Beruflich Dokumente

Kultur Dokumente

Apolomea Baz (A4 HD HCR) Eta10 0280 Engl

Hochgeladen von

willy1234512Originalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Apolomea Baz (A4 HD HCR) Eta10 0280 Engl

Hochgeladen von

willy1234512Copyright:

Verfügbare Formate

Page 9 of European Technical Approval ETA-10/0280

Apolo MEA Quick fix anchor

S

KA

H (stainless steel)

K (hot dip galvanized)1)

Max.

fixture thickness:

M8 M16

Thread

size:

Material:

Max. fixture thickness: f tfix

Marking:

Marking:

Identifying

Identifying

mark:mark:

Anchor

Anchor

identity:

identity:

*1)

Category:

Category

:

*1)

Material :

Examples:

Examples: BAZ:

BAZ HD:

BAZ A4:

*1)

: Where applicable

BAZ HCR:

HCR*1)

S-KA 10/20

S-KAK 10/20

S-KAH 10/20

S-KAH 10/20 HCR

- zinc plated

- hot dip galvanized

- stainless steel A4

- stainless steel HCR

Apolo MEA Quick fix anchor after installation

Apolo MEA Quick fix anchor

Product and intended use

Annex 1

of European

Technical Approval

ETA - 10 / 0280

Page 10 of European Technical Approval ETA-10/0280

Apolo MEA Quick fix anchor

Table 1a: Materials BAZ and BAZ HD

Part

Designation

Material 1) 2)

Diameters

M10 + M12

M8 + M16

Cold forged steel, EN 10263-2

fyk

fuk

[N/mm] [N/mm]

560

660

475

560

Bolt

Sleeve

M8 - M16

Cold rolled galvanized steel strip,

EN 10147

Washer

M8 - M16

Steel, electroplated, EN ISO 7089

Hexagonal Nut

M8 - M16

Steel, electroplated, EN ISO 4032,

grade 8

1)

BAZ: Parts 1, 3 and 4 are zinc electroplated according to EN ISO 4042 5m and bright passivated.

2)

BAZ HD: Parts 1, 3 and 4 are hot dip galvanized according to EN ISO 10684.

Table 1b: Materials BAZ A4

Part

Designation

Diameters

Bolt

M8 - M16

Sleeve

M8 - M16

Washer

M8 - M16

Hexagonal Nut

M8 - M16

fyk

fuk

[N/mm] [N/mm]

Material

Cold forged stainl. steel, EN 10088-3

1.4578

Stainless steel strip, EN 10088-2

1.4401 / 1.4404 / 1.4571

Stainless steel, EN ISO 7089

1.4401 / 1.4404 / 1.4571

Stainless steel, EN ISO 4032

1.4401 / 1.4404 / 1.4571 - grade 80

530

600

Table 1c: Materials BAZ HCR

Part

Designation

Diameters

Bolt

M8 - M16

Sleeve

M8 - M16

Washer

M8 - M16

Hexagonal Nut

M8 - M16

Cold forged stainl. steel, EN 10088-3

1.4529 / 1.4565

Stainless steel strip, EN 10088-2

1.4401 / 1.4404 / 1.4571

Stainless steel, EN ISO 7089

1.4529 / 1.4565

Stainless steel, EN ISO 4032

1.4529 / 1.4565 - grade 70

Apolo MEA Quick fix anchor

Materials

fyk

fuk

[N/mm] [N/mm]

Material

530

600

Annex 2

of European

Technical Approval

ETA - 10 / 0280

Page 11 of European Technical Approval ETA-10/0280

Apolo MEA Quick fix anchor

Table 2: Dimensions of the anchor

Stud

bolt

Main dimensions

Anchor type

Size

[mm]

[mm]

Cone

bolt

dcf

dnom

lc

[mm] [mm] [mm]

Expansion

sleeve

ls

[mm]

Hexagonal

nut

Washer

s

d1

d2

sw

[mm] [mm] [mm] [mm] [mm]

8 / 0....358

M8 62420 22...220

7,1

20,9

15,9

1,6

8,4 17,0 13,0

6,5

10 / 0......338

M10 82420 37215

9,0

10

25,7

17,9

2,0 10,5 21,0 17,0

8,0

12 / 0..322

M12 98420 48210 10,8

12

30,3

19,1

2,5 13,0 24,0 19,0

10,0

16 / 0..302

M16 118..420 60202 14,6

16

38,1

26,3

3,0 17,0 30,0 24,0

13,0

Apolo MEA Quick fix anchor

Dimensions of the anchor

Annex 3

of European

Technical Approval

ETA - 10 / 0280

Page 12 of European Technical Approval ETA-10/0280

Table 3: Installation data

Anchor size

Apolo MEA Quick fix anchor

d0

Drill hole diameter

Cutting diameter at the upper tolerance

limit (maximum diameter bit)

dcut,max [mm]

M10

M12

M16

10

12

16

8,45

10,45

12,5

16,5

Depth of drilled hole to deepest point

h1

[mm]

60

75

90

110

Effective anchorage depth

hef

[mm]

45

60

70

85

Diameter of clearance hole in the fixture

df

[mm]

12

14

18

0358

0338

0322

0302

13

17

19

24

tfix,minmax [mm]

Thickness of fixture

Width across flats

Required

torque

1)

[mm]

M8

SW

BAZ / BAZ HD

BAZ A4 / BAZ HCR

Tinst

[mm]

[Nm]

20 / 15

20

1)

35

50

120

35

70

120

Installation torque for BAZ is 20 Nm and for BAZ HD 15 Nm

Table 4: Minimum thickness of concrete member, spacing and edge distance

Anchor size

Apolo MEA Quick fix anchor

Minimum thickness of concrete member

Minimum spacing

Minimum edge distance

M8

M10

M12

M16

hmin

[mm]

100

120

140

170

smin

[mm]

50

55

60

70

c

cmin

[mm]

50

80

90

120

[mm]

50

50

55

85

[mm]

50

100

145

150

Intervalues may be interpolated linearly.

Apolo MEA Quick fix anchor

Installation data,

Minimum thickness of concrete member,

Spacing and edge distance

Annex 4

of European

Technical Approval

ETA - 10 / 0280

Page 13 of European Technical Approval ETA-10/0280

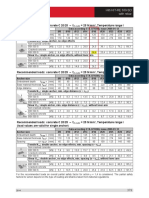

Table 5: Design method A - Characteristic values for tension loads

Anchor size

Apolo MEA Quick fix anchor

M8

M10

M12

M16

Steel failure

Characteristic resistance BAZ / BAZ HD

NRk,s

[kN]

13

26

38

69

Characteristic resistance BAZ A4 / BAZ HCR

NRk,s

[kN]

15

24

35

75

1)

[-]

Partial safety factor

Ms

1,40

Pull-out failure

Characteristic resistance

in cracked concrete C20/25

NRk,p

[kN]

12

20

Characteristic resistance in

non cracked concrete C20/25

NRk,p

[kN]

16

20

35

Increasing factor for NRk,p

Partial safety factor

Mp

1)

C25/30

1,04

C30/37

1,10

C35/45

1,16

C40/50

1,20

C45/55

1,24

C50/60

1,28

1,80 2)

[-]

1,50 3)

Concrete cone failure

hef

[mm]

45

60

70

85

Spacing

scr,N

[mm]

135

180

210

255

Edge distance

ccr,N

[mm]

68

90

105

128

Effective anchorage depth

Partial safety factor

Mc

1)

[-]

1,80

2)

1,50 3)

Concrete splitting failure

Spacing ( splitting )

scr,sp

[mm]

180

240

280

340

Edge distance ( splitting )

ccr,sp

[mm]

90

120

140

170

Partial safety factor

Msp

1)

[-]

1,80

2)

1,50 3)

1)

In absence of other national regulations.

The installation safety factor of 2 = 1,2 is included.

3)

The installation safety factor of 2 = 1,0 is included.

2)

Table 6: Displacements under tension loads

Anchor size

Apolo MEA Quick fix anchor

Cracked and non-cracked concrete

C20/25 - C50/60

M8

M10

M12

M16

3,6

0,6

4,8

0,6

9,5

0,7

1,6

2,0

1,4

[kN]

N0

N

[mm]

2,0

0,3

[mm]

1,8

Apolo MEA Quick fix anchor

Design method A :

Characteristic values for tension loads and displacements

Annex 5

of European

Technical Approval

ETA - 10 / 0280

Page 14 of European Technical Approval ETA-10/0280

Table 7:

Design method A - Characteristic values for shear loads

Anchor size

Apolo MEA Quick fix anchor

M8

M10

M12

M16

Steel failure without lever arm

Characteristic resistance BAZ / BAZ HD

VRk,s

[kN]

10

18

23

44

Characteristic resistance BAZ A4 / BAZ HCR

VRk,s

[kN]

11

17

25

47

Partial safety factor

Ms

1)

1,50

[-]

Steel failure with lever arm

Characteristic resistance BAZ / BAZ HD

Characteristic resistance BAZ A4 / BAZ HCR

Partial safety factor

M0Rk,s

0

Rk,s

[Nm]

21

48

72

186

[Nm]

22

45

79

200

Ms 1)

[-]

[-]

Mc 1)

[-]

lf

[mm]

45

60

70

85

dnom

[mm]

10

12

16

1,50

Concrete pryout failure

Factor in equation ( 5.6 ) of

ETAG Annex C, 5.2.3.3

Partial safety factor

1

1,50

Concrete edge failure

Effective length of anchor under shear load

Outside diameter of anchor

Cracked concrete without any edge

reinforcement

Cracked concrete with straight edge

reinforcement > 12 mm

1,00

ucr,V

1,20

[-]

Cracked concrete with edge reinforcement

and closely spaced stirrups (a 100mm)

or non cracked concrete

Partial safety factor

1)

1,40

Mc 1)

1,50

[-]

In absence of other national regulations.

Table 8:

Displacements under shear loads

Anchor size

Apolo MEA Quick fix anchor

Cracked and non-cracked concrete

C20/25 - C50/60

M8

M10

M12

M16

[kN]

5,7

10,3

13,1

25,1

V0

[mm]

1,7

1,7

2,4

3,2

[mm]

2,6

2,6

3,6

4,8

Apolo MEA Quick fix anchor

Design method A:

Characteristic values for shear loads and displacements

Annex 6

of European

Technical Approval

ETA - 10 / 0280

Apolo MEA Quick fix anchor

Fire resistance duration

M8

M10

M12

M16

R [min]

30

60

90

120

30

60

90

120

30

60

90

120

30

60

90

120

BAZ / BAZ HD

1,3

0,7

0,4

0,3

2,3

1,3

0,8

0,5

3,6

2,0

1,3

0,9

5,3

3,0

1,8

1,3

BAZ A4 / BAZ HCR

5,7

3,9

2,0

1,1

9,1

6,1

3,2

1,8 13,2 8,9

4,7

2,6 24,5 16,6 8,7

4,8

Steel failure

Characteristic resistance

NRk,s,fi [kN]

Pull-out failure

Characteristic resistance

NRk,p,fi [kN]

1,3

1,0

2,3

1,8

3,0

2,4

5,0

4,0

N0Rk,c,fi [kN]

2,4

2,0

5,0

4,0

7,4

5,9

12,0

9,6

Concrete cone failure

Characteristic resistance

Annex 7

of European

Technical Approval

ETA - 10 / 0280

4 x hef

scr,N [mm]

Spacing

smin [mm]

50

55

2 x hef

ccr,N [mm]

Edge distance

cmin [mm]

60

Fire attack from one side:

Fire attack from more than one side:

cmin = 2 x hef

cmin 300 mm

In absence of other national regulations the partial safety factor for resistance under fire exposure M,fi = 1,0 is recommended.

70

Page 15 of European Technical Approval ETA-10/0280

Anchor size

Apolo MEA Quick fix anchor

Characteristic values of tension load resistance

under fire exposure

Table 9: Design method A - Characteristic tension resistance in cracked and non-cracked C20/25 to C50/60

under fire exposure

Apolo MEA Quick fix anchor

Fire resistance duration

R [min]

M8

M10

M12

M16

30

60

90

120

30

60

90

120

30

60

90

120

30

60

90

120

BAZ / BAZ HD

1,3

0,7

0,4

0,3

2,3

1,3

0,8

0,5

3,6

2,0

1,3

0,9

5,3

3,0

1,8

1,3

BAZ A4 / BAZ HCR

5,7

3,9

2,0

1,1

9,1

6,1

3,2

1,8 13,2 8,9

4,7

2,6 24,5 16,6 8,7

4,8

BAZ / BAZ HD

1,8

1,3

0,8

0,6

3,6

2,6

1,6

1,1

2,8

1,9 16,2 11,7 7,2

4,9

BAZ A4 / BAZ HCR

5,8

4,0

2,1

1,1 11,7 7,9

4,2

2,3 20,4 13,9 7,3

Steel failure without lever arm

Characteristic resistance

VRk,s,fi [kN]

Steel failure with lever arm

Characteristic resistance

M0Rk,s,fi [Nm]

6,4

4,6

4,0 52,0 35,2 18,5 10,2

Concrete pryout failure

Annex 8

of European

Technical Approval

ETA - 10 / 0280

Factor in equation (5.6) of

ETAG 001 Annex C, 5.2.3.3

k [-]

Characteristic resistance

V0Rk,cp,fi [kN]

1,0

2,4

2,0

2,0

10,0

2,0

2,0

8,0

14,8

11,8

Concrete edge failure

The initial value V0Rk,c,fi of the characteristic resistance in concrete C20/25 to C50/60 under fire exposure may be determined by:

V0Rk,c,fi = 0,25 x V0Rk,c ( R90)

V0Rk,c,fi = 0,20 x V0Rk,c (R120)

with V0Rk,c initial value of the characteristic resistance in cracked concrete C20/25 under normal temperature.

In absence of other national regulations the partial safety factor for resistance under fire exposure M,fi = 1,0 is recommended.

24,0

19,2

Page 16 of European Technical Approval ETA-10/0280

Anchor size

Apolo MEA Quick fix anchor

Characteristic values of shear load resistance

under fire exposure

Table 10: Design method A - Characteristic shear resistance in cracked and non-cracked C20/25 to C50/60

under fire exposure

Das könnte Ihnen auch gefallen

- Spun Piles PDFDokument2 SeitenSpun Piles PDFhoetapeaNoch keine Bewertungen

- Product Catalogue.27214653 PDFDokument28 SeitenProduct Catalogue.27214653 PDFJohny GharialNoch keine Bewertungen

- All-in-One Manual of Industrial Piping Practice and MaintenanceVon EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceBewertung: 5 von 5 Sternen5/5 (1)

- BP - AC-LOP - 365A5664P006 - 220-Heb PDFDokument73 SeitenBP - AC-LOP - 365A5664P006 - 220-Heb PDFwilly1234512100% (1)

- Declaratie de Conformitate Ancore MTH PDFDokument3 SeitenDeclaratie de Conformitate Ancore MTH PDFFerencz ZsoltNoch keine Bewertungen

- Chumbador HiltDokument14 SeitenChumbador HiltSamanta FigueredoNoch keine Bewertungen

- Hilti Hvu HasDokument12 SeitenHilti Hvu HasAMCRUZ77Noch keine Bewertungen

- Hilti - Calculo Manual de Re500Dokument41 SeitenHilti - Calculo Manual de Re500James ClaytonNoch keine Bewertungen

- Hilti - Hit Hy 150 Max Cu Hit TZ - 1Dokument12 SeitenHilti - Hit Hy 150 Max Cu Hit TZ - 1Mihnea-Bogdan NicolaescuNoch keine Bewertungen

- FTM '12 HKD Push-In AnchorDokument14 SeitenFTM '12 HKD Push-In AnchorShankerNoch keine Bewertungen

- Eta - 17-0183 - 2021 R-XPT - enDokument9 SeitenEta - 17-0183 - 2021 R-XPT - enNG Wee JunNoch keine Bewertungen

- Hilti HVZ 1Dokument13 SeitenHilti HVZ 1Mihnea-Bogdan NicolaescuNoch keine Bewertungen

- Annex AllemandDokument13 SeitenAnnex AllemandsobhiNoch keine Bewertungen

- 44 - HVZ Adhesive AnchorDokument14 Seiten44 - HVZ Adhesive AnchorHuan VoNoch keine Bewertungen

- WIT-PE 500 Design Manual RBDokument24 SeitenWIT-PE 500 Design Manual RBMadusha TisseraNoch keine Bewertungen

- THRUMAXX ZPL DoP 30551rev1 EngDokument3 SeitenTHRUMAXX ZPL DoP 30551rev1 EngRicardo MagalhãesNoch keine Bewertungen

- Rothoblaas - Abs Red - Technical Data Sheets - enDokument1 SeiteRothoblaas - Abs Red - Technical Data Sheets - enAndrei GheorghicaNoch keine Bewertungen

- Hilti HST 1Dokument11 SeitenHilti HST 1Mihnea-Bogdan NicolaescuNoch keine Bewertungen

- PROFIS Anchor 2.2.0: WWW - Hilti.deDokument6 SeitenPROFIS Anchor 2.2.0: WWW - Hilti.deCollin NguNoch keine Bewertungen

- HSL-3 Heavy Duty AnchorDokument12 SeitenHSL-3 Heavy Duty AnchorMihnea-Bogdan NicolaescuNoch keine Bewertungen

- Fiala Chimica Chemical Capsule Capsule Chimiche Chemische PatroneDokument4 SeitenFiala Chimica Chemical Capsule Capsule Chimiche Chemische Patronerazvan65Noch keine Bewertungen

- European Technical Assessment ETA 17/0185: Technical and Test Institute For Construction PragueDokument12 SeitenEuropean Technical Assessment ETA 17/0185: Technical and Test Institute For Construction PragueLi Juen GamNoch keine Bewertungen

- Company Name: Job InformationDokument6 SeitenCompany Name: Job InformationAlvin LeongNoch keine Bewertungen

- Peikko Designer, Printing-20140828Dokument6 SeitenPeikko Designer, Printing-20140828Filipe FeioNoch keine Bewertungen

- ESA en SpezialDokument1 SeiteESA en SpezialOlivia JacksonNoch keine Bewertungen

- Hilti HIT HY 150 MAX With RebarDokument14 SeitenHilti HIT HY 150 MAX With RebarNelly BuquironNoch keine Bewertungen

- Company Name: Job InformationDokument7 SeitenCompany Name: Job InformationAlvin LeongNoch keine Bewertungen

- ETABS 2015 Concrete Frame Design: ETABS 2015 15.0.0 License # 1TYYZ6WT9WKC6EXDokument8 SeitenETABS 2015 Concrete Frame Design: ETABS 2015 15.0.0 License # 1TYYZ6WT9WKC6EXTeomnerCabreraNoch keine Bewertungen

- Rothoblaas - Ab7.technical Data Sheets - enDokument1 SeiteRothoblaas - Ab7.technical Data Sheets - enAndrei GheorghicaNoch keine Bewertungen

- Montavimo Technika Armaturos StrypamsDokument5 SeitenMontavimo Technika Armaturos StrypamsHafidh BaequnieNoch keine Bewertungen

- ETABS 2016 Concrete Frame Design: ETABS 2016 16.0.0 License # 1ES7YK4AC6GBPC8Dokument1 SeiteETABS 2016 Concrete Frame Design: ETABS 2016 16.0.0 License # 1ES7YK4AC6GBPC8Sham TajasNoch keine Bewertungen

- PES Hilti M10 HSA ReportDokument4 SeitenPES Hilti M10 HSA ReportCollin NguNoch keine Bewertungen

- MEFA Beam ClampsDokument3 SeitenMEFA Beam ClampsgeorgecisNoch keine Bewertungen

- Base CHS X 10tDokument7 SeitenBase CHS X 10tCollin NguNoch keine Bewertungen

- (Eurocode 2) Design of Concrete Structures: Brian O'RourkeDokument20 Seiten(Eurocode 2) Design of Concrete Structures: Brian O'RourkeselinaNoch keine Bewertungen

- ETA 13-0730 MaxxFast PromaxDokument11 SeitenETA 13-0730 MaxxFast PromaxXavierNoch keine Bewertungen

- 05 Price ScheduleDokument23 Seiten05 Price Scheduletoylovechom2013Noch keine Bewertungen

- FCD VLENTB0200 Mark200TB AQ PDFDokument36 SeitenFCD VLENTB0200 Mark200TB AQ PDFmetal_dung2Noch keine Bewertungen

- 2011 HSC-I Safety AnchorDokument3 Seiten2011 HSC-I Safety AnchorDifa LiuNoch keine Bewertungen

- ETABS 2016 Concrete Frame Design: ETABS 2016 16.0.0 License # 1ES7YK4AC6GBPC8Dokument2 SeitenETABS 2016 Concrete Frame Design: ETABS 2016 16.0.0 License # 1ES7YK4AC6GBPC8Sham TajasNoch keine Bewertungen

- Technical Data Sheet For HSL-3 Heavy Duty Anchor Technical Information ASSET DOC 2331111Dokument11 SeitenTechnical Data Sheet For HSL-3 Heavy Duty Anchor Technical Information ASSET DOC 2331111Fer VFNoch keine Bewertungen

- Arval Floline E-Floline Curved Metal PanelsDokument24 SeitenArval Floline E-Floline Curved Metal PanelsCorbean AlexandruNoch keine Bewertungen

- Chemical Anchor BoltDokument1 SeiteChemical Anchor BoltdeepuVNITNoch keine Bewertungen

- ETABS 2013 Concrete Frame DesignDokument2 SeitenETABS 2013 Concrete Frame DesignGabriel LagunaNoch keine Bewertungen

- PC Spun PilesDokument2 SeitenPC Spun PilesBahrul AliemNoch keine Bewertungen

- PC Spun PilesDokument2 SeitenPC Spun PilesJoglo Solo100% (1)

- Spun PilesDokument2 SeitenSpun Pileshoetapea100% (1)

- Pipe Rack Hilti Bolt CalculationsDokument6 SeitenPipe Rack Hilti Bolt CalculationsAnonymous MAQrYFQDzVNoch keine Bewertungen

- CS PipingDokument15 SeitenCS PipingJavierSeimanNoch keine Bewertungen

- Norgren - MufflersDokument14 SeitenNorgren - Mufflerssh4kzyNoch keine Bewertungen

- Ramset Specifiers Anchoring Resource Book ANZ - TruBolt Mechanical AnchoringDokument10 SeitenRamset Specifiers Anchoring Resource Book ANZ - TruBolt Mechanical AnchoringjlolhnpNoch keine Bewertungen

- HIT-TZ Injection Adhesive Anchor: HIT-HY 150 Foil Pack, MixerDokument11 SeitenHIT-TZ Injection Adhesive Anchor: HIT-HY 150 Foil Pack, Mixerlael00Noch keine Bewertungen

- European Technical Assessment ETA 20/0640: Technical and Test Institute For Construction PragueDokument11 SeitenEuropean Technical Assessment ETA 20/0640: Technical and Test Institute For Construction PragueDavid SeeNoch keine Bewertungen

- PB TW10 GBDokument6 SeitenPB TW10 GBfebri_bontangNoch keine Bewertungen

- Technical Data Sheet For HST Stud Anchor Technical Information ASSET DOC 2331133Dokument14 SeitenTechnical Data Sheet For HST Stud Anchor Technical Information ASSET DOC 2331133giovanni perozziNoch keine Bewertungen

- Hilti D16Dokument1 SeiteHilti D16Ina RoseNoch keine Bewertungen

- Fisa Tehnica Ancore Mecanice Cu InelDokument3 SeitenFisa Tehnica Ancore Mecanice Cu InelCristian RezNoch keine Bewertungen

- Catalogue PoralDokument10 SeitenCatalogue Poralashish2783Noch keine Bewertungen

- DIN 3015 ClampsDokument20 SeitenDIN 3015 ClampsRasheshNoch keine Bewertungen

- Ageing and Life Extension of Offshore Structures: The Challenge of Managing Structural IntegrityVon EverandAgeing and Life Extension of Offshore Structures: The Challenge of Managing Structural IntegrityNoch keine Bewertungen

- Renr8482-07 2cDokument2 SeitenRenr8482-07 2cwilly1234512Noch keine Bewertungen

- Specifications: 14M and 16M Motor Graders Power TrainDokument40 SeitenSpecifications: 14M and 16M Motor Graders Power Trainwilly1234512Noch keine Bewertungen

- Kenr6019 05 01 AllDokument148 SeitenKenr6019 05 01 Allwilly1234512Noch keine Bewertungen

- RENR9004-07 545 Testing and Adjusting Section: M Series Transmission Chassis Ecm - J1 ConnectionsDokument4 SeitenRENR9004-07 545 Testing and Adjusting Section: M Series Transmission Chassis Ecm - J1 Connectionswilly1234512Noch keine Bewertungen

- Renr9004-07-01-All-Power Train ElectronicDokument550 SeitenRenr9004-07-01-All-Power Train Electronicwilly1234512100% (1)

- Renr8482-07-01-All-Power Train-SystemDokument108 SeitenRenr8482-07-01-All-Power Train-Systemwilly12345120% (1)

- Kenr6017 03 01 AllDokument88 SeitenKenr6017 03 01 Allwilly1234512Noch keine Bewertungen

- Vision LF CNC Operacion y Manual PartesDokument180 SeitenVision LF CNC Operacion y Manual Parteswilly1234512Noch keine Bewertungen

- 04 - Howden - Installation-Maintenance D-Series Fans PDFDokument20 Seiten04 - Howden - Installation-Maintenance D-Series Fans PDFwilly12345120% (1)

- Vision LF CNCDokument98 SeitenVision LF CNCwilly1234512Noch keine Bewertungen

- Hot Work PESB 01 PDFDokument4 SeitenHot Work PESB 01 PDFShureendran Muniandy RajanNoch keine Bewertungen

- Sri Ganesh Engg - ProfileDokument19 SeitenSri Ganesh Engg - Profileshikharc100% (1)

- Rooftex - Technical Data SheetDokument5 SeitenRooftex - Technical Data SheetTRAG ProjectsNoch keine Bewertungen

- PDC Drill Bits: Manufacturer IADC Code Bit Name/model NumberDokument16 SeitenPDC Drill Bits: Manufacturer IADC Code Bit Name/model NumberYaqoob IbrahimNoch keine Bewertungen

- A. B. C. D. Answer & ExplanationDokument16 SeitenA. B. C. D. Answer & Explanationahmish kabbaxeNoch keine Bewertungen

- Semiconductor Manufacturing Technology: OxidationDokument50 SeitenSemiconductor Manufacturing Technology: Oxidationboulainine houriaNoch keine Bewertungen

- PaintsDokument5 SeitenPaintsDeepak DhakalNoch keine Bewertungen

- Modular CNC Mini Mill Assy-01Dokument1 SeiteModular CNC Mini Mill Assy-01ModularCNC100% (1)

- Fire SprinkleDokument6 SeitenFire Sprinklersgs gunungsawoNoch keine Bewertungen

- Fosroc Acid Etch : Concrete Remover, Cleaning and Etching AgentDokument2 SeitenFosroc Acid Etch : Concrete Remover, Cleaning and Etching AgentVincent JavateNoch keine Bewertungen

- Sweeney 503 Moly Paste India Call +91-98851-49412Dokument3 SeitenSweeney 503 Moly Paste India Call +91-98851-49412Project Sales CorpNoch keine Bewertungen

- Extrusion Processing Guide: ABS - Acrylonitrile-Butadiene-StyreneDokument5 SeitenExtrusion Processing Guide: ABS - Acrylonitrile-Butadiene-StyreneMalwadkar P.B.0% (1)

- PX MicDokument6 SeitenPX MicSoraire LucasNoch keine Bewertungen

- Connecting Rod FaultDokument66 SeitenConnecting Rod FaultAbdallah MansourNoch keine Bewertungen

- Prepare The Necessary Tools and Equipment For The Specific Nail Care ActivityDokument33 SeitenPrepare The Necessary Tools and Equipment For The Specific Nail Care Activitydiane carol roseteNoch keine Bewertungen

- S355MLDokument2 SeitenS355MLMohammed ShamilNoch keine Bewertungen

- AMERICAN Pipe Manual Linings and Coatings 5 24 21Dokument15 SeitenAMERICAN Pipe Manual Linings and Coatings 5 24 21Ludi D. LunarNoch keine Bewertungen

- En-13445-5 5Dokument1 SeiteEn-13445-5 5panalcaNoch keine Bewertungen

- Study Case - Electric Saw CasingDokument8 SeitenStudy Case - Electric Saw CasingvrjrNoch keine Bewertungen

- 3 Glass Bead Making ProjectsDokument11 Seiten3 Glass Bead Making ProjectsAngela R. Lacey100% (1)

- Croda Coatings Product Overview EuropeDokument4 SeitenCroda Coatings Product Overview Europemanox007100% (1)

- Powder MetallurgyDokument8 SeitenPowder MetallurgyPritamNoch keine Bewertungen

- History of LithoDokument5 SeitenHistory of LithoKapeed RamukNoch keine Bewertungen

- 11 Common Welding Defects and How To Prevent ThemDokument7 Seiten11 Common Welding Defects and How To Prevent ThemRez HabloNoch keine Bewertungen

- Milling Collet Chuck: DIN 6388 # 25 SERIES MAS 403 Bt-Shank OZ-25 Collet Holder With Bt-ShankDokument10 SeitenMilling Collet Chuck: DIN 6388 # 25 SERIES MAS 403 Bt-Shank OZ-25 Collet Holder With Bt-ShankJunior Salcedo MuñozNoch keine Bewertungen

- WIS5 Con 06Dokument30 SeitenWIS5 Con 06QC-Metinca Prima Industrial WorksNoch keine Bewertungen

- CWI Exam Sample Question Paper For Practice - UpWeldDokument16 SeitenCWI Exam Sample Question Paper For Practice - UpWeldAhmed Shaban Kotb100% (2)

- AP Chapter 14 JeopardyDokument33 SeitenAP Chapter 14 JeopardyLama DebanyNoch keine Bewertungen

- Heat Treatment Part 2Dokument46 SeitenHeat Treatment Part 2Naman DaveNoch keine Bewertungen

- REPORT ABOUT INDUSTRIAL VISIT IN Autotech - 2022111301Dokument2 SeitenREPORT ABOUT INDUSTRIAL VISIT IN Autotech - 2022111301Kavin KavinNoch keine Bewertungen