Beruflich Dokumente

Kultur Dokumente

EN Waler

Hochgeladen von

vsnsfbOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

EN Waler

Hochgeladen von

vsnsfbCopyright:

Verfügbare Formate

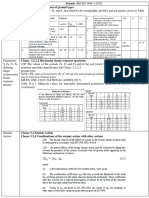

Steel member design (EN1993-1-1:2005)

In accordance with EN1993-1-1:2005 incorporating Corrigenda February 2006 and April 2009 and the recommended values

Section details

Section type;

UC 356x406x393 (BS4-1)

Steel grade;

S355

From table 3.1: Nominal values of yield strength fy and ultimate tensile strength fu for hot rolled structural steel

Nominal thickness of element;

t = max(tf, tw) = 49.2 mm

Nominal yield strength;

fy = 335 N/mm2

Nominal ultimate tensile strength;

fu = 470 N/mm2

Modulus of elasticity;

E = 210000 N/mm2

Partial factors - Section 6.1

Resistance of cross-sections;

M0 = 1.00

Resistance of members to instability;

M1 = 1.00

Resistance of tensile members to fracture;

M2 = 1.25

Lateral restraint

Distance between major axis restraints;

Ly = 5000 mm

Distance between minor axis restraints;

Lz = 2500 mm

Effective length factors

Effective length factor in major axis;

Ky = 0.700

Effective length factor in minor axis;

Kz = 0.700

Effective length factor for torsion;

KLT = 0.750

Classification of cross sections - Section 5.5

= [235 N/mm2 / fy] = 0.84

Internal compression parts subject to bending and compression - Table 5.2 (sheet 1 of 3)

Width of section;

c = d = 290.2 mm

= min([h / 2 + NEd / (2 tw fy) - (tf+ r)] / c, 1) = 0.771

c / tw = 11.3

Class 1

Outstand flanges - Table 5.2 (sheet 2 of 3)

Width of section;

c = (b - tw - 2 r) / 2 = 173 mm

c / tf = 4.2

Class 1

Section is class 1

Check shear - Section 6.2.6

Height of web;

hw = h - 2 tf = 320.6 mm

Shear area factor;

= 1.000

hw / tw < 72 /

Shear buckling resistance can be ignored

Design shear force parallel to z axis;

Vz,Ed = 2035 kN

Shear area - cl 6.2.6(3);

Av = max(A - 2 b tf + (tw + 2 r) tf, hw tw) =

Design shear resistance - cl 6.2.6(2);

Vc,z,Rd = Vpl,z,Rd = Av (fy / [3]) / M0 = 2516.3 kN

PASS - Design shear resistance exceeds design shear force

Combined bending, shear and axial force - Section 6.2.10

Reduction factor (6.2.10(3));

v = [(2 Vz,Ed / Vpl,z,Rd) - 1]2 = 0.381

Design shear force parallel to y axis;

Vy,Ed = 5 kN

Shear area - cl 6.2.6(3);

Av = max(2 b tf + (tw + 2 r) tf, A - (hw tw)) = 43050

Design shear resistance - cl 6.2.6(2);

Vc,y,Rd = Vpl,y,Rd = Av (fy / [3]) / M0 = 8326.4 kN

PASS - Design shear resistance exceeds design shear force

Check bending moment major (y-y) axis - Section 6.2.5

Design bending moment;

My,Ed = 1500 kNm

Design bending resistance moment - eq 6.13;

Mc,y,Rd = Mpl,y,Rd = W pl.y (1 - v) fy / M0 = 1704.3 kNm

Slenderness ratio for lateral torsional buckling

Correction factor - Table 6.6;

kc = 1

C1 = 1 / kc2 = 1

Curvature factor;

g = [1 - (Iz / Iy)] = 0.789

Poissons ratio;

= 0.3

Shear modulus;

G = E / [2 (1 + )] = 80769 N/mm2

Unrestrained length;

L = 0.75 Lz = 1875 mm

Elastic critical buckling moment;

Mcr = C1 2 E Iz / (L2 g) [Iw / Iz + L2 G It / (2 E Iz)] = 85759 kNm

Slenderness ratio for lateral torsional buckling;

LT

Limiting slenderness ratio;

LT,0

LT

<

LT,0

= [W pl.y fy / Mcr] = 0.179

= 0.4

- Lateral torsional buckling can be ignored

Design resistance for buckling - Section 6.3.2.1

Buckling curve - Table 6.5;

Imperfection factor - Table 6.3;

b

LT = 0.34

Correction factor for rolled sections;

= 0.75

LTB reduction determination factor;

LT = 0.5 [1 + LT (

LTB reduction factor - eq 6.57;

LT = min(1 / [LT + (

Modification factor;

f = min(1 - 0.5 (1 - kc) [1 - 2 (

Modified LTB reduction factor - eq 6.58;

LT,mod = min(LT / f, 1) = 1.000

Design buckling resistance moment - eq 6.55;

Mb,Rd = LT,mod W pl.y (1 - v) fy / M1 = 1704.3 kNm

PASS - Design buckling resistance moment exceeds design bending moment

LT

2

LT

LT,0

) +

2

LT

2

LT

] = 0.475

)], 1, 1 /

2

LT

) = 1.000

- 0.8) ], 1) = 1.000

2

LT

Check bending moment minor (z-z) axis - Section 6.2.5

Design bending moment;

Mz,Ed = 10 kNm

Design bending resistance moment - eq 6.13;

Mc,z,Rd = Mpl,z,Rd = W pl.z (1 - v) fy / M0 = 861 kNm

PASS - Design bending resistance moment exceeds design bending moment

Check compression - Section 6.2.4

Design compression force;

NEd = 1610 kN

Design resistance of section - eq 6.10;

Nc,Rd = Npl,Rd = A fy / M0 = 16769.3 kN

Slenderness ratio for major (y-y) axis buckling

Critical buckling length;

Lcr,y = Ly Ky = 3500 mm

Critical buckling force;

Ncr,y = 2 ESEC3 Iy / Lcr,y2 = 248067.9 kN

Slenderness ratio for buckling - eq 6.50;

= [A fy / Ncr,y] = 0.260

Design resistance for buckling - Section 6.3.1.1

Buckling curve - Table 6.2;

Imperfection factor - Table 6.1;

b

y = 0.34

Buckling reduction determination factor;

y = 0.5 [1 + y (

Buckling reduction factor - eq 6.49;

y = min(1 / [y + ( -

Design buckling resistance - eq 6.47;

Nb,y,Rd = y A fy / M1 = 16410.8 kN

- 0.2) +

2

y

2

y

2

y

] = 0.544

)], 1) = 0.979

PASS - Design buckling resistance exceeds design compression force

Slenderness ratio for minor (z-z) axis buckling

Critical buckling length;

Lcr,z = Lz Kz = 1750 mm

Critical buckling force;

Ncr,z = 2 ESEC3 Iz / Lcr,z2 = 374711.1 kN

Slenderness ratio for buckling - eq 6.50;

= [A fy / Ncr,z] = 0.212

Design resistance for buckling - Section 6.3.1.1

Buckling curve - Table 6.2;

Imperfection factor - Table 6.1;

c

z = 0.49

Buckling reduction determination factor;

z = 0.5 [1 + z (

Buckling reduction factor - eq 6.49;

z = min(1 / [z + ( -

Design buckling resistance - eq 6.47;

Nb,z,Rd = z A fy / M1 = 16670.5 kN

- 0.2) +

2

z

2

z

2

z

] = 0.525

)], 1) = 0.994

PASS - Design buckling resistance exceeds design compression force

Check torsional and torsional-flexural buckling - Section 6.3.1.4

Torsional buckling length factor;

KT = 0.70

Torsional buckling length;

Lcr,T = max(Ly, Lz) KT = 3500 mm

Distance from shear centre to centroid in y axis;

y0 = 0.0 mm

Distance from shear centre to centroid in z axis;

z0 = 0.0 mm

Radius of gyration;

i0 = [iy2 + iz2] = 200.9 mm

Elastic critical torsional buckling force;

Ncr,T = 1 / i02 [G It + 2 ESEC3 Iw / Lcr,T2] = 150333.9

Torsion factor;

T = 1 - (y0 / i0)2 = 1.000

Elastic critical torsional-flexural buckling force

Ncr,TF = Ncr,y / (2 T) [1 + Ncr,T / Ncr,y - [(1 - Ncr,T / Ncr,y)2 + 4 (y0 / i0)2 Ncr,T / Ncr,y]] = 150333.9 kN

Elastic critical buckling force;

Ncr = min(Ncr,T, Ncr,TF) = 150333.9 kN

Slenderness ratio for torsional buckling - eq 6.52;

= [A fy / Ncr] = 0.334

Design resistance for buckling - Section 6.3.1.1

Buckling curve - Table 6.2;

Imperfection factor - Table 6.1;

c

T = 0.49

Buckling reduction determination factor;

T = 0.5 [1 + T (

Buckling reduction factor - eq 6.49;

T = min(1 / [T + (T2 -

Design buckling resistance - eq 6.47;

Nb,T,Rd = T A fy / M1 = 15624.5 kN

- 0.2) +

2

T

] = 0.589

)], 1) = 0.932

2

T

PASS - Design buckling resistance exceeds design compression force

Biaxial bending - Section 6.2.9

Plastic moment resistance (y-y);

MN,y,Rd = Mpl,y,Rd = 2754.5 kNm

Plastic moment resistance (z-z);

MN,z,Rd = Mpl,z,Rd = 1391.5 kNm

Normal force to plastic resistance force ratio;

n = NEd / Npl,Rd = 0.10

Parameter introducing effect of biaxial bending;

bi = 2.00

Parameter introducing effect of biaxial bending;

bi = 5 n = 0.48

Interaction formula eq (6.41);

(My,Ed / MN,y,Rd)_bi + (Mz,Ed / MN,z,Rd)_bi = 0.390

PASS - Biaxial bending check is satisfied

Check combined bending and compression - Section 6.3.3

Cmy = 1.000

Equivalent uniform moment factors - Table B.3;

Cmz = 1.000

CmLT = 1.000

Interaction factors kij for members susceptible to torsional deformations - Table B.2

Characteristic moment resistance;

My,Rk = W pl.y fy = 2754.5 kNm

Characteristic moment resistance;

Mz,Rk = W pl.z fy = 1391.5 kNm

Characteristic resistance to normal force;

NRk = A fy = 16769.3 kN

Interaction factors;

kyy = Cmy [1 + min(

- 0.2, 0.8) NEd / (y NRk /

kzy = min(0.6 + z, 1 - 0.1

kzz = Cmz [1 + min(2

NEd / ((CmLT - 0.25)

- 0.6, 1.4) NEd / (z NRk

kyz = 0.6 kzz = 0.590

Interaction formulae - eq 6.61 & eq 6.62;

NEd / (y NRk / M1) + kyy My,Ed / (LT My,Rk / M1) + kyz Mz,Ed

NEd / (z NRk / M1) + kzy My,Ed / (LT My,Rk / M1) + kzz Mz,Ed

PASS - Combined bending and compression checks are satisfied

commended values

, hw tw) = 13010 mm2

- (hw tw)) = 43050 mm2

= 1704.3 kNm

2

LT

] = 0.475

1 /

2

LT

) = 1.000

- 0.8) ], 1) = 1.000

2

= 1704.3 kNm

Lcr,T2] = 150333.9 kN

/ (y NRk / M1)] = 1.006

((CmLT - 0.25) z NRk / M1)) = 0.812

NEd / (z NRk / M1)] = 0.983

) + kyz Mz,Ed / (Mz,Rk / M1) = 0.650

) + kzz Mz,Ed / (Mz,Rk / M1) = 0.546

Das könnte Ihnen auch gefallen

- Weld Design BS 5950-1 (Ok)Dokument16 SeitenWeld Design BS 5950-1 (Ok)Zaido Al HalabiNoch keine Bewertungen

- 9.shear Capacity of Steel Frame Member Rev 0.2Dokument22 Seiten9.shear Capacity of Steel Frame Member Rev 0.2WahidAgungNoch keine Bewertungen

- Crack WidthDokument2 SeitenCrack Widthhabibur Rahman KhanNoch keine Bewertungen

- Bolt Design & Development LengthDokument3 SeitenBolt Design & Development LengthShamik ChowdhuryNoch keine Bewertungen

- Eccentric Footing Design PDFDokument9 SeitenEccentric Footing Design PDFmsiddiq1Noch keine Bewertungen

- Axial Load Capacity For Deep Foundations Piles: Sand Input ResultsDokument8 SeitenAxial Load Capacity For Deep Foundations Piles: Sand Input Resultsacidrisamuel2656Noch keine Bewertungen

- ACI TSecDokument3 SeitenACI TSecمصطفى عبدالرحيمNoch keine Bewertungen

- Dam I33Dokument47 SeitenDam I33Trung ConNoch keine Bewertungen

- 1.0 Design of Bracket: Load On Bracket Type LevelDokument4 Seiten1.0 Design of Bracket: Load On Bracket Type LeveldsureshcivilNoch keine Bewertungen

- 008 - Column Load AnalysisDokument17 Seiten008 - Column Load AnalysisVAIBHAVNoch keine Bewertungen

- Slab Manual DesignDokument1 SeiteSlab Manual DesignAtul ShrivastavaNoch keine Bewertungen

- Design of Long Wall: Tank Full and No Soil PressureDokument6 SeitenDesign of Long Wall: Tank Full and No Soil PressureAshoka YadavNoch keine Bewertungen

- Metro Standard StructDwgs 080613Dokument41 SeitenMetro Standard StructDwgs 080613rpazbNoch keine Bewertungen

- Design of Lacing: 2.5% of Axial Load Force in Each Lacing Bar (Flac)Dokument4 SeitenDesign of Lacing: 2.5% of Axial Load Force in Each Lacing Bar (Flac)Prasad SamantNoch keine Bewertungen

- CV DM 001 100dpiDokument58 SeitenCV DM 001 100dpighazi andonoNoch keine Bewertungen

- JEC Prog - Design of CorbelDokument4 SeitenJEC Prog - Design of CorbelAaron O'SullivanNoch keine Bewertungen

- Xxx-Type (H XM, B M) (Superstructure Type: PSC (Span 50m) ) : 1.design Condition 1.1 Type: 1.2 Foundation TypeDokument9 SeitenXxx-Type (H XM, B M) (Superstructure Type: PSC (Span 50m) ) : 1.design Condition 1.1 Type: 1.2 Foundation TypesudipNoch keine Bewertungen

- Combined Footing-RgDokument101 SeitenCombined Footing-RgkumsbamaNoch keine Bewertungen

- Deflection For Cantilever Beam or Salb: Size B D FCK Fe E M.IDokument2 SeitenDeflection For Cantilever Beam or Salb: Size B D FCK Fe E M.IHemant SonawadekarNoch keine Bewertungen

- Ultimate Moment Capacity of Reinforced Concrete Section To EN 1992-2 - Clause 6.1Dokument5 SeitenUltimate Moment Capacity of Reinforced Concrete Section To EN 1992-2 - Clause 6.1Randhir BharatNoch keine Bewertungen

- Spring Stiffnes CalculationDokument13 SeitenSpring Stiffnes Calculationyadav04_abhishekNoch keine Bewertungen

- Young's ModuleDokument12 SeitenYoung's Modulelazy catNoch keine Bewertungen

- Design of RCC Footing As Per ACI 318 95 EdDokument2 SeitenDesign of RCC Footing As Per ACI 318 95 EdMaad Ahmed Al-MaroofNoch keine Bewertungen

- C Section PropertiesDokument2 SeitenC Section PropertiesnavinzhereNoch keine Bewertungen

- Wind Load Calculation Using EurocodeDokument3 SeitenWind Load Calculation Using EurocodeemmanuelNoch keine Bewertungen

- Shallow Foundation Design 2: SettlementDokument32 SeitenShallow Foundation Design 2: SettlementPhanna MongNoch keine Bewertungen

- Chapter 13 ExamplesDokument8 SeitenChapter 13 ExamplesAnonymous kBl0u3nNoch keine Bewertungen

- 01-Retaining Wall Counterfort L ShapedDokument15 Seiten01-Retaining Wall Counterfort L ShapedBijendra Man Pradhan MRBNoch keine Bewertungen

- Wildlife Crossing Design Based On AASHTO-17th & ACI 318-14Dokument1 SeiteWildlife Crossing Design Based On AASHTO-17th & ACI 318-14jklo12Noch keine Bewertungen

- Design Calculation of Rss Building 3VIN 9 554 D1 S1 202 R0 Design of Foundations DataDokument56 SeitenDesign Calculation of Rss Building 3VIN 9 554 D1 S1 202 R0 Design of Foundations DataARUNKUMAR KNoch keine Bewertungen

- Analysis of 2 - Pile Group - Pc2 MX Design Data: Load Case 100 DL+LL Joint No MZ Grid Mark Column LoadDokument9 SeitenAnalysis of 2 - Pile Group - Pc2 MX Design Data: Load Case 100 DL+LL Joint No MZ Grid Mark Column LoadMythili BysaniNoch keine Bewertungen

- ACI BendDokument3 SeitenACI Bendمصطفى عبدالرحيمNoch keine Bewertungen

- Thiet Ke Cot Composite - EC4. V1.0 (MS03)Dokument5 SeitenThiet Ke Cot Composite - EC4. V1.0 (MS03)luuvandong48xf396Noch keine Bewertungen

- Isolated FootingsDokument30 SeitenIsolated FootingsBanda 007Noch keine Bewertungen

- Crack WidthDokument6 SeitenCrack Widthnitin400Noch keine Bewertungen

- Loads For Supporting Beams: LX Ly UDL On SlabDokument6 SeitenLoads For Supporting Beams: LX Ly UDL On SlabAnonymous sfkedkymNoch keine Bewertungen

- Geotechnical Investigations of Mumbai-Pune ExpresswayDokument17 SeitenGeotechnical Investigations of Mumbai-Pune Expresswayblackberry7100gNoch keine Bewertungen

- Column Interaction DiagramDokument4 SeitenColumn Interaction DiagramAhmedNoch keine Bewertungen

- PILE CAP PC1-FOUR Pile (IBL SHED)Dokument5 SeitenPILE CAP PC1-FOUR Pile (IBL SHED)vikas WaghmareNoch keine Bewertungen

- Detail Estimate of RailingDokument5 SeitenDetail Estimate of Railingdebasispal78Noch keine Bewertungen

- Lateral Pile Capacity Caculation Using Broms's Method (Free Head Type)Dokument8 SeitenLateral Pile Capacity Caculation Using Broms's Method (Free Head Type)Mohammad Tawfiq WaraNoch keine Bewertungen

- Gardez - Khost Bridge No. 5 I - GIRDER 0.600 X 1.450 X 25.700 MDokument5 SeitenGardez - Khost Bridge No. 5 I - GIRDER 0.600 X 1.450 X 25.700 MBrian UrciaNoch keine Bewertungen

- Deck Slab DesignDokument19 SeitenDeck Slab DesignManvendra NigamNoch keine Bewertungen

- Concentric Column: Design of Square/Rectangular Isolated FootingDokument21 SeitenConcentric Column: Design of Square/Rectangular Isolated FootingangeladolfoNoch keine Bewertungen

- CHS With Concrete CalculationDokument23 SeitenCHS With Concrete CalculationYanfei JinNoch keine Bewertungen

- Cladding& Runner DesignDokument1 SeiteCladding& Runner DesignDeepmalaJayeshNoch keine Bewertungen

- Culvert Design 1Dokument66 SeitenCulvert Design 1kanishkaNoch keine Bewertungen

- Chequred Plate CheckDokument2 SeitenChequred Plate Check_jessecaNoch keine Bewertungen

- 41-Pile FoundationDokument56 Seiten41-Pile Foundationsharif uddinNoch keine Bewertungen

- Gusset BaseDokument2 SeitenGusset Basemanish mehtaNoch keine Bewertungen

- 2015-0075 1 5 KH Tann 3/20/2018 Dawson Deep Beam Formworks: 149b Selegie Road Singapore 188314Dokument6 Seiten2015-0075 1 5 KH Tann 3/20/2018 Dawson Deep Beam Formworks: 149b Selegie Road Singapore 188314jasekan.dcNoch keine Bewertungen

- Monorail 0.5 TonDokument9 SeitenMonorail 0.5 TonAndreas HendiNoch keine Bewertungen

- Dynamic Earth PressureDokument2 SeitenDynamic Earth PressureMahadev D. BhandareNoch keine Bewertungen

- 5-Design of Raft FoundationDokument2 Seiten5-Design of Raft FoundationheshamNoch keine Bewertungen

- Ec9 Ex94 Beam Column HAZDokument5 SeitenEc9 Ex94 Beam Column HAZimotalpNoch keine Bewertungen

- TEDDS Calculation Version 3.0.09: - Section Is CompactDokument2 SeitenTEDDS Calculation Version 3.0.09: - Section Is CompactSupun Aravinda JayawardhaneNoch keine Bewertungen

- IS800 2007 Tee Detailed CalculationDokument5 SeitenIS800 2007 Tee Detailed CalculationVembuarasi VaithiyanathanNoch keine Bewertungen

- Steel Column DesignDokument10 SeitenSteel Column DesignWazini D. IzaniNoch keine Bewertungen

- 5.15 Swing Barrier v.1.0Dokument190 Seiten5.15 Swing Barrier v.1.0rfvz6sNoch keine Bewertungen

- Ponniyin Selvan - SynopsisDokument5 SeitenPonniyin Selvan - Synopsisvsnsfb100% (1)

- Load Cases Circular ShaftsDokument1 SeiteLoad Cases Circular ShaftsvsnsfbNoch keine Bewertungen

- HouseDokument3 SeitenHousevsnsfbNoch keine Bewertungen

- Fillet Welding Capacity in KNDokument2 SeitenFillet Welding Capacity in KNvsnsfbNoch keine Bewertungen

- Dwall Force & DeflectionDokument1 SeiteDwall Force & DeflectionvsnsfbNoch keine Bewertungen

- For Reference Only (Confidential) : Ryobi Geotechnique International Pte LTDDokument8 SeitenFor Reference Only (Confidential) : Ryobi Geotechnique International Pte LTDvsnsfbNoch keine Bewertungen

- Daily Task List - 20150414Dokument10 SeitenDaily Task List - 20150414vsnsfbNoch keine Bewertungen

- Corroded Bar Treatment 2Dokument1 SeiteCorroded Bar Treatment 2vsnsfbNoch keine Bewertungen

- Bending Moment Shear ForceDokument3 SeitenBending Moment Shear ForcevsnsfbNoch keine Bewertungen

- Toilet East Elevation - SketchDokument1 SeiteToilet East Elevation - SketchvsnsfbNoch keine Bewertungen

- Corroded Bar TreatmentDokument1 SeiteCorroded Bar TreatmentvsnsfbNoch keine Bewertungen

- Steel Plate Gate DesignDokument5 SeitenSteel Plate Gate DesignvsnsfbNoch keine Bewertungen

- Checklist For PPEDokument1 SeiteChecklist For PPEvsnsfbNoch keine Bewertungen

- Corroded Bar Treatment2Dokument1 SeiteCorroded Bar Treatment2vsnsfbNoch keine Bewertungen

- Pile C.width CalculatorDokument2 SeitenPile C.width CalculatorvsnsfbNoch keine Bewertungen

- Design CalculationDokument4 SeitenDesign CalculationvsnsfbNoch keine Bewertungen

- Design CriteriaDokument4 SeitenDesign CriteriavsnsfbNoch keine Bewertungen

- Tunnel LiningDokument3 SeitenTunnel Liningvsnsfb100% (1)

- Connections For Tilt Up WallsDokument46 SeitenConnections For Tilt Up WallsMichael James100% (1)

- Bhabha Student Front PagDokument7 SeitenBhabha Student Front PagimranNoch keine Bewertungen

- Popeye SpecificationsDokument436 SeitenPopeye Specificationspascal rosasNoch keine Bewertungen

- Material TestingDokument59 SeitenMaterial TestingWilliam Salazar100% (4)

- Introduction Power System ProtectionDokument110 SeitenIntroduction Power System ProtectionjameelahmadNoch keine Bewertungen

- PDH Post Tensioned Concrete Design PDFDokument8 SeitenPDH Post Tensioned Concrete Design PDFabdulmananNoch keine Bewertungen

- Shubham Shukla CVDokument4 SeitenShubham Shukla CVShubham ShuklaNoch keine Bewertungen

- CV Rizzieri EnglishDokument6 SeitenCV Rizzieri EnglishGiampaoloRizzieriNoch keine Bewertungen

- Solid AssignmentDokument8 SeitenSolid AssignmentPaviNoch keine Bewertungen

- Sar EcDokument363 SeitenSar EcdhananjayslambNoch keine Bewertungen

- Ketentuan Detail Tulangan Pada Struktur Beton Bertulang - Yogyakarta - 14-15nov.20118 BW PDFDokument235 SeitenKetentuan Detail Tulangan Pada Struktur Beton Bertulang - Yogyakarta - 14-15nov.20118 BW PDFAris AriyadiNoch keine Bewertungen

- 4 Strengths of Recycled Aggregate Concrete Made Using Field-Demolished Concrete As AggregateDokument9 Seiten4 Strengths of Recycled Aggregate Concrete Made Using Field-Demolished Concrete As Aggregateget100% (2)

- Syllabus Signal and System IIDokument2 SeitenSyllabus Signal and System IIkuntjoroNoch keine Bewertungen

- Rectangular Concrete TanksDokument10 SeitenRectangular Concrete Tanksferchov_coNoch keine Bewertungen

- Resume Terkini 2016 / 2017Dokument1 SeiteResume Terkini 2016 / 2017syarul77% (13)

- CSR of WiproDokument26 SeitenCSR of WiproAshok Solanki79% (14)

- Clause For Seismic DesignDokument10 SeitenClause For Seismic DesignFarhanah Binti FaisalNoch keine Bewertungen

- Date Tested: Performance Check of Sieves With Designation Larger Than 4.75mm/no. 4 (ASTM E11)Dokument64 SeitenDate Tested: Performance Check of Sieves With Designation Larger Than 4.75mm/no. 4 (ASTM E11)Hamza MukhtarNoch keine Bewertungen

- Robert Kavetsky Et Al - Energetic Systems and Nanotechnology - A Look AheadDokument10 SeitenRobert Kavetsky Et Al - Energetic Systems and Nanotechnology - A Look AheadSteemWheelNoch keine Bewertungen

- PLAXIS - The-Spring-Constant-and-Soil-structure-Interaction PDFDokument16 SeitenPLAXIS - The-Spring-Constant-and-Soil-structure-Interaction PDFDedy KristiantoNoch keine Bewertungen

- Crossing Boundaries, Building Bridges - Comparing The History of Women Engineers, 1870s-1990sDokument310 SeitenCrossing Boundaries, Building Bridges - Comparing The History of Women Engineers, 1870s-1990sThaísReginaNoch keine Bewertungen

- Caixa Gbox - DocDokument15 SeitenCaixa Gbox - Docsimao.bolaNoch keine Bewertungen

- Features: Measurement of Residual Stresses in Uoe-Saw Line PipesDokument5 SeitenFeatures: Measurement of Residual Stresses in Uoe-Saw Line PipesMaulana HendraNoch keine Bewertungen

- The Reality of Project Management Office For Construction PDFDokument8 SeitenThe Reality of Project Management Office For Construction PDFyveseoneNoch keine Bewertungen

- Cat Fluids - Oils: Recommended UseDokument4 SeitenCat Fluids - Oils: Recommended UseAndrei Bleoju100% (2)

- The Application of Reliability Centered Maintenance (RCM)Dokument6 SeitenThe Application of Reliability Centered Maintenance (RCM)Ðian KpNoch keine Bewertungen

- Analysis of Epoxy Coated & Glass Fiber Bamboo & Steel ReinforcedConcrete BeamsDokument7 SeitenAnalysis of Epoxy Coated & Glass Fiber Bamboo & Steel ReinforcedConcrete BeamsInternational Journal of Innovative Science and Research TechnologyNoch keine Bewertungen

- Cooper B Line Pipe HangersDokument332 SeitenCooper B Line Pipe HangersAhmed EmadNoch keine Bewertungen

- Algroup Enterprises - Company Profile 2014-1Dokument6 SeitenAlgroup Enterprises - Company Profile 2014-1Faquruddin AliNoch keine Bewertungen