2012Tan Lian KiatNoch keine Bewertungen

- Coils TransponderDokument4 SeitenCoils TransponderGuadalajara JaliscoNoch keine Bewertungen

- NJAPA-PaveXpress V2 PresentationDokument75 SeitenNJAPA-PaveXpress V2 PresentationLuis MogrovejoNoch keine Bewertungen

- ION Enterprise 6.0 System RequirementsDokument2 SeitenION Enterprise 6.0 System RequirementsAlberto SalazarNoch keine Bewertungen

- AHU-Guideline 01 General Requirements Fo PDFDokument24 SeitenAHU-Guideline 01 General Requirements Fo PDFkayden chinNoch keine Bewertungen

- Industrial Hose Products - DAYCODokument200 SeitenIndustrial Hose Products - DAYCOHebert CcahuanaNoch keine Bewertungen