Beruflich Dokumente

Kultur Dokumente

1104A-44TG1 ElectropaK PN1783

Hochgeladen von

Francisco Martinez OrtizCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

1104A-44TG1 ElectropaK PN1783

Hochgeladen von

Francisco Martinez OrtizCopyright:

Verfügbare Formate

1100 Series 1104A-44TG1

Diesel Engine ElectropaK

64.3 kWm at 1500 rpm

75.5 kWm at 1800 rpm

Building upon Perkins proven reputation within the power

generation industry, the 1100 Series range of ElectropaK

engines now fit even closer to customers needs.

Product support

l

Perkins actively

pursues product

support excellence

by ensuring our

distribution network

invest in their territory

strengthening

relationships and

providing more value

to you, our customer

Through an

experienced global

network of distributors and

dealers, fully trained engine experts deliver total service

support around the clock, 365 days a year. They have a

comprehensive suite of web based tools at their fingertips

covering technical information, parts identification and

ordering systems, all dedicated to maximising the

productivity of your engine

Throughout the entire life of a Perkins engine, we provide

access to genuine OE specification parts and service. We

give 100% reassurance that you receive the very best in

terms of quality for lowest possible cost .. wherever your

Perkins powered machine is operating in the world

In the world of power generation success is only gained by

providing more for less. With the 1104A-44TG1 Perkins has

engineered even higher levels of reliability, yet lowered the cost

of ownership.

1100A units are designed for territories that do not require

compliance to EPA or EU emissions legislation. These units are

able to meet TA luft legislation.

Compact, efficient power

l

1100 Series is the result of an intensive period of customer

research that has guided the development of the range

The new 4.4 litre cylinder block ensures bore roundness is

maintained under the pressures of operation. It also ensures

combustion and mechanical noise is lowered

A new cylinder head has re-established Perkins mastery of

air control

Quality by design

l

Product design and Class A manufacturing improvements

enhance product reliability while maintaining Perkins

legendary reputation for durability

Cost effective power

l

Compact size and low noise

Lower fuel consumption and oil use

500 hour service intervals

2 year warranty

Engine Speed

(rev/min)

Type of

Operation

Engine Power

Typical Generator

Output (Net)

Gross

Net

kVA

kWe

kWm

bhp

kWm

bhp

65.0

52.0

59.6

79.9

58.4

78.3

88.0

64.3

86.2

94.8

68.6

92.0

75.5

101.2

1500

Prime Power

Standby Power

71.5

57.2

65.6

1800

Prime Power

76.0

60.8

70.7

Standby Power

83.6

66.9

77.8

104.3

The above ratings represent the engine performance capabilities to conditions specified in ISO 8528/1, ISO 3046/1:1986, BS5514/1. Derating may be required for conditions outside these;

consult Perkins Engines Company Limited.

Generator powers are typical and are based on an average alternator efficiency and a power factor (cos. q) of 0.8. Fuel specification: BS 2869: Part 2 1998 Class A2 or DIN EN 590.

Lubricatingoil: 15W40 to API CG4.

Rating Definitions

Prime Power: Variable load. Unlimited hours usage with an average load factor of 80% of the published prime power over each 24 hour period. A 10% overload is available for 1 hour in every 12hours

of operation. Standby Power: Variable load. Limited to 500 hours annual usage, up to 300 hours of which may be continuous running. No overload is permitted.

Photographs are for illustrative purposes only and may not reflect final specification.

All information in this document is substantially correct at time of printing and may be altered subsequently.

Publication No. PN1783/09/12 Produced in England 2012 Perkins Engines Company Limited

1100 Series 1104A-44TG1 Diesel Engine ElectropaK

64.3 kWm at 1500 rpm

75.5 kWm at 1800 rpm

629 mm

1241 mm

951 mm

1046 mm

Fuel Consumption

Standard ElectropaK specification

Engine Speed

1500 rev/min

1800 rev/min

g/kWh

l/hr

g/kWh

l/hr

Air inlet

Standby

207

16.2

211

19.5

Prime Power

208

14.8

211

17.7

75% of Prime Power

209

11.2

214

13.5

50% of Prime Power

224

8.0

229

9.6

Mounted air filter

Fuel system

l

Rotary type pump

l Ecoplus fuel filter

General data

Lubrication system

l

Wet sump with filler and dipstick

l Spin-on oil filter

Cooling system

l

Thermostatically-controlled system with gear-driven

circulation pump and belt-driven pusher fan

l Mounted radiator and piping

Electrical equipment

l

12 volt starter motor and 12 volt 65 amp alternator with DC

output

l 12 volt shutdown solenoid energised to run

l Glow plug cold start aid

Flywheel housing

l

l

High inertia flywheel to SAE J620 size 10/1112

SAE 3 flywheel housing

Number of cylinders............................................ 4 vertical in-line

Bore and stroke.....................................................105 x 127 mm

Displacement................................................................. 4.4 litres

Aspiration...............................................................Turbocharged

Cycle...............................................................................4 stroke

Combustion system...............................................Direct injection

Compression ratio........................................................... 17.25:1

Rotation................................Anti-clockwise viewed from flywheel

Cooling system........................................................Water-cooled

Total lubrication system capacity.................................... 8.0 litres

Total coolant capacity................................................... 13.0 litres

Dimensions Length................................................... 1241 mm

Width....................................................... 629 mm

Height...................................................... 951 mm

Dry weight (approx.).......................................................... 463 kg

Final weight and dimensions will depend on completed specification

Literature

l

Users Handbook

Optional equipment

l

Woodward electronic governor (LCG2)

Workshop manual

l Parts book

l

Photographs are for illustrative purposes only and may not

reflect final specification.

All information in this document is substantially correct at time

of printing and may be altered subsequently.

Publication No. PN1783/09/12 Produced in England

2012 Perkins Engines Company Limited

Perkins Engines Company Limited

Peterborough PE1 5FQ

United Kingdom

Telephone +44 (0)1733 583000

Fax +44 (0)1733 582240

www.perkins.com

Das könnte Ihnen auch gefallen

- Generador PerkinsDokument5 SeitenGenerador PerkinsDave ChecaNoch keine Bewertungen

- Perkins 1104 44GDokument5 SeitenPerkins 1104 44GJorge Enrique Fuentes MarinNoch keine Bewertungen

- Deutch ConectorsDokument92 SeitenDeutch Conectorshector gutierrezNoch keine Bewertungen

- 1104A-44TG1 PerkinsDokument8 Seiten1104A-44TG1 PerkinsMario Eduardo Santos MartinsNoch keine Bewertungen

- Catalogue: Professional Power Solution For Greater Value!Dokument241 SeitenCatalogue: Professional Power Solution For Greater Value!aldy yasiNoch keine Bewertungen

- N45sm1a 51 To 59KWDokument3 SeitenN45sm1a 51 To 59KWsaiyedasadNoch keine Bewertungen

- Ashok Leyland ALGP WO4D.E4, ALGPWO4DMK1 - HA4, AL4DTG3 - HA4D, AL4DTIG2 - HA4DT Operator's and Maintenance ManualDokument82 SeitenAshok Leyland ALGP WO4D.E4, ALGPWO4DMK1 - HA4, AL4DTG3 - HA4D, AL4DTIG2 - HA4DT Operator's and Maintenance ManualFLORES SANTIAGO CESAR MIGUELNoch keine Bewertungen

- TAD1641GE: Volvo Penta Genset EngineDokument2 SeitenTAD1641GE: Volvo Penta Genset EnginesIMPEX sHARMANoch keine Bewertungen

- Data SheetDokument34 SeitenData SheetsatyajitNoch keine Bewertungen

- C87 Te4Dokument3 SeitenC87 Te4Daniel MuratallaNoch keine Bewertungen

- Doosan Electronic Engine DP222 C - Series: For GeneratorDokument2 SeitenDoosan Electronic Engine DP222 C - Series: For GeneratorSergio Raul Baez100% (1)

- Aracer Smart - 20190816 PDFDokument17 SeitenAracer Smart - 20190816 PDFLưuTrầnNoch keine Bewertungen

- Catálogo MTUDokument2 SeitenCatálogo MTUPedro Henrique TavaresNoch keine Bewertungen

- Electronic Engine Governor Controller Operation ManualDokument7 SeitenElectronic Engine Governor Controller Operation ManualVinhNoch keine Bewertungen

- Ricardo 6105AZLD PDFDokument2 SeitenRicardo 6105AZLD PDFLogistician MALCOMSONNoch keine Bewertungen

- DYN1-10693-001-0-12 or DYN1-10693-001-0-24 PDFDokument8 SeitenDYN1-10693-001-0-12 or DYN1-10693-001-0-24 PDFSyed Mohammad Naveed100% (1)

- Data Sheets QSL9 G5Dokument4 SeitenData Sheets QSL9 G5Héctor VilaNoch keine Bewertungen

- Navistar and Ford Electronic Injectors ListDokument2 SeitenNavistar and Ford Electronic Injectors Listjesus perezNoch keine Bewertungen

- Installation Manual MDKBHDokument34 SeitenInstallation Manual MDKBHDaniel CastellanosNoch keine Bewertungen

- UC22/UC27: Aftermarket Parts ListDokument14 SeitenUC22/UC27: Aftermarket Parts Listshinichie100% (1)

- D6-350/DPR: Volvo Penta Aquamatic DuopropDokument2 SeitenD6-350/DPR: Volvo Penta Aquamatic DuopropНиколай АксёновNoch keine Bewertungen

- BF C275DDokument7 SeitenBF C275DLebahMaduNoch keine Bewertungen

- Twin Disc PDFDokument6 SeitenTwin Disc PDFLuis J. CastroNoch keine Bewertungen

- Fuel Optimized: Specification SheetDokument3 SeitenFuel Optimized: Specification SheetArslan AnnaNoch keine Bewertungen

- Dief SGC 120 Genset ControllerDokument10 SeitenDief SGC 120 Genset Controllerகோவி கோபால் ஆர்ட்ஸ்Noch keine Bewertungen

- DPS 20Dokument10 SeitenDPS 20Timo LilienbergNoch keine Bewertungen

- GTA38 Service Parts With Images (Oil Heater Pp13y14)Dokument36 SeitenGTA38 Service Parts With Images (Oil Heater Pp13y14)foroNoch keine Bewertungen

- Fire Pump EnginesDokument2 SeitenFire Pump Enginessugax00Noch keine Bewertungen

- Perkins 1006TAGDokument2 SeitenPerkins 1006TAGNathia Roa100% (1)

- Hoja de Datos QSK60G5 - fr6321Dokument3 SeitenHoja de Datos QSK60G5 - fr6321acere18100% (1)

- Appendix 1b, Engine DatasheetDokument4 SeitenAppendix 1b, Engine DatasheetdimasrimantiktoNoch keine Bewertungen

- TCD 2013 Automotive enDokument4 SeitenTCD 2013 Automotive enluizNoch keine Bewertungen

- Atlas Battery PDFDokument80 SeitenAtlas Battery PDFJaleel Sherazi100% (1)

- Kipor KDE Silent GeneratorDokument4 SeitenKipor KDE Silent GeneratorbacNoch keine Bewertungen

- 37MT 40M 41MT 42MT 50MT-Installation-Instructions-10511650Dokument2 Seiten37MT 40M 41MT 42MT 50MT-Installation-Instructions-10511650Supriyo AdiNoch keine Bewertungen

- Operation and Maintenance Manual Bulletin Nh220Dokument4 SeitenOperation and Maintenance Manual Bulletin Nh220Cordova MarcosNoch keine Bewertungen

- Doosan 4v222ti MotorlarıDokument2 SeitenDoosan 4v222ti MotorlarıhgulecNoch keine Bewertungen

- Technical Specifications Scania 176 Kva Natural GasDokument6 SeitenTechnical Specifications Scania 176 Kva Natural GasTomas Leon JuliaNoch keine Bewertungen

- 6BT5.9-DM Non-Certified Ratings SSDokument2 Seiten6BT5.9-DM Non-Certified Ratings SStempro100% (1)

- John Deere - Especificaciones Marinas - Oct. 2017Dokument15 SeitenJohn Deere - Especificaciones Marinas - Oct. 2017AlbertoNoch keine Bewertungen

- Massey Ferguson 7726S Dyna 6 SiiiiiiDokument3 SeitenMassey Ferguson 7726S Dyna 6 SiiiiiiAndres Felipe Mejía RivasNoch keine Bewertungen

- SM D0102 emDokument32 SeitenSM D0102 emStelian CrisanNoch keine Bewertungen

- Hatz 2g40Dokument8 SeitenHatz 2g40Tesla EcNoch keine Bewertungen

- Perkins 1103A-33T - 50 kVA - 17653 - Generators - Roban TrucksDokument8 SeitenPerkins 1103A-33T - 50 kVA - 17653 - Generators - Roban TrucksAbdulrahman Al Huriby100% (1)

- Silent Type 30kw Diesel Generator 480v 60hz - Buy 30kw Diesel Generator 480v 60hz, Chinese Engine Generators, Engine Generator Product On PDFDokument6 SeitenSilent Type 30kw Diesel Generator 480v 60hz - Buy 30kw Diesel Generator 480v 60hz, Chinese Engine Generators, Engine Generator Product On PDFM-Aulan Niam AunimNoch keine Bewertungen

- 2506 New Product CourseDokument43 Seiten2506 New Product CourseAli ToamaNoch keine Bewertungen

- 928-0222-Supl Onan ES Genset 04146 WOODWARD TQ-125 CONTROLER MANUALDokument4 Seiten928-0222-Supl Onan ES Genset 04146 WOODWARD TQ-125 CONTROLER MANUALfarar100% (1)

- MWM D234Dokument4 SeitenMWM D234Riki AkbarNoch keine Bewertungen

- KAMA KM376AG Operation ManualDokument25 SeitenKAMA KM376AG Operation ManualAlisabel Muñoz de Morales100% (1)

- 8-730kVA Product BrochureDokument16 Seiten8-730kVA Product BrochureRajeshwar Singh Urff RajNoch keine Bewertungen

- Installation Instructions: WarningDokument35 SeitenInstallation Instructions: WarningwcuevasmNoch keine Bewertungen

- Self-Regulating Alternators: User ManualDokument182 SeitenSelf-Regulating Alternators: User Manual754812Noch keine Bewertungen

- EMS98R3 User GuideDokument22 SeitenEMS98R3 User GuideAnas BasarahNoch keine Bewertungen

- Manual - 489 Generator Management RelayDokument308 SeitenManual - 489 Generator Management RelayKiko OliveiraNoch keine Bewertungen

- Fire Pump Diesel Engine CatalogueDokument3 SeitenFire Pump Diesel Engine CatalogueAnoir AkkariNoch keine Bewertungen

- 2206a-E13tag2 Electropak Pn1880Dokument2 Seiten2206a-E13tag2 Electropak Pn1880ibrahemNoch keine Bewertungen

- 1104A-44TG2 ElectropaK PN1784Dokument2 Seiten1104A-44TG2 ElectropaK PN1784NedhoNerimo TroyaNoch keine Bewertungen

- Perkins 1103a-33tg1 45kva PDFDokument2 SeitenPerkins 1103a-33tg1 45kva PDFYosi Darmawansyah0% (1)

- 1103A-33TG1 ElectropaK (PN1781 Jan08)Dokument2 Seiten1103A-33TG1 ElectropaK (PN1781 Jan08)tanmeng96Noch keine Bewertungen

- Perkin 2500sDokument5 SeitenPerkin 2500sYosi Darmawansyah71% (7)

- EGSA Membership App 2015Dokument2 SeitenEGSA Membership App 2015Francisco Martinez OrtizNoch keine Bewertungen

- Ecu 02Dokument1 SeiteEcu 02Francisco Martinez OrtizNoch keine Bewertungen

- AMF 10 FinalDokument21 SeitenAMF 10 FinalFrancisco Martinez OrtizNoch keine Bewertungen

- Lehf0117 00Dokument4 SeitenLehf0117 00Francisco Martinez OrtizNoch keine Bewertungen

- HP 7540 Schematic DiagramDokument1 SeiteHP 7540 Schematic DiagramFrancisco Martinez OrtizNoch keine Bewertungen

- Common American National Standard Pipe Taper ThreadsDokument2 SeitenCommon American National Standard Pipe Taper ThreadsFrancisco Martinez OrtizNoch keine Bewertungen

- PM-KISAN: Details of Eligible and Ineligible FarmersDokument2 SeitenPM-KISAN: Details of Eligible and Ineligible Farmerspoun kumarNoch keine Bewertungen

- How We Organize Ourselves-CompletedupDokument5 SeitenHow We Organize Ourselves-Completedupapi-147600993Noch keine Bewertungen

- LP.-Habitat-of-Animals Lesson PlanDokument4 SeitenLP.-Habitat-of-Animals Lesson PlanL LawlietNoch keine Bewertungen

- History RizalDokument6 SeitenHistory RizalIrvin LevieNoch keine Bewertungen

- EntropyDokument38 SeitenEntropyPreshanth_Jaga_2224Noch keine Bewertungen

- The Saving Cross of The Suffering Christ: Benjamin R. WilsonDokument228 SeitenThe Saving Cross of The Suffering Christ: Benjamin R. WilsonTri YaniNoch keine Bewertungen

- Chapter - 2: Project AdministrationDokument69 SeitenChapter - 2: Project AdministrationRenish RanganiNoch keine Bewertungen

- Analysis of Effectiveness of Heat Exchanger Shell and Tube Type One Shell Two Tube Pass As Cooling OilDokument6 SeitenAnalysis of Effectiveness of Heat Exchanger Shell and Tube Type One Shell Two Tube Pass As Cooling OilHendrik V SihombingNoch keine Bewertungen

- Chapter 6 - Scheduling AlgorithmDokument42 SeitenChapter 6 - Scheduling AlgorithmBinyam KebedeNoch keine Bewertungen

- An Objective of Dress Code PolicyDokument4 SeitenAn Objective of Dress Code PolicySiddhraj Singh KushwahaNoch keine Bewertungen

- Current MBA GradesDokument2 SeitenCurrent MBA GradesDiptarghya KunduNoch keine Bewertungen

- Machine DesignDokument34 SeitenMachine DesignMohammed Yunus33% (3)

- The Intelligent Investor NotesDokument19 SeitenThe Intelligent Investor NotesJack Jacinto100% (6)

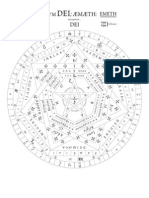

- John Dee - Sigillum Dei Aemeth or Seal of The Truth of God EnglishDokument2 SeitenJohn Dee - Sigillum Dei Aemeth or Seal of The Truth of God Englishsatyr70286% (7)

- Noceda vs. Court of Appeals (Property Case)Dokument3 SeitenNoceda vs. Court of Appeals (Property Case)jokuanNoch keine Bewertungen

- Operations Research Letters: Meichun Lin, Woonghee Tim Huh, Guohua WanDokument8 SeitenOperations Research Letters: Meichun Lin, Woonghee Tim Huh, Guohua WanQuỳnh NguyễnNoch keine Bewertungen

- Checkpoint PhysicsDokument12 SeitenCheckpoint PhysicsRishika Bafna100% (1)

- Impulsive Buying PDFDokument146 SeitenImpulsive Buying PDFrukwavuNoch keine Bewertungen

- The Novel TodayDokument3 SeitenThe Novel Todaylennon tanNoch keine Bewertungen

- Bootstrap Aggregating Multivariate Adaptive Regression Spline For Observational Studies in Diabetes CasesDokument8 SeitenBootstrap Aggregating Multivariate Adaptive Regression Spline For Observational Studies in Diabetes CasesTika MijayantiNoch keine Bewertungen

- 1.3 Digital Communication and AnalogueDokument6 Seiten1.3 Digital Communication and AnaloguenvjnjNoch keine Bewertungen

- Mein Leben Und Streben by May, Karl Friedrich, 1842-1912Dokument129 SeitenMein Leben Und Streben by May, Karl Friedrich, 1842-1912Gutenberg.orgNoch keine Bewertungen

- AIW Unit Plan - Ind. Tech ExampleDokument4 SeitenAIW Unit Plan - Ind. Tech ExampleMary McDonnellNoch keine Bewertungen

- Khutbah About The QuranDokument3 SeitenKhutbah About The QurantakwaniaNoch keine Bewertungen

- TSH TestDokument5 SeitenTSH TestdenalynNoch keine Bewertungen

- Worksheet For Mathematics For ManagementDokument3 SeitenWorksheet For Mathematics For Managementabel shimeles100% (1)

- United States v. Government of The Virgin Islands, 363 F.3d 276, 3rd Cir. (2004)Dokument19 SeitenUnited States v. Government of The Virgin Islands, 363 F.3d 276, 3rd Cir. (2004)Scribd Government DocsNoch keine Bewertungen

- Sales Purchases Returns Day BookDokument8 SeitenSales Purchases Returns Day BookAung Zaw HtweNoch keine Bewertungen

- Simple Past TenseDokument6 SeitenSimple Past Tenseanggun muslimahNoch keine Bewertungen

- Prayer For Stages On The PathDokument6 SeitenPrayer For Stages On The PathEijō JoshuaNoch keine Bewertungen