Beruflich Dokumente

Kultur Dokumente

HF 111 Particle Drag Coefficients

Hochgeladen von

Dina Widya ShaquilaOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

HF 111 Particle Drag Coefficients

Hochgeladen von

Dina Widya ShaquilaCopyright:

Verfügbare Formate

HF 111 PARTICLE DRAG COEFFICIENTS

1. GENERAL DESCRIPTION

The apparatus is designed to study the drag of particle in a liquid

under various Reynold numbers.

This is done by dropping a particle into a vertical liquid column

and timing its fall between two points. Particle cross section is no more

than 1% of the tube cross section. Various sizes and density of particles

are supplied including stream lined shaped objects.

A guide at the top of the tube is provided to minimize

disturbance to the liquid. Double valves at the bottom of the tubes

provide a mean for particle removal with minimum loss of the liquid. A

fluorescent tube light at the back of the liquid tube allows clear

observation of the particle fall.

1.1

technical Data

1.1.1 Glass tube

x1,5m

: Two 100mm outside diameter

long

1.1.2 Tube top with guide

: 2 ea

1.1.3 Tube bottom with valves

: 2 ea

1.1.4 Ball spheres:

1.1.4.1 Steel

: Diameter: 3, 6, 9 mm

1.1.4.2 Glass or plastics: 2 sizes diameter

1.1.5

Streamlined object

: Steel, diameter 6 and 9

1.1.6

Fluorescent lamp

: 40 W

1.1.7

Stop watch

: 1 ea

Power supply

: 220V, 1 Ph, 50 Hz. Other

mm

1.1.8

power supply

is available on

1.2

Typical Test

1.2.1 Measurement of drag coefficients of sphere under

various Reynold

Numbers

1.2.2 Effect of [article shape on rate of fall and drag

coefficient

1.2.3 Effect of boundary layer separation on motion of sphere

1.2.4 Exploration of dynamic similarity

2. THEORY

When a body is completely immersed in a relatively large

expanse of fluid,

the fluid exerts a resultant force on the body arising from the

relative motion between the body and the fluid. In common practice,

this resultant force is resolved into two kinds or components of

forces as shown in figure 2. The first force component is parallel to

the motion of the body and againsts the movement direction of the

body. This component of force is thereforce called Drag Force.

On the other hand, the second force component which acts at

right angle to the motion of the body is called Lift Force. This lift

force enables the airplane to float in the air.

2.1

Drag

Drag force on a body may be determined by the following

equation:

Where,

Fd

= Drag force,

Cd

= Drag coefficient,

Dimensionless

Kg/m

= Density of fluid,

A

= Projected area of body normal to direction of

motion,m2

V

2.2

= Velocity of body,

m/s

Lift

Lift force on a body may also be determined by the following

equation:

When,

FL

= Lift force,

CL

= Lift coefficient,

Dimensonless

= Density of fluid,

kg/m3

2.3

= Projected area of body normal to lift vector,

= Velocity of the body,

m2

m/s

Free Falling Of A Body In Liquid Column

When a small ball is sinking in liquid, in the first duration

that the ball is dropped the ball will move at accelerated rates

because the forces acting on the ball is not yet in equilibrium.

This accelaration will cause the ball to move down at higher

velocity and against higher drag force. The drag force will be

heigher until this acting force against the body is in an

equilibrium state as shown in Figure 3 below.

The ball will move at constant velocity. Thus force acting on

the ball by free falling in liquid column will be :

FZ = W FB FD = m.a = 0

................ (3)

Where,

W

= Weight of the ball,

FB

= Buoyant force of the ball,

FD

= Drag force of the ball,

= Mass of the ball,

= Acceleration of the ball = 0

kg

The buoyant force of the body can be determined by the

following equation :

FB

. V

Where,

=Specific weight of the liquid,

=Volume of the body,

N/m3

m3

Thus, from equation (3) gives

FD

= W - FB

Subtitute FD from equation (1) in the above equation, give

In case of the tree falling body in fluid at very low Reynolds number

[(VD/)] < 1, where D is diameter of the spherical body, the flow is

considered laminar of viscous flow, total drag can be determined by

Stokes Law, i.e.

FD = 3VD

Substitute this value FD in equation (2) and also substitute A = D2/4

then we get

CD = 24/ReD

The value of CD of spherical body at very low Reynolds numbers may

be obtained from the graph at left hand side of Figure 4.

If the Reynolds number is increased beyond 1, the laminar

boundary layer will separate from the surface of the spherical body,

starting behind the point of zero velocity called stagnation point. At this

point the pressure gradient is very high, which can be seen from Figure 4

that the curve of CD begins to deviate fro the horizontal axis as the drag

force from the pressure is increased and the drag beconmes more

proportional to V2. As the value of the Reynolds number increases further,

the separation point where the boundary layer is separated from the

surface will move forward on the sphere until, at the Reynolds numbers of

about 1,000, the point of separation remains at an angle of about 80

degrees from the stagnation point.

For a considered range og Reynolds numbers with stable condition,

the laminar boundary layer with depart from the surface in the front half

section of the sphere whereby the value of CD is rather constant at about

0.45. However,the value of CD of the mnooth sphere is decreased rapidly

to about 50% when Reynolds number is about 250,000 as shown in Figure

4. This is because of the flow within the boundary layer changes from

laminar flow to turbulent flow;point. Consequently it also result in a

decrease in the size of the make and the pressure drag.

If the level og turbulence in free stream is high, the laminar

boundary layer will transform to the turbulent bpundary layer at lower

Reynolds numbers. Because of the change in position of the separation

point is well defined, the sphere is thus often used as a turbulence

indicator. For value of CD = 0,3, the Reynolads number which is in the

middle range of the curve section on the left side of the graph in Figure 4

will be used for accurate measure of the turbulence.

3. TEST PROCEDURES

3.1 Measure the diameter of the ball or the streamlined body.

3.2 Turn on the fluorescent lamp.

3.3 Fill in an oil of known viscosity into the glass tubes up to the

operating level.

3.4 Measure the temperature of the oil for determination of

density and releasing.

3.5 Drop the ball or the streamlined body through guide tube

section for releasing.

3.6 Start timing for the movement of the ball (or the streamlined

body) from the upper level mark to the lower level mark and

record the time interval.

3.7 Repeat 3.5 and 3.6 many times to find an average velocity of

the ball.

Note: Viscosity of an oil can be obtained from the oil company.

Das könnte Ihnen auch gefallen

- Math 30-1 Review PackageDokument28 SeitenMath 30-1 Review PackageMarc Lambert100% (1)

- Chapter 12 - Wave Forces On Slender CylinderDokument78 SeitenChapter 12 - Wave Forces On Slender CylinderJuan Carlos GonzálezNoch keine Bewertungen

- Nuclear Engineering Question BankDokument5 SeitenNuclear Engineering Question Bankaerochandru.87Noch keine Bewertungen

- Drag Coefficient of Hemispheres in FlowDokument29 SeitenDrag Coefficient of Hemispheres in FlowAbdul RahmanNoch keine Bewertungen

- Rolling Contact BearingDokument29 SeitenRolling Contact BearingBimlendra RayNoch keine Bewertungen

- Using Displacement As Level MeasurementDokument11 SeitenUsing Displacement As Level MeasurementAlessio ScarabelliNoch keine Bewertungen

- Laminar and Turbulent FlowDokument10 SeitenLaminar and Turbulent FlowGera DiazNoch keine Bewertungen

- Measuring Drag Coefficient of a SphereDokument13 SeitenMeasuring Drag Coefficient of a SphereMuhamad Aiman0% (1)

- Fluid Mechanics Tutorial 8C Pumped Piped Systems: Let's Start by Examining The Meaning of Specific Speed of PumpsDokument17 SeitenFluid Mechanics Tutorial 8C Pumped Piped Systems: Let's Start by Examining The Meaning of Specific Speed of Pumps12Noch keine Bewertungen

- Principles of Finned Tube Heat Exchanger Design For Enhanced Heat TransferDokument20 SeitenPrinciples of Finned Tube Heat Exchanger Design For Enhanced Heat Transferunknown8787Noch keine Bewertungen

- Response Spectrum Analysis Using Femap and NX NastranDokument40 SeitenResponse Spectrum Analysis Using Femap and NX NastranGana C Rover100% (1)

- Drag Force in Flow Over A BodyDokument11 SeitenDrag Force in Flow Over A Bodyamin67% (3)

- Concept of Drag On Immersed BodiesDokument11 SeitenConcept of Drag On Immersed BodiesShourya SaraswatNoch keine Bewertungen

- Flow Past a Circular CylinderDokument16 SeitenFlow Past a Circular CylinderShiva UNoch keine Bewertungen

- Flow Over A Circular CylinderDokument6 SeitenFlow Over A Circular CylinderMOFEEZALAMNoch keine Bewertungen

- DRAG FORCE MEASUREMENT OF A CYLINDER USING PENDULUM METHODDokument9 SeitenDRAG FORCE MEASUREMENT OF A CYLINDER USING PENDULUM METHODHarsh MehtaNoch keine Bewertungen

- Motion of Particles in Fluid PDFDokument57 SeitenMotion of Particles in Fluid PDFRanya JamalNoch keine Bewertungen

- Edexcel National Certificate/Diploma Principles and Applications of Fluid Mechanics Unit 13 NQF Level 3 Outcome 4 - Dynamic Fluid Systems Tutorial 1 - Model TestingDokument12 SeitenEdexcel National Certificate/Diploma Principles and Applications of Fluid Mechanics Unit 13 NQF Level 3 Outcome 4 - Dynamic Fluid Systems Tutorial 1 - Model TestingrianrureNoch keine Bewertungen

- Flow Pass A Circular CylinderDokument3 SeitenFlow Pass A Circular CylinderAdry AqilNoch keine Bewertungen

- Motion of Particles in FluidDokument62 SeitenMotion of Particles in FluidYolla MirandaNoch keine Bewertungen

- Eme1122 CN4Dokument7 SeitenEme1122 CN4MAENYA BRUCE OYONDINoch keine Bewertungen

- Analytical Method: TheoryDokument5 SeitenAnalytical Method: TheoryRaj AnbuNoch keine Bewertungen

- 1st Year Physics Notes Chap06Dokument7 Seiten1st Year Physics Notes Chap06phooolNoch keine Bewertungen

- Open Ended PrintDokument14 SeitenOpen Ended PrintSalleh SaidNoch keine Bewertungen

- DragDokument13 SeitenDragAbu NaserNoch keine Bewertungen

- Head Loss in Pipe - Lab Report MannualDokument4 SeitenHead Loss in Pipe - Lab Report MannualRampukar SahNoch keine Bewertungen

- Level MeasurementDokument16 SeitenLevel MeasurementhiuNoch keine Bewertungen

- Fluid Mechanics I CE-407: Pressure MeasurementDokument23 SeitenFluid Mechanics I CE-407: Pressure Measurementtaha zafar100% (1)

- Viscosity and Fluid Flow PDFDokument3 SeitenViscosity and Fluid Flow PDFLy Ca TieuNoch keine Bewertungen

- Dimensional Analysis Handout PDFDokument10 SeitenDimensional Analysis Handout PDFHafiz Mudaser AhmadNoch keine Bewertungen

- FM Immersed BodiesDokument40 SeitenFM Immersed Bodiesjsrajoyd_224488661Noch keine Bewertungen

- Two-Phase Pressure Drop: October 2015Dokument37 SeitenTwo-Phase Pressure Drop: October 2015Vimal RajNoch keine Bewertungen

- Mechanical Operation 2 PDFDokument49 SeitenMechanical Operation 2 PDFIlyas PashaNoch keine Bewertungen

- DRG PDFDokument4 SeitenDRG PDFMustafa MowfakNoch keine Bewertungen

- Hydraulics Laboratory Manual: Flow Visualization ExperimentsDokument66 SeitenHydraulics Laboratory Manual: Flow Visualization ExperimentsMülêtæ FîkírúNoch keine Bewertungen

- Levicky Fluid Kinematics PDFDokument15 SeitenLevicky Fluid Kinematics PDFivana83Noch keine Bewertungen

- Drag Force ReportDokument8 SeitenDrag Force ReportMateus RodriguesNoch keine Bewertungen

- Faculty of Engineering and Quantity Surveying (FEQS) MEE3221 Fluids Mechanics 2Dokument18 SeitenFaculty of Engineering and Quantity Surveying (FEQS) MEE3221 Fluids Mechanics 2Dion LimNoch keine Bewertungen

- Flow Past a Circular Cylinder ExperimentDokument15 SeitenFlow Past a Circular Cylinder ExperimentNguyen Duy Thao75% (4)

- Drag and Lift - Lecture Notes PDFDokument66 SeitenDrag and Lift - Lecture Notes PDFsanjana jainNoch keine Bewertungen

- Chemical Engineering Laboratory IDokument54 SeitenChemical Engineering Laboratory IAndini DamayantiNoch keine Bewertungen

- Flow Over Spheres and Cylinders: Drag CoefficientsDokument2 SeitenFlow Over Spheres and Cylinders: Drag Coefficientsromy kahalehNoch keine Bewertungen

- Report Fluid (LAb Manual)Dokument9 SeitenReport Fluid (LAb Manual)darkzainiNoch keine Bewertungen

- Unit-Ii Flow of Fluids and Flow Through Pipes 2.1. Flow of FluidsDokument14 SeitenUnit-Ii Flow of Fluids and Flow Through Pipes 2.1. Flow of FluidsJeevanandam ShanmugasundaramNoch keine Bewertungen

- CL 254: Process Fluid Mechanics 2022 (S1) Tutorial 2: Due Date - 24 Jan 2022, 23:59Dokument2 SeitenCL 254: Process Fluid Mechanics 2022 (S1) Tutorial 2: Due Date - 24 Jan 2022, 23:59bcghgfckhNoch keine Bewertungen

- Flow Over Cylinder Lab ReportDokument17 SeitenFlow Over Cylinder Lab ReportT D Harshith ReddyNoch keine Bewertungen

- Effects of Gravity On The Shape of Liquid DropletsDokument4 SeitenEffects of Gravity On The Shape of Liquid Dropletspepper100Noch keine Bewertungen

- 8b. Multiple Particles & Porous MediaDokument6 Seiten8b. Multiple Particles & Porous MediaLiuShangMingNoch keine Bewertungen

- Maxwell - Ucdavis.edu Cole Phy9b Notes Fluids Ch3Dokument24 SeitenMaxwell - Ucdavis.edu Cole Phy9b Notes Fluids Ch3Bryan WolnikNoch keine Bewertungen

- Using Wind Tunnel Tests To Study Pressure Distributions Around A Bluff Body: The Case of A Circular CylinderDokument6 SeitenUsing Wind Tunnel Tests To Study Pressure Distributions Around A Bluff Body: The Case of A Circular CylinderjhNoch keine Bewertungen

- Two Phase Flow, Rheology and Powder Flow: Chapters 6, 9 & 10 in FundamentalsDokument44 SeitenTwo Phase Flow, Rheology and Powder Flow: Chapters 6, 9 & 10 in FundamentalsUmesh PatelNoch keine Bewertungen

- Fluid Mechanics UNIT-1 (Part-2)Dokument28 SeitenFluid Mechanics UNIT-1 (Part-2)Achyutha AnilNoch keine Bewertungen

- 4.2.1.2.1.1 M Ercury Barometers and U-Tube M Anometers: Print This Section Save ZoomDokument6 Seiten4.2.1.2.1.1 M Ercury Barometers and U-Tube M Anometers: Print This Section Save ZoomchatuusumitavaNoch keine Bewertungen

- Fluid Mechanics d203Dokument302 SeitenFluid Mechanics d203Vignesh SundaramNoch keine Bewertungen

- Abhishek Thakur Xi-F 15 Physics Project File: Mechanical Properties of FluidsDokument14 SeitenAbhishek Thakur Xi-F 15 Physics Project File: Mechanical Properties of FluidsAbhishek ThakurNoch keine Bewertungen

- Milli Kan Oil Drop ExperimentDokument12 SeitenMilli Kan Oil Drop ExperimentAli AhmedNoch keine Bewertungen

- Fluid MechanicsDokument32 SeitenFluid MechanicsShristyNoch keine Bewertungen

- Principles of Momentum Transfer and ApplicationsDokument9 SeitenPrinciples of Momentum Transfer and ApplicationsjaiminNoch keine Bewertungen

- Report SimulationDokument19 SeitenReport SimulationRajkumarNoch keine Bewertungen

- Lab OrificeDokument14 SeitenLab OrificemarkNoch keine Bewertungen

- Misinterpretations of Bernoullis Law 2011 InternetDokument11 SeitenMisinterpretations of Bernoullis Law 2011 InternetzazaNoch keine Bewertungen

- Volumes by Shell MethodDokument16 SeitenVolumes by Shell Methodayesha noorNoch keine Bewertungen

- Aqa 84031 W MS Jun13 PDFDokument18 SeitenAqa 84031 W MS Jun13 PDFdadajee420Noch keine Bewertungen

- ADV-1 Phase-2 ITR B-Lot T-171473Dokument15 SeitenADV-1 Phase-2 ITR B-Lot T-171473Ashish SharmaNoch keine Bewertungen

- Chemical Bonding (F Only)Dokument28 SeitenChemical Bonding (F Only)Raju SinghNoch keine Bewertungen

- Sa (CM)Dokument5 SeitenSa (CM)Sagar SwarupNoch keine Bewertungen

- Unbalanced Magnetic Pull Forces in Cage Induction Motors with AsymmetryDokument5 SeitenUnbalanced Magnetic Pull Forces in Cage Induction Motors with AsymmetryRohan ChandrashekarNoch keine Bewertungen

- Matrix CalculusDokument9 SeitenMatrix CalculusAndrewNoch keine Bewertungen

- SsssDokument17 SeitenSsssPhysicsNoch keine Bewertungen

- UntitledDokument3 SeitenUntitledFarah EssidNoch keine Bewertungen

- #Part 1 2021 PSM NMRDokument26 Seiten#Part 1 2021 PSM NMRMely Yunior SafitriNoch keine Bewertungen

- 3001 Machine Design Elements SampleDokument14 Seiten3001 Machine Design Elements SampleCGD ReviewNoch keine Bewertungen

- The Preparation of Magnetic Nanoparticles For Applications in BiomedicineDokument17 SeitenThe Preparation of Magnetic Nanoparticles For Applications in BiomedicineMadavat Prem Pai LópezNoch keine Bewertungen

- Syllabus For Written Test at IIT KanpurDokument2 SeitenSyllabus For Written Test at IIT KanpurNikhil WaniNoch keine Bewertungen

- Partial Differential Equation MCQ For M.Sc. From T. AmaranatjDokument10 SeitenPartial Differential Equation MCQ For M.Sc. From T. AmaranatjSanket K Mohare100% (5)

- Power System Lab021-1Dokument10 SeitenPower System Lab021-1Montosh RoyNoch keine Bewertungen

- 55-1-1 Physics Marking Scheme 2020Dokument18 Seiten55-1-1 Physics Marking Scheme 2020jyotibhalaNoch keine Bewertungen

- CLS Aipmt 18 19 XII Phy Study Package 5 SET 2 Chapter 1Dokument36 SeitenCLS Aipmt 18 19 XII Phy Study Package 5 SET 2 Chapter 1Adil Ahmed83% (12)

- SF6 Circuit Breakers AdvantagesDokument4 SeitenSF6 Circuit Breakers Advantagessekhar_ntpcNoch keine Bewertungen

- Nucleophilic Substitution Reactions of Alkyl HalidesDokument36 SeitenNucleophilic Substitution Reactions of Alkyl HalidesmaulidyaNoch keine Bewertungen

- Allen DLP Major-3eng QDokument24 SeitenAllen DLP Major-3eng Qrk467111Noch keine Bewertungen

- CH 34 - Total SolutionsDokument24 SeitenCH 34 - Total SolutionsLemonn LemonnNoch keine Bewertungen

- Algorithmic Advances in Riemannian Geometry and ApplicationsDokument216 SeitenAlgorithmic Advances in Riemannian Geometry and ApplicationsasgfsagNoch keine Bewertungen

- AP Chemistry 2010 Free-Response Questions Form B: The College BoardDokument13 SeitenAP Chemistry 2010 Free-Response Questions Form B: The College BoardDharul Handri PranawaNoch keine Bewertungen

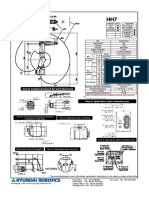

- Hh7 CatalogDokument1 SeiteHh7 Catalogjitender kumarNoch keine Bewertungen

- Chem 113 - Water Sample Lab ReportDokument16 SeitenChem 113 - Water Sample Lab Reportapi-356033847Noch keine Bewertungen