Beruflich Dokumente

Kultur Dokumente

Solutions To Sewing Problems

Hochgeladen von

Ashraf Ali100%(1)100% fanden dieses Dokument nützlich (1 Abstimmung)

204 Ansichten4 SeitenSEWING PROBLEM WITH SOLUTION

Originaltitel

Solutions to Sewing Problems

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenSEWING PROBLEM WITH SOLUTION

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

100%(1)100% fanden dieses Dokument nützlich (1 Abstimmung)

204 Ansichten4 SeitenSolutions To Sewing Problems

Hochgeladen von

Ashraf AliSEWING PROBLEM WITH SOLUTION

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 4

C O AT S

Bulletin Post

S E W I N G

S O L U T I O N S

Solutions to Sewing Problems

Contents

Common Sewing Problems

Needle Thread Breakage

Bobbin / Looper Thread Breakage

Thread Fusing

Skipped Stitches

Imbalanced / Variable Stitching

Staggered Stitching

Variable Stitch Density

Seam Pucker

Contact our Technical Team

Bulletin Post

Common Sewing Problems

Causes and Remedies

There can be many reasons behind the problems that arise while sewing and knowing the cause of these problems

and a solution for each particular cause is essential. These problems can be minimised by avoiding errors during

handing of materials / machines and by following the right working methods.

Some common sewing problems are;

Needle thread breakage

Bobbin or looper thread breakage

Thread fusing when the machine stops

Skipped stitches

Imbalanced / variable stitching

Staggered stitching

Variable stitch density

Seam pucker

The causes and solutions for each of the above problems are discussed in the following sections.

Needle Thread Breakage:

Cause

Remedy

Misaligned off winding from

Ensure that the overhead guide is directly above cop stand

thread package

pin, at 2 times the height of the thread package. Use a

foam pad to prevent package tilting

Trapping at package base

Reduce the thread stand height to prevent vibration and

spillage. Use a foam pad to prevent trapping after spillage

Thread trapped at thread guide

Can occur after thread breaks. Rethread correctly

Snarling before tension disc

Increase the wraps on pre-tension thread guides and reduce

Excessive tension

Use a stronger thread or adjust tension

disc tension. Ensure discs are smooth

Broken check spring

Replace and adjust

Sharp edges on throat plate, hook point,

Polish rough edges and replace if necessary. Replace the

needle guard, bobbin case,

needle being used with a higher quality needle

needle groove or eye

Thread fraying at needle

Use finer thread or coarser needle, as appropriate

Excessive needle heat; groove or eye

Improve the fabric finish. Change to a better needle, style and

blocked with melted fabric

finish. Apply needle lubricant via thread. Use a needle cooler

Hook overheating

Ensure adequate oil supply. Check the needle to

hook clearance

Poor quality thread

Change to a correctly finished thread of better quality

Bobbin or Looper Thread Breakage:

Cause

Remedy

Badly wound thread on the bobbin

Adjust bobbin winder alignment. Use pre-wound bobbins

Tension too tight or bobbin over-running

Adjust bobbin case tension. Insert a washer or

a spring to prevent over-running

Sharp edges on bobbin case or spring or

Polish edges and correct surfaces

looper eyelet

Bobbin case not fitting correctly

Check the size / type of bobbin for flange distortion

Thread Fusing when the Machine Stops:

Cause

Remedy

Poorly finished or incorrect thread

Use better quality thread

Densely woven fabric that is poorly or

Improve fabric finish. Change to more suitable

harshly finished

needles. Apply needle coolants

Damaged or overheated needle

Change the needle.

after thread breakage

Cause

Remedy

Hook, looper or needle failing to enter

Check machine clearances and timings. Check if the needle

thread loops at the correct time

is inserted and aligned correctly. Use a needle with

a deeper scarf

Thread loop failure caused by incorrect

Change needle size / style

needle size / style for thread size / type

Thread loop failure due to incorrect setting

Reset to standard and check loop formation

of thread control mechanism causing

with a strobe

thread loop starvation

Flagging of fabric due to poor presser foot

Re-adjust the presser foot pressure. Change the

control or too large a throat plate hole

throat plate to match the needle

Needle deflections or bent needle

Use a reinforced needle, reset the needle guard

and replace the needle

Incorrect sewing tension in the needle or

Re-adjust the tensions

under threads

Poor thread loop formation

Check with a strobe. Change to superior spun polyester or

filament based corespun threads

Imbalanced / Variable Stitching:

Cause

Remedy

Incorrect sewing tensions

Check for snarling, adjust thread tensions

Incorrect threading

Rethread machine

Needle thread snagging on bobbin case or

Polish bobbin case surfaces. Reset positioning finger

positioning finger

and opening finger

Variable tension due to poor

Switch to superior quality threads

thread lubrication

Staggered Stitching:

Cause

Remedy

Needle vibration or deflection

Increase needle size or change to a reinforced

Incorrect or blunt needle point

Change the needle

Incorrect needle-to-thread size relationship

Change needle or thread size as appropriate

Feed dog sway

Tighten the feed dog

Poor fabric control, presser foot bounce

Reset the presser foot. Change the feed mechanism

or tapered needle

Bulletin Post

Skipped Stitches:

Bulletin Post

Variable Stitch Density:

Cause

Remedy

Poor fabric feed control

Increase the presser foot pressure. Change to a more

positive feed mechanism

Seam Pucker:

Cause

Remedy

Variable differential fabric feed

Improve the fabric feed mechanism. Replace worn out

High thread tension

Keep the bobbin tension as low as possible and set the

Incorrect thread balance

Ensure proper balance between the top and

Improper thread type

Use threads with controlled

feed dogs. Reduce the maximum sewing speed

needle thread tension accordingly

bottom thread

elongation. Properly maintain tension guides

As a Coats customer, you have access to the finest technical expertise in the thread industry. Our technical

consultants are available to assist you in finding solutions for all your shop floor issues. They can give you insights on

improving your sewing processes, which will help you deliver products with better quality.

www.coatsindustrial.com

November 2014

Das könnte Ihnen auch gefallen

- Stitches and Seams: Essential Sewing Skills for the Beginner Sewist, Tailor, and DIY CrafterVon EverandStitches and Seams: Essential Sewing Skills for the Beginner Sewist, Tailor, and DIY CrafterNoch keine Bewertungen

- Seam PuckeringDokument4 SeitenSeam PuckeringRavi Jain100% (1)

- Minimizing Needle Cutting On Knits 2-3-101Dokument3 SeitenMinimizing Needle Cutting On Knits 2-3-101BalaNoch keine Bewertungen

- Sewing Defects and Its RemediesDokument3 SeitenSewing Defects and Its RemediesNiharika JainNoch keine Bewertungen

- Sewing Machine Needle Troubleshooting GuideDokument3 SeitenSewing Machine Needle Troubleshooting GuideEti ChiranjeeviNoch keine Bewertungen

- The T-Shirt Quilt Book: Recycle Your Tees into One-of-a-Kind KeepsakesVon EverandThe T-Shirt Quilt Book: Recycle Your Tees into One-of-a-Kind KeepsakesNoch keine Bewertungen

- 3A Hand Sewing Machine Check List 2009Dokument2 Seiten3A Hand Sewing Machine Check List 2009Gramma Jo100% (1)

- Basic Garment Pattern Design ConsizpdfDokument11 SeitenBasic Garment Pattern Design ConsizpdfAhmad El TahanNoch keine Bewertungen

- KnittingDokument13 SeitenKnittingrakibNoch keine Bewertungen

- Fabric and Garment FinishingDokument33 SeitenFabric and Garment FinishingSurya Bakshi100% (4)

- Professional Ruffles and Pleats: Preparing The Sewing Machine: Attaching Ruffles For Fancy EffectsDokument1 SeiteProfessional Ruffles and Pleats: Preparing The Sewing Machine: Attaching Ruffles For Fancy EffectsJohn DoverNoch keine Bewertungen

- Selection & Sewing Tips For Fleece FabricDokument3 SeitenSelection & Sewing Tips For Fleece Fabricdigi1webNoch keine Bewertungen

- Seam, Classification of Seam, Features of Seam, Uses of SeamDokument13 SeitenSeam, Classification of Seam, Features of Seam, Uses of SeamJahidul IslamNoch keine Bewertungen

- Manual Bernina B330 B350 B380 enDokument50 SeitenManual Bernina B330 B350 B380 enNora StoiaNoch keine Bewertungen

- CT MMB 198Dokument2 SeitenCT MMB 198Rosana BarakatNoch keine Bewertungen

- Facing, Interfacings, Interlinings and Linings: Submitted By-Shruti Verma (FD-4) 2022183Dokument35 SeitenFacing, Interfacings, Interlinings and Linings: Submitted By-Shruti Verma (FD-4) 2022183ShrutiNoch keine Bewertungen

- SeamsDokument17 SeitenSeamsNidhi Shah0% (1)

- Decoding The PatternDokument3 SeitenDecoding The PatternCherry Escolano0% (1)

- Princess Seam Pencil Skirt 04/2012: By: Burda Style MagazineDokument4 SeitenPrincess Seam Pencil Skirt 04/2012: By: Burda Style MagazinedidomessiNoch keine Bewertungen

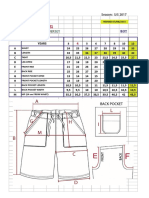

- Short Pants - Jersey: Old N: Mnmbo019 Season: S/S 2017Dokument1 SeiteShort Pants - Jersey: Old N: Mnmbo019 Season: S/S 2017kannraNoch keine Bewertungen

- Puckering On Power Strech Fabrics (ORTArevision4.4.2012) - 1Dokument14 SeitenPuckering On Power Strech Fabrics (ORTArevision4.4.2012) - 1nubackNoch keine Bewertungen

- 100 Class StitchesDokument9 Seiten100 Class StitchesVishakha ChopraNoch keine Bewertungen

- Dartspleats and TucksDokument34 SeitenDartspleats and TucksArcade W MiguelNoch keine Bewertungen

- Machine Settings For Sewing Knit Fabrics ChartDokument1 SeiteMachine Settings For Sewing Knit Fabrics ChartUTKARSH UPADHYAY100% (1)

- Everyday CardiganDokument3 SeitenEveryday CardiganmxpxaxoNoch keine Bewertungen

- Notched Jacket LapelDokument6 SeitenNotched Jacket LapelwasyihunNoch keine Bewertungen

- Dress Making /sewing Technology - Semester 1 Module 1: Textile and HandworkDokument28 SeitenDress Making /sewing Technology - Semester 1 Module 1: Textile and HandworkRakesh MauryaNoch keine Bewertungen

- Spec Sheet Tank TopDokument3 SeitenSpec Sheet Tank TopGurjeetNoch keine Bewertungen

- Sewing MachinesDokument61 SeitenSewing Machinesaqsa imranNoch keine Bewertungen

- A0 GBSB Colour Blocked TopDokument1 SeiteA0 GBSB Colour Blocked TopSean ColonNoch keine Bewertungen

- Sewing ThreadsDokument27 SeitenSewing ThreadsRikhil NagpalNoch keine Bewertungen

- Burda Pattern Alteration For Petites OriginalDokument3 SeitenBurda Pattern Alteration For Petites OriginalRuza100% (1)

- Sewing Yokes MKDokument11 SeitenSewing Yokes MKEddy TangaNoch keine Bewertungen

- Little Girls Dress Making Course BookDokument100 SeitenLittle Girls Dress Making Course BookEthy Wa WaleNoch keine Bewertungen

- The Sewability of Elastic FabricDokument8 SeitenThe Sewability of Elastic Fabricapi-26494555Noch keine Bewertungen

- Garment DefectsDokument5 SeitenGarment DefectsSayed Aasim JawaidNoch keine Bewertungen

- Knitting File: August 7Dokument23 SeitenKnitting File: August 7Nitika SharmaNoch keine Bewertungen

- Asymmetric Aline Dress LETTERDokument31 SeitenAsymmetric Aline Dress LETTERanaugustoNoch keine Bewertungen

- Bomber JacketDokument3 SeitenBomber JacketLaura Carrascosa FusterNoch keine Bewertungen

- In-Plant Training Report PresentationDokument60 SeitenIn-Plant Training Report Presentationrajhossie9335100% (3)

- How To Add Sleeves To A Sleeveless Garment PDFDokument1 SeiteHow To Add Sleeves To A Sleeveless Garment PDFdidomessiNoch keine Bewertungen

- Specification Sheet LayoutDokument9 SeitenSpecification Sheet LayoutSharvari ShankarNoch keine Bewertungen

- Selecting The Right SPIDokument4 SeitenSelecting The Right SPIshreay12345Noch keine Bewertungen

- Women Vest PDFDokument2 SeitenWomen Vest PDFPakistanNoch keine Bewertungen

- Áo Thu Đông Cổ Cao SIZE XS-XXL - 1Dokument30 SeitenÁo Thu Đông Cổ Cao SIZE XS-XXL - 1ThuNoch keine Bewertungen

- Linen Pants Construction DiagramDokument1 SeiteLinen Pants Construction DiagramVishnu Priya SahasranamanNoch keine Bewertungen

- Patrón FOB Mediano y Grande PañalesDokument6 SeitenPatrón FOB Mediano y Grande PañalesNazareth KeyNoch keine Bewertungen

- Lining Facing Trims and FastnersDokument52 SeitenLining Facing Trims and FastnersrakibNoch keine Bewertungen

- 4h Sewing Project Fabric Dare and Use GuideDokument37 Seiten4h Sewing Project Fabric Dare and Use GuideJuan CubasNoch keine Bewertungen

- Sewing Terminology 1Dokument7 SeitenSewing Terminology 1Ruth AgNoch keine Bewertungen

- Body - Fashion: Student: Madalina Maria IancuDokument21 SeitenBody - Fashion: Student: Madalina Maria IancuMadalinaNoch keine Bewertungen

- Seam Finishes 2Dokument8 SeitenSeam Finishes 2riteshbansal23Noch keine Bewertungen

- Molde de ColeteDokument20 SeitenMolde de ColeteDivane SoaresNoch keine Bewertungen

- Stitch LengthDokument4 SeitenStitch LengthAjeet KumarNoch keine Bewertungen

- How To Make A Quick & Easy Tabard or T-TunicDokument0 SeitenHow To Make A Quick & Easy Tabard or T-TunicRochelle DeNoch keine Bewertungen

- Stitch TypesDokument21 SeitenStitch TypesAjaz777100% (1)

- Sewing SleevesDokument4 SeitenSewing SleevesMohammed ElmorsyNoch keine Bewertungen

- Save The Children: SubjectDokument2 SeitenSave The Children: SubjectAshraf AliNoch keine Bewertungen

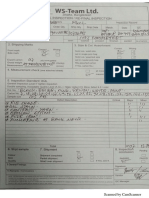

- Ispahani Biotech 1600PCS T-ShirtDokument1 SeiteIspahani Biotech 1600PCS T-ShirtAshraf AliNoch keine Bewertungen

- RFQ/SCI/CXB/FY-20/00790 SL No Description Specification Unit Req. Quantity Unit Price VAT/AIT/STC/SRT 15% Amount RemarkDokument1 SeiteRFQ/SCI/CXB/FY-20/00790 SL No Description Specification Unit Req. Quantity Unit Price VAT/AIT/STC/SRT 15% Amount RemarkAshraf AliNoch keine Bewertungen

- UMBRELLA - 314343 Final Project Report D1.5 1Dokument94 SeitenUMBRELLA - 314343 Final Project Report D1.5 1Wael AlmahdiNoch keine Bewertungen

- RFQ/SCI/CXB/FY-20/00792 SL No Description Specification Unit Req. Quantity Unit Price VAT/AIT/STC/SRT 15% Amount RemarkDokument1 SeiteRFQ/SCI/CXB/FY-20/00792 SL No Description Specification Unit Req. Quantity Unit Price VAT/AIT/STC/SRT 15% Amount RemarkAshraf AliNoch keine Bewertungen

- RFQ18473 PDFDokument2 SeitenRFQ18473 PDFAshraf AliNoch keine Bewertungen

- RFQ18462 - Sample of Proposed Case Worker KitDokument4 SeitenRFQ18462 - Sample of Proposed Case Worker KitAshraf AliNoch keine Bewertungen

- Catalog - Foam and FabricDokument3 SeitenCatalog - Foam and FabricAshraf AliNoch keine Bewertungen

- LionDokument2 SeitenLionAshraf AliNoch keine Bewertungen

- Save The Children: SubjectDokument2 SeitenSave The Children: SubjectAshraf AliNoch keine Bewertungen

- Bangladesh Labour Rules 2015 BNDokument2 SeitenBangladesh Labour Rules 2015 BNAshraf AliNoch keine Bewertungen

- Quality MGT in Garments Industry of BangladeshDokument8 SeitenQuality MGT in Garments Industry of BangladeshRefat Rasul ChowdhuryNoch keine Bewertungen

- Bangladesh Labor Law Service Rules 2015 ( )Dokument344 SeitenBangladesh Labor Law Service Rules 2015 ( )touhedur90% (118)

- Minimizing The Eighth Waste of Lean-Absenteeism Through Six Sigma MethodologyDokument6 SeitenMinimizing The Eighth Waste of Lean-Absenteeism Through Six Sigma MethodologyAshraf AliNoch keine Bewertungen

- KB 04 92 & MB 04 92 Final in Spection Report Fac Alauddin Buyer KatagDokument2 SeitenKB 04 92 & MB 04 92 Final in Spection Report Fac Alauddin Buyer KatagAshraf AliNoch keine Bewertungen

- CV AshrafDokument4 SeitenCV AshrafAshraf Ali75% (8)

- Final Inspection ReportDokument1 SeiteFinal Inspection ReportAshraf AliNoch keine Bewertungen

- MB 0492 All QC ReportDokument16 SeitenMB 0492 All QC ReportAshraf AliNoch keine Bewertungen

- Wcms 228220Dokument166 SeitenWcms 228220ranjann349Noch keine Bewertungen

- S C L (SCL) - Beximco B C & P B - S C - , 3,000 &, - , & - T, S 35 Usa, C, Uk, G, F, I, S, N, T, J, A, Uae, B, CDokument2 SeitenS C L (SCL) - Beximco B C & P B - S C - , 3,000 &, - , & - T, S 35 Usa, C, Uk, G, F, I, S, N, T, J, A, Uae, B, Cshaky4uNoch keine Bewertungen

- 1ThreadSelection Guide For Apparel 2-15-10Dokument14 Seiten1ThreadSelection Guide For Apparel 2-15-10Roberto TrujilloNoch keine Bewertungen

- Level1 Syllabus For IP V1.1Dokument68 SeitenLevel1 Syllabus For IP V1.1Ashraf AliNoch keine Bewertungen

- Bangladesh ConstitutionDokument57 SeitenBangladesh ConstitutionderaafatNoch keine Bewertungen

- Ceramic Manufactur PDFDokument13 SeitenCeramic Manufactur PDFYogie S PrabowoNoch keine Bewertungen

- Bulletin 14B 046Dokument1 SeiteBulletin 14B 046Ashraf AliNoch keine Bewertungen

- Full Peacocks - SEPT 2010Dokument31 SeitenFull Peacocks - SEPT 2010Ashraf AliNoch keine Bewertungen

- Lean ManufacturingDokument8 SeitenLean ManufacturingAshraf AliNoch keine Bewertungen

- INDITEX Safe To Wear enDokument104 SeitenINDITEX Safe To Wear enAshraf Ali100% (2)

- Child Safety For Apparel ProductionDokument20 SeitenChild Safety For Apparel ProductionAshraf AliNoch keine Bewertungen

- Bulletin 10B 122Dokument1 SeiteBulletin 10B 122Ashraf AliNoch keine Bewertungen

- Calibrating Images TutorialDokument14 SeitenCalibrating Images TutorialtrujillomadrigalNoch keine Bewertungen

- Higher Unit 11 Topic Test: NameDokument17 SeitenHigher Unit 11 Topic Test: NamesadiyaNoch keine Bewertungen

- VF (Kyhkkjrh VK Qfozkkulalfkku) - F'KDS"K) MRRJK (K.M& 249201Dokument3 SeitenVF (Kyhkkjrh VK Qfozkkulalfkku) - F'KDS"K) MRRJK (K.M& 249201RajaNoch keine Bewertungen

- PIANC SMART Rivers Proceedings OkDokument190 SeitenPIANC SMART Rivers Proceedings OkMartin PrietoNoch keine Bewertungen

- Nasa ThesisDokument8 SeitenNasa Thesisdnr3krf8100% (2)

- Better Place - Heaven or HellDokument3 SeitenBetter Place - Heaven or HellToto SammyNoch keine Bewertungen

- IJHIM 6 - Nur Husnina (36 SD 42)Dokument7 SeitenIJHIM 6 - Nur Husnina (36 SD 42)RSU Sayang BundaNoch keine Bewertungen

- CP Lithium Ion BatteriesDokument4 SeitenCP Lithium Ion BatteriesvaseemalikhanNoch keine Bewertungen

- Worksheet 3 (Partial Pressures)Dokument2 SeitenWorksheet 3 (Partial Pressures)Jose Ruben SortoNoch keine Bewertungen

- Proposed Bedroom Enhancement: Jenel C. Tangonan Archi 1A (Stem) Architectural Design Plate No.1Dokument1 SeiteProposed Bedroom Enhancement: Jenel C. Tangonan Archi 1A (Stem) Architectural Design Plate No.1Jehan TangonanNoch keine Bewertungen

- Sample Paper English: Kendriya Vidyalaya SangathanDokument7 SeitenSample Paper English: Kendriya Vidyalaya SangathanVines and ScienceNoch keine Bewertungen

- Action Research MAPEHDokument9 SeitenAction Research MAPEHEloPoPo100% (4)

- HISTOPATHDokument38 SeitenHISTOPATHDennis Louis Montepio BrazaNoch keine Bewertungen

- YES-O Action-Plan - 2022-2023Dokument2 SeitenYES-O Action-Plan - 2022-2023carmina duldulao100% (6)

- Type of TrucksDokument8 SeitenType of TrucksYojhan VelezNoch keine Bewertungen

- 10 de Thi Tieng Anh Hướng Dẫn Giải Chi TiếtDokument145 Seiten10 de Thi Tieng Anh Hướng Dẫn Giải Chi TiếtVuong DiepNoch keine Bewertungen

- Marcelo - GarciaDokument6 SeitenMarcelo - GarciaNancy FernandezNoch keine Bewertungen

- Essentials of o Ste 00 DaveDokument112 SeitenEssentials of o Ste 00 DaveGeki Iovan100% (1)

- Corrosion Resistant Steels: Stainless Steel AlloysDokument11 SeitenCorrosion Resistant Steels: Stainless Steel AlloysPraveen SamarthiNoch keine Bewertungen

- Astro 429 Assignment 2 AlbertaDokument2 SeitenAstro 429 Assignment 2 AlbertatarakNoch keine Bewertungen

- Aljac Sampler: Environmentally Acceptable, Operationally Efficient and Safe, Eliminating Any Product LossDokument3 SeitenAljac Sampler: Environmentally Acceptable, Operationally Efficient and Safe, Eliminating Any Product LossT. LimNoch keine Bewertungen

- Formula SheetDokument16 SeitenFormula SheetgwerNoch keine Bewertungen

- Mechanical Reasoning - Test 2: 40 QuestionsDokument14 SeitenMechanical Reasoning - Test 2: 40 Questionskyloz60% (5)

- Ags 30Dokument1 SeiteAgs 30Anonymous jIzz7woS60% (1)

- Dave Graham Literature CatalogDokument640 SeitenDave Graham Literature CatalogPierce PetersonNoch keine Bewertungen

- C-81-9903-17-82 Halal 100g 2024-06-08Dokument1 SeiteC-81-9903-17-82 Halal 100g 2024-06-08NURUL FAUZANY BINTI MOHD BASARUDDINNoch keine Bewertungen

- STAN Statistika 12 PDFDokument25 SeitenSTAN Statistika 12 PDFPembelajaran Jarak JauhNoch keine Bewertungen

- Netrunner AllCardsDokument154 SeitenNetrunner AllCardsIvo PantaleaoNoch keine Bewertungen

- Bilingual-Paper WDokument4 SeitenBilingual-Paper WzNoch keine Bewertungen

- Sediments and Sedimentary Rock-Week 4Dokument61 SeitenSediments and Sedimentary Rock-Week 4qomaruzzaman5740Noch keine Bewertungen

- Crochet Zodiac Dolls: Stitch the horoscope with astrological amigurumiVon EverandCrochet Zodiac Dolls: Stitch the horoscope with astrological amigurumiBewertung: 4 von 5 Sternen4/5 (3)

- Swatch This, 3000+ Color Palettes for Success: Perfect for Artists, Designers, MakersVon EverandSwatch This, 3000+ Color Palettes for Success: Perfect for Artists, Designers, MakersBewertung: 3.5 von 5 Sternen3.5/5 (3)

- Edward's Menagerie New Edition: Over 50 easy-to-make soft toy animal crochet patternsVon EverandEdward's Menagerie New Edition: Over 50 easy-to-make soft toy animal crochet patternsNoch keine Bewertungen

- House Rules: How to Decorate for Every Home, Style, and BudgetVon EverandHouse Rules: How to Decorate for Every Home, Style, and BudgetNoch keine Bewertungen

- The Martha Manual: How to Do (Almost) EverythingVon EverandThe Martha Manual: How to Do (Almost) EverythingBewertung: 4 von 5 Sternen4/5 (11)

- 100 Micro Amigurumi: Crochet patterns and charts for tiny amigurumiVon Everand100 Micro Amigurumi: Crochet patterns and charts for tiny amigurumiBewertung: 5 von 5 Sternen5/5 (2)

- Crochet Creatures of Myth and Legend: 19 Designs Easy Cute Critters to Legendary BeastsVon EverandCrochet Creatures of Myth and Legend: 19 Designs Easy Cute Critters to Legendary BeastsBewertung: 4.5 von 5 Sternen4.5/5 (10)

- Crochet with London Kaye: Projects and Ideas to Yarn Bomb Your LifeVon EverandCrochet with London Kaye: Projects and Ideas to Yarn Bomb Your LifeBewertung: 5 von 5 Sternen5/5 (2)

- Amigurumi Cats: Crochet Sweet Kitties the Japanese Way (24 Projects of Cats to Crochet)Von EverandAmigurumi Cats: Crochet Sweet Kitties the Japanese Way (24 Projects of Cats to Crochet)Noch keine Bewertungen

- Crochet Impkins: Over a million possible combinations! Yes, really!Von EverandCrochet Impkins: Over a million possible combinations! Yes, really!Bewertung: 4.5 von 5 Sternen4.5/5 (10)

- The Botanical Hand Lettering Workbook: Draw Whimsical & Decorative Styles & ScriptsVon EverandThe Botanical Hand Lettering Workbook: Draw Whimsical & Decorative Styles & ScriptsBewertung: 4.5 von 5 Sternen4.5/5 (2)

- Crochet Cute Dolls with Mix-and-Match Outfits: 66 Adorable Amigurumi PatternsVon EverandCrochet Cute Dolls with Mix-and-Match Outfits: 66 Adorable Amigurumi PatternsBewertung: 4 von 5 Sternen4/5 (5)

- Colorful Crochet Knitwear: Crochet sweaters and more with mosaic, intarsia and tapestry crochet patternsVon EverandColorful Crochet Knitwear: Crochet sweaters and more with mosaic, intarsia and tapestry crochet patternsNoch keine Bewertungen

- Crochet Pattern Books: The Ultimate Complete Guide to Learning How to Crochet FastVon EverandCrochet Pattern Books: The Ultimate Complete Guide to Learning How to Crochet FastBewertung: 5 von 5 Sternen5/5 (1)

- Crochet Home: 20 Vintage Modern Crochet Projects for the HomeVon EverandCrochet Home: 20 Vintage Modern Crochet Projects for the HomeBewertung: 4.5 von 5 Sternen4.5/5 (7)

- Shetland Fine Lace Knitting: Recreating Patterns from the Past.Von EverandShetland Fine Lace Knitting: Recreating Patterns from the Past.Bewertung: 2 von 5 Sternen2/5 (1)

- Crochet Southwest Spirit: Over 20 Bohemian Crochet Patterns Inspired by the American SouthwestVon EverandCrochet Southwest Spirit: Over 20 Bohemian Crochet Patterns Inspired by the American SouthwestBewertung: 5 von 5 Sternen5/5 (2)

- Harter's Picture Archive for Collage and IllustrationVon EverandHarter's Picture Archive for Collage and IllustrationBewertung: 4.5 von 5 Sternen4.5/5 (3)

- Friends: The One with the Crochet: The Official Crochet Pattern BookVon EverandFriends: The One with the Crochet: The Official Crochet Pattern BookBewertung: 5 von 5 Sternen5/5 (1)

- Dream Sewing Spaces: Design & Organization for Spaces Large & SmallVon EverandDream Sewing Spaces: Design & Organization for Spaces Large & SmallBewertung: 4 von 5 Sternen4/5 (24)

- The Beading Bible: A Comprehensive Guide to Beading TechniquesVon EverandThe Beading Bible: A Comprehensive Guide to Beading TechniquesNoch keine Bewertungen

- Celtic Line Drawing - Simplified InstructionsVon EverandCeltic Line Drawing - Simplified InstructionsBewertung: 5 von 5 Sternen5/5 (4)

- Build Your Skills Crochet Tops: 26 Simple Patterns for First-Time Sweaters, Shrugs, Ponchos & MoreVon EverandBuild Your Skills Crochet Tops: 26 Simple Patterns for First-Time Sweaters, Shrugs, Ponchos & MoreBewertung: 4.5 von 5 Sternen4.5/5 (6)

- Treasure Bookmaking: Crafting Handmade Sustainable JournalsVon EverandTreasure Bookmaking: Crafting Handmade Sustainable JournalsNoch keine Bewertungen

- Cozy Crochet: 26 Fun Projects from Fashion to Home DecorVon EverandCozy Crochet: 26 Fun Projects from Fashion to Home DecorNoch keine Bewertungen

- The Fellowship of the Knits: Lord of the Rings: The Unofficial Knitting BookVon EverandThe Fellowship of the Knits: Lord of the Rings: The Unofficial Knitting BookBewertung: 4.5 von 5 Sternen4.5/5 (2)

- Edward's Menagerie: Dogs: 50 canine crochet patternsVon EverandEdward's Menagerie: Dogs: 50 canine crochet patternsBewertung: 3 von 5 Sternen3/5 (5)

- Basic Black: 26 Edgy Essentials for the Modern WardrobeVon EverandBasic Black: 26 Edgy Essentials for the Modern WardrobeBewertung: 4 von 5 Sternen4/5 (10)